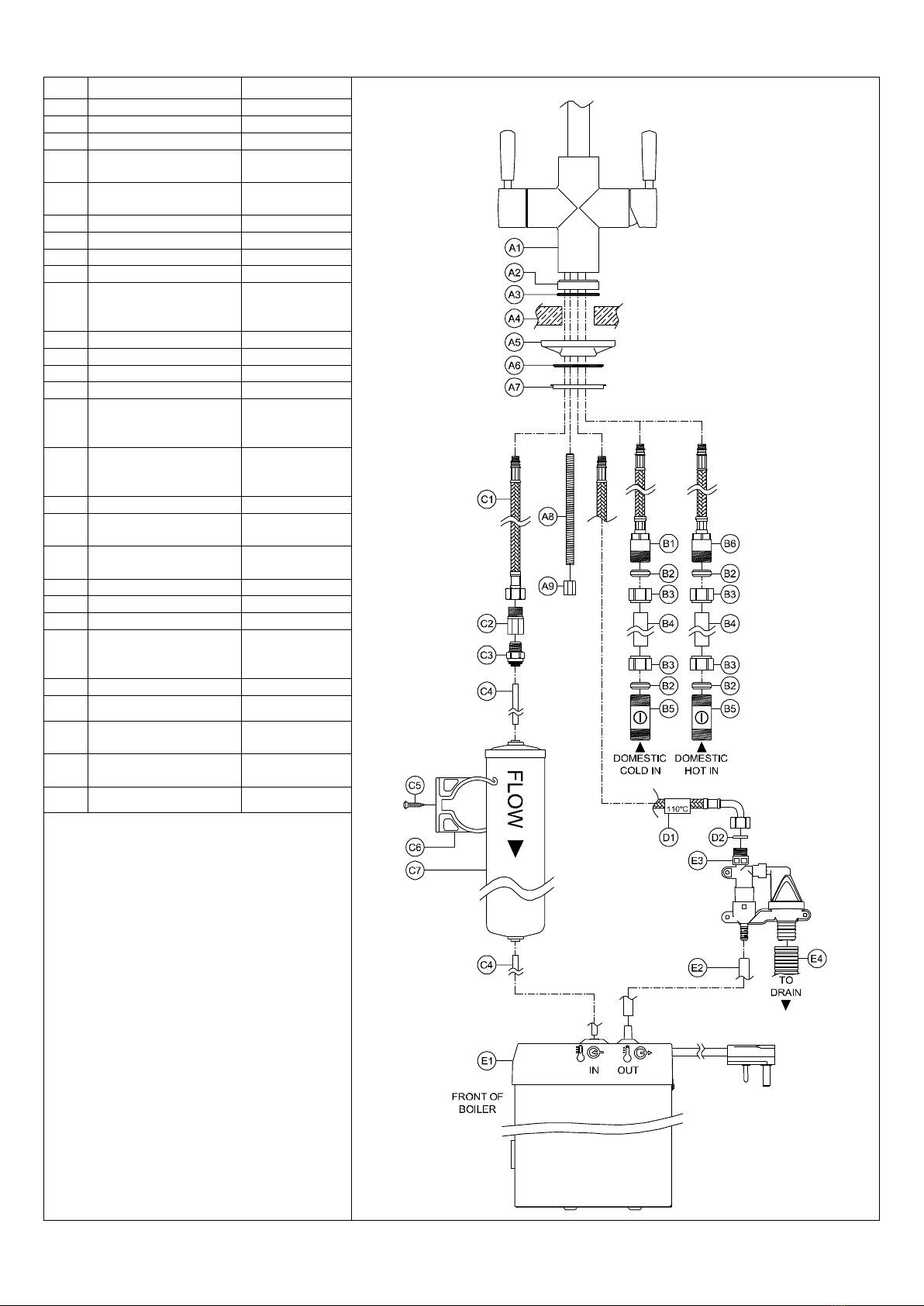

Tap & Filter installation

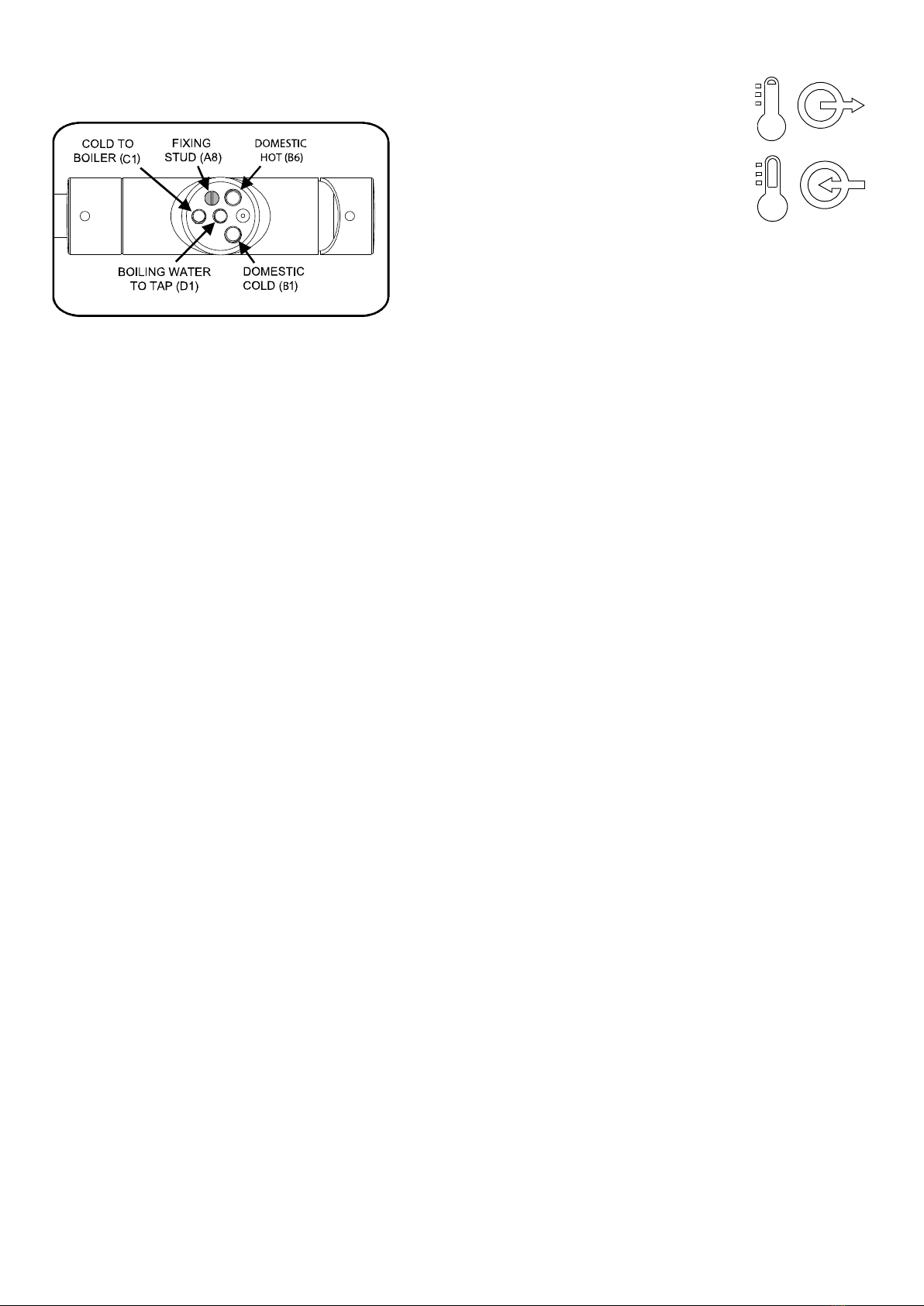

This diagram shows the view of the base of the tap (A1) with the

boiling water handle to the left of the body.

