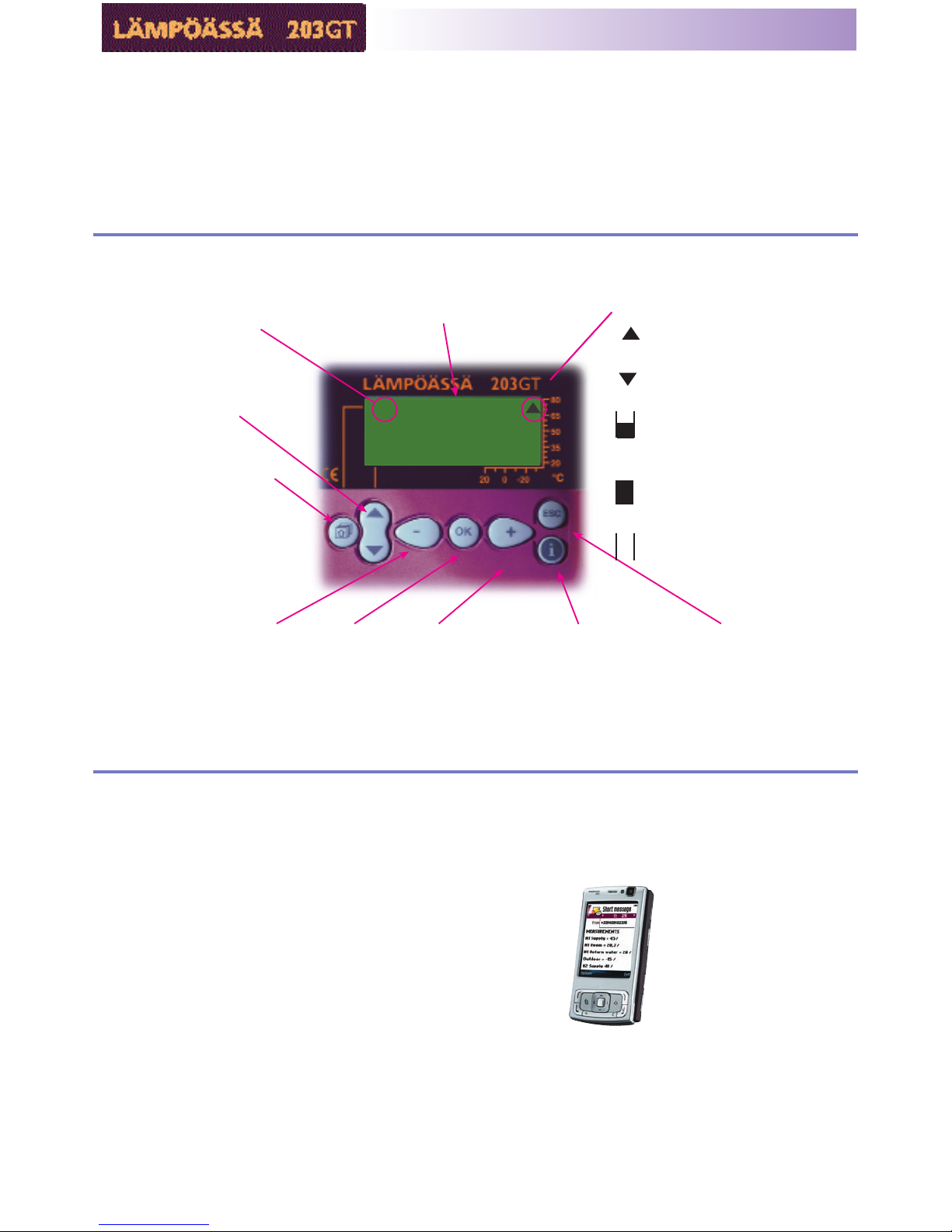

Ajan asetus

Explanation:

Range:

Factory

Settings

Settings: Attention!

Additional information about settings

H1 SETTINGS

/

/

=/

H1 Settings

Room temp.

Temp drop

Min. Limit

Max. Limit

Room compens.

=/

=

=

=

21,5

0

15

8

0

Domestic hot water temperature setting.

Because of danger of bacteria, it is recommended that the domestic hot

water temperature is not set below +55°C.

DomHot wat. 55.0°C 5.0...95.0°C

8

KEYWORDS:

H1 Settings

H2 Settings

DHW Settings

Full effect geothermal heating (see also p. 25-26).

Temperature setting of measurement 9.

the temperature of the accumulator's upper

part (meas. 9) drops below [ ( / 2)].

The compressor stops running when the temperature of the

accumulator's upper part (meas. 9) rises above the [

( / 2)] temperature the temp. of the accumulator's

lower part is high enough (see the AccumLowerMin setting).

Temperature setting of measurement 10.

the temperature of the accumulator's lower

part (meas. 10) drops below the setting.

the temperature of the

accumulator's upper part (meas. 9) rises above the [

( / 2)] temperature the temperature of the

accumulator's lower part (meas. 10) rises above the [

5° C] the temperature of the accumulator's

lower part (meas. 10) rises above the [“AccumLowerMin “

“AccumLowHyst”] temperature

Compressor control has been on for an hour and the temperature of the

accumulator's lower part has not risen a degree the compressor alarm

is active and an attempt has been made to restart the compressor after a

delay time of 5 minutes.

The temperature of the compressor's upper part is below

[ ( /2) ” ]orthe

temperature of the accumulator's upper part (meas.9) is below the

[."]

