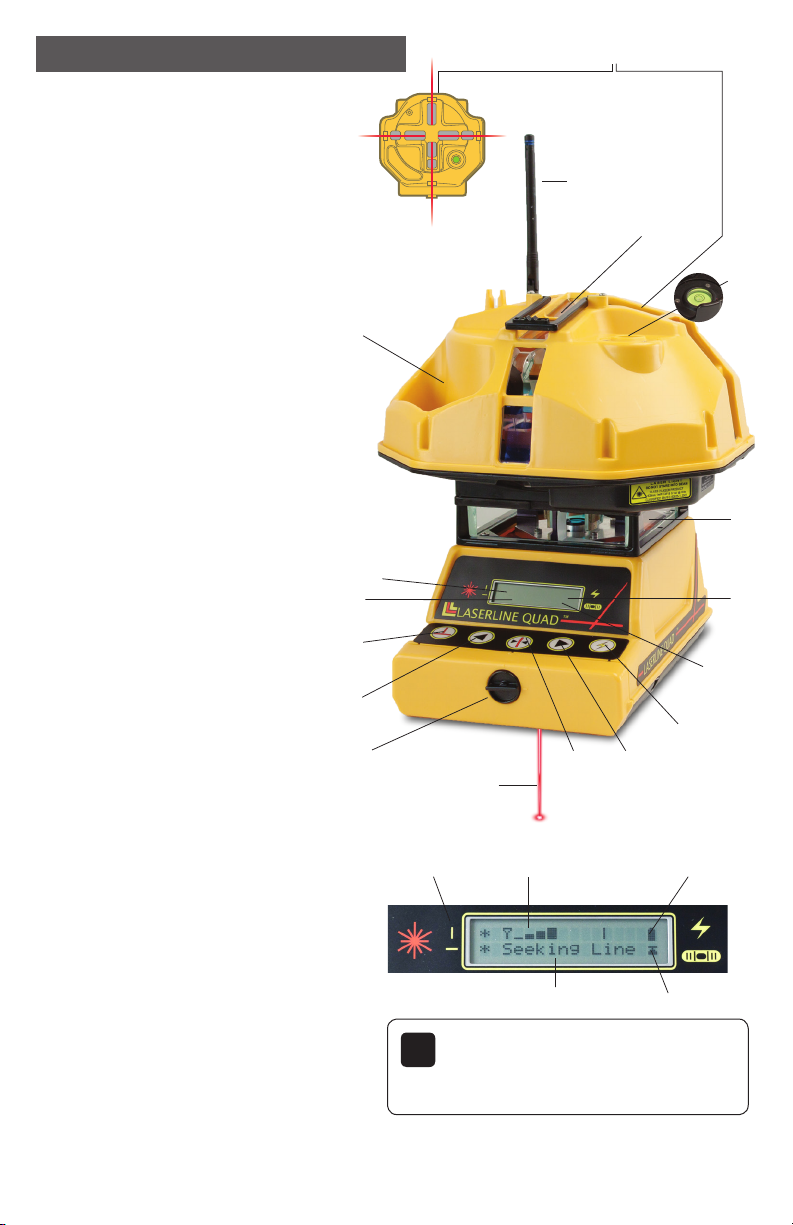

5QUAD 4000

LINELOKR™TECHNOLOGY (LLT) AUTOMATICALLY LOCKS YOUR

LASER ONLINE AND KEEPS IT THERE UP TO 600 FEET AWAY.

LLT provides a two-way communication between the Quad 4000

Laser and the LineLokr Line Control Module for vertical control

applications such as plumb, squaring and line layout.

LLT allows you to setup your laser at one point and then merely

push a button to obtain line. The Quad 4000 and LineLokr

communicate via a special radio link causing the Quad 4000 to

automatically drive itself to centerline and lock onto your far

point. The Quad 4000 and LineLokr continuously communicate

to maintain centerline and will not drift off due to wind and

temperature changes throughout the day.

