Site Preparation

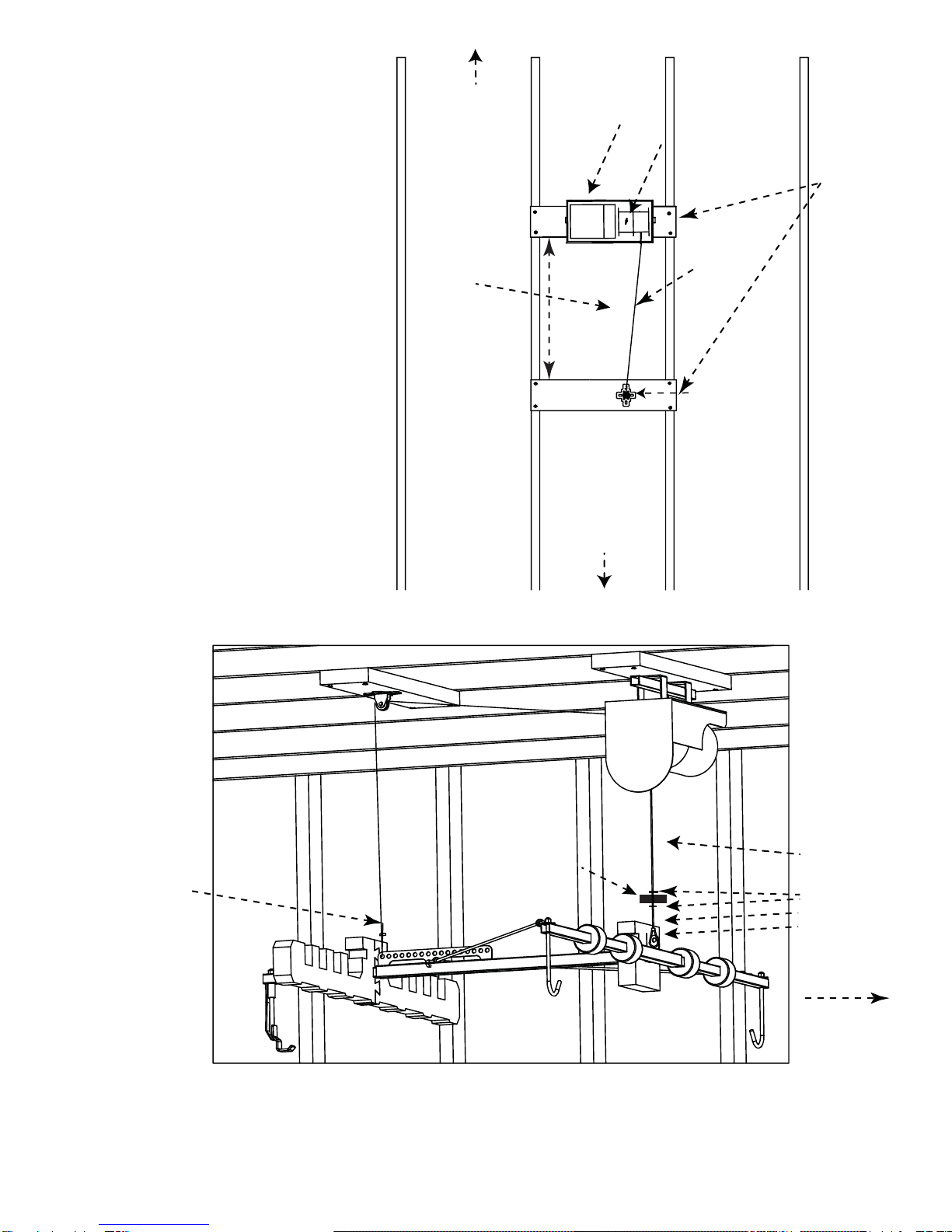

Determine whether to do a side wall mount, or a directly-over-hardtop ceiling

mount. The largest determining factor of this is ceiling height. Garages with 7-9 ft

ceiling it is recommended that a side wall installation is done. Garages over 9 ft tall it

is recommended that the power unit is installed in an overhead ceiling mount

conguration. If your ceiling is vaulted, or abnormal (anything other than parallel to

the oor) consult a contractor/professional, you will be required to build additional

supports for your power unit. Plug your power unit into a wall and test it up and

down while holding the cable centered in the fair-lead before beginning installation.

®

Lifting Cautions

Never lift your top so it is tight against the ceiling. This puts undue stress on the top and the hoist. Keep your body,

especially your hands away from edges of the top. We recommend you push or pull the top from the side and not

use the bottom edge. There is a natural tendency to align the top with your ngers under the edge.

Periodically check nuts and bolts on the Hoist-a-Top® system for tightness. Also, inspect the ceiling mounting points

for damage, or bent parts.

