Table of Contents

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M 2/03/12

©Copyright 2012 All rights Reserved

Land Pride provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the

preparationofthismanual,Land Prideassumes noresponsibilityforerrorsoromissions.Neitheris anyliabilityassumedfordamagesresultingfrom theuse

ofthe information containedherein. Land Pride reservesthe right toreviseand improveits productsas it sees fit.This publicationdescribesthestate of this

product at the time of its publication, and may not reflect the product in the future.

Land Pride is a registered trademark.

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

Table of Contents

Important Safety Information . . . . . . . . . . . . . 1

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . . 1

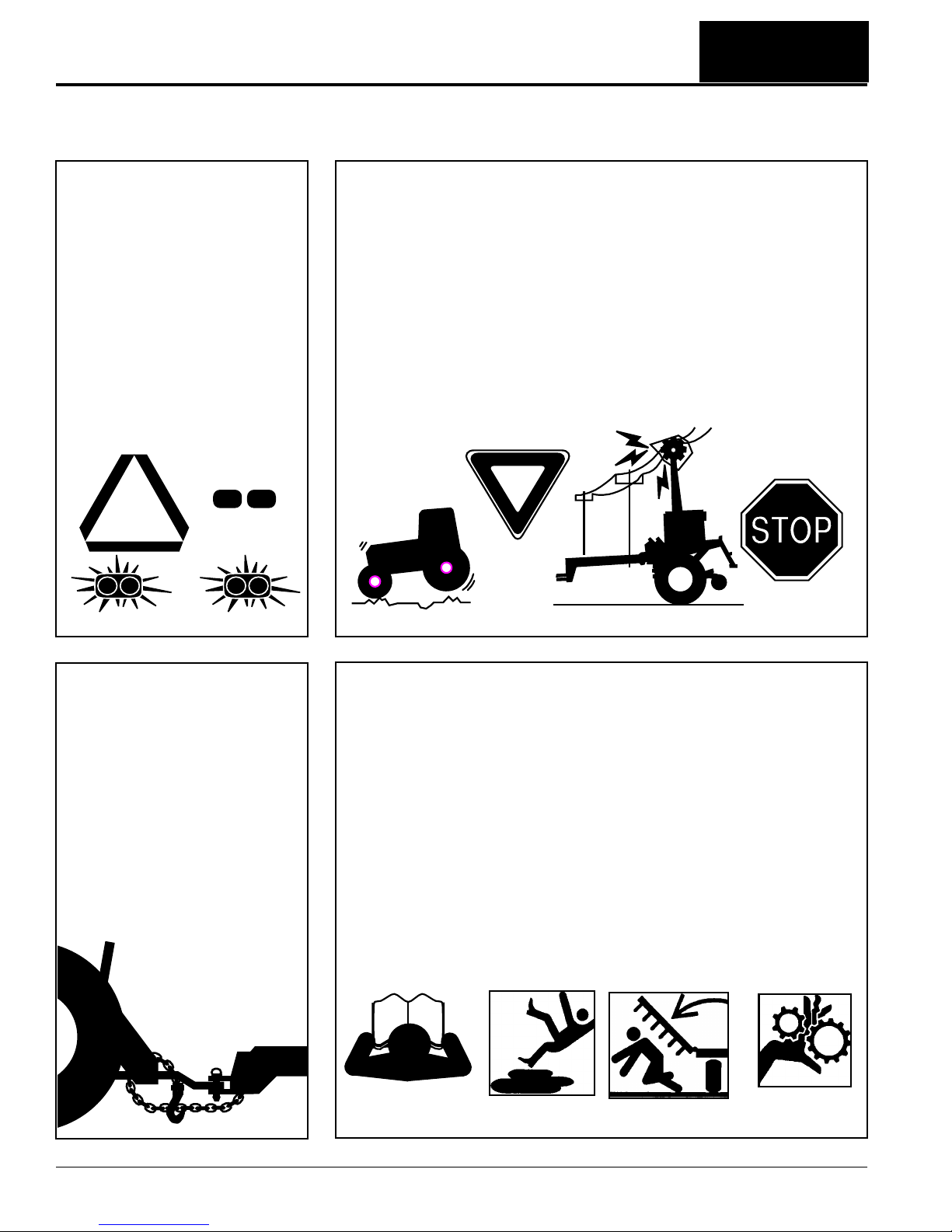

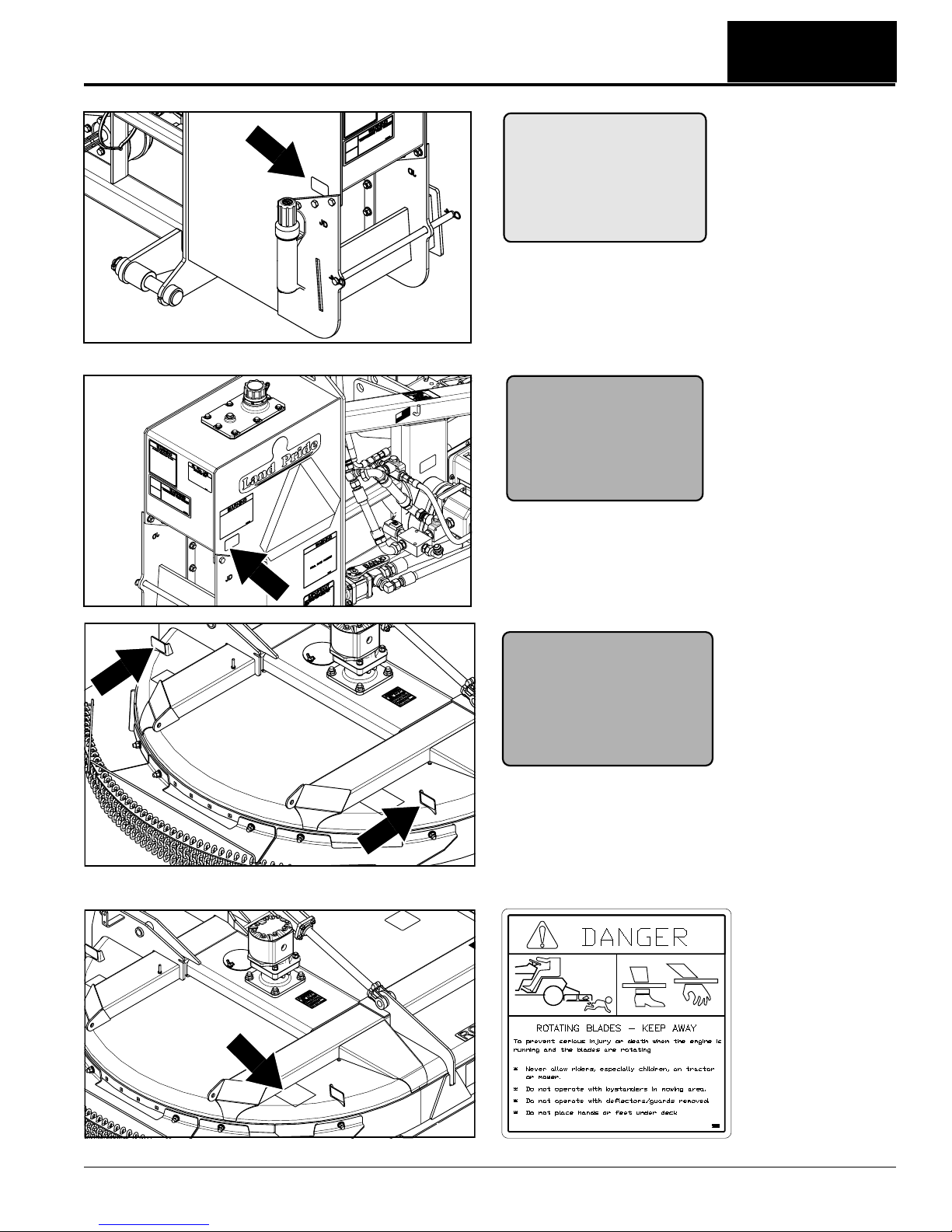

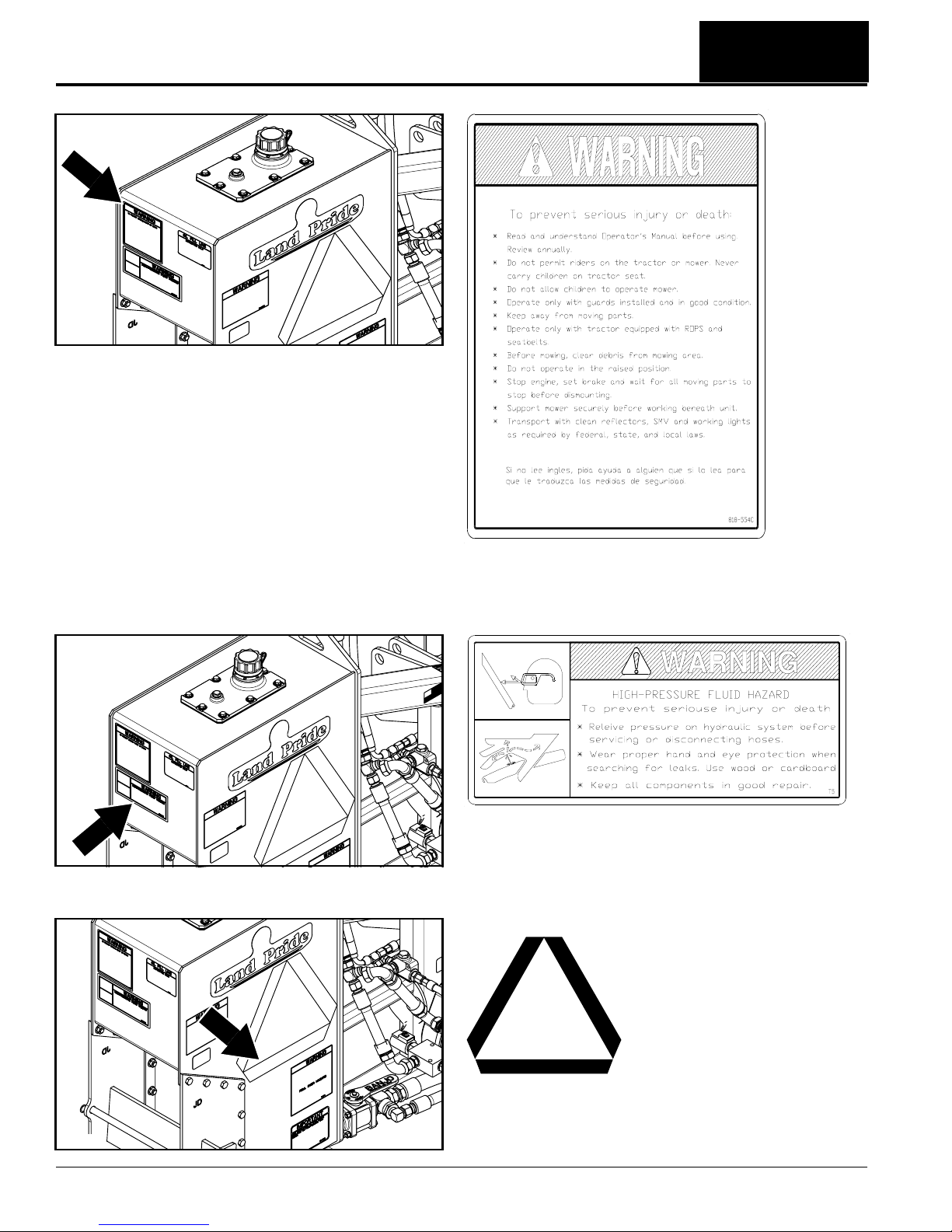

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . 10

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 10

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Section 1: Assembly & Set-up . . . . . . . . . . . 12

