9

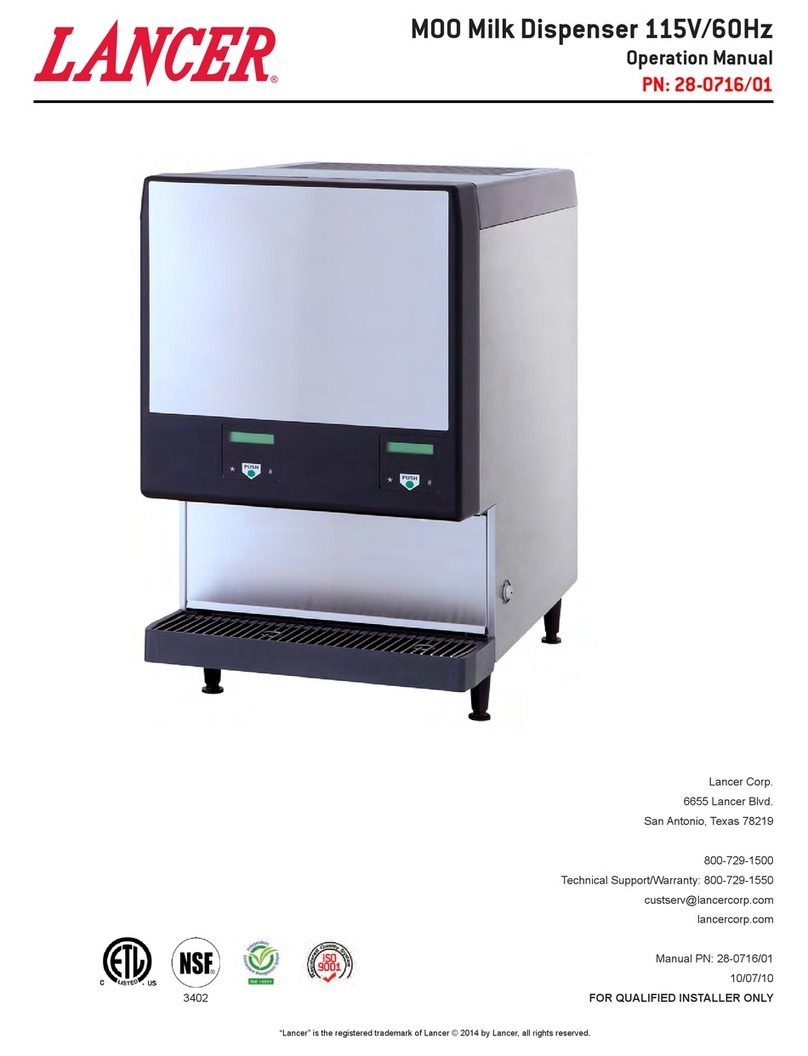

AUTOMATIC AGITATION/AGITACIÓN AUTOMÁTICA/

! Units are equipped with an automatic agitation system and will activate unexpectedly. Do not place hands or for-

eign objects in the water bath tank. Unplug the dispenser during servicing, cleaning, and sanitizing. To avoid personal

injury, do not attempt to lift the dispenser without assistance. For heavier dispensers, use a mechanical lift.

! Las unidades están equipadas con un sistema automático de agitación, por lo que se pueden activar repentina-

mente. No ponga las manos ni objetos extraños en el compartimiento donde se guarda el hielo. Durante el servicio,

la limpieza y la esterilización, desenchufe el dispensador. Para evitar lesiones personales, no trate de levantar el

dispensador sin ayuda. Para los dispensadores más pesados, use un elevador mecánico.

! Les appareils sont équipés d’un système d’agitation automatique qui s’activera de manière inattendue. Ne mettez

pas les mains ou des corps étrangers dans le compartiment d’entreposage de glace. Débranchez le distributeur

pendant l’entretien/la réparation, le nettoyage et l’aseptisation. Pour éviter des blessures, n’essayez pas de soulever

le distributeur sans aide. Pour les distributeurs plus lourds, utilisez un chariot élévateur.

WATER NOTICE/AGUA AVISO/ PRÉAVIS DE L’EAU

! Provide an adequate potable water supply. Water pipe connections and xtures directly connected to a potable

water supply must be sized, installed, and maintained according to federal, state, and local laws. The water

supply line must be at least a 3/8 inches (9.525 mm) pipe with a minimum of 20 PSI (0.138 MPA) line pressure, but

not exceeding a maximum of 50 PSI (0.345 MPA). Water pressure exceeding 50 PSI (0.345 MPA) must be reduced

to 20 PSI (0.138 MPA) with the provided pressure regulator. Use a lter in the water line to avoid equipment damage

and beverage off-taste. Check the water lter periodically, as required by local conditions. The water supply must be

protected by means of an air gap, a backow prevention device (located upstream of the CO2 injection system) or

another approved method to comply with NSF standards. A leaking inlet water check valve will allow carbonated

water to ow back through the pump when it is shut off and contaminate the water supply. Ensure the backow pre-

vention device complies with ASSE and local standards. It is the responsibility of the installer to ensure compliance.

! Proporcione un suministro adecuado de agua potable. La línea de suministro de agua debe ser de una tubería de

por lo menos 3/8 pulgadas (9.525 mm) con una presión de línea mínima de 20 PSI (0.138 MPA) , pero sin superar

el máximo de 50 PSI (0.345 MPA). La presión de agua que supere los 50 PSI (0.345 MPA) se debe reducir a 20 PSI

(0.138 MPA) con un regulador de presión. Use un ltro en la línea de agua para evitar daños al equipo y cierto sabor

raro en las bebidas. Verique periódicamente el ltro de agua de acuerdo con las condiciones imperantes. El

suministro de agua debe estar protegido por una separación de aire, un dispositivo de prevención del contraujo

(situado antes del sistema de inyección de CO2) u otro método aprobado para cumplir las normas NSF. Si la válvula

de retención de entrada de agua tuviera pérdidas, permitiría el contraujo del agua carbonatada a través de la

bomba cuando se la detiene y contaminaría el suministro de agua. Asegúrese de que el dispositivo de prevención del

contraujo cumpla con las normas locales y de ASSE. Es responsabilidad del instalador cumplir con estos requisitos.

! Fournissez une alimentation en eau potable adéquate. Les connexions et les dispositifs de conduite d’eau

con- nectés directement à une alimentation en eau potable doivent être calibrés, installés et maintenus selon les lois

fédérales, provinciales et locales. La conduite d’alimentation en eau doit être un tuyau d’au moins 3/8 pouces (9.525

millimètres) avec une pression de ligne minimum de 20 LPC (0.138 MPA) , mais ne doit pas dépasser un maximum

de 50 LPC (0.345 MPA). Une pression d’eau de plus de 50 LPC (0.345 MPA) doit être réduite à 20 LPC (0.138

MPA) avec le régu- lateur de pression fourni. Utilisez un ltre dans la conduite d’eau pour éviter des dommages à

l’équipement et un goût des boissons qui n’est pas juste. Vériez le ltre à eau périodiquement, selon les exigences

des conditions locales. L’alimentation en eau doit être protégée au moyen d’un intervalle d’air, un disconnecteur

hydraulique (situé en amont du système d’injection de CO2) ou une autre méthode approuvée pour se conformer

aux normes de la NSF. Un clapet antiretour pour l’eau entrante qui fuie permettra à l’eau gazeuse de repasser par

la pompe quand elle est fermée et de contaminer l’alimentation en eau. Assurez-vous que le disjoncteur hydraulique

soit conforme aux normes de l’ASSE et locales. L’installateur est responsable d’assurer la conformité.

! !