LawnMaster BC451 Installation manual

LMCG260EH

SAFETY AND OPERATING MANUAL

PLEASE READ THIS MANUAL CAREFULLY BEFORE OPERATING THE UNIT

45CC

BRUSH CUTTER

PROUDLY

NZ OWNED

A STEELFORT PRODUCT

BC451

2A STEELFORT PRODUCT

OPERATOR SAFETY 3

GETTING STARTED 5

Assembly

FEATURES & TECHNICAL DATA 9

OPERATION 10

Fuel & Oil Mixture

Rules for Operation

Preparing for Operation

STARTING THE BRUSH CUTTER 11

Starting the Engine

Fitting the Belt

Cutting with the Brush Cutter

Extending the Cutting Line

Stopping the Engine

MAINTENANCE & STORAGE 14

Maintenance Schedule

Air Filter

Spark Plug

Cleaning

Angle Transmission

Storage

TROUBLESHOOTING 18

WARRANTY 19

TABLE OF CONTENTS

3

A STEELFORT PRODUCT

Thank you for purchasing our LawnMaster BC451

Brushcutter , the information contained within this

manual will help you to have many years of safe

and trouble free use of this Lawnmaster product.

OPERATOR SAFETY

SAFETY RULES

This manual contains important safety information

and instructions to operate the LawnMaster Brush

Cutter.

PLEASE READ THIS MANUAL CAREFULLY BEFORE

USING THE UNIT.

Failure to adhere to the safety instructions could

result in property damage and/or serious personal

injury.

This manual should be considered a permanent part

of the brush cutter and should remain with the unit at

all times. All information in this publication is based

on the latest product information available at the

time of printing.

Product Information and specications can be

altered and/or improved without notice.

Content from this publication may not be reproduced

without written consent.

DANGER

Indicates a hazardous situation which, if not strictly

complied with, will result in substantial property

damage and or serious injury.

WARNING

Indicates a hazardous situation which, if not strictly

complied with, may result in property damage

CAUTION

Indicates a hazardous situation which, if not strictly

complied with, could result in property damage or

personal injury.

The warnings and precautions discussed in this

manual does not cover all possible conditions and or

scenarios that may occur.

It must be understood by the operator that common

sense and caution must be taken into consideration

when operating this product, as these are factors

which cannot be built into this manual.

DANGER

TOXIC FUMES

• The exhaust of the engine contains carbon

monoxide, an odorless, colorless poison gas.

Using the engine in conned/indoor spaces can

be extremely dangerous and life threatening.

FIRE

• When operating the unit, the engine may create

sparks that could trigger res.

• When operating around dry vegetation such as

agricultural crops, forest, bush, grass, or other

similar environments please be careful.

• This engine may not be equipped with a spark

arresting muer. In some countries and

regions, a spark arrester is required by law.

Please contact your local council and or re

agency for laws and regulations relating to re

prevention requirements.

• Petrol is highly ammable and explosive. A re

and or explosion from petrol can cause severe

burns or result in serious personal injury includ-

ing death.

• Keep ammable items away while handling

petrol. Fill fuel tank outdoors and in a well

ventilated area with the engine stopped.

• Always wipe spilled fuel and wait until the fuel

has dried before starting the engine.

• DO NOT operate the engine with known leaks

in the fuel system. Use proper fuel storage and

handling procedures.

• Empty the fuel tank before storing or

transporting the brush cutter.

• Keep re extinguisher handy at all times.

HOT SURFACE

• Running the brush cutter will produce heat and

severe burns may occur upon contact. DO NOT

touch the engine while under operation or just

after stopping the unit.

• Avoid contact with hot exhaust gases and or

hot surfaces.

• Maintain at least 1m of clearance on all sides to

ensure adequate cooling. Combustible material

can catch re upon contact. Maintain at least

3m of clearance from combustible materials.

GENERAL WARNINGS

• Before use, check for loose or damaged parts,

signs of oil or fuel leaks, and any other

condition that may impact operation.

4A STEELFORT PRODUCT

• Repair or replace all damaged and or defective

parts immediately.

• Locate all operating controls and safety labels.

• Make sure all the safety instructions are in

correct working condition.

• Keep all safety guards in place and in proper

working order at all times.