nstall the Tap:

This diagram

shows the

markings on

boiler (E1) to

indicate the inlet

and outlet, see

the boiler

instructions for

further detail.

boiler hot water outlet

boiler cold water inlet

1. Screw the fixing stud (A8) into the base of tap (A1) as shown on the diagram.

2. Place the base plinth (A2) and base plinth seal (A3) onto the base of the tap (A1).

3. Hand tighten the domestic hot flexi hose (B6) into the base of tap (A1) as shown in the diagram above.

4. Hand tighten the domestic cold flexi hose (B1) into the base of tap (A1) as shown in the diagram above.

5. Hand tighten the cold out flexi hose (C1) into the base of tap (A1) as shown in the diagram above.

6. Hand tighten the 110° rated hot flexi hose (D1) into the centre inlet as shown on the diagram and marked on the tap body.

7. Place the tap (A1-A3) centrally and straight to the tap hole, passing the fixing stud (A8), flexi hoses (B1, B6, C1, D1) through the

tap hole.

8. Pass the lower gasket (A6) then the metal horseshoe (A7) over the fixing stud (A8). Note: only if the tap is to be fitted to a

stainless steel sink then the white triangular plate (A5) can be fitted where shown to improve the stability of the tap.

9. Using an 13mm box spanner or small adjustable spanner tighten fixing nut (A9) onto the fixing stud (A8).

10. Screw pushfit (C3) into adaptor (C2), we recommend using PTFE tape (do not use sealing compound) on the thread of

pushfit (C3) to make a good seal without applying excessive force (which may damage the plastic pushfit if

overtightened).

11. Screw pushfit (C3) and adaptor (C2) into the cold out flexi hose (C1).

12. Connect the cold water flexi hose (B1) to the cold water isolation valve (B5) using a section of 15mm pipe (B4) and compression

nuts (B3) and olives (B2). Repeat the process to connect the domestic hot flexi hose (B6) to the domestic hot water supply.

nstall the Filter:

1. Find a suitable place to mount the filter cartridge (C7) under the sink, it must be mounted vertically as shown, easily accessible

(to be changed periodically), away from any heat source and close enough not to exceed the available length of the ¼” plastic

pipe (C4) supplied.

2. Using the self-tapping screw (C5) securely fix the filter bracket (C6) to the cabinet wall.

3. Write the installation date onto the filter label in permanent pen then clip the filter cartridge (C7) into the bracket (C6) as shown.

You must respect the direction of flow as indicated.

4. Measure and then cut required length of ¼” pipe (C4) to connect pushfit (C3) to the filter cartridge (C7) inlet, then from the filter

cartridge (C7) outlet to the boiler inlet (E1) leave a little additional length on both pipes to allow the filter cartridge (C7) to be

unclipped and replaced more easily by the customer. The ¼” pipe (C4) must be cut cleanly and squarely with a sharp tube snip.

5. Firmly push connect the ¼” pipe (C4) between pushfit (C3) and filter cartridge inlet (C7), repeat this from the filter cartridge (C7)

outlet to the boiler inlet (E1).

After installation of the tap and filter is complete

1. Please refer to ‘boiler installation and user guide’ for the next steps and complete the installation. Do not plug in the boiler until

advised.

2. Reconnect the domestic hot and cold water supplies then open isolation valves (B5). As the system starts to refill, check carefully

all new water connections for leaks. After the product installation is complete we recommend you recheck for any slower leaks.

