iv

4.1

Checking Hardware Installation .................................................................................................21

4.2

Checking Electrical Connections .................................................................................................21

4.3

Checking Cable Installation .......................................................................................................21

5

Commissioning .....................................................................................................................................22

5.1

Connecting the AC Power S pply ...............................................................................................22

5.2

Setting the Display Lang age ....................................................................................................22

5.3

Setting the Date and Time ........................................................................................................22

5.4

Setting Battery Parameters .......................................................................................................22

5.5

(Optional) Setting the Hibernation Parameter .............................................................................23

5.6

Setting Comm nication Parameters ...........................................................................................23

5.6.1

Setting Parameters before Using the SNMP Management .....................................................23

5.7

Connecting the Battery S pply ..................................................................................................25

6

Maintenance ........................................................................................................................................26

6.1

Performing Ro tine Maintenance ...............................................................................................26

6.2

Tro bleshooting Proced re .......................................................................................................26

A

Technical Specifications ....................................................................................................................27

B

Electrical Concept al Diagram...........................................................................................................29

C

Associations Between Alarms and Dry Contacts on the DCU ...............................................................30

D

Acronyms and Abbreviations .............................................................................................................31

E

Smoke Sensor Accessory Safety Notification ......................................................................................32

Man fact rer’s Warranty ..........................................................................................................................33

Doc ment Control and Revision History ........................................................................................................34

Table of Figures

Fig re 1 – Concept al Diagram ..................................................................................................................... 1

