408-8716

2of 3

Rev A

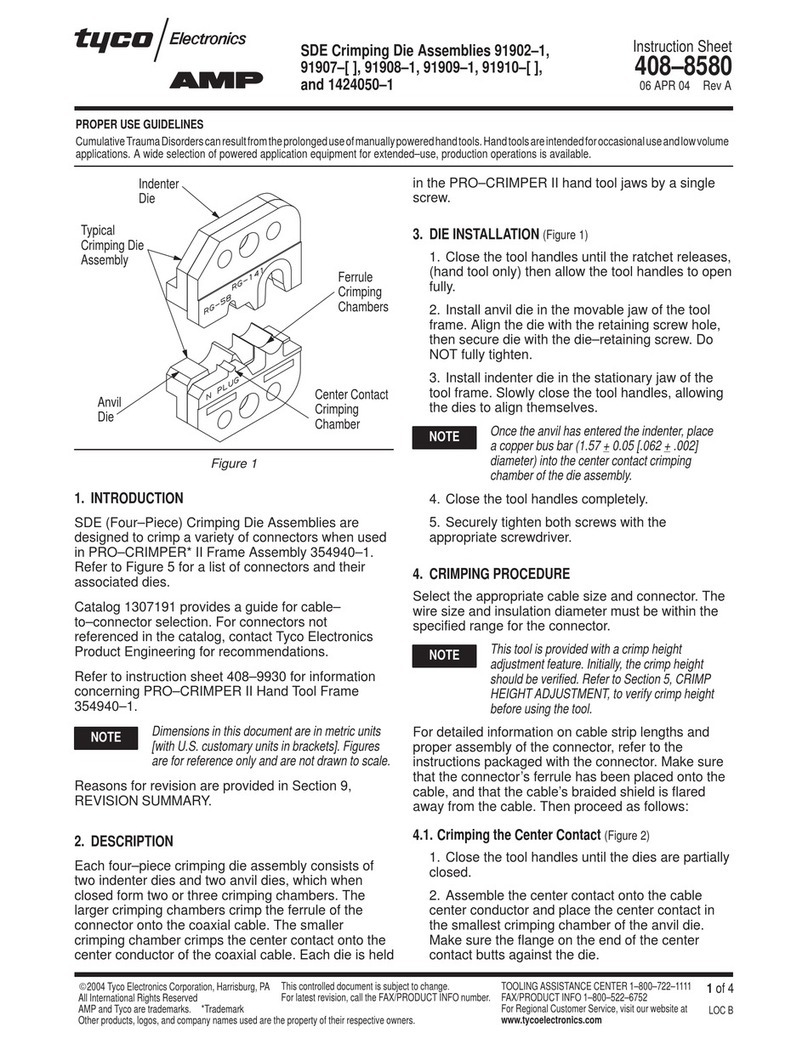

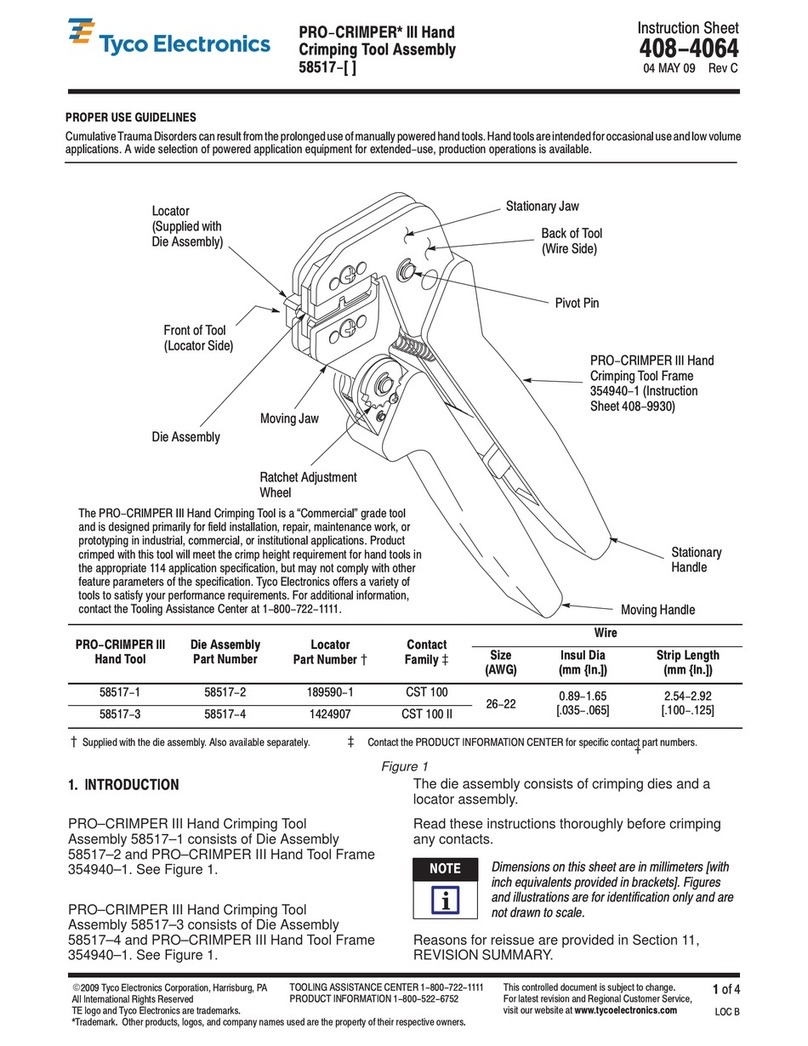

2. Insert the terminal or splice in stationary die

according to instruction sheet packaged with

dies.

To avoid personal injury, be sure to exercise

caution while holding terminals, splices, or wire in

the crimping area.

3. Pump movable lever until moving die grips

terminal or splice.

Do not deform wire barrel of terminal or splice.

4. Insert stripped wire into wire barrel of terminal

or splice.

5. Continue pumping movable lever. A slight click

may be heard, indicating the pump has shifted

into the high-pressure stage. Continue pumping

movable lever and completely crimp the

connector. This tool has a built-in by-pass

cartridge that will automatically activate when full

pressure is reached. There will be a noticeable

decrease in handle pressure when the by-pass is

reached.