(This calculation takes into account that the temperature of the controller

indicated H1 supply water temperature is a maximum of 50° C.)

the temperature of

the accumulator's upper part (meas. 9) is above the [

( / 2)] temperature the temp. of the accumulator's

upper part is above the [ ] the

temperature of the accumulator's upper part is above 55° C

A compressor running

command is given when

+

and

A compressor running

command is given when

The compressor stops running when

+

and

+ and

+

The electrical heating resistor switches on if

1.

or

2.

The electrical heating resistor switches off when

and

or

“AccumUpperMin” “AccumUppHyst”

“AccumUpperMin”

“AccumUppHyst”

“AccumLowerMin”

“AccumUpperMin”

“AccumUppHyst”

controller indicated

H1 supply water temp.

“AccumUpperMin” “AccumUppHyst” ElHeatUppHyst”

controller indicated H1 supply water temp El.HeatUppHyst”

“AccumUpperMin”

“AccumUppHyst”

controller indicated H1 supply water temp

-

--

-

-

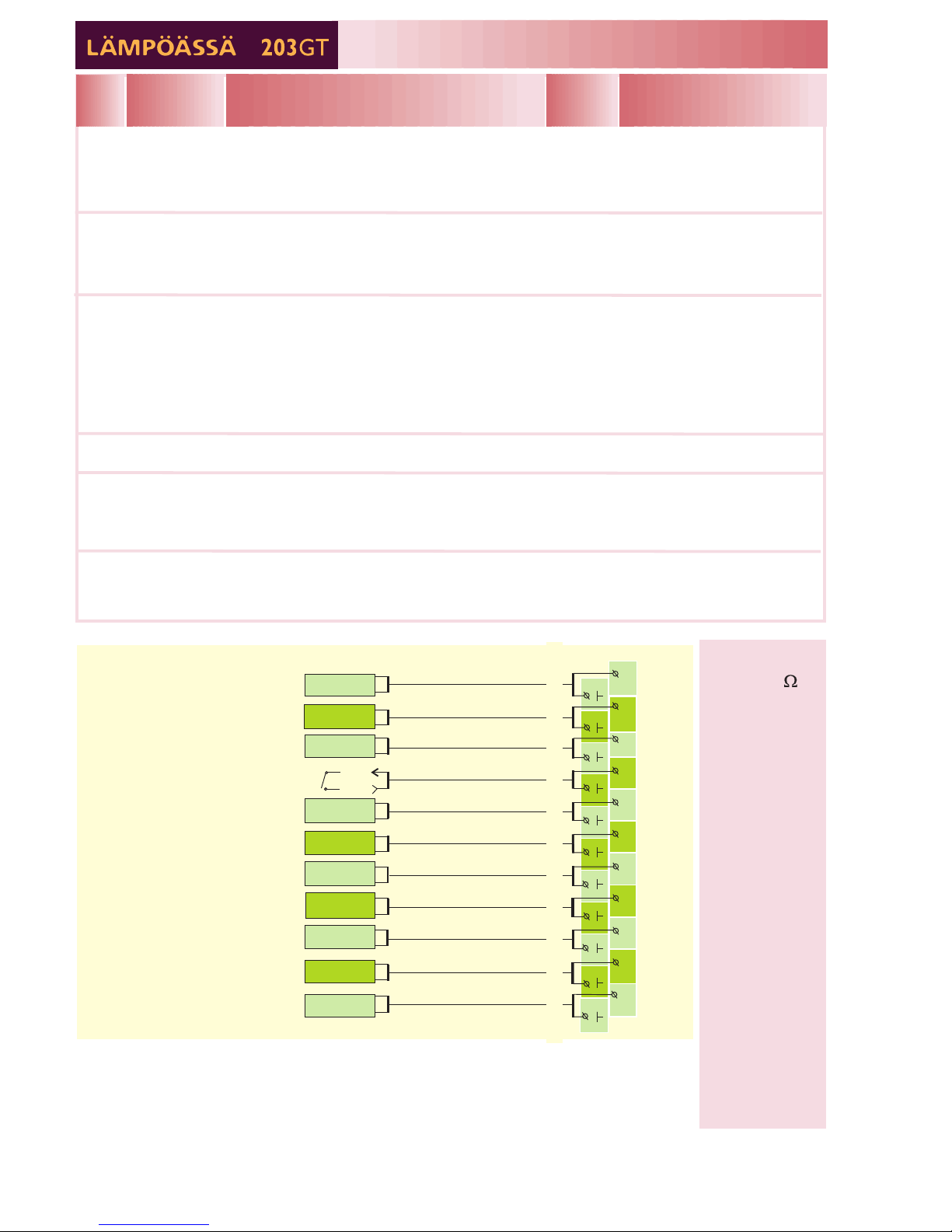

Accumulator's

upper part min.

temperature

Accumulator's

lower part min

temperature

Additional

hysteresis for

electrical heating

resistor control

"AccumUpperMin"

"AccumLowerMin"

"ElHeatUppHyst"

5...55°C

30...55°C

2...10°C

55°C

45°C

10°C

The same as full effect geothermal heating except that with partial effect

geothermal heating the controller uses a calculated temperature for the

accumulator's upper part (outdoor compensation) in place of the

“AccumUpperMin” setting. (Additional information about outdoor

compensated “Upper part setting” on p. 27)

The same as full effect geothermal heating.

The same as full effect geothermal heating except that in partial effect

geothermal heating the electrical heating resistor and compressor can be

on at the same time. The electrical heating resistor switches on without

an hour's delay when the conditions for electrical heating control have

been met.

Partial effect geothermal heating (see also p. 27-28)

“AccumUpperMin”

“AccumLowerMin”

“El.HeatUppHyst”

5...80°C

30...55°C

2...10°C

55°C

45°C

2°C

Domestic hot water regulating circuit