iv

3.8Installing Battery Cables.........................................................................................................18

3.9Reinstalling AC Dual-Live Wire Input Power Cables...................................................................18

3.9.1Installing AC Input Ground Cable................................................................................................19

3.9.2Installing AC Input Power Cable..................................................................................................20

4Verifying the Installation................................................................................................................23

4.1Checking Hardware Installation...............................................................................................23

4.2Checking Electrical Connections ..............................................................................................23

4.3Checking Cable Installation.....................................................................................................23

5Commissioning .............................................................................................................................23

5.1Connecting the AC Power Supply ............................................................................................23

5.2Setting the Display Language..................................................................................................23

5.3Setting the Date and Time......................................................................................................24

5.4Setting Battery Parameters.....................................................................................................24

5.5(Optional) Setting the Hibernation Parameter...........................................................................25

5.6Setting Communication Parameters.........................................................................................25

5.6.1Installing AC Input Power Cable..................................................................................................25

5.6.2Setting Parameters before Using the SNMP Management..............................................................26

5.7Connecting the Battery Supply................................................................................................28

6Maintenance.................................................................................................................................29

6.1Performing Routine Maintenance.............................................................................................29

6.2Troubleshooting Procedure.....................................................................................................29

ATechnical Specification ..................................................................................................................30

BElectrical Conceptual Diagram........................................................................................................32

CAssociations Between Alarms and Dry Contacts on the DCU..............................................................33

DAcronyms and Abbreviations..........................................................................................................34

Manufacturer’s Warranty.......................................................................................................................35

Document Control and Revision History...................................................................................................366

Table of Figures

Figure 1 - A36D Case Footprint...................................................................................................................1

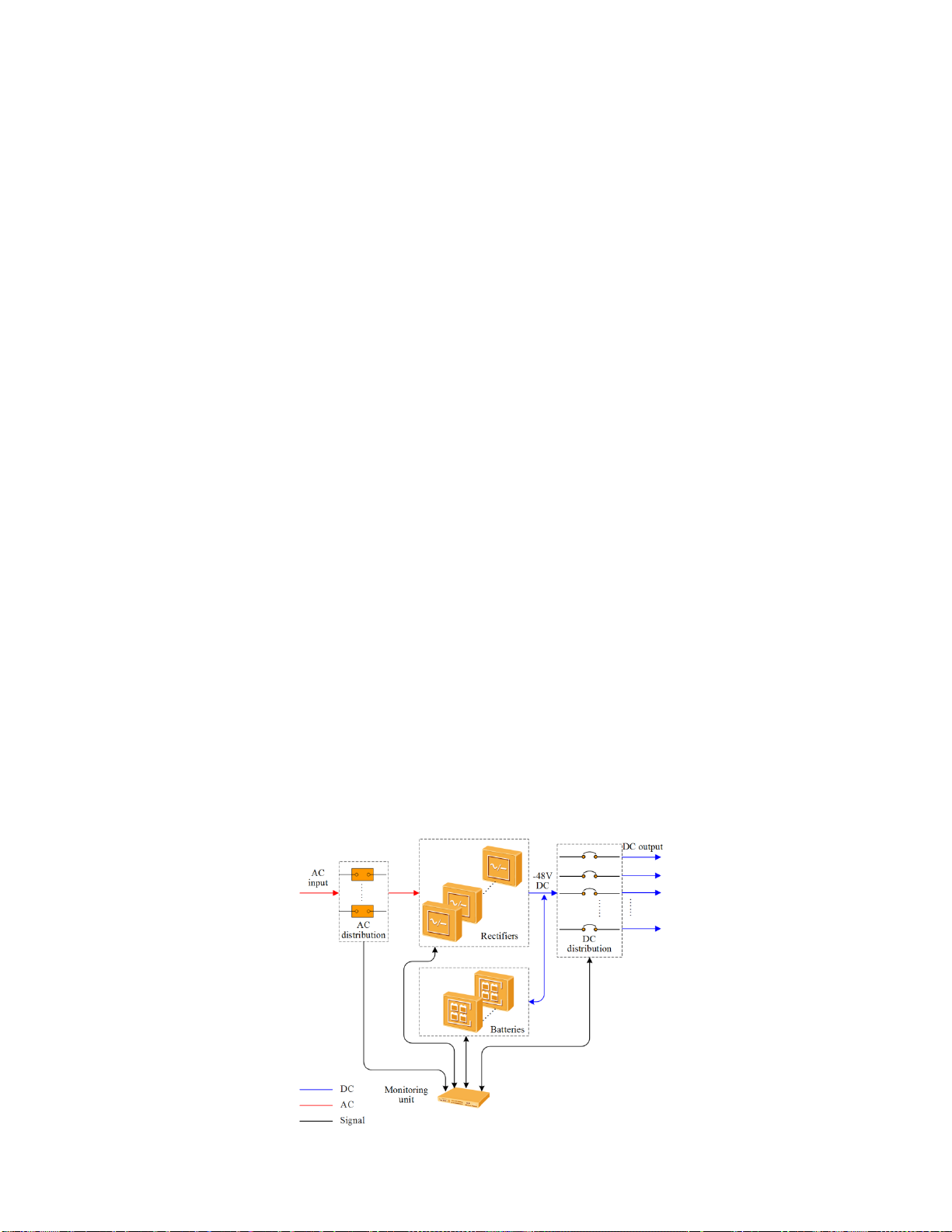

Figure 1 – Conceptual diagram ...................................................................................................................1

Figure 2 – DCPS ........................................................................................................................................2

Figure 3 – DC DCD for DCPS.......................................................................................................................3

Figure 4 – AC DCD for DCPS.......................................................................................................................3

Figure 5 – Rectifier ....................................................................................................................................4

Figure 6 – Rectifier Panel ...........................................................................................................................4

Figure 7 – DCSC........................................................................................................................................5

Figure 8 – DCSC panel ...............................................................................................................................6

Figure 9 – Pins in the FE port and RS485/RS232 port....................................................................................7

Figure 10 – DCU panel...............................................................................................................................8

Figure 11 – DCU pin numbers.....................................................................................................................9

Figure 12 – Installation Tools....................................................................................................................11

Figure 13 – Installing mounting ears (normal installation) ...........................................................................12