We reserve all rights according to DIN ISO 16016.

3. Description of the tool

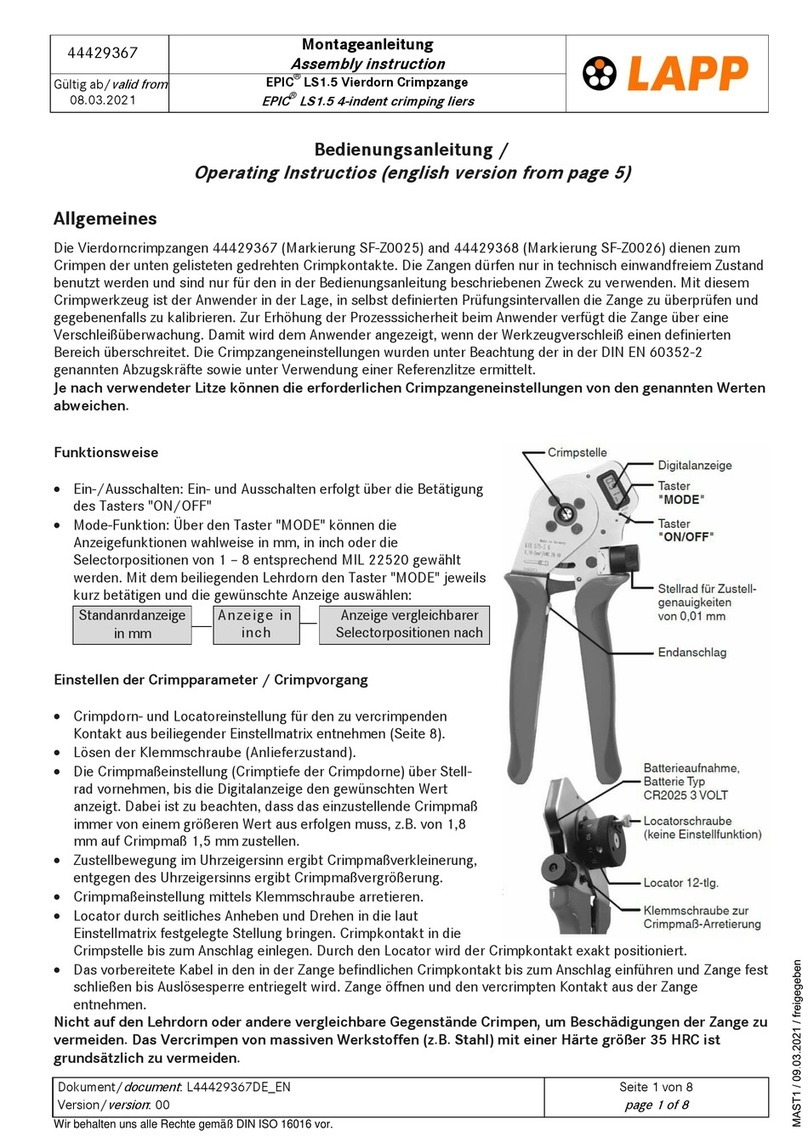

The tool consists of a movable handle with precision ratchet mechanism, a fixed handle with a metric scale, an

adjustment system by micro setting of 0.01 mm tolerance, four indenter jaws and a 12-position locator, fully

rotatable, for accurate positioning of contacts. A reference table marked onto the crimp tool’s surface informs on

the locator position and crimp depth to be selected to match a particular contact. The tool can be adjusted to any

crimp depths that might be requested by the contact manufacturer.

4. Function

Loosen the clamping screw on the opposite site of the adjusting screw before using the tool (don’t remove

the clamping screw!).

The reference table indicates the correct locator position to be selected and the crimp depth to be adjusted

for the contact to be crimped.

The contact is then inserted through the entry hole of the tool on the opposite side of the locator.

The contact is fixed by closing the handles to the first lock-in position thus preventing the contact falling out

of the tool and facilitating insertion of cable into the contact.

The precision ratchet assures consistently accurate crimps every time by forcing the tool to be closed to its fullest

extent, completing the crimping cycle before the tool opens automatically.

Changing the Locators

Loosen the hexagon socket with the enclosed allen-key. Remove the locator by turning it counter clockwise.

CAUTION:

Do not crimp onto the gauge when inserted or any other items that are not meant for the intended application! Do

not crimp on solid material exceeding 35 HRC (e.g. steel)!