1. Power Button: Depress to activate LineLokr and

communicate with the Quad 4000 (When first

activated, unit will Self Test Mode 4 seconds)

When turning off, hold power button down for two

seconds

2. MM/Inches Button: Changes display only – Not

operational in LineLokr

3. Speaker Button: Increase or decrease volume

4. Widen/Narrow Deadband Button: Regardless of the

LCD display, the LineLokr will continue to lock to the

highest possible accuracy (LineLokr accuracy is

not affected by deadband setting)

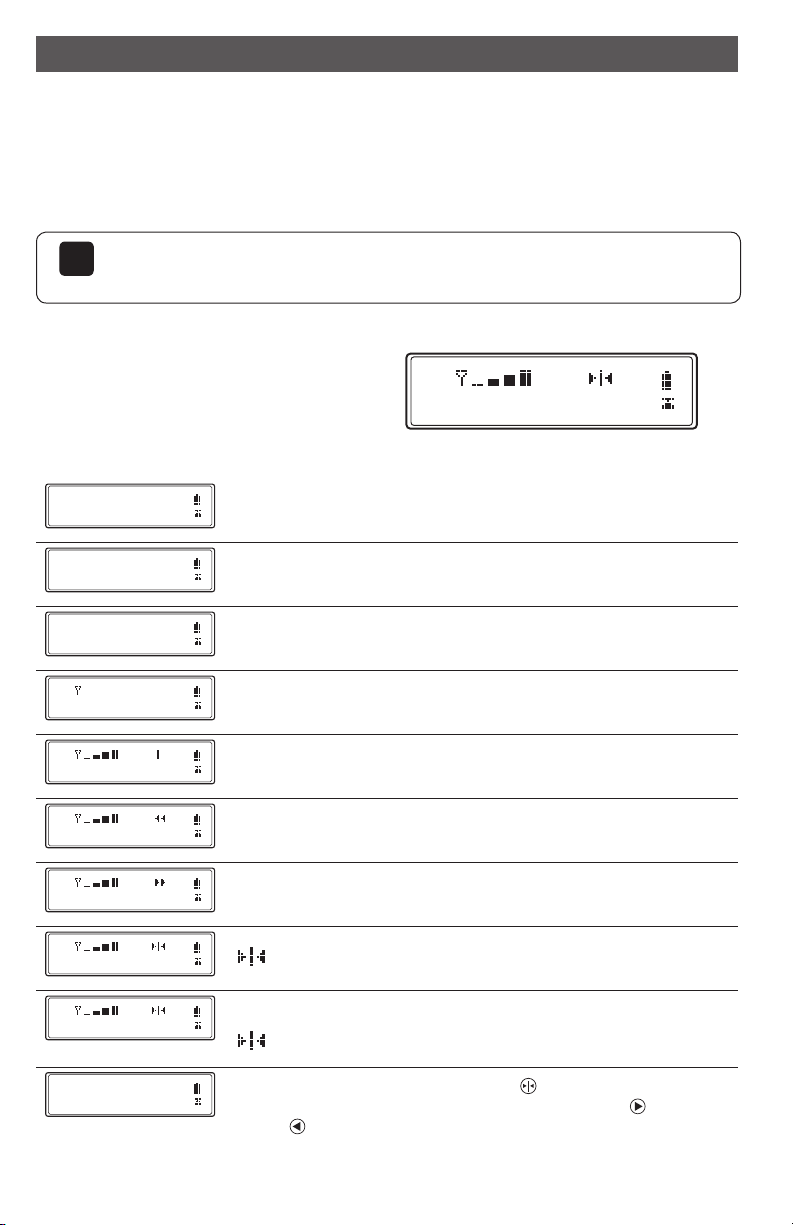

5. LCD Display: Indicates whether Quad 4000 is

driving left, driving right or is on center and locked

on line.

