2

Table of contents

General information

Safety ............................................................................................................................................................................................................ 3

Power supply ......................................................................................................................................................................................... 3

Heat pump domestic hot water ......................................................................................................................................................... 3

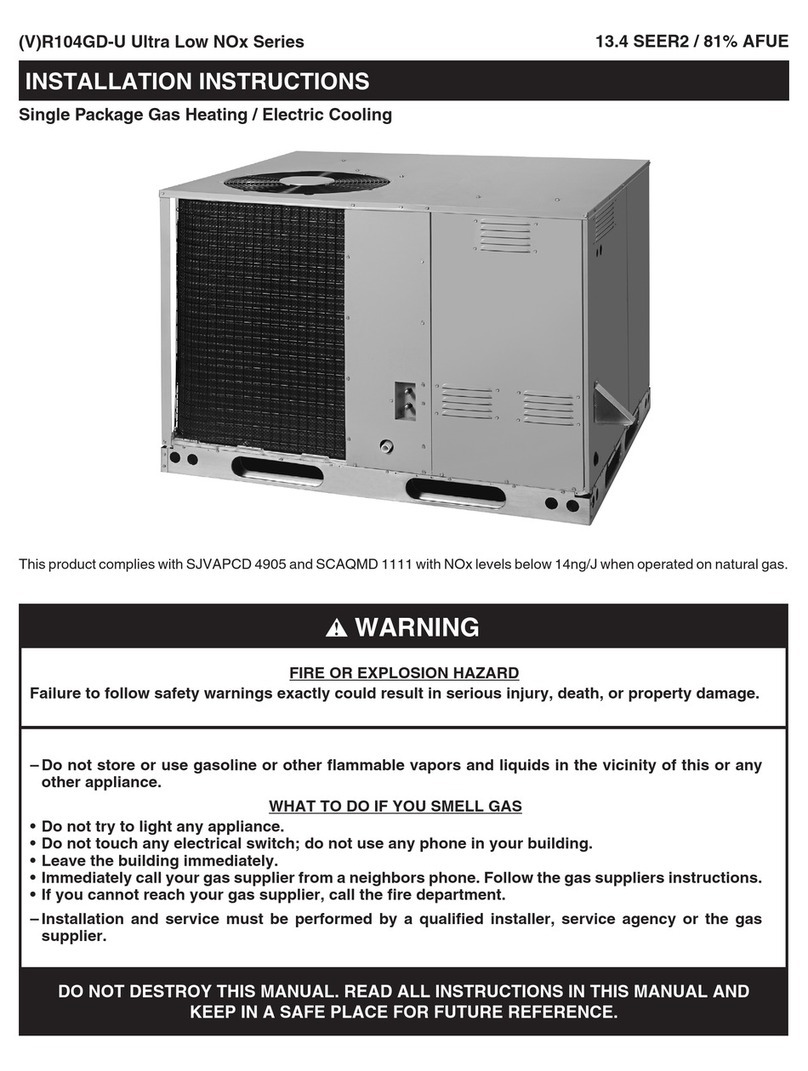

Introduction .................................................................................................................................................................................................. 4

Documentation ..................................................................................................................................................................................... 4

Type plate .............................................................................................................................................................................................. 4