• DO NOT allow any material to block the cooling

slots.

• DO NOT allow children or untrained people to

operate the unit.

• Read the instructions carefully. Be familiar

with the controls and the proper use of the

appliance.

• This product has been designed for use in

cutting grass, and it should never be used for

any other purpose.

• Never use while people, especially children, or

pets are nearby.

• The operator or user is responsible for

accidents of hazards occurring to other people

or their property.

• Always store fuel in a properly marked

container that complies with New Zealand

standards.

• Do not mix fuel in an enclosed room or near an

open ame, ensure adequate ventilation.

• Never attempt to make engine adjustments

while the engine is running and strapped to the

operator.

PREPARATION

• Petrol is highly ammable: Store fuel in con-

tainers specically designed for this purpose;

refuel outdoors only and do not smoke while

refueling;add fuel before starting the engine.

Never remove the cap of fuel tank or add petrol

while the engine is running or when the engine

is hot; if petrol is spilled, do not attempt to

start the engine but move the machine away

from the area of spillage and avoid creating

any source of ignition until petrol vapors have

dissipated. Replace all fuel tank and container

caps securely.

• Replace faulty silencer.

• Before using, always visually inspect to see that

the tools are not worn or damaged. Replace

worn or damaged elements and bolts in sets to

preserve balance.

• Never put any items into the ventilation open-

ings. Non-observance may lead to injury, or

damage to the machine.

• It is necessary reduction in power due to use in

higher temperatures, altitudes and humidity as

below conditions.

Max Working Temperature: 40°C

Max Altitude: 1000 m

Max Humidity: 95%

OPERATION

• Do not operate the engine in a conned space

where dangerous carbon monoxide fumes can

collect.

• Keep the machine free of oil, dirt and other

impurities.

• Always place the appliance on even and stable

surfaces.

• Never operate the appliance inside buildings or

in an environment without proper ventilation.

• Do not operate or store the appliance in wet or

humid surroundings.

• Ensure the sound absorber and air lter work

properly.

• Do not touch the exhaust system or other parts

that become hot during operation.

• The engine must not be operated with

excessive rotary speed. The operation of the

engine with excessive rotary speed raises the

risk of injury.

• Regularly check for leakage or traces of

abrasion in the fuel system, such as porous

pipes, loose or missing clamps and damage to

the tank or tank cap.

• Work only in daylight or in good articial light.

• Never pick up or carry a machine while the

engine is running.

• Stop the engine whenever you leave the

machine and before refueling.

• Before checking or adjusting the machine, the

ignition plug and the ignition wire respectively

must be removed to prevent accidental

starting.

• Do not use the machine when the operator is

tired, ill or under the inuence of alcohol or the

drugs.

• Wear safety goggles and ear protection.

• Ensure that you maintain a steady foothold.

• Only use the brush cutter on at surfaces

where you have a rm footing.

• Always wear substantial footwear and long

trousers. Do not operate the equipment when

barefoot or wearing open sandals.

5

A STEELFORT PRODUCT

• Always hold the brush cutter with two hands

• Always use the harness when operating, adjust

the length of the harness to ensure it is suitable

for operation.

• Always use the correct blade and spool

recommended by the manufacturer.

• Always ensure that the ventilation openings are

kept clear of debris.

• Perform inspection before use and after any fall

or other impact to identify signicant defects.

• Rest frequently and change working positions.

Keep balance position during operation, use the

harness.

WARNING

It has been reported that, for some people, the

vibrations produced by the motorized hand tools can

lead to develop a disease called Raynaud’s syndrome

or white nger. Symptoms may include tingling,

numbness and blanching of the ngers, usually

caused by exposure to cold. There is currently no

evidence that a certain type of vibration or exposure

actually contributes to the development of this

assignment. Some measures that can reduce the

effects of vibration, can be taken by the operator:

• Keep your body warm in cold weather. During

use, wear gloves to keep your hands and wrists

warm. It has been reported that cold weather is

one of the main causes of Raynaud’s Syndrome.

• After each period of operation, exercise to

increase circulation.

• Take frequent breaks. Limit the duration of

daily exposure.

• Keep the tool well maintained, all fasteners

tightened and worn parts replaced.