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . . 12

Protective Equipment Requirements . . . . . . . . . . . 13

Dealer Preparations . . . . . . . . . . . . . . . . . . . . . . . 13

Hooking-up the Rotary Cutter . . . . . . . . . . . . . . . . 14

Driveline Installation . . . . . . . . . . . . . . . . . . . . . . . 15

Check Driveline Collapsible Length . . . . . . . . . . 15

Shorten Driveline . . . . . . . . . . . . . . . . . . . . . . . . 16

Check Driveline Maximum Length . . . . . . . . . . . 16

Check Driveline Interference . . . . . . . . . . . . . . . 16

Hydraulic Reservoir Oil Fill . . . . . . . . . . . . . . . . . . 17

Transport Safety Chain . . . . . . . . . . . . . . . . . . . . . 17

Breakaway Cylinder . . . . . . . . . . . . . . . . . . . . . . . 17

Weight Hanger . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Gauge Wheels (Optional) . . . . . . . . . . . . . . . . . . . 18

Section 2: Hydraulic Set-up Options . . . . . . 19

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Tractor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Hydraulic Hose Hook-up . . . . . . . . . . . . . . . . . . 19

Console Control Lever Functional Checks . . . . . 20

Solenoid Control . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Independent Control . . . . . . . . . . . . . . . . . . . . . . . 22

Solenoid Valve Block Functions . . . . . . . . . . . . . . 22

Independent Control . . . . . . . . . . . . . . . . . . . . . . 22

Solenoid Control . . . . . . . . . . . . . . . . . . . . . . . . . 22

Control Sticks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Control Stick Hook-up . . . . . . . . . . . . . . . . . . . . 24

Control Stick Operation . . . . . . . . . . . . . . . . . . . 25

Control Stick Functional Checks . . . . . . . . . . . . . 25

Section 3: Adjustments . . . . . . . . . . . . . . . . . 28

Hydraulic Flow Control . . . . . . . . . . . . . . . . . . . . . 28

Flow Control Valve on the Rotary Cutter . . . . . . 28

Turtle/Rabbit Flow Control at the Tractor . . . . . . 28

Deck Level Adjustments . . . . . . . . . . . . . . . . . . . . 29

Without Gauge Wheels . . . . . . . . . . . . . . . . . . . 29

With Gauge Wheels . . . . . . . . . . . . . . . . . . . . . . 29

Section 4: Operating Procedures . . . . . . . . . 30

Operating Checklist . . . . . . . . . . . . . . . . . . . . . . . . 30

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Basic Operating Instructions . . . . . . . . . . . . . . . . . 31

Breakaway Instructions . . . . . . . . . . . . . . . . . . . . . 32

Shear Bolt Replacement . . . . . . . . . . . . . . . . . . 32

Un-hooking the Rotary Cutter . . . . . . . . . . . . . . . .32

General Operating Instructions . . . . . . . . . . . . . . .33

Section 5: Optional Equipment . . . . . . . . . . . 34

Parallel Arm Rotary Cutter Options . . . . . . . . . . . .34

Weight Hangers . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Operator Protective Shield . . . . . . . . . . . . . . . . . . .36

Section 6: Hydraulic Plumbing . . . . . . . . . . . 37

Breakaway Cylinder . . . . . . . . . . . . . . . . . . . . . . . .37

Pressure Shut Down Valve Operation . . . . . . . .37

Tractor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Solenoid Control . . . . . . . . . . . . . . . . . . . . . . . . . .38