A high pitched squeaking sound is normal when the

tool is operating in the high pressure stage,

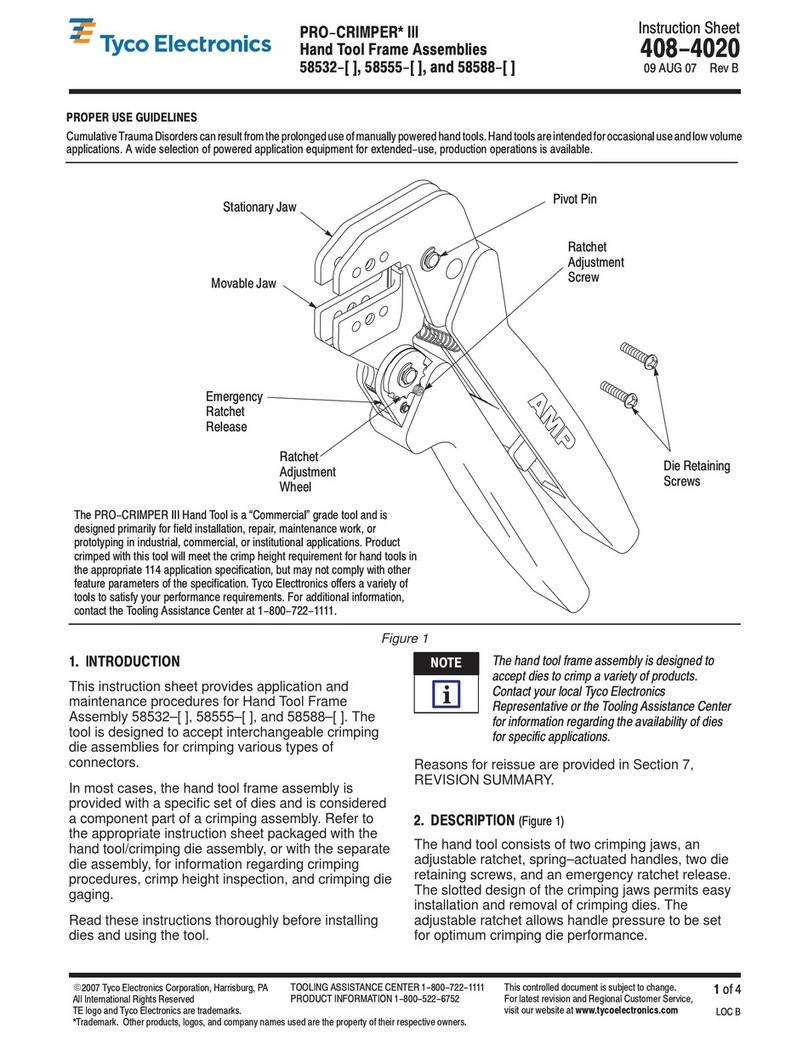

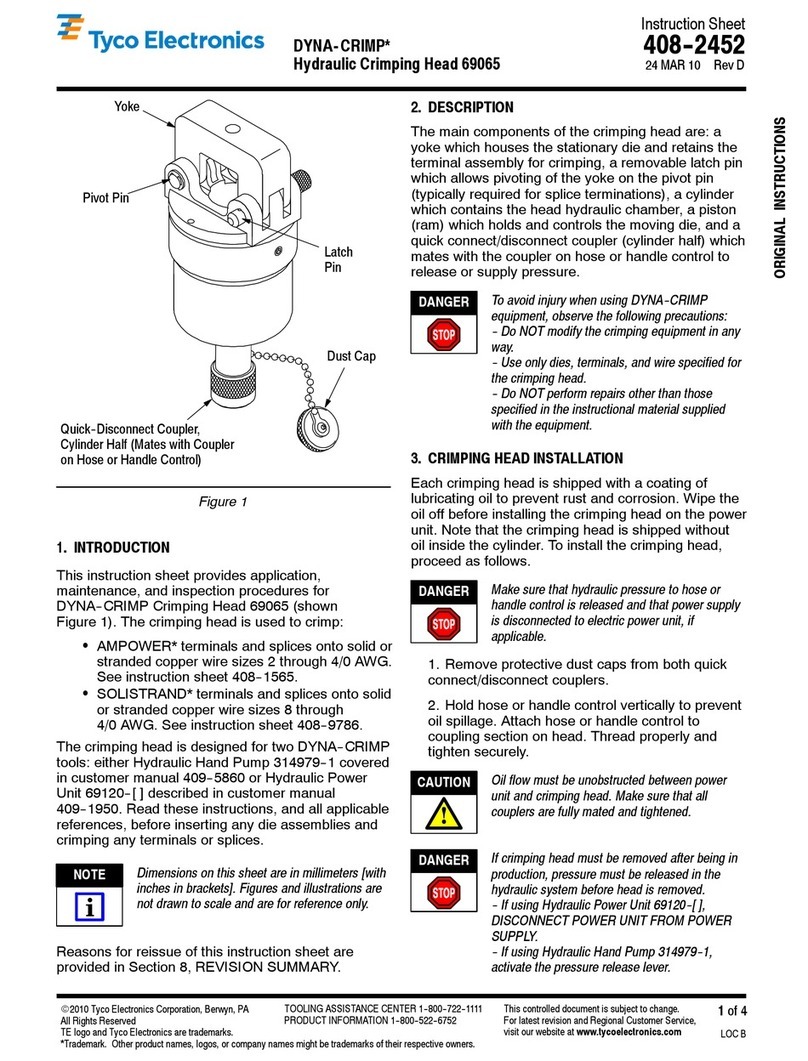

6. Turn movable lever (to actuate striker), and

compress levers to depress plunger. Movable die

will now retract. See Figure 1.

7. Remove the crimped terminal or splice.

If terminal or splice sticks in die after crimping,

apply a rocking action to remove it from die.

8. Inspect the crimped terminal or splice

according to inspection procedure on instruction

sheet packaged with the dies.

5. MAINTENANCE AND INSPECTION

It is recommended that a maintenance and inspection

program be performed periodically to ensure

dependable and uniform terminations.

The hand tool is inspected before being shipped;

however, It is recommended that the tool be inspected

immediately upon arrival at your facility to ensure that

the tool has not been damaged during shipment.

5.1. Daily Maintenance

1. Immerse the hand tool (levers partially closed)

in a reliable commercial degreasing compound to

remove accumulated dirt, grease, and foreign

matter. When degreasing compound is not

available, wipe the tool clean with a soft, lint-free

cloth. Do NOT use hard or abrasive objects that

could damage the tool.

2. Protect all pins, pivot points, and bearing

surfaces with a THIN coat of any good grade

SAE‡ 20 motor oil. Do NOT oil excessively.

3. When the tool is not in use, keep the levers

closed to prevent objects from becoming lodged