• In case of occurrence of one or more of the

symptoms described above, stop using the tool

and seek medical attention.

•

GETTING STARTED

The brush cutter is a high-speed and fast cutting

power tool. All safety precaution must be

observed to reduce the risk of personal injury. Please

read this manual carefully and become familiar with

the controls before using the unit.

ASSEMBLY

When assembling this machine, please follow the

instructions for assembly printed.

INSTALL THE MAIN BODY

Connect the engine (A) to the tube (B) with four

screws (C).

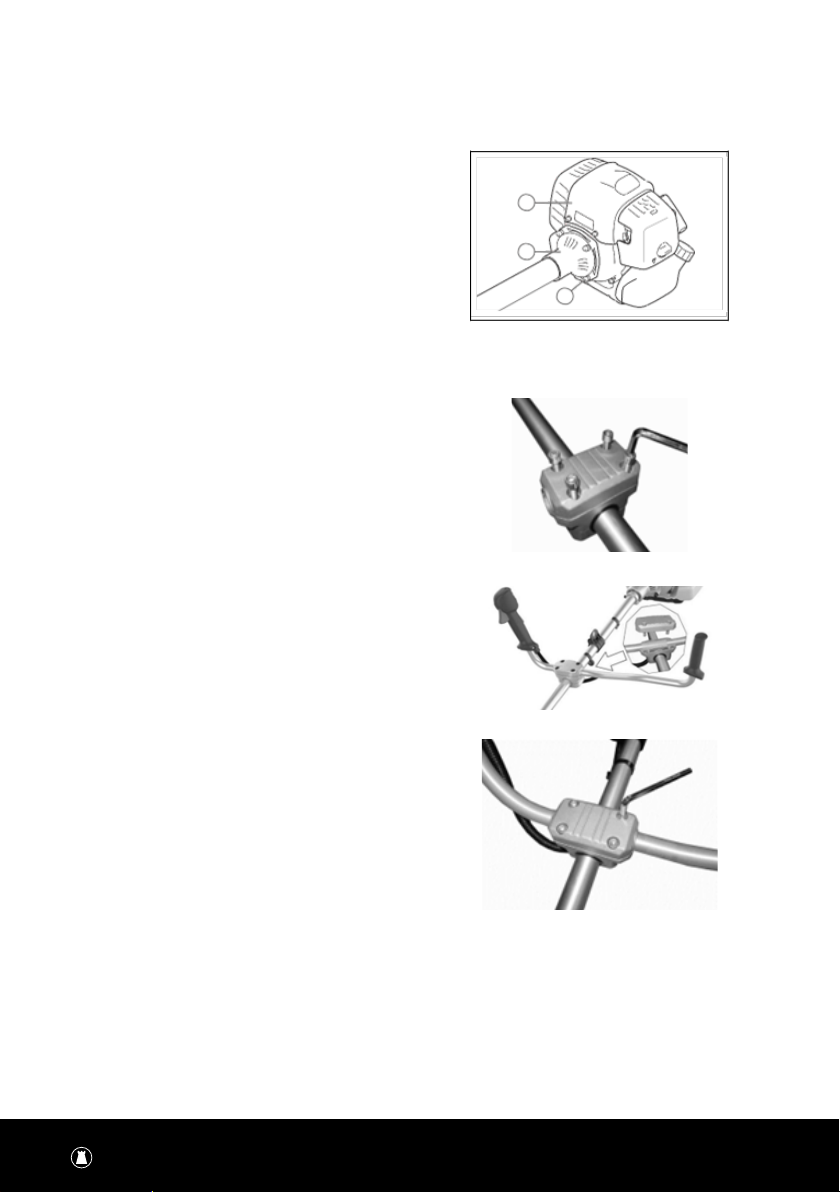

ASSEMBLY OF THE HANDLE

(FIG.1-1,1-2,1-3)

1. Remove the screws inxing device and remove

the upper cover. (Fig.1-1)

2. Place the handle in position and assemble the

upper cover. (Fig.1-2)

3. Assemble and tighten the screw. (Fig.1-3)

FIG.1-1

FIG.1-2

FIG.1-3

6A STEELFORT PRODUCT

CONNECT THE TROTTLE CABLE AND STOP SWITCH

WIRES

1. Remove the air lter cover

2. Install the throttle cable (A) through the

carburettor bracket (B)

3. Turn the cable adjuster sleeve (C) into the

carburettor bracket fully

4. Put the slot tting (D) on the carburettor. At this

time the recessed hole (E) throttle cable plug

(F) is away from the cable adjuster sleeve (C)

5. Rotate the carburettor throttle cam and move

the throttle cable (A) through the slot in the slot

tting.