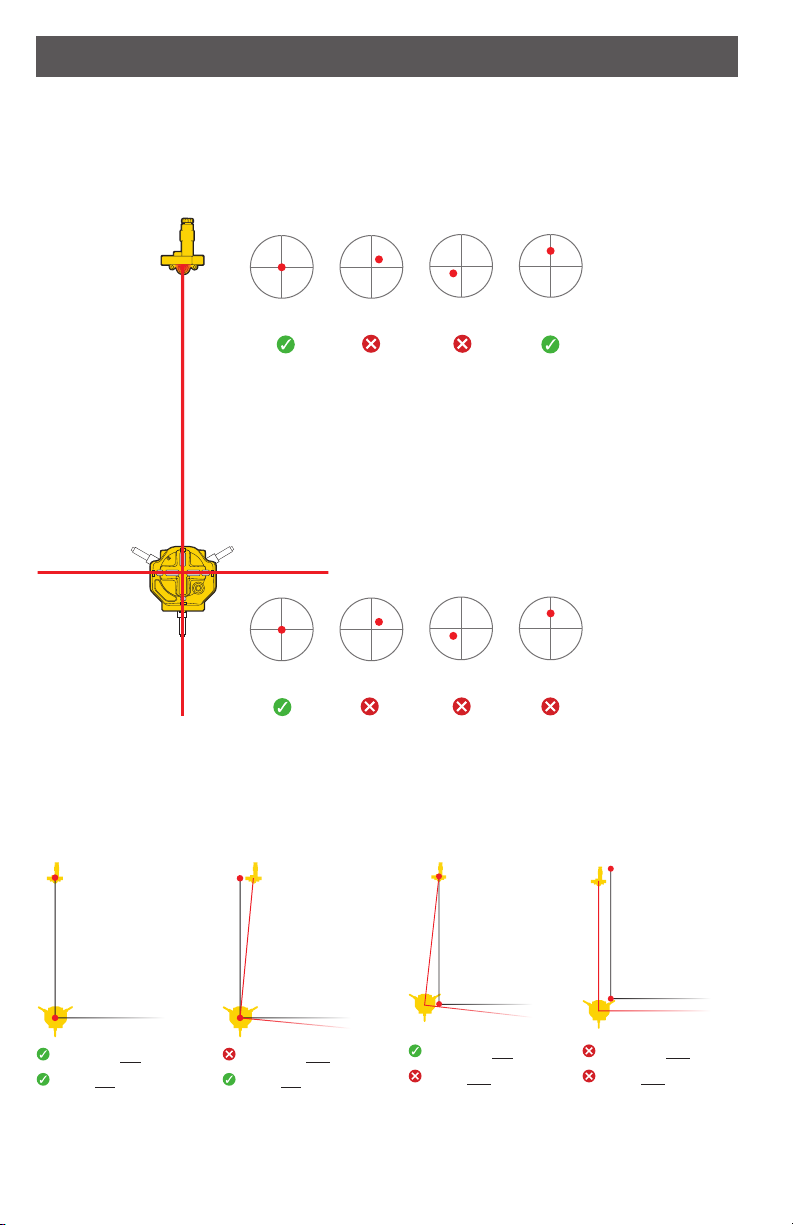

6. Leveling Screws: Used to level the bulls eye bubble

when the LineLokr is mounted on a tripod in order to

get the laser plumb bob (8) over your point

7. Bulls Eye Bubble: Used when LineLokr is

mounted to tripod or floor to insure laser

plumb bob is plumb and over your point

8. Laser Plumb Bob: For tripod set up, allows

you to set LineLokr over your point

9. Laser Plumb Bob Battery Door Access:

For laser plumb bob battery access (4ea. Alkaline

batteries)

10. Laser Plumb Bob Power Button: Activates laser

plumb bob; Automatically turns off after 3 minutes

to save battery power

11. Batter Board Line Indicator: Lines up with line

reference on the batter board to get LineLokr on

line

12. Batter Board Lock Knob: Used to attach and

tighten LineLokr to batter board

13. LineLokr Battery Door: Allows access to LineLokr

batteries (2ea. AA Alkaline batteries)

14. LineLokr Communication Antenna: Sends Line

control information to Quad – drive right, drive left

for centerline and “locked on”

1

14

3

6

8

9

7

5

10

13

11

12

9

2

4

LINELOKR CONTROLS & FEATURES