Page 2of 55

Checking your new 3D Pro upon arrival

Please check for any damages caused during shipping, if any damage is found, please report it immediately. If

damage is not reported on the day of arrival, the customer will be responsible for any repair costs. Calibrate

the machine when your finished setting up the software as instructed on the following pages. The tracing

function for duplicating keys works only on metal; don’t try to duplicate plastic keys.

• Make sure the plastic covers on the 3D Pro are not cracked or broken.

• Check that the tracer swing arm flips up and down properly

• The machine should have no major scratches or markings

• All missing parts should be reported upon day of arrival

1 x Jaw 1 (High security Jaw)

1 x Jaw 2 (Standard Jaw)

1 x Jaw 3 (VW Jaw)

1 x TR 2.5 Single Ended Cutter

1 x Tip Stop

1 x USB Cable

1 x AC Power Cord

Optional Parts: Bolt-Down Kit - Laptop Mount - Tibbe Adapter – Tubular Jaw

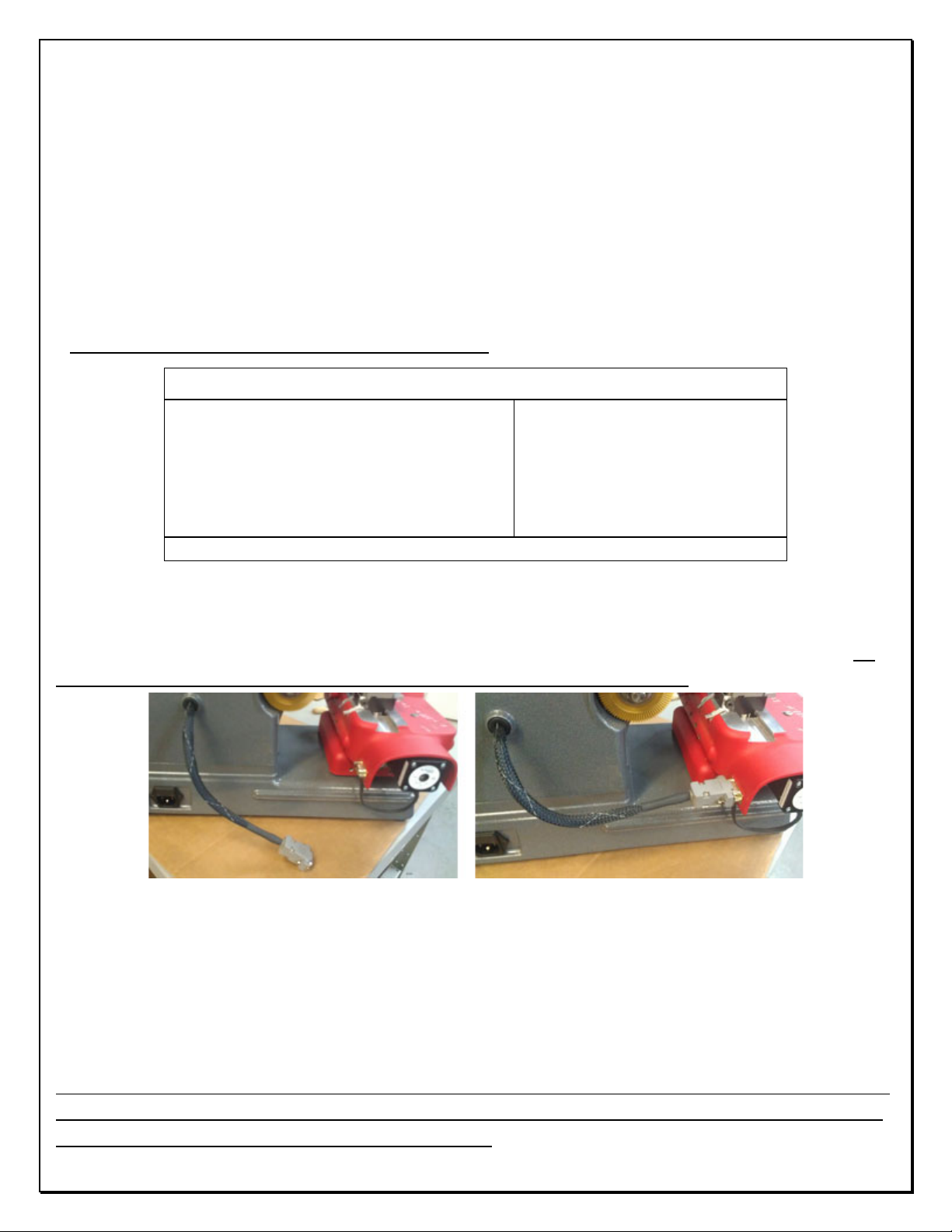

Newer 3D Pro Xtreme key machines have a hard wired motor control cable but on older machines the 9 pin

serial cable exiting the left side of the machine case should only be plugged into the 9 pin serial plug on the

left side of the X table. (see pics below) Be sure to tighten down the two small flathead attaching screws. Do

not plug the 9 pin serial cable into a computer, this will short out the control board.

