iv

3.6

Output Voltage Adjustments .........................................................................................................24

3.7

TPS 2 Customer Configuration Menu Structure .............................................................................25

4

Frequently Asked Questions ..................................................................................................................26

5

Service ................................................................................................................................................27

5.1

Performing Routine Maintenance ...................................................................................................27

5.2

Troubleshooting Procedure ...........................................................................................................28

5.3

Troubleshooting Chart ..................................................................................................................29

5.3.1

Ground and Short Circuit Test. ..................................................................................................30

5.3.2

Troubleshooting the TRIAC .......................................................................................................30

5.3.3

Troubleshooting and Replacing Power Silicon iodes/Modules .....................................................31

5.3.4

Checking Capacitors .................................................................................................................31

Appendix A: A36 Specifications ..................................................................................................................32

Appendix B: A36 Current raw and Feeder Breaker Sizes (Single Phase) .....................................................33

Appendix C: A36 Current raw and Feeder Breaker Sizes (Three Phase) ......................................................34

Appendix : A36 Heat Losses (Based on 85% efficiency / 0.9 Power Factor at rated load) ............................35

Appendix E: Manufacturer’s Warranty ..........................................................................................................36

Appendix F: Manufacturer’s Extended Parts Warranty ...................................................................................37

Appendix G: ocument Control and Revision History .....................................................................................38