Solenoid Plumbing . . . . . . . . . . . . . . . . . . . . . . .38

Hydraulic Cylinder Plumbing . . . . . . . . . . . . . . . .38

Deck Motor Plumbing . . . . . . . . . . . . . . . . . . . . .39

Independent Control . . . . . . . . . . . . . . . . . . . . . . .40

Cylinder Pump Plumbing . . . . . . . . . . . . . . . . . .40

Hydraulic Cylinder Plumbing . . . . . . . . . . . . . . . .40

Deck Motor Plumbing . . . . . . . . . . . . . . . . . . . . .41

Section 7: Electrical Wiring Schematics . . . . 42

Solenoid Control Option . . . . . . . . . . . . . . . . . . . . .42

Wiring Schematic Without Gauge Wheels . . . . .42

Wiring Schematic With Gauge Wheels . . . . . . . .43

Independent Control Option . . . . . . . . . . . . . . . . . .44

Wiring Schematic Without Gauge Wheels . . . . .44

Wiring Schematic With Gauge Wheels . . . . . . . .45

Section 8: Maintenance & Lubrication . . . . . 46

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Rotary Cutter Blades . . . . . . . . . . . . . . . . . . . . . . .46

Skid Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Solenoid Valve Block . . . . . . . . . . . . . . . . . . . . . . .48

Hydraulic Hose Replacement . . . . . . . . . . . . . . . .48

Tractor Maintenance . . . . . . . . . . . . . . . . . . . . . . . 49

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . .50

Parallel Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Deck Pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Parallel Arm Pivot . . . . . . . . . . . . . . . . . . . . . . . . 50

Driveline Yokes . . . . . . . . . . . . . . . . . . . . . . . . . 51

Driveline Profile . . . . . . . . . . . . . . . . . . . . . . . . .51

Gauge Wheel Yoke and Wheel Bearing . . . . . . .51

Ratchet Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Motor Spindle Hub . . . . . . . . . . . . . . . . . . . . . . . . . 52