in the dies. Store the tool in a clean dry area.

5.2. Periodic Inspection

Though recommendations call for at least one

inspection a month, actual frequency depends on:

•The care, amount of use, and handling of the hand

tool.

•The presence of abnormal amounts of dust and

dirt.

•The degree of operator skill, and

•Your own established standards.

A. Lubrication

Keep all pins, pivot points, and bearing surfaces

lubricated with SAE 20 motor oil as follows:

- Tool used in daily production-lubricate daily

- Tool used daily (occasionally)-lubricate weekly

- Tool used weekly-lubricate monthly

Wipe excess oil from tool, particularly from crimping

area. Oil transferred from the crimping area onto

certain terminations may affect the electrical

characteristics of an application.

A slight weeping of oil from the ram and pump

seals is normal and required to keep the moving

parts lubricated. Excessive leakage indicates a

need for seal replacement. Refer to Section 6,

RETURN/REPLACEMENT.

B. Visual Inspection

1. Make certain all retaining pins are in place and

secured with retaining rings. If replacements are

necessary, return the tool for repair. See Section

6, RETURN/REPLACEMENT.

2. Inspect for worn, cracked, or broken areas. If

damage is evident, return the tool for evaluation

and repair as described in Section 6, RETURN/

REPLACEMENT.

C.Crimping Pressure Inspection

‡ SAE is a trademark of SAE International Corporation. Society of Automotive Engineering.