If this phase converter does not start in less than 2 seconds, TURN IT OFF!

1. Make sure the wire size meets our minimum recommended size.

2. All loads INCLUDING TRANSFORMERS must be DISCONNECTED before starting the phase converter

each time. This includes small control transformers that run controls inside your equipment. If you need an

economical 3-phase disconnect switch, please visit www.larsonelectronics.com or call 1-800-369-6671

for assistance.

If your converter still takes more than 2 seconds to start, call our Toll-Free Technical support line

1-800-369-6671. You will be asked to verify conditions 1 and 2 above are met. Failing to meet these two

condition account for 99% of starting problems and can result in damage to the starting capacitors.

This converter is quiet. If it does not sound quiet and smooth, TURN IT OFF!

3. Make sure the idler motor is mounted on rubber. DO NOT BOLT THE IDLER MOTOR DOWN! This can

cause bearing failure.

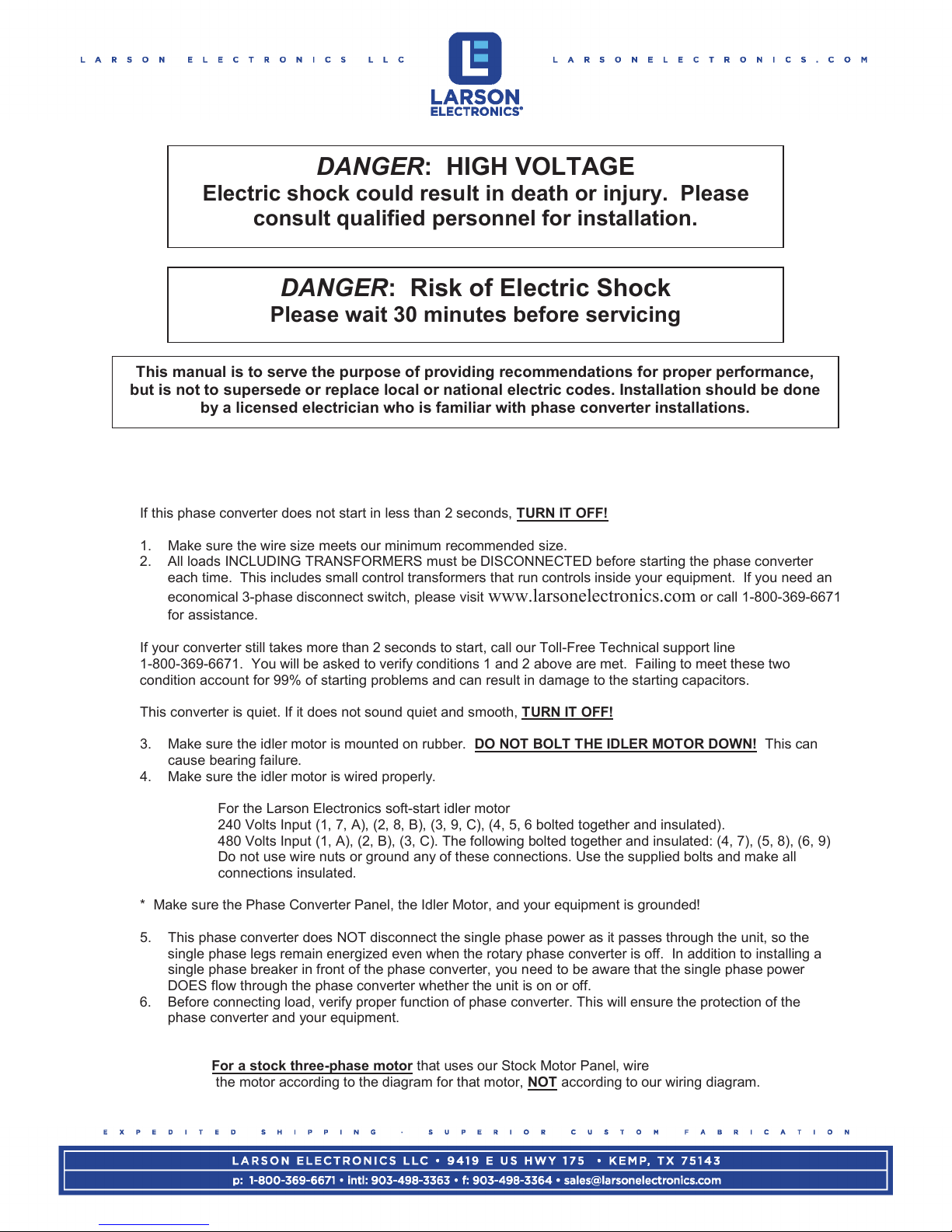

4. Make sure the idler motor is wired properly.

For the Larson Electronics soft-start idler motor

240 Volts Input (1, 7, A), (2, 8, B), (3, 9, C), (4, 5, 6 bolted together and insulated).

480 Volts Input (1, A), (2, B), (3, C). The following bolted together and insulated: (4, 7), (5, 8), (6, 9)

Do not use wire nuts or ground any of these connections. Use the supplied bolts and make all

connections insulated.

* Make sure the Phase Converter Panel, the Idler Motor, and your equipment is grounded!

5. This phase converter does NOT disconnect the single phase power as it passes through the unit, so the

single phase legs remain energized even when the rotary phase converter is off. In addition to installing a

single phase breaker in front of the phase converter, you need to be aware that the single phase power

DOES flow through the phase converter whether the unit is on or off.

6. Before connecting load, verify proper function of phase converter. This will ensure the protection of the

phase converter and your equipment.

For a stock three-phase motor that uses our Stock Motor Panel, wire

the motor according to the diagram for that motor, NOT according to our wiring diagram.

Electric shock could result in death or injury. Please

consult qualified personnel for installation.

DANGER: Risk of Electric Shock

Please wait 30 minutes before servicing

This manual is to serve the purpose of providing recommendations for proper performance,

but is not to supersede or replace local or national electric codes. Installation should be done

by a licensed electrician who is familiar with phase converter installations.