All Garages are dierent. Carefully read and watch the video and written instructions before installing. If you are

unsure or uncomfortable with installing this product contact a structural professional. Always test this mechanism

using a static and live load. Never stand, allow children, or pets under a lifted object on this mechanism. Misuse or

improper installation of this product can result in serious injury or death. Follow all safety rules and regulations of

tools and ladders while installing this product. Wear safety glasses, gloves, and boots while installing this product.

Never walk under or allow others to either play, stand, or work under the top.

If you need help or are missing a part DO NOT CALL YOUR DEALER. You will receive faster support though

the factory 1-866-284-7428 We oer technical support Monday through Friday 9:00 AM to 4:30 PM Mountain

Standard Time. Send us an inquiry via our website hoistatop.com anytime, or contact1@langeoriginals.com. No

question or problem is trivial so we'll try and help any way we can. We use these products ourselves and like them,

we hope you will too. Lange Originals® is not responsible for damage or personal injury due to improper installa-

tion, custom installation that doesn’t follow the instructions, or neglect.

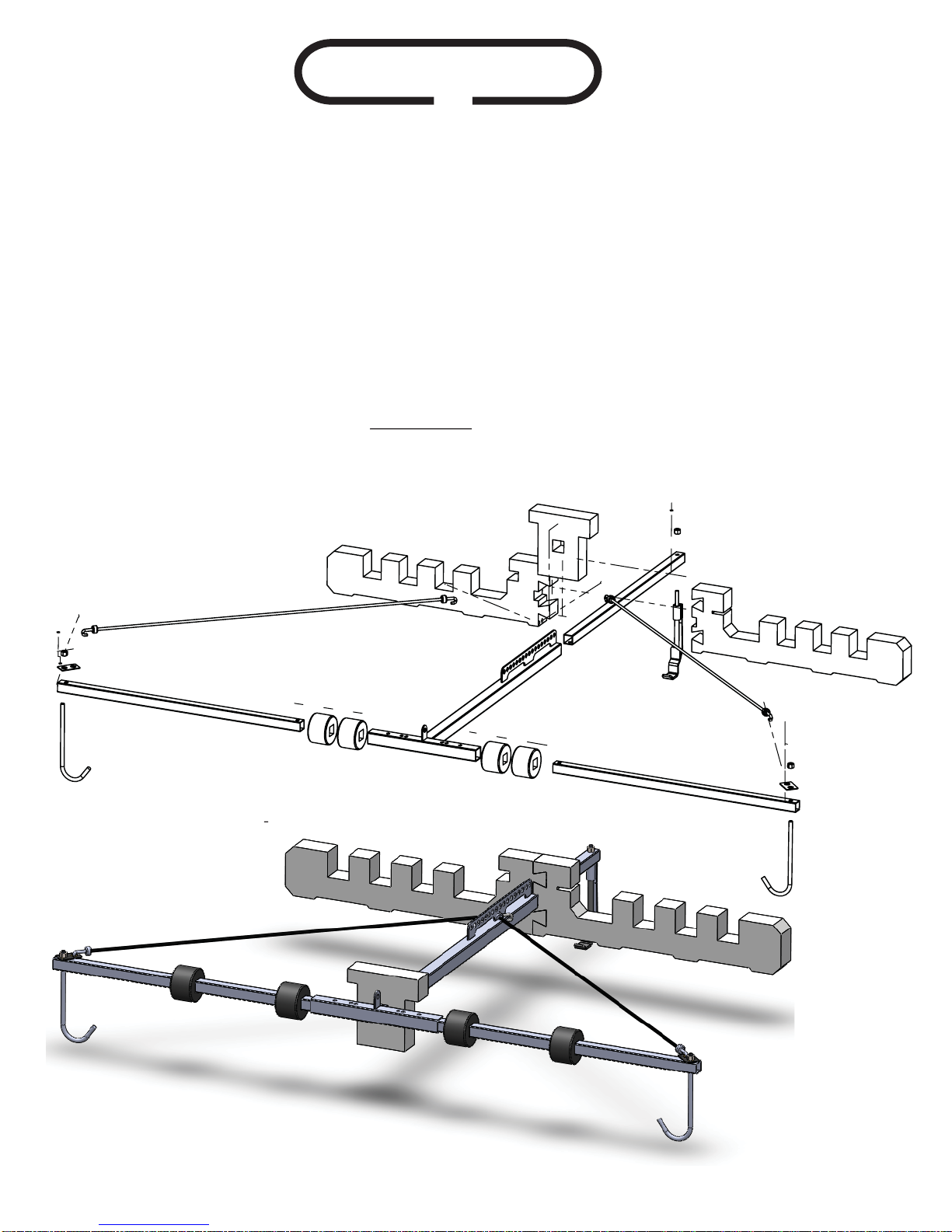

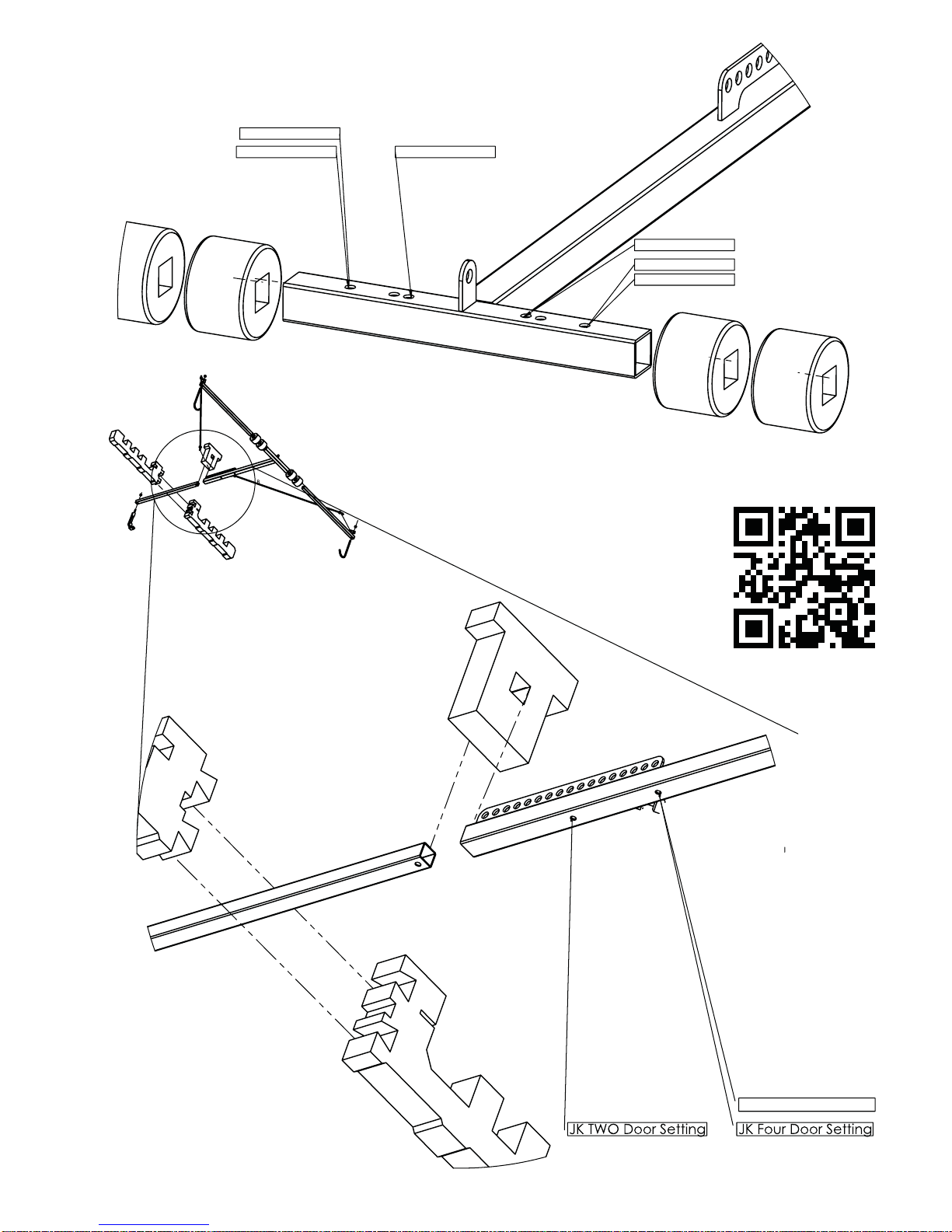

There is an online video that is extremely helpful for this product. Most questions are answered visually by watching

us do it in the video. Scanning the QR codes will open an video menu page . You can also browse to langeinstruc-

tions.com. We also have a section in the video for removing the hard top latches and wiring etc. Which can be tricky

the rst couple of times.

Warranty: This product has a 1 year limited warranty from the invoice date of purchase for defective parts only.

Lange will repair or replace parts at their discretion. For full warranty information please see langeoriginals.com and

click on warranty, and nd your specic ordered part number. Valid invoice/receipt required.

Huh? What's this thing? It’s a QR code!

Scan it with your phone to get video help,

or additional instructions. Or go to:

www.langeinstructions.com

ORIGINALS

Lange Power Unit Installation Instructions

Tools needed: Safety glasses , gloves, screwdrivers, socket wrench set with driver and sockets, drill, stan-

dard drill bits, stud-nder, and chop saw/skill saw.

Installation Time: 1-3 hours depending on experience

Installation Diculty: 3 out of 5. Person should have a basic knowledge of common household tools and

be able to nd a wall stud without diculty. Specialized tools not required. Note that text underlined in

the installation guide is found in a glossary of terms in the back of the guide.

Page 2