ECO GOLD

28.04.10/ YACE0088 Table of contents 5

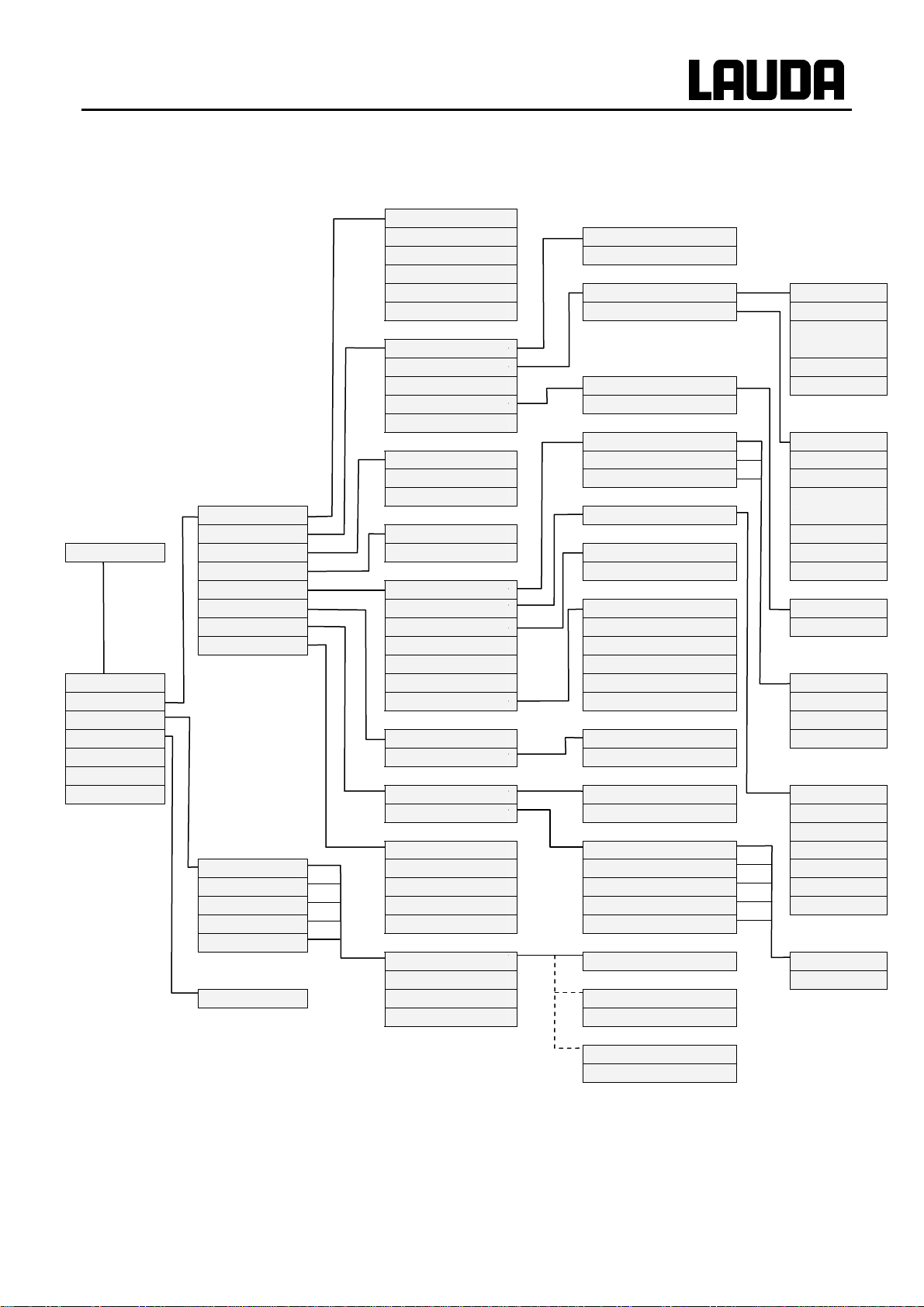

7.8.2 Creating or changing a program (editing) ..................................................................................................53