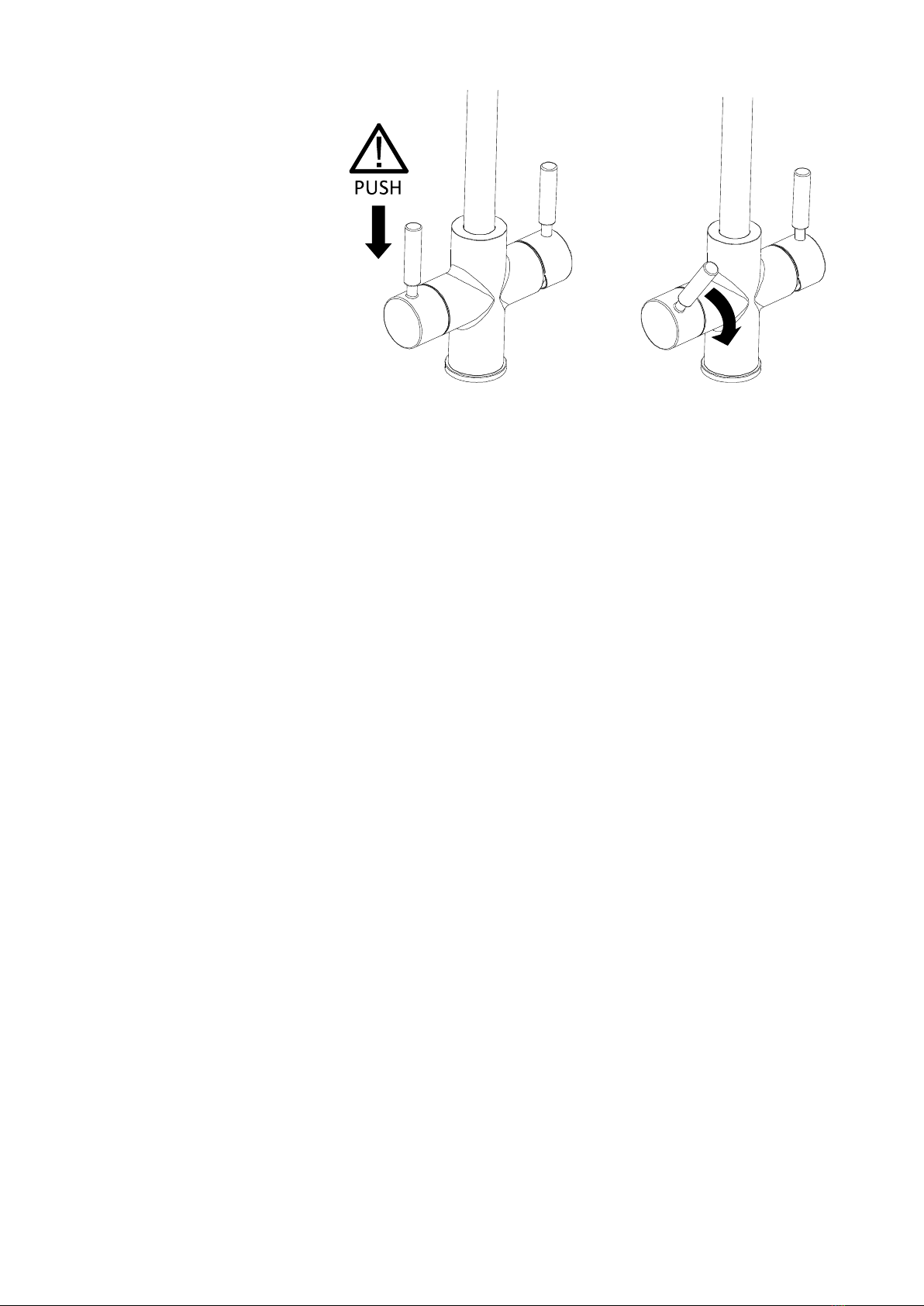

3. Turn on the hot water handle fully, keep the lever open until all air is expelled and cold (unboiled) water exits the centre channel

of the tap spout, flush a further 10 litres of cold (unboiled) water through the filter, boiler and tap. You may notice a discolouration

to the water at first, this is loose carbon fines from the optional filter it is normal, harmless and will pass with flushing. Once

complete turn off the left hand hot water handle.

4. Plug in and switch on the boiler, wait until the water has finished heating fully.

5. Clean the tap with a damp soft cloth and a mild dish soap to remove any grease marks created during installation as per the care

instructions.