User panel

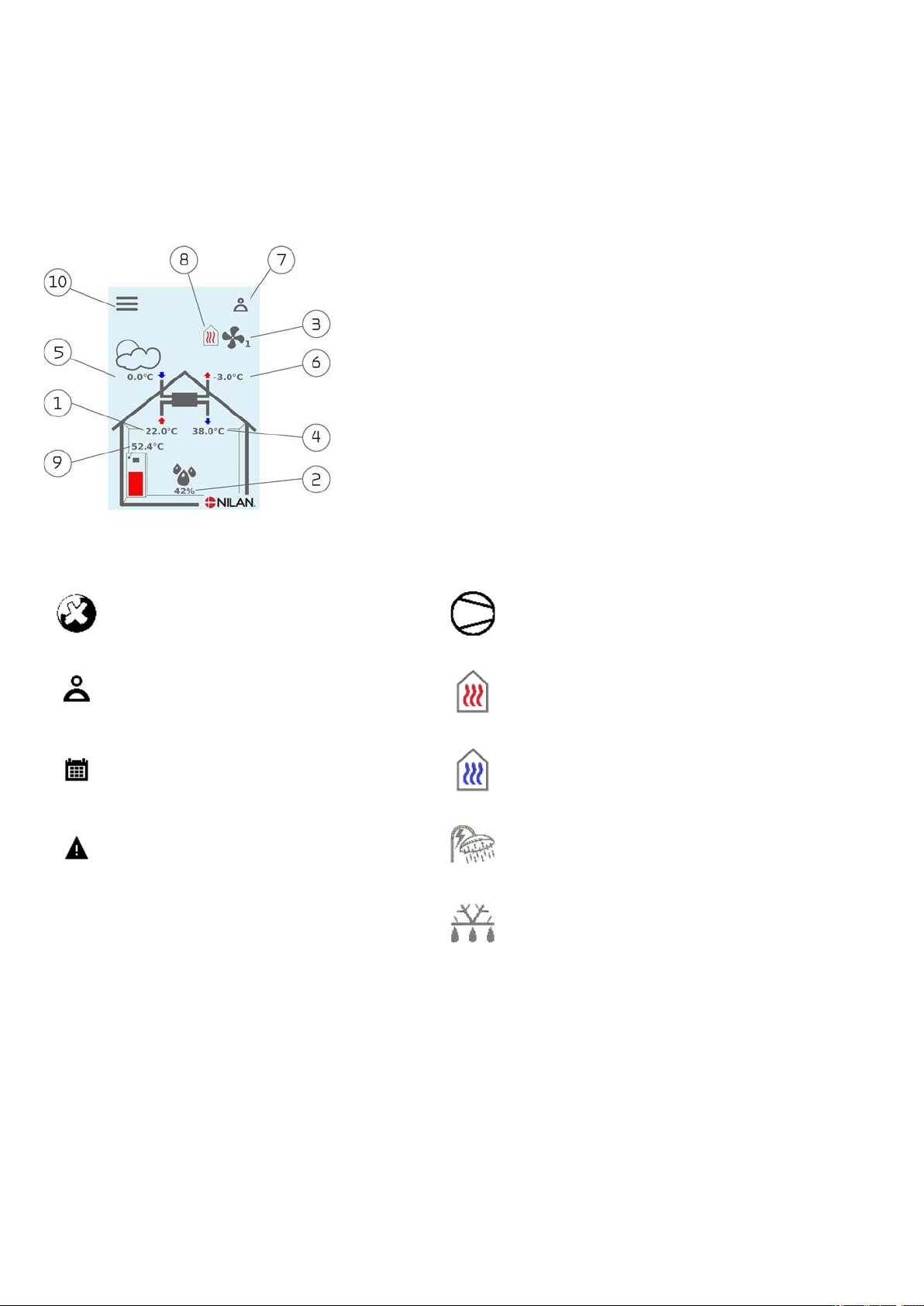

Functions in the user panel ........................................................................................................................................................................ 5

Main screen elements .......................................................................................................................................................................... 5

Settings options on the main screen ................................................................................................................................................. 6

Warning and alarms ............................................................................................................................................................................. 7

Settings menu overview ..................................................................................................................................................................... 7

Service and maintenance

General information ................................................................................................................................................................................... 8

Regular maintenance ................................................................................................................................................................................. 8

Operation of the ventilation unit ....................................................................................................................................................... 8

Illustration of filter change ................................................................................................................................................................. 9

Service ........................................................................................................................................................................................................10

General cleaning .................................................................................................................................................................................10

Water trap ............................................................................................................................................................................................10

Heat exchanger ...................................................................................................................................................................................10

Checking the sacrificial anode ..........................................................................................................................................................11

Checking the safety valve .................................................................................................................................................................11

Check the air intake and outlet ........................................................................................................................................................11

Check ventilation ducts .....................................................................................................................................................................11

The heat pump ....................................................................................................................................................................................11

User settings

Setting the unit ..........................................................................................................................................................................................12

Turn off the ventilation unit .............................................................................................................................................................12

Operating function .............................................................................................................................................................................12

Alarm ....................................................................................................................................................................................................13

Show data ............................................................................................................................................................................................13

Date/Time ............................................................................................................................................................................................14

Week program .....................................................................................................................................................................................14

Heating of supply air ..........................................................................................................................................................................15

Domestic hot water ............................................................................................................................................................................17

After heating element .......................................................................................................................................................................17

Cooling ..................................................................................................................................................................................................18

Air humidity .........................................................................................................................................................................................19

CO2 Control ..........................................................................................................................................................................................20

Air exchange ........................................................................................................................................................................................20

Air filter ................................................................................................................................................................................................21

Temperature control .........................................................................................................................................................................22

Language ..............................................................................................................................................................................................22

Alarm list

Compact ......................................................................................................................................................................................................23

Alarm list ..............................................................................................................................................................................................23

Troubleshooting

Emergency operation domestic hot water ....................................................................................................................................25

Errors and solutions domestic hot water .......................................................................................................................................26

Technical data

EU/EC Declaration of Conformity ...................................................................................................................................................27

Ecodesign data - Hot water production ..........................................................................................................................................28

Disposal

The environment - part of the solution .................................................................................................................................................29

Ventilation unit ...................................................................................................................................................................................29