3

Instruction Manual

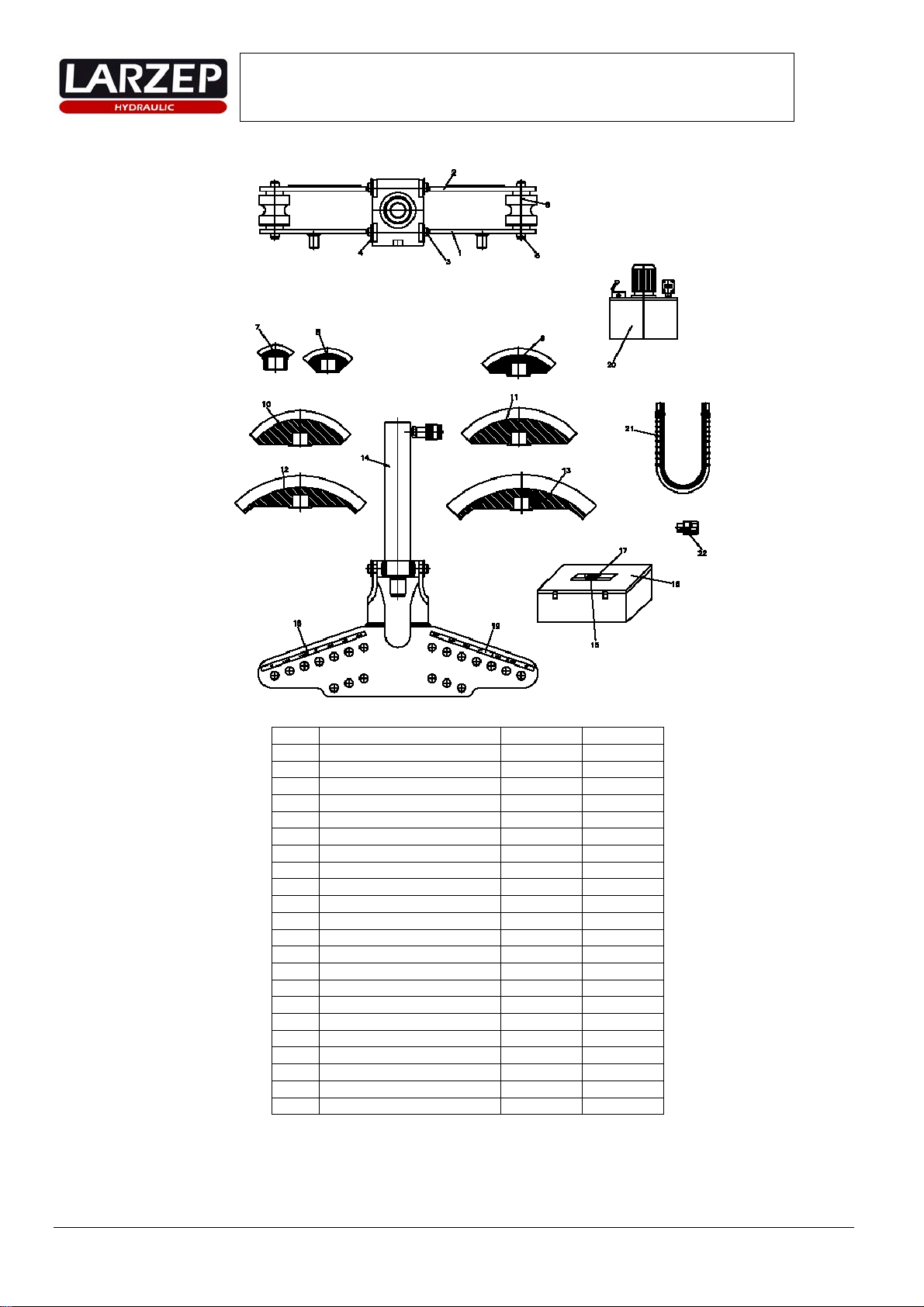

Hydraulic Bender

“VA1225” “VC1225” “VA1227” “VB1227”

MODEL VA1225 VC1225 VA1227 VB1227

DESCRIPTION Bender with cylinder and manual

pump Bender with cylinder and electro

pump Bender with horizontal

bottle jack Bender with horizontal

bottle jack and tripod.

