Retractable screen does not

operate

Screen cassette may have come out of

brackets

Remove screen assembly cover and make sure screen is

seated properly.

Screen cassette is caught Open your door and lower the glass insert approximately

half way. Place a hand on both sides of the screen material.

Pull down on the screen about six inches and then release

it. This should let it snap up and reset the tension.

Screen cassette has failed Replace screen cassette. Contact Larson.

Screen cassette may be too tight or shifted

to one side which will cause binding

Remove screen assembly cover and make sure screen is

seated properly. Screen cassette should free float.

Open door and lower glass half way. Place a hand on both

sides of the screen. Gently pull down on the screen about

six inches. This should allow it to snap back up and reset.

Screen fray caught in screen roll Remove screen assembly cover. Do not remove screen

roll or spring tension will be lost. Occasionally the screen

will fray and a loose strand will wrap around the end of the

screen roll. If this happens, carefully cut the thread off of the

screen roll.

Screen is out of track Screen blowing out The screen is made to blow out in heavy winds or extreme

pressure. This is normal and prevents damage. To reset the

screen, raise glass insert completely, then lower.

Raise glass insert to vent less of the screen.

Window won’t latch Top glass frame is separating in corners Replace glass Insert. Contact Larson.

Bottom glass frame is bowed on top Tap top edge back in place.

Top glass frame is bowed in middle Tap bowed frame back in place, or replace. Contact Larson.

Shipping clip is still in place on screen

cover

Remove shipping clip.

Bottom glass corner wedges are broken or

cracked

Replace wedges if damaged. Contact Larson.

Glass sash will not stay up in

up position

Missing sash handle Install sash handle per instructions.

Sash handle not catching Push glass sash all the way up to engage the sash lock for

glass. Replace if broken.

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE SOLUTION

General

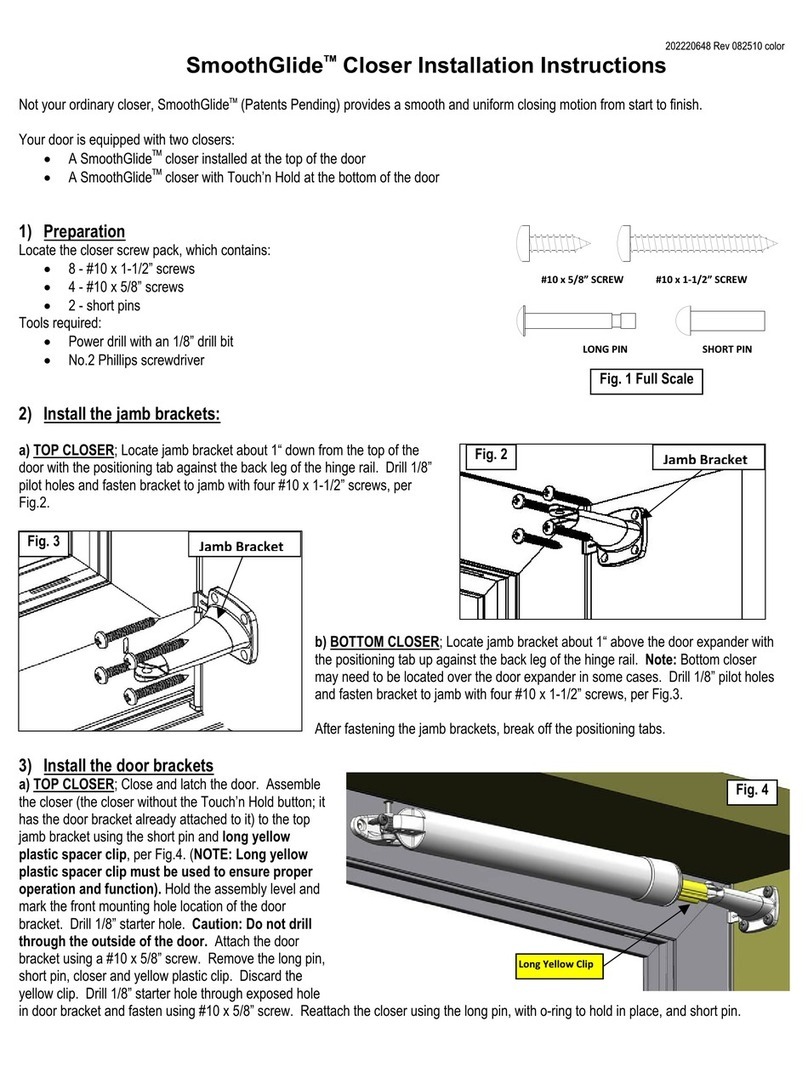

Door leaking Water getting behind door Caulk behind and around drip cap.

