1GENERAL INSTRUCTIONS FOR MULTIPLATE COUPLING E-MEQD-II003-E December 2020 www.eaton.com

1.0 INTRODUCTION

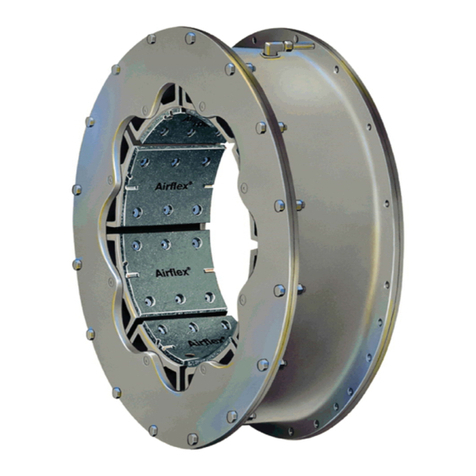

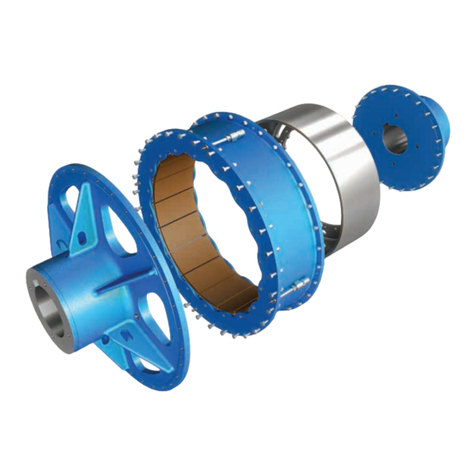

This document illustrates operating instructions for Eaton’s Multi-FF series Multiplate quick disconnect coupling. This user

manual also provides guidance about preventive maintenance of Multiplate coupling and steps for servicing in case of

malfunction.

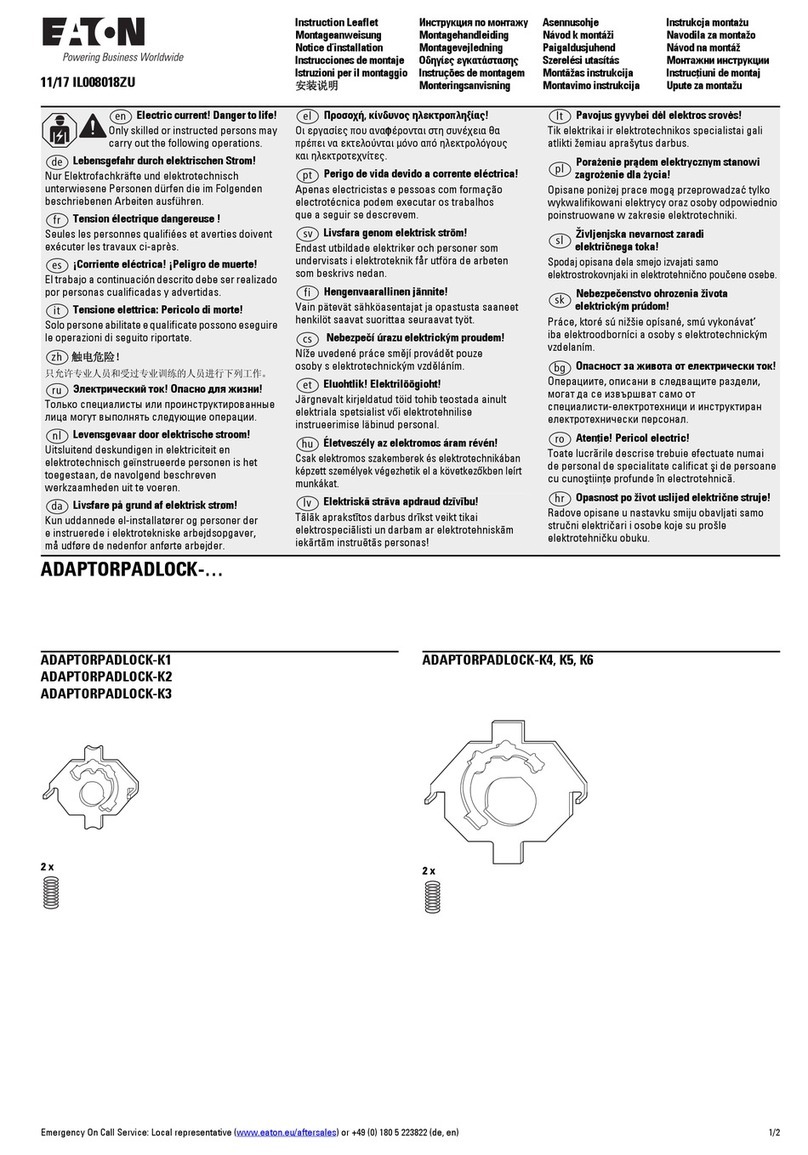

2.0 SAFETY INSTRUCTIONS

• It is recommended to wear hand-gloves while making connection or disconnection of Eaton’s Multi-FF device.