6. Make sure the cable lug (F) drops into the

recessed hole.

7. Operate the throttle trigger some times to make

sure that it operates correctly.

8. Adjust the cable adjuster sleeve (C).

9. Make sure the stop on the carburettor throttle

cam touches the throttle stop correctly.

10. Make sure the cable position keeps 1-2 mm

between cable lug (F) and slot tting when the

throttle trigger is fully pushed.

11. When the throttle cable (A) is adjusted correctly,

tighten the lock nut (G).

12. Connect the stop switch wires (H) with the

connectors from the engine.

13. Install the air lter cover.

WARNING

Do not tighten the screws until you have set the

handle in optimal working position. Please always

adjust the handle position with full assembled

accessories. The black cable tie can be used to x

the throttle cable to the metal tube. (Fig.2)

ASSEMBLE THE GUARD

(FIG.3-1, FIG.3-2)

1. Place the guard on the xture. (Fig3-1)

2. Assemble and tighten the screws. (Fig.3-2)

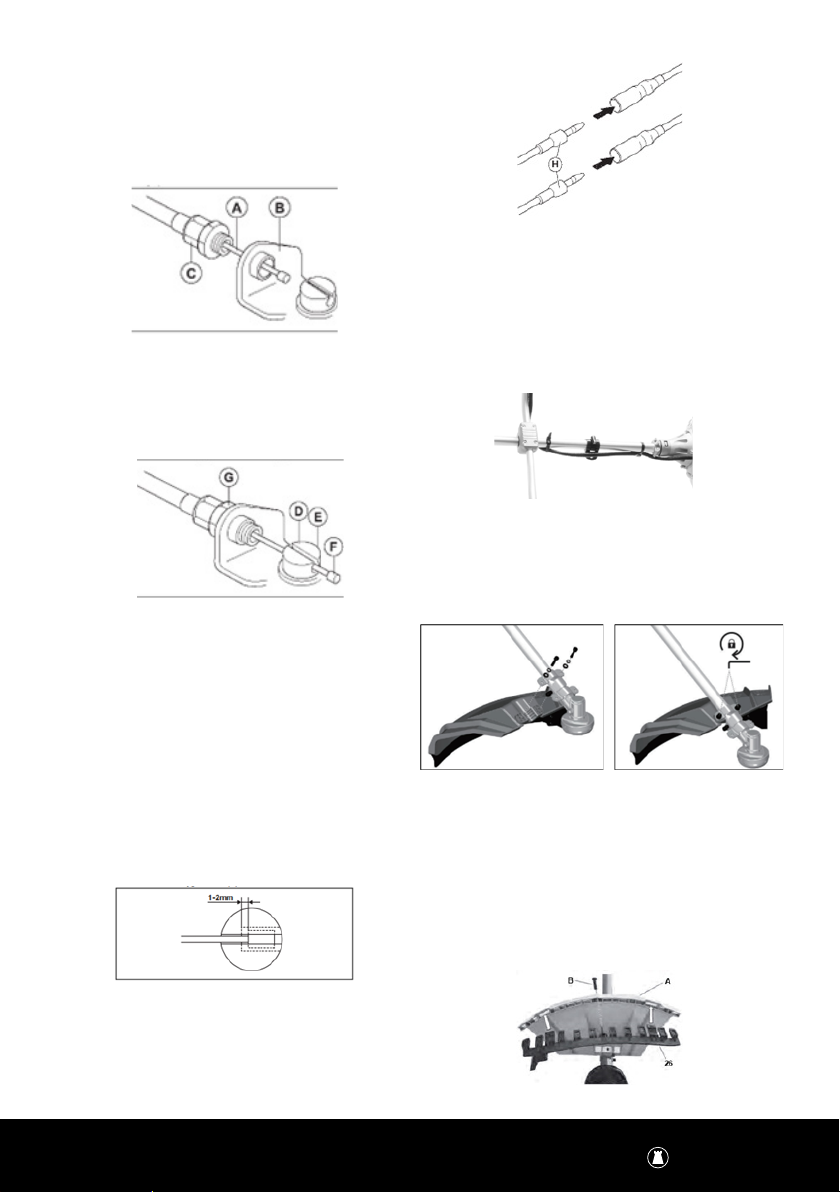

WARNING

When using the cutting line head, the additional

guard, with line cutting knife, must always be tted.