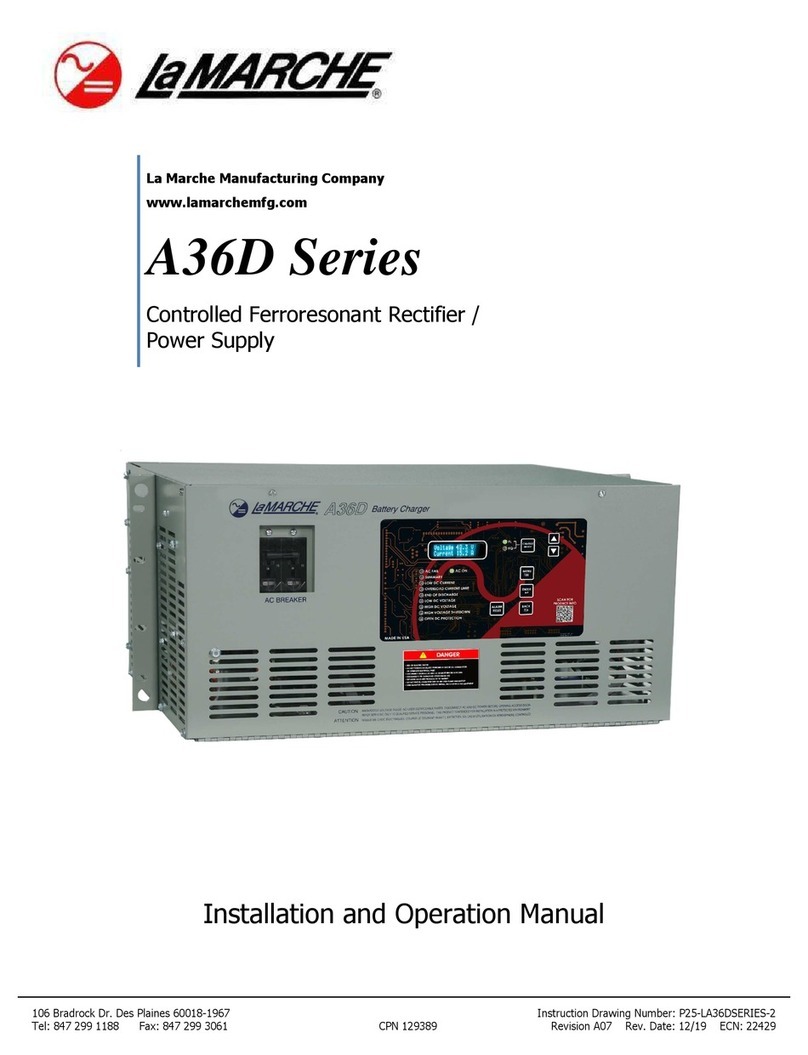

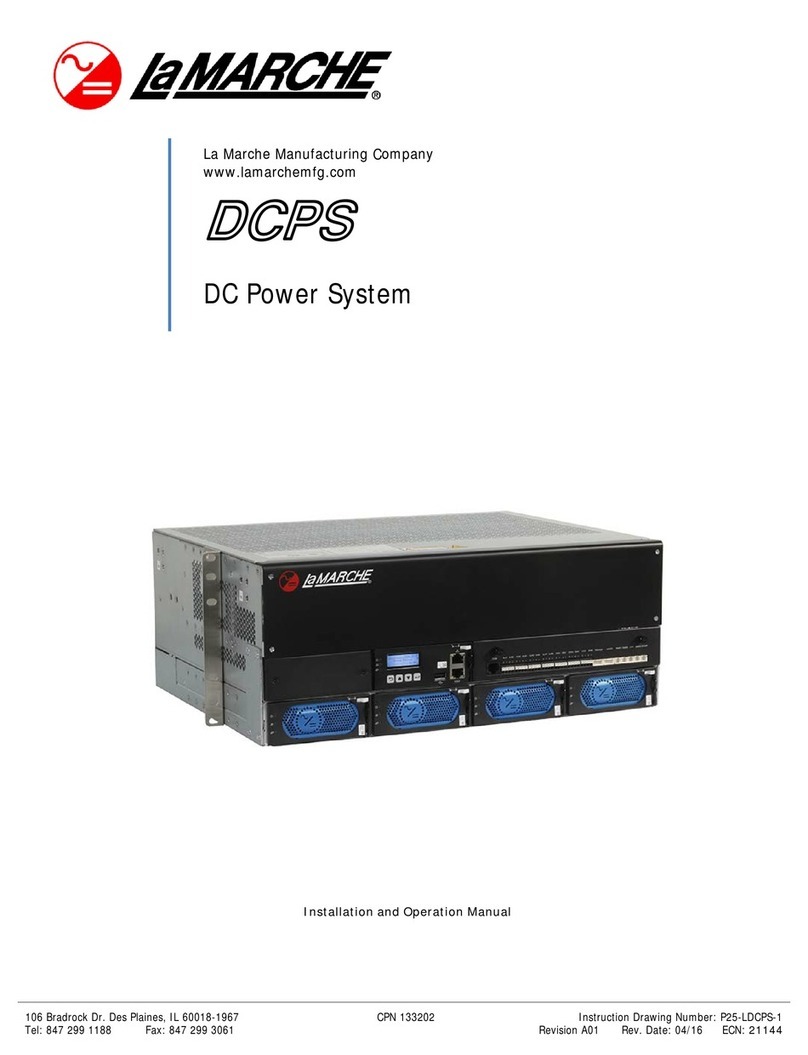

Fig re 2 – DCPS Front View .......................................................................................................................... 2

Fig re 3 – DCPS Top View ............................................................................................................................ 2

Fig re 4 – DCPS Back View .......................................................................................................................... 3

Fig re 5 – DCR (Rectifier) ............................................................................................................................ 3

Fig re 6 – DCR Panel ................................................................................................................................... 4

Fig re 7 – DCSC (System Controller) ............................................................................................................. 5

Fig re 8 – DCSC Panel ................................................................................................................................. 5

Fig re 9 – RS485/RS232 Port and FE Port Pino t ........................................................................................... 6

Fig re 10 – DCU Panel ................................................................................................................................. 7

Fig re 11 – DCU Pin N mbers ...................................................................................................................... 9

Fig re 12 – Installation Tools ......................................................................................................................10

Fig re 13 – Installing Mo nting Brackets (Normal Installation) ......................................................................11

Fig re 14 – Installing Mo nting Brackets (Reverse Installation) .....................................................................12

Fig re 15 – Installing the S brack ................................................................................................................12

Fig re 16 – Installing a Rectifier ..................................................................................................................13

Fig re 17 – Removing the Front Panel from the DCPS ...................................................................................13

Fig re 18 – Removing the Top Cover ...........................................................................................................14

Fig re 19 – Removing the Top Cover ...........................................................................................................14

Fig re 20 – Removing the Top Cover ...........................................................................................................14

Fig re 21 – S brack Gro nd Terminals .........................................................................................................15

Fig re 22 – Installing a Dry Contact Signal Cable ..........................................................................................15

Fig re 23 – Installing DC Power O tp t Cables .............................................................................................16

Fig re 24 – Installing Battery Cables ............................................................................................................17

Fig re 25 – Removing the Rear Cover from the DCPS ...................................................................................17