• Hold top plate / movable plate on hose lines or on to a surface perpendicular to handle strips, to avoid finger

entrapment during engagement with fixed plate.

• Once two plates / sub-systems are engaged, remove your hand off the plate and only rotate the handle. Do not put

hand/fingers in between 2 plates.

• Ensure that fingers are not entrapped in between bottom/fixed plate and handle of the device during operation

• Ensure absence of pressure inside the Multi-FF before initiating disconnection of system or carrying out any

maintenance work.

3.0 OPERATING CONDITIONS

This section covers general operating conditions to obtain long life of multiplate coupling without unpredicted failure.

It is advisable to use multi plate coupling under same operation conditions.

The allowed operating temperature lies between -20°C to 100°C. This is operating temperature of multiplate coupling

assembly and subjected to change based on seal material configuration of Coupling half. The permitted storage

temperature lies between +10°C and +35°C.

The maximum operating relative air humidity should not exceed 75%. Similarly, it should not exceed 60% for storage.

Dust & vibration free environment will ensure correct functionality of multiplate coupling.

Maximum operating pressure for multiplate coupling is as follow. These are tested at 1:4 times operating pressure and it

is advisable that system pressure for continuous service shall not exceed maximum operating pressure recommended

below.

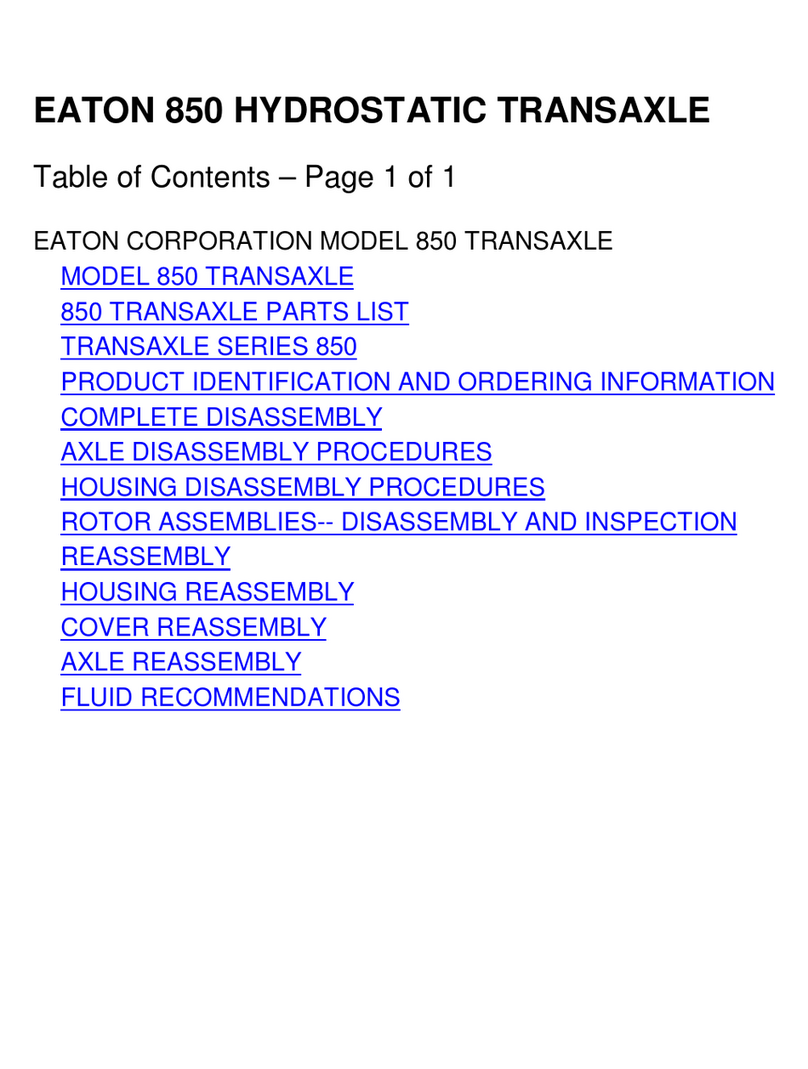

MultiFF Part

number

No. of

coupling

ports Coupling

body size Max. operating

pressure

4MFC-10CUP15LS11 4ISO 10 250 bar

4MFCE1-12CUP15L 4ISO 12 350 bar

4MFC-12CUP15L 4ISO 12 350 bar

4MFC-1015L 4ISO 10 350 bar

4MFCE1-1015L 4ISO 10 350 bar

6MFC-1015L 6ISO 10 350 bar

User Manual