II

1 BRIEF OPERATING INSTRUCTIONS.......................................................................................1

2 CONTROL AND FUNCTIONAL ELEMENTS.............................................................................3

3 UNIT DESCRIPTION..................................................................................................................4

3.1 Unit types ...........................................................................................................................4

3.2 Pumps.................................................................................................................................4

3.3 Temperature indication, control, and safety circuit........................................................ 4

3.4 Materials.............................................................................................................................5

3.5 Refrigeration system.........................................................................................................5

3.6 Serial Interfaces RS 232, RS 485 ......................................................................................6

3.6.1 RS 232 Interface ............................................................................................................................6

3.6.2 RS 485 Interface ............................................................................................................................8

3.6.3 Write commands (data commands to the thermostat)............................................................10

3.6.4 Read commands (data requested from thermostat)................................................................11

3.6.5 Error messages...........................................................................................................................12

3.6.6 Driver software for LABVIEW®...................................................................................................12

4 UNPACKING............................................................................................................................13

5 PREPARATIONS.....................................................................................................................14

5.1 Assembly and setting up................................................................................................. 14

5.2 Filling and emptying........................................................................................................15

5.3 Bath liquids and hose connections................................................................................ 17

5.4 Connection of external circuits ......................................................................................19

6 STARTING UP.........................................................................................................................20

6.1 Connection to the supply................................................................................................20

6.2 Switching on .................................................................................................................... 20

6.3 Setpoint selection (level 0) .............................................................................................. 21

6.4 Menu functions................................................................................................................22

6.4.1 Refrigeration system (level 1).....................................................................................................22

6.4.2 Pump output................................................................................................................................23

6.4.3 Setting the setpoint resolution..................................................................................................24

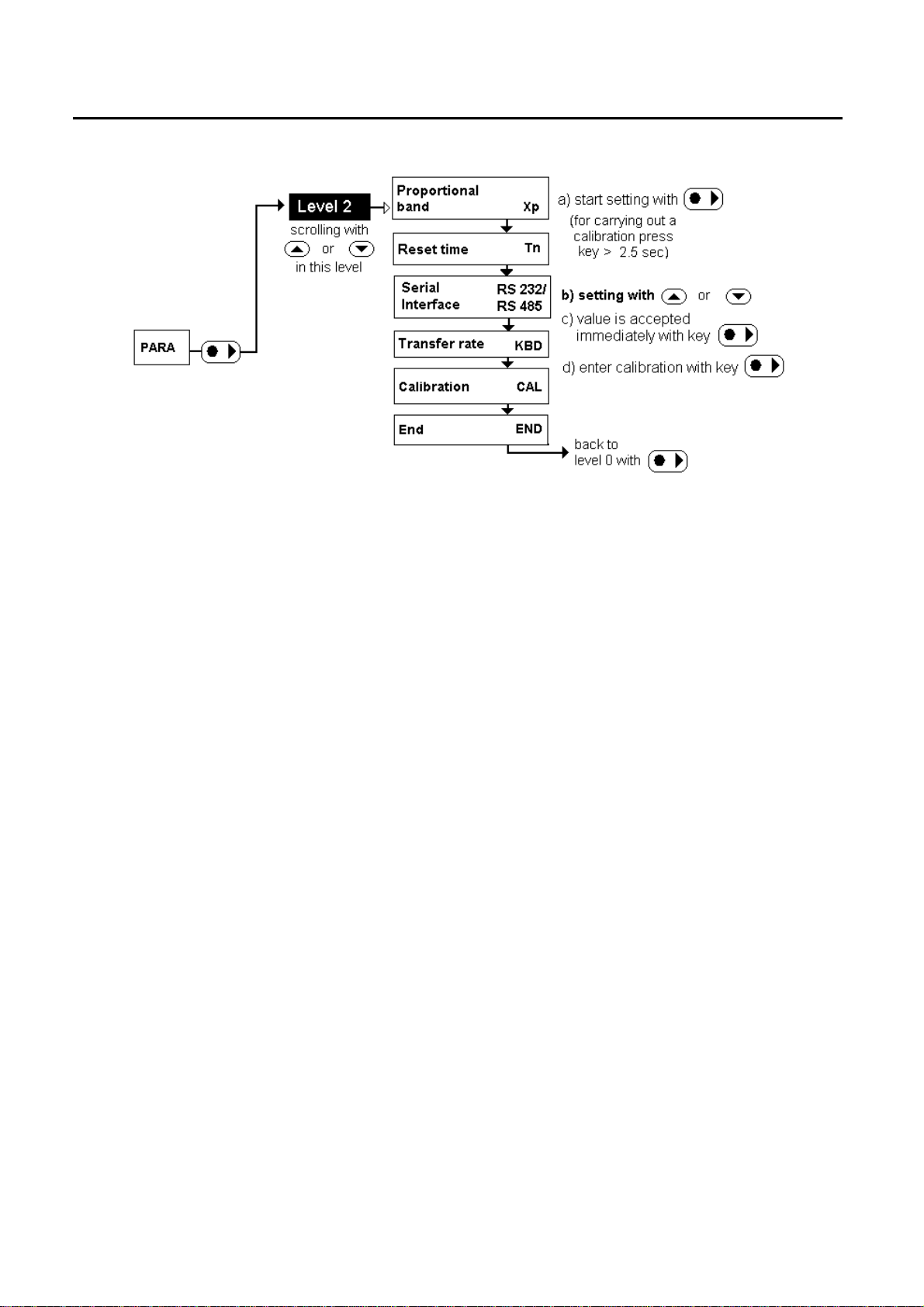

6.4.4 Parameters...................................................................................................................................25

6.4.4.1 Setting the proportional band of the PID-controller ...................................................................26

6.4.4.2 Setting the reset time of the PID-controller................................................................................27