Hydraulic Reservoir . . . . . . . . . . . . . . . . . . . . . . . .52

Speed Increaser . . . . . . . . . . . . . . . . . . . . . . . . . .52

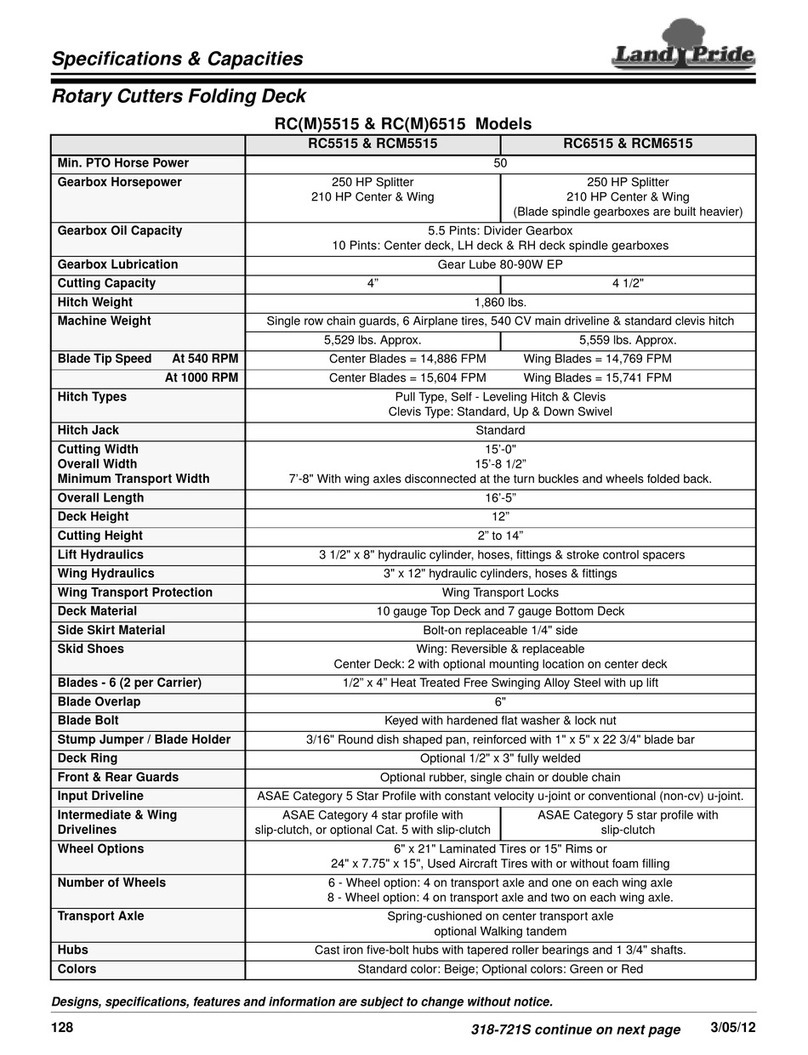

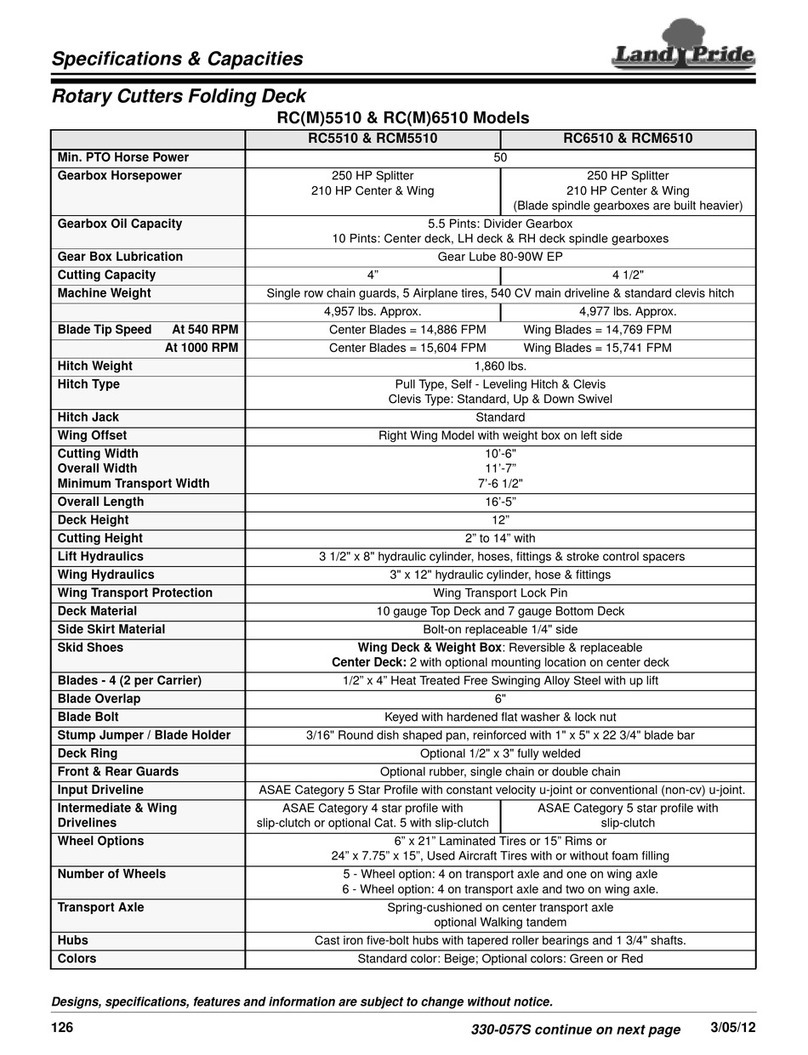