CYLINDER SM01025 single acting and spring

return SM01025 single acting and spring

return - -

JACK - - AV1227 Horizontal

Bottle jack with internal

spring return

AV1227 Horizontal

Bottle jack with internal

spring return

PUSH CAPACITY 11.1 ton 11.1 ton 11.1 ton 11.1 ton

PISTON STROKE 262 mm 262 mm 285 mm 285 mm

PUMP W00607 YAM1114 - -

TANK CAPACITY 660 cc 2 Litres - -

FLOW PER STROKE 2.6 cc 0.35 L/min. 4.2 cc 4.2 cc

POWER - .37 Kw380 V 50Hz 3 ph - -

WEIGHT 55 Kg 50 Kg 61 Kg 70 Kg

3. START UP.

The bender is packed in a sturdy wooden box, which protects it from the knock damage throughout the transportation. Once the tool is used, clean it and

keep it into the box, to be stored until next usage.

Unpack the equipment assuring that all the parts indicated in the drawing provided in the manual are found and the material has not been damaged.

The hydraulic part is provided threaded to the structure plate of the grounds. Mount in this plate the lower and upper grounds. (Stick with the tube

measures up faced) with the axles and clips. Checking that the upper ground tilts free.

In model VB1227, assemble the tripod by screwing the coupling into the support plate and inserting it into the tripod shaft.

MODEL VA1225 MODEL VC1225 MODEL VA1227 MODEL VB1227

1. Connect the pump to the cylinder

via the hose and the quick plug. 1. Connect the electric pump to the

cylinder via the hose and the quick plug. 1. This model does not require

any type of hydraulic connection. 1. This model does not require any type

of hydraulic connection.

2. Enable a few pump strokes using

the lever with the screw slightly

loose (turn anticlockwise) in order to

bleed the circuit.

2. Replace the electric pump’s transport

plug with its operating plug. 2. Enable a few pump strokes

using the lever with the screw

slightly loose (turn anticlockwise)

in order to bleed the circuit.

2. Enable a few pump strokes using the

lever with the screw slightly loose (turn

anticlockwise) in order to bleed the

circuit.

3. Tighten the screw manually (turn

clockwise). 3. Make sure that the voltage in the mains

corresponds to that required by the

machine and that the motor rotates in the

direction indicated by the arrow.

3. Tighten the screw manually

(turn clockwise). 3. Tighten the screw manually (turn

clockwise).

4. When you pump now, the cylinder

piston will move forward. 4. With the manual distributor control set

to tank (lever towards the motor), press

the switch in order to start the motor.

4. When you pump now, the jack

piston will move forward. 4. When you pump now, the jack piston

will move forward.

5. When the screw is loosened once

again, the piston moves back due to

the action of an internal spring.

5. Alter making sure that the working

zone is unoccupied and all the elements

are fixed in place moves the distributor

lever to its open position by turning 90º.

The cylinder piston will move forward.

5. When the screw is loosened

once again, the piston moves back

due to the action of an internal

spring.

5. When the screw is loosened once

again, the piston moves back due to the

action of an internal spring.

6. When the lever is moved back to its

tank position, the piston will move back

due to the pressure applied by the cylinder

spring.

BENDING OPERATION

Once you know the dimensions of the pipe you need to bend, proceed as follows:

1. Lift the upper template so that it is vertical. (1)

2. Place the shafts in the corresponding holes in accordance with the pipe dimensions, as indicated on the chart.

3. Place the shafts rollers in the position corresponding to the pipe to be bent. See the makings on the rollers.

4. Place the bender corresponding to the pipe on the protruding end of the piston.

5. Close the upper template, thereby fixing all elements in place.

6. Insert the pipe to be bent in one side, between the two templates. Be careful not to rotate the rollers out of their correct position and make sure that the

bender stays on the end of the piston. (2)

7. Activate the hydraulic element as described in the previous section.

8. Move the piston out as far as necessary in order to achieve the desired curve angle, bearing in mind the elasticity of the pipe at all times. (3)

9. Depressurise the hydraulic element, the piston will move back in releasing the pipe.

10. Lift the template and remove the pipe. The bender will normally remain attached to the pipe. Use a plastic mallet to separate them. (4)