7.8.3 Starting the program....................................................................................................................................56

7.8.4 Interrupting, continuing or terminating the program..................................................................................56

7.8.5 Defining the number of program loops (Loops) ..........................................................................................57

7.9 CONTROL PARAMETERS........................................................................................................................................58

7.9.1 Internal control variable (internal temperature sensor)..............................................................................58

7.9.2 External control variable.............................................................................................................................60

7.9.2.1 Setting the correcting quantity limit.........................................................................................................62

7.9.2.2 Procedure for setting the control parameters for external control............................................................63

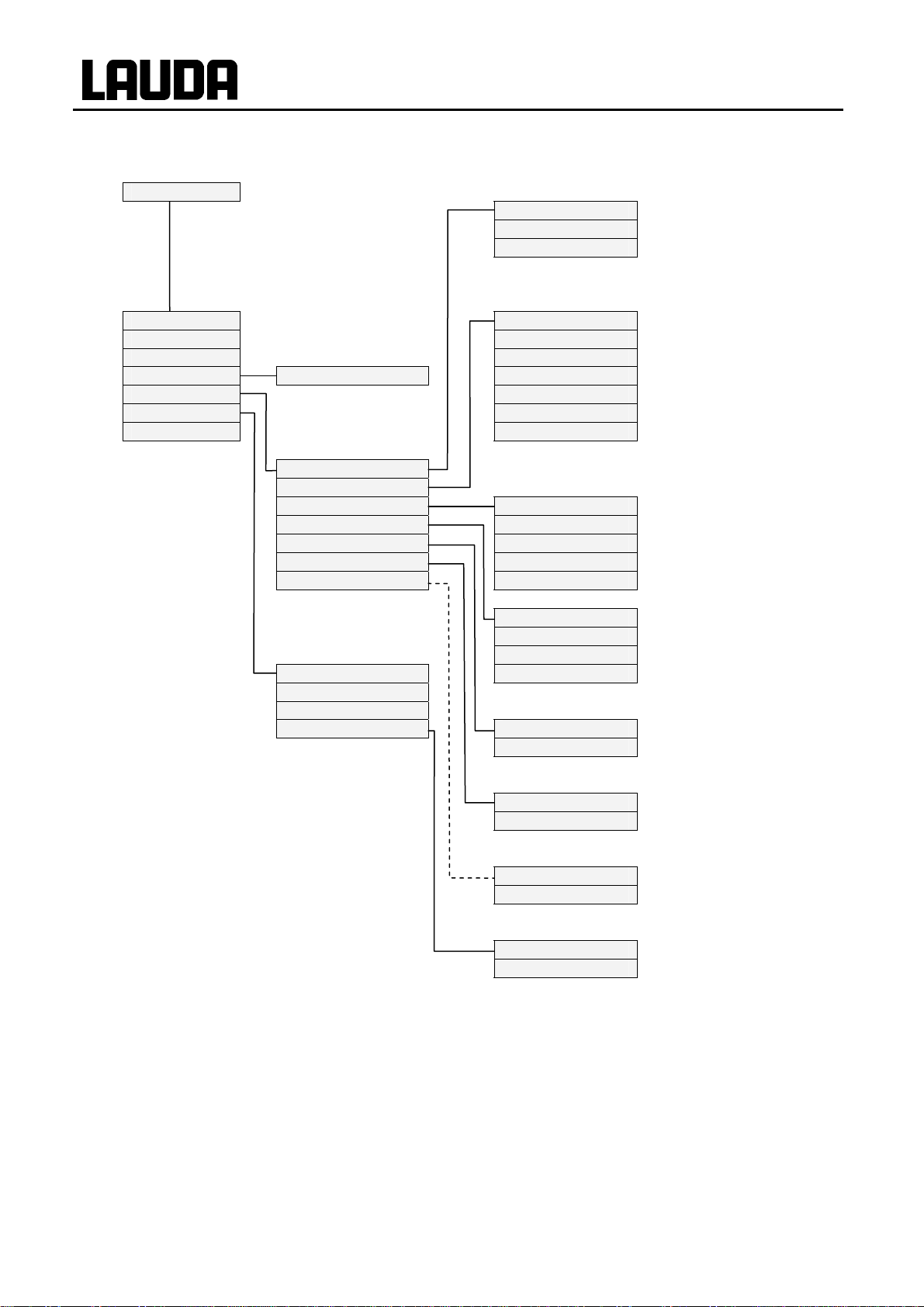

8INTERFACE MODULES.........................................................................................................................................64

8.1 INSTALLATION OF MODULES.................................................................................................................................64

8.2 MENU STRUCTURE OF THE MODULES....................................................................................................................66

8.3 ANALOGUE MODULE.............................................................................................................................................67

8.4 RS 232/485 INTERFACE MODULE..........................................................................................................................68

8.4.1 Connecting lead and interface test RS 232..................................................................................................68

8.4.2 RS 232 protocol ...........................................................................................................................................69

8.4.3 RS 485 connecting lead................................................................................................................................69

8.4.4 RS 485 protocol ...........................................................................................................................................70

8.5 USB INTERFACE ...................................................................................................................................................71

8.5.1 Description ..................................................................................................................................................71

8.5.2 Installation of the USB driver......................................................................................................................71

8.5.3 Connecting the thermostat to the PC...........................................................................................................72

8.5.4 Where is the ECO Virtual COM Port? ........................................................................................................74

8.6 COMMANDS AND ERROR MESSAGES APPLICABLE TO THE RS 232/485 INTERFACE MODULE AND TO THE USB

INTERFACE........................................................................................................................................................................76

8.6.1 Write commands (data issued to the thermostat).........................................................................................76

8.6.2 Read commands (data request from the thermostat) ...................................................................................77

8.6.3 Error messages............................................................................................................................................79

