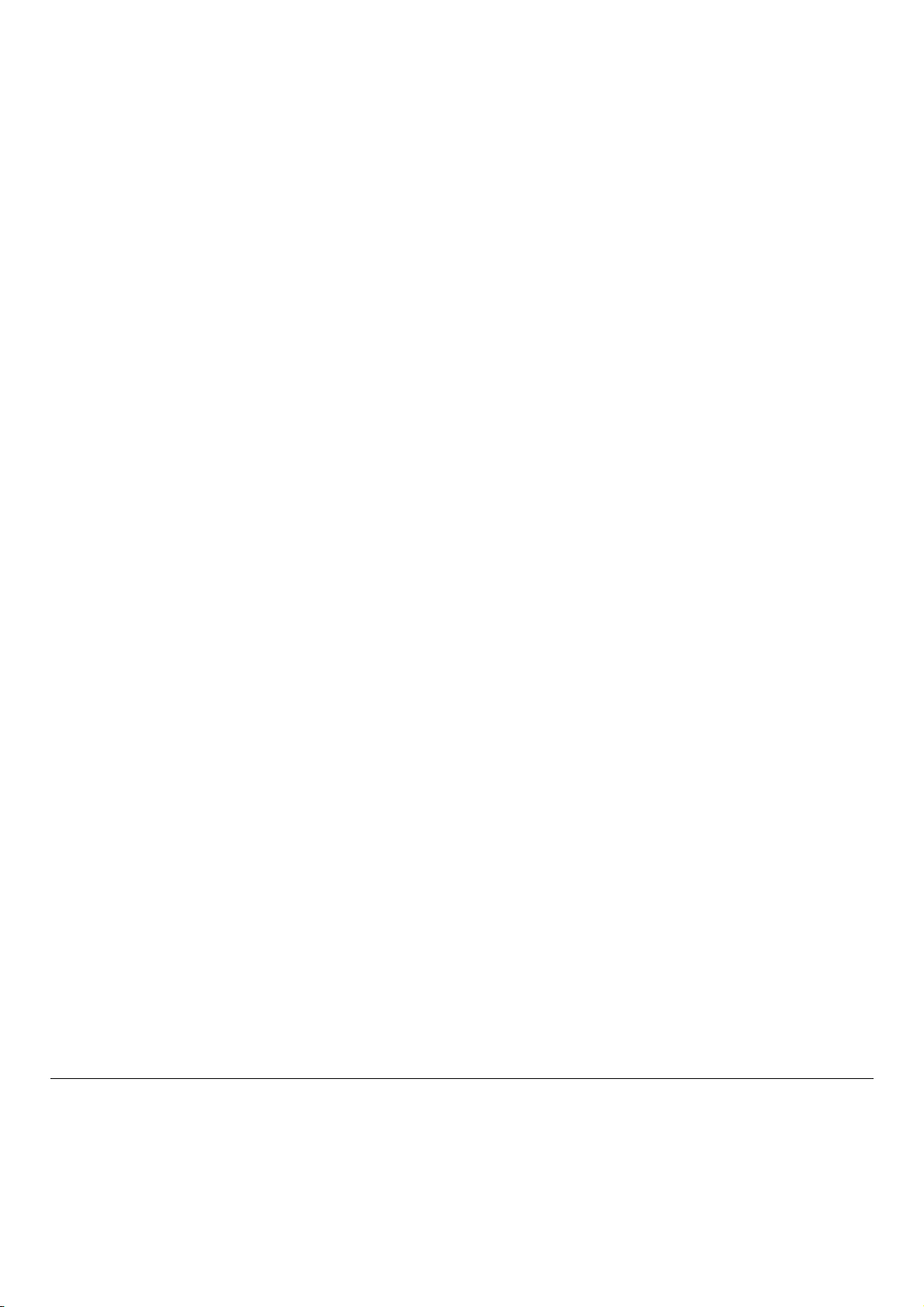

(H=H1-H2+h/2),and mark O’the highest dot among A, B, C and D. to measure H va ue, it is the reference dot of

p acing the instrument transverse y.

(5)Measure h’ from E to O’, if h'≤6mm, the instrument accuracy is qua ified. If 6mm<h'≤30mm, the instrument

accuracy is out of to erance, if h'>30mm, the instrument accuracy is out of to erance, p ease contact the distributor.

5.2 Accuracy cali ration

According to the accuracy check resu t, mark O at h/2(the distance of highest and owest dot among A. B , C and D)..

(1) enter into ca ibration status

a power off the instrument, face X axis to the wa

b. press on/off key and TILT mode key at the same time, and then re ease on/off key and continue ho d TILT mode key,

after X.Y LEDS f ash three times, re ease TILT mode key, the instrument wi enter ca ibration status, and continue

rotating.

(2)X axis direction

a. Press se f-ca ibration direction on remote contro , the X ca ibration LED f ash on the instrument keypad, the

instrument wi enter X direction ca ibration.

b. Press the se f-ca ibration adjustment key on remote contro , move the aser ine up and down, unti it coincide with dot

O.

(3)Y axis direction ca ibration

a. Under ca ibration status, turn the instrument by 90 degree, make Y axis face to the wa .

b. Press se f-ca ibration direction se ect key on remote contro , Y ca ibration LED on instrument keypad f ash, the

instrument wi enter into Y direction ca ibration.

c. Press se f-ca ibration adjustment on remote contro , the aser ine move up and down, unti it coincides with dot O.

(4)Ca ibration confirmation

When X direction and Y direction confirmation are finished, press se f-ca ibration confirmation key, ca ibration LED is off,

ca ibration va ue is saved, the instrument exit ca ibration status.

(5)Z axis direction ca ibration

a. P ace the instrument vertica y

b. Press ON/OFF key and TILT mode key simu taneous y, and then re ease ON/OFF key and continue ho ding TILT

mode key, unti X,Y two LEDs f ash three times, and then re ease TILT mode key, the instrument enter Z axis ca ibration

status, rotate continuous y, Y direction LED f ash.

c. Press se f-ca ibration adjustment key on remote contro , the aser dot move up and down, unti it coincide with dot

O’.

(6) Ca ibration confirmation

When Z direction ca ibration is finished, press se f-ca ibration confirmation key, ca ibration LED is off, the ca ibration

va ue is saved, the instrument exit ca ibration status.

Note: after ca ibration is finished, it is necessary to power off instrument, after power on it again, the ca ibration is va id

fina y.

X axis is ca ibrated, it is necessary to make Y axis accuracy check, after Y axis id ca ibrated, it is necessary to make X

axis accuracy test, unti X and Y accuracy conform to requirement, then the instrument ca ibration is finished.