Table of Figures

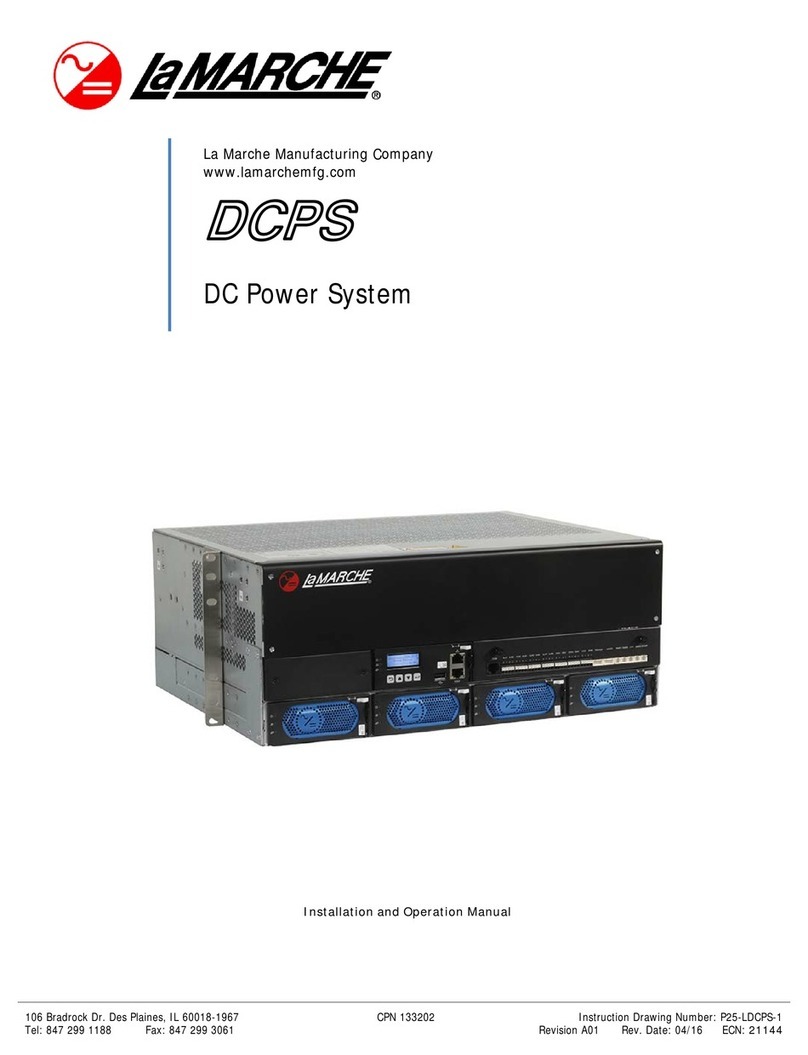

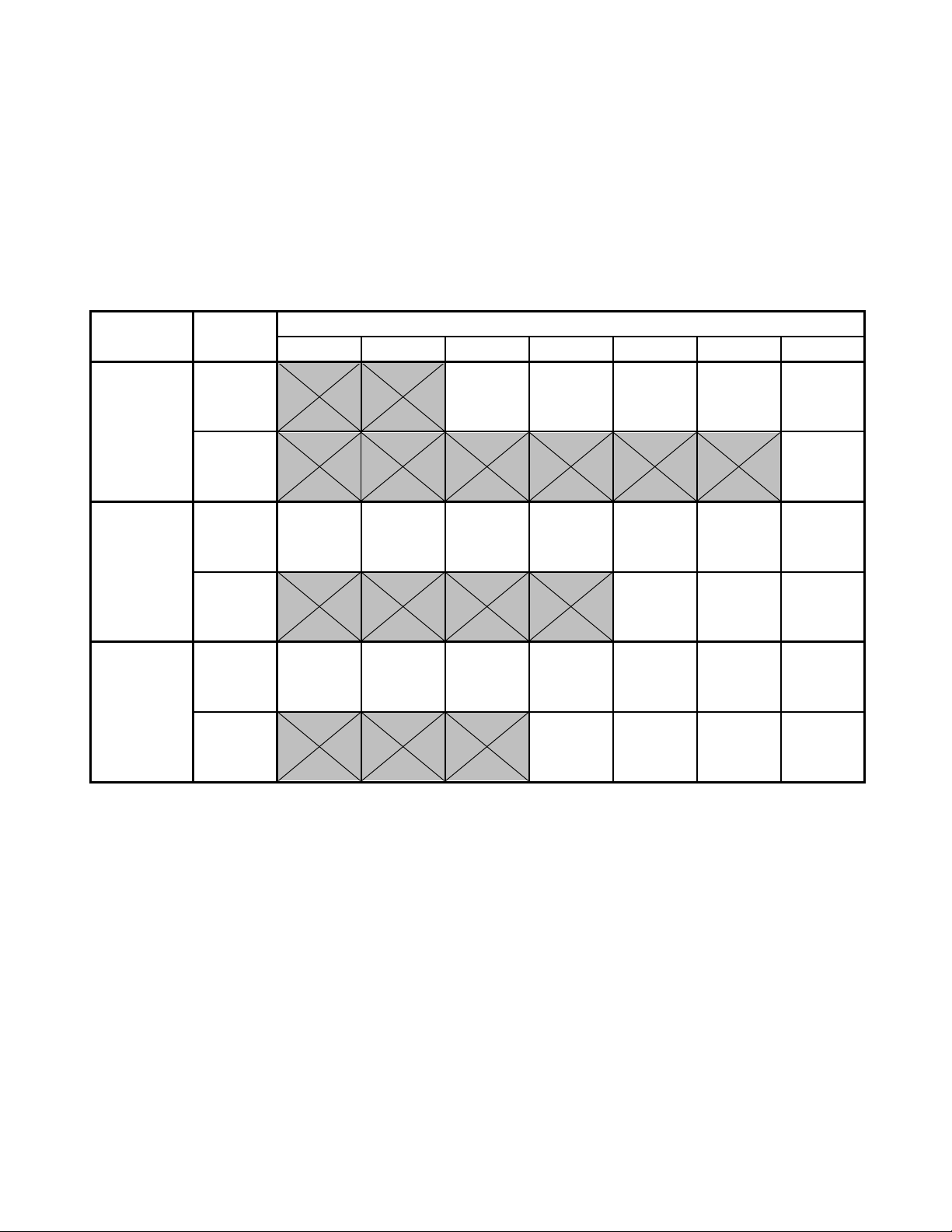

Figure 1 - 39 Enclosure Bolt Pattern .............................................................................................................. 5

Figure 2 - 9E Enclosure Bolt Pattern .............................................................................................................. 5

Figure 3 - 4 Enclosure Bolt Pattern ............................................................................................................. 5

Figure 4 - 33E Enclosure Bolt Pattern ............................................................................................................ 5

Figure 5 - 33 Enclosure Bolt Pattern .............................................................................................................. 5

Figure 6 - A36 Enclosure Footprint .............................................................................................................. 6

Figure 7 - Input Terminals Connection Schematic (240VAC Input Shown) ....................................................... 7

Figure 8 - User Connections to Alarm Contacts on S2A-198 Board..................................................................10

Figure 9 - S2A-341S isplay/Control Board ...................................................................................................10

Figure 10 - Example Connections (Customer Provided Equipment) .................................................................11

Figure 11 - Temperature Compensation Connection (External and Internal) ...................................................13

Figure 12 - Load Sharing Connection (Schematic Wiring)...............................................................................14

Figure 13 - NP 3.0 / Modbus Communication Board ....................................................................................15

Figure 14 - A36 Front Panel.......................................................................................................................18

Table 1 - Case Type and Weight (10-50 A C) ................................................................................................ 2

Table 2 - Case Type and Weight (75-400 A C) .............................................................................................. 3

Table 3 - Case Type and Weight (19” Rack Mount Case) ................................................................................ 3

Table 4 - Available Mounting Methods ........................................................................................................... 4

Table 5 - Input Terminal Connections ........................................................................................................... 7

Table 6 - AC/ C & Ground Wire Size Minimum Requirements ......................................................................... 8

Table 7 - Wire Size/Area Table ..................................................................................................................... 9

Table 8 - Alarms Relay Logic ....................................................................................................................... 11

Table 9 - Alarm Contact Specifications .........................................................................................................11

Table 10 - Factory efault Values ................................................................................................................16