8.6.4 Driver software for LABVIEW®..................................................................................................................79

8.7 CONTACT MODULE ...............................................................................................................................................80

8.7.1 Contact module LRZ 914 with 1 input and 1 output....................................................................................80

8.7.2 Contact module LRZ 915 with 3 inputs and 3 outputs.................................................................................81

9MAINTENANCE.......................................................................................................................................................82

9.1 ALARMS,WARNINGS AND ERRORS........................................................................................................................82

9.1.1 Overtemperature protection alarm and overtemperature protection check ................................................82

9.1.2 Low level protection alarm and low level protection check.........................................................................83

9.2 CLEANING ............................................................................................................................................................84

9.3 DEVICE STATUS ....................................................................................................................................................84

9.3.1 Error store...................................................................................................................................................85

9.3.2 Device data..................................................................................................................................................85

9.3.3 Software version ..........................................................................................................................................85

9.3.4 Displaying and changing the device type.....................................................................................................86

9.3.5 Displaying serial numbers...........................................................................................................................86

9.4 SERVICING AND REPAIR........................................................................................................................................87

9.4.1 Servicing intervals to VDI 3033...................................................................................................................87

9.4.2 Inspecting the heat transfer liquid...............................................................................................................87

9.4.3 Cleaning the condenser................................................................................................................................87

9.5 DISPOSAL INFORMATION ......................................................................................................................................88

9.5.1 Disposal of the coolant ................................................................................................................................88

9.5.2 Disposal of the packaging............................................................................................................................88

9.6 ORDERING REPLACEMENT PARTS..........................................................................................................................89

10 ACCESSORIES.........................................................................................................................................................90

11 TECHNICAL DATA AND GRAPHS......................................................................................................................92

12 INDEX ........................................................................................................................................................................99

CONFIRMATION……………………………………………………………………………………………………….101