Door not closing properly Unpainted portion of closer rod

extended too far or not far enough

Review instruction sheet for proper closer installation.

Door closer requires adjustment Review instructions for proper closer installation.

Doors with visible closers: Adjust screws to increase or

decrease speed (on models with two closers, adjust each closer

individually by disconnecting the other closer from the door).

Closing force may be increased by repositioning the jamb

bracket farther (up to 1”) from the door.

Doors with hidden closers: Turn the screw on top of the closer

to increase (counterclockwise) or decrease (clockwise) the

speed of the door. Ensure that the slider pad moves freely in the

drip cap by loosening the bolt connecting the slider pad to the

closer arm slightly. 3-in-1 multi-purpose oil can also be applied

to the slider pad, if necessary.

Mortise latch not lined up with strike

plate

Align latch and strike plate.

Air pressure between prime and

storm door

Raise expander or leave window open to allow air to escape.

Increase closer speed.

Hinge rail screws may be too tight Loosen hinge rail screws (1/4 turn) to relax tension.

Door opening out of square Shim behind the latch or hinge rail to square up opening.

Expander dragging on threshold Raise expander so that sweeps only touch top of threshold.

Hinge rail is bent or hinge is broken Replace. Contact Larson.

Heat build up Air is not circulating enough Raise expander or leave window open to allow air to circulate.

Condensation Warm air being trapped between

storm door and primary door

Possible leak around prime door. Check prime door seals and

replace if necessary.

Use dehumidifier.

Vent storm door (retract glass or raise expander).

Surface of storm door

is dirty

Manufacturing dust or glue on

surface of door

DuraTech®surface models: Apply a small amount of Goo Gone®

Xtreme using a soft cloth. After cleaning, wipe down with soap

and water. Do not use soft scrub or any abrasive cleaner on

DuraTech or vinyl surfaces, as they will remove the surface’s

texture.

Aluminum surface models: Use SoftScrub®or mild cleaner to

clean surface.

Surface of storm door is

cracking or peeling

Weather seal damage may have

occurred

Contact Larson.

Retractable Screens

SYMPTOM POSSIBLE CAUSE SOLUTION

Hardware

I have to lift up my mortise

handle to open door

(Easy Vent®models)

The handle set is installed upside down Following the handle instructions, reverse latch nose. Install

with the key cylinder below the outside handle.

Deadbolt will not work or is

stuck in the lock position

Deadbolt is hitting edge of latch rail Might be necessary to chisel out clearance in brick mold to

freely accept the lock. Minimum depth of ¾” is required.

Deadbolt is binding against back of brick

mold frame

Push button sticks Handle screws may be too tight Loosen handle screws.

Spindle hole too small Enlarge hole. Refer to template.

Spring behind push button may be

reversed. The narrow end may slip in the

hole on the door and not function properly

Make sure spring behind push button has the wide end

against the door’s surface.

Spindle may not be in center of push

button

Verify spindle is in center of push button.

Door does not latch Latch is not engaged into strike plate Adjust strike plate.

Keyed alike option May be purchased if compatible with

your model

Contact Larson.

Storm doors are not 100% waterproof. They are designed to protect the prime entry door by slowing the elements.

The prime door is the primary seal for the opening.

Drip cap interferes with door

closing

Hinge rail not positioned correctly

or

Factory installed pilot hole not in

proper location or missing

Make sure hinge rail overlaps

the top of the door by 1/16" to

1/8". Once you have the hinge

rail properly placed (1/16" to

1/8" overlap above top of door)

mark, pre-drill hinge screws and

attach to door as instructed in

instructions.

Excess gap between door

and drip cap

Screw covers May be purchased if compatible with

your model

Visit www.LARSONdoors.com or call 1-888-483-3768.

Hinge Rail

Door closes up against the

latch side z-bar at the top or

bottom but the other end or

middle does not touch

Opening is not plumb Shim behind the latch or hinge rail to square and plumb

the opening.

Screw covers May be purchased if compatible with

your model

Contact Larson.

Latch Rail

TOP OF DOOR

RAIL