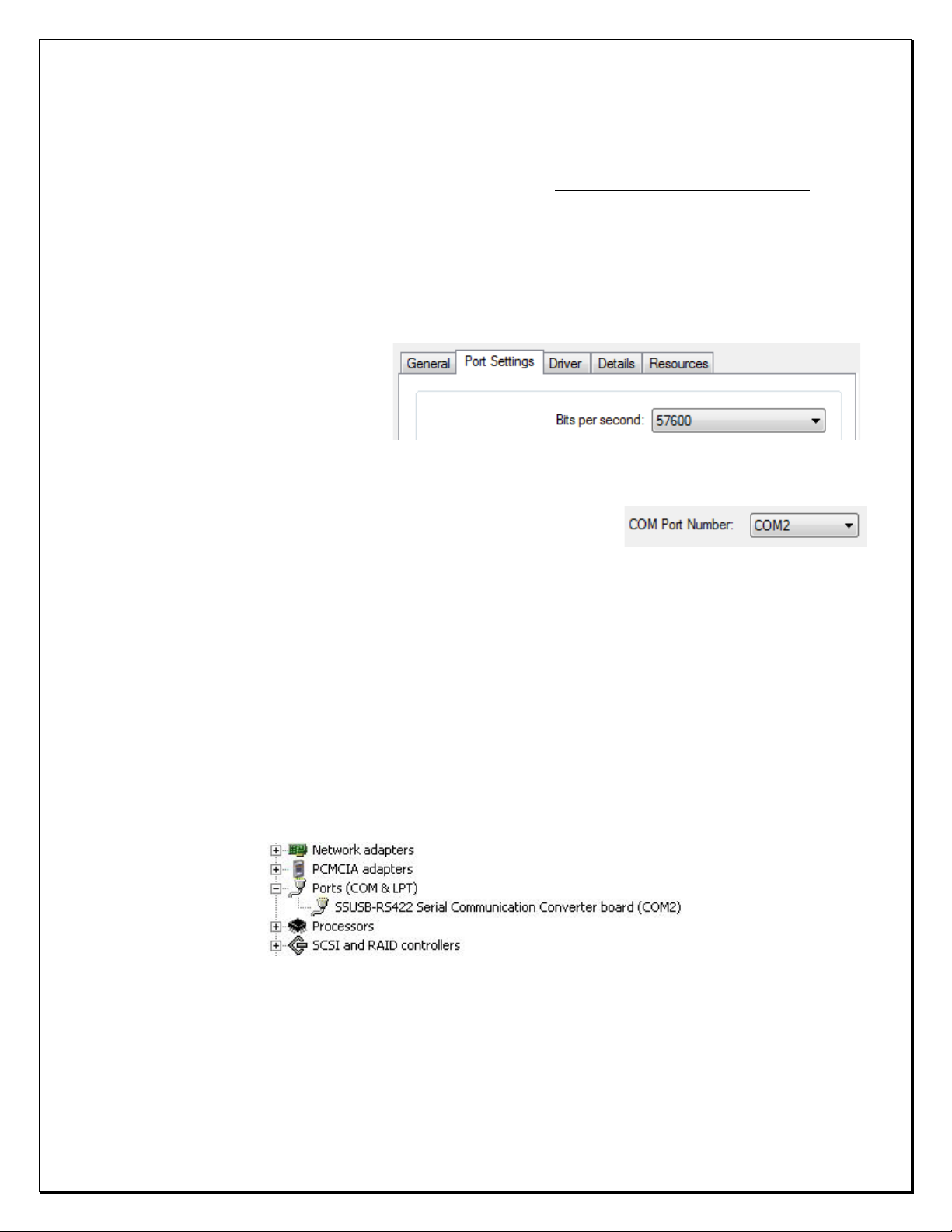

Computer Hardware Requirements

• Windows XP - SP2 or higher, Windows Vista, 7 and 8 with 2 GB of RAM

• We recommend a 1,500 watt pure sine wave inverter to extend the life of your 3D Pro and laptop.

• If using an inverter to power the 3D Pro, make sure the inverter is properly grounded to the vehicles chassis otherwise

you may experience problems with the operation of the machine. Please follow your inverter manufactures installation

instructions and refer to the “Using an Inverter” page of this manual.

When cleaning key shavings from the machine, please use a brush, please do not use compressed air as doing

so will likely blow shavings into the machine and over time causing problems such as gumming up the axis’ to

where the tables could seize up or cause electrical shorts.