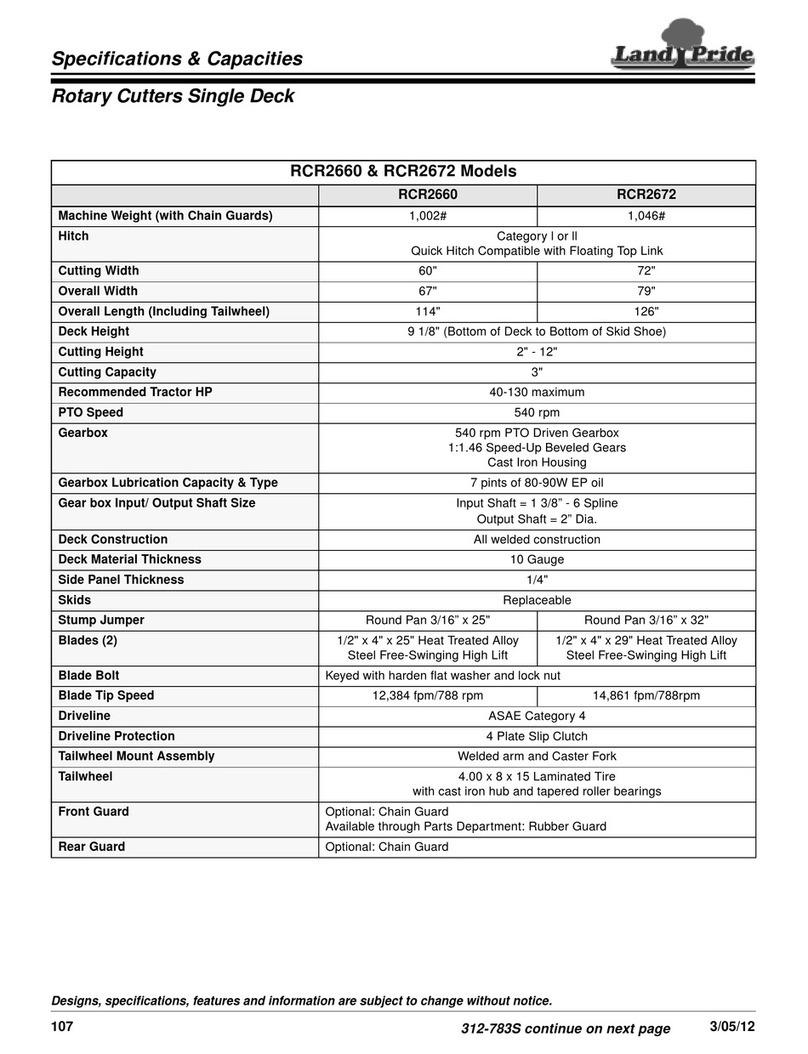

Section 9: Specifications & Capacities . . . . . 53

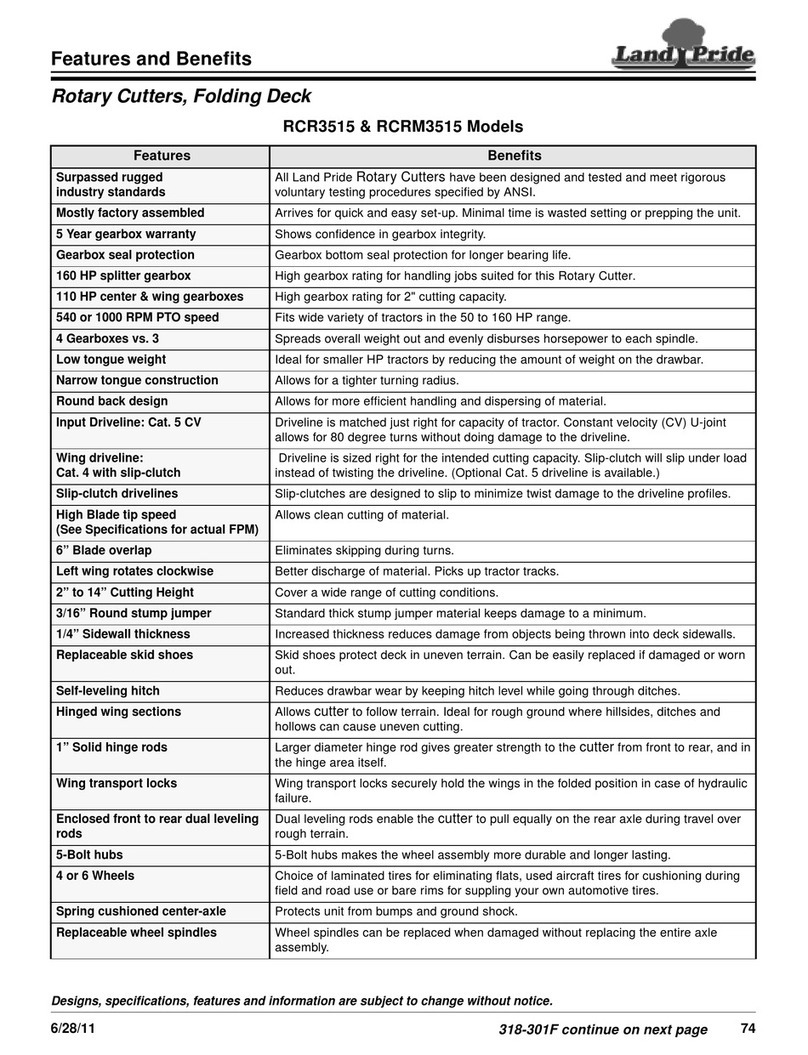

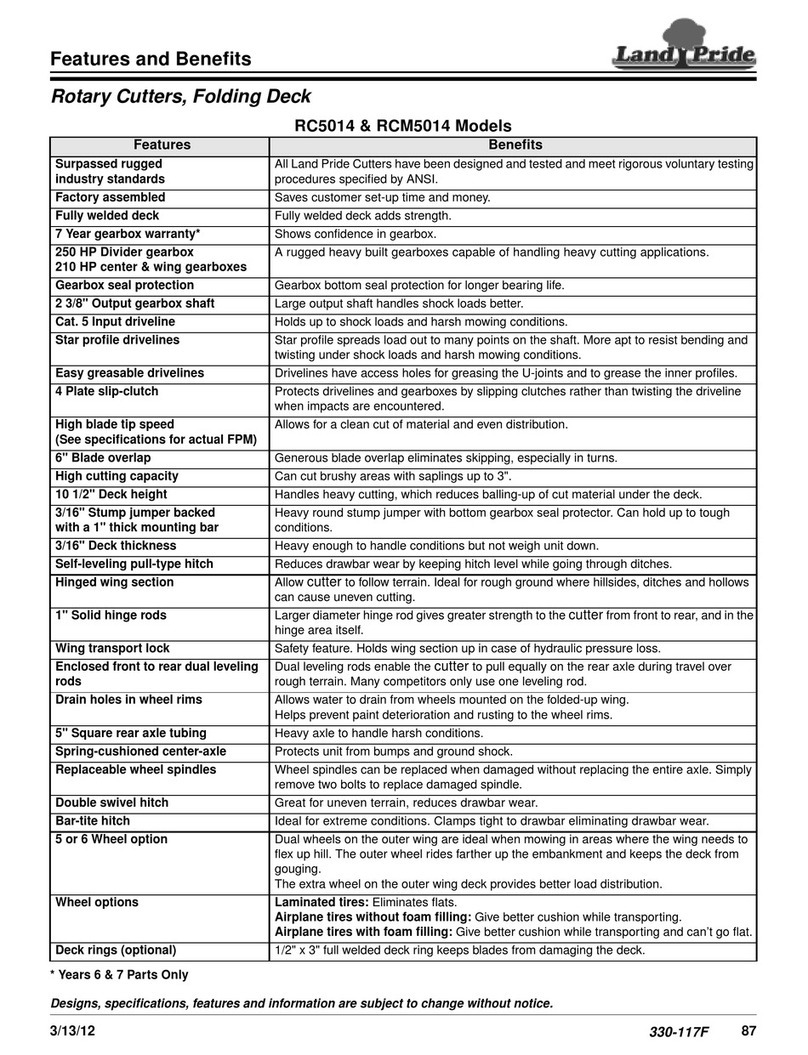

Section 10: Features & Benefits . . . . . . . . . . 55

Section 11: Troubleshooting . . . . . . . . . . . . . 56

Section 12: Torque Values Chart . . . . . . . . . . 58

Section 13: Warranty . . . . . . . . . . . . . . . . . . . 59