(Fig.3-3,Fig.3-4)

Secure the additional guard (26) using the screw (B).

(Fig.3-3)

FIG.3-1 FIG.3-2

FIG.3-3

7

A STEELFORT PRODUCT

TAKE OFF ADDITONAL GUARD

1. Screw off the screw (B); (Fig. 3-3)

2. Push the clip (C), and pull out the additional

guard. (Fig.3-4)

WARNING

Please check the blade and output shaft after

each adjustment or assembly, it must be correctly

assembled and running smoothly. Wear protective

gloves when handling the guard.

FITTING THE 3T BLADE

(FIG. 4)

Take the outer ange off after release the nut, then

put the blade, outer ange, shield and nut according

to priority as below picture. Note the blade rotation

direction needs be same as below picture. Use

screw driver to hold ange and tighten nut counter-

clockwise, ensure the nut is tightened enough.

RELEASE THE BLADE

(FIG 5)

Use screw driver to hold ange and release nut, the

blade can be took off.

WARNING

Please make sure the cutting head has been

FIG.3-4

assembled correctly before use!

NYLON HEAD

RELEASE THE NUT

(FIG.6)

Line up the two holes of ange and shield, use one

screw driver to hold the ange as below and turn the

socket wrench clockwise, the nut will be released

FIT THE NYLON CUTTING HEAD

(FIG.7)

Remove another shield after release the nut. Still hold

the ange, take the Nylon cutting head on the shaft

and rotate counter-clockwise, the Nylon cutting head

is tted.

RELEASE THE NYLON CUTTING HEAD

(FIG.8)

Remove another shield after release the nut. Still hold

the ange, take the Nylon cutting head on the shaft

and rotate counter-clockwise, the Nylon cutting head

is tted.

FIG.4-1

FIG.5-1 FIG.5-2

FIG.6

FIG.7

FIG.8

8A STEELFORT PRODUCT

REPLACING LINE

1. Unclip the housing from the line trimmer and

remove spool from the spindle.

2. Remove all remaining cutting line from the

spool.

3. Cut 2m of line. Fold in half and attach the mid-

dle of the line into the grove/slot located in the

center of the spool.

4. Wind both sides of the line on to the

spool with tension in the same direction as

shown on the inside of the spool. (See above

right image)

5. Continue to wind the line until you have 150mm

of line left on each end. Note: It is helpful to

clip and fasten the line on opposite ends of the

spool to keep the line from unraveling during

the next step.

6. Put the spool into housing. Unclip the line from

the spool and place line through the open eyelet

on opposite ends of the housing. Ensure the line

has not tangled.

7. Clip the housing back onto the line trimmer

9

A STEELFORT PRODUCT

FEATURES & TECHNICAL DATA

1. Tube

2. Throttle Trigger

3. Engine Switch

4. Throttle Trigger Lockout

5. Suspension Point

6. Cable

7. Muer Cover

8. Cylinder Cover

9. Spark Plug Cover

10. Air Filter Cover

11. Choke Lever

12. Fuel Tank Cap

13. 3T Blade

14. Gearbox

15. Guard Fixture

16. Cutting Attachment Guard

17. Socket Wrench

18. Spanner

19. Allen Keys S5

20. Allen Keys S4

21. Trimmer Head

22. Harness

23. Fuel Mixture Container

24. Line Cutter

25. Additional Guard

Technical Data is subject to change without notice.

MODEL LMBC451

Idle speed (r/min) 2500 +/ - 500

Nylon Head Twin Line Tap & Go Head

Engine Air-Cooling, 2 Stroke

Spark Plug NGK BPMR7A / BOSCH WSR6F

Displacement (cc) 44.8

Maximum Cutting Speed 10000 +/- 500

Maximum Cutting Diameter 430mm

Maximum Output (kw) 1.6

Ignition Electronic

Spool For Grass Trimmer 2.7 Diameter Line x 2m Length

Method of Starting Soft Start Recoil

Fuel Used Gasoline mixed with 2 stroke oil 25:1

Fuel Tank Capacity 920ml

Weight 9kg

10 A STEELFORT PRODUCT

OPERATION

1. FUEL & OIL MIXTURE

Never use oil for 4-cycle engine use or water-cooled

2-cycle engine. It can cause spark plug fouling

exhaust port blocking or piston ring sticking.

Mixed fuels, which have been left unused for a period

of one month or more may clog the carburetor

or result in the engine failing to operate properly. Put

remaining fuel into an airtight container and

keep it in the dark and cool room.

WARNING

The brush cutter is tted with a two-stroke engine;

use fuel mixed with oil only.

DANGER

Fuel is explosive. Turn off and cool the motor down

before lling the tank with fuel. You must observe all

safety instructions relating to handing fuel.

Fuel used for this model is a mixture of unleaded

gasoline and approved engine lubricant. When mixing

petrol with two-cycle engine oil, use only petrol that

DOES NOT contain ETHANOL or METHANOL (types of

alcohols).

Use 91 unleaded petrol to fuel the unit. This will help

avoid possible damage to the engine fuel lines and

other engine parts.

FUEL

The engine uses two-stroke fuel. If you have

emission requirements, the mixture ratio of the fuel

to oil should be 25:1

Be careful, a wrong mixture of the fuel will cause

machine failure.

PETROL

Use 91 and above unleaded fuel.

We recommend unleaded petrol as it leaves fewer

residues inside the motor and on the ignition plug, and

prolongs the life cycle of the exhaust system. Never

use old or dirty petrol or oil/petrol mixtures

STORING FUEL

The tank to store the fuel should be clean, anti-static,

high-temperature-resistant, re prevention and safe.

IMPORTANT

Two-stroke fuel may separate. Shake fuel container

thoroughly before every use. Do not mix more fuel

than you expect to use within a month. Take care of

the emission of exhaust gases. Always shut off en-

gine before fueling. Never add fuel to a machine with

a running or hot engine. Never smoke whilst refueling

and avoid inhaling the petrol fumes. Carefully open

the tank top as pressure could have formed inside.

BEFORE REFUELING

• Shake the fuel mixture container well.

• Make sure the machine is turned off, by turn the

engine switch to the “off” position.

• Check the fuel by a visual check, remove the

fuel cap and review the fuel level.

• Fill unleaded fuel / oil mix from an approved

fuel container into the fuel tank, because of

fuel expands, please ll the tank to the neck of

tank only.

• Turn the fuel cap clockwise to assemble it in

position.

DRAINING FUEL

• Hold a collection container beneath the fuel

drain bolt.

• Unscrew the fuel cap and remove it.

• Allow the fuel to run out completely

• Screw the fuel cap on rmly by hand.

FUEL MIXTURE CONTAINER

• Place the fuel mixture container on even and

steady surface.

• First ll the gasoline to the scale marked gas

“500”.

• Then ll the 2-stroke engine oil until the scale

marked oil “25:1”.

• Shake the container gently, and then ll into the

fuel tank.

Oil - 1 Part

Gasoline - 25 Part

Emissions

Petrol 2-Stroke Oil

1 Litre 40 ml

2 Litre 80 ml

5 Litre 200 ml

11

A STEELFORT PRODUCT

2. RULES FOR SAFE OPERATION

WARNING

Read the “Rules for Safe Operation “with care and

follow the instructions in the manual to operate the

unit safely.

Read and be thorough with the basic controls and

functions of the unit. It is important that you know

how to stop and to shut off the engine, and to unhook

a harnessed unit quickly.

Do not allow anyone without proper instruction or

training to operate the unit. All operators of the unit

should wear appropriate foot, leg, eye, face and

hearing protection. Do not rely on the debris shield on

the unit to protect your eyes from thrown objects.

Keep the area clear of bystanders, children and pets.

Never allow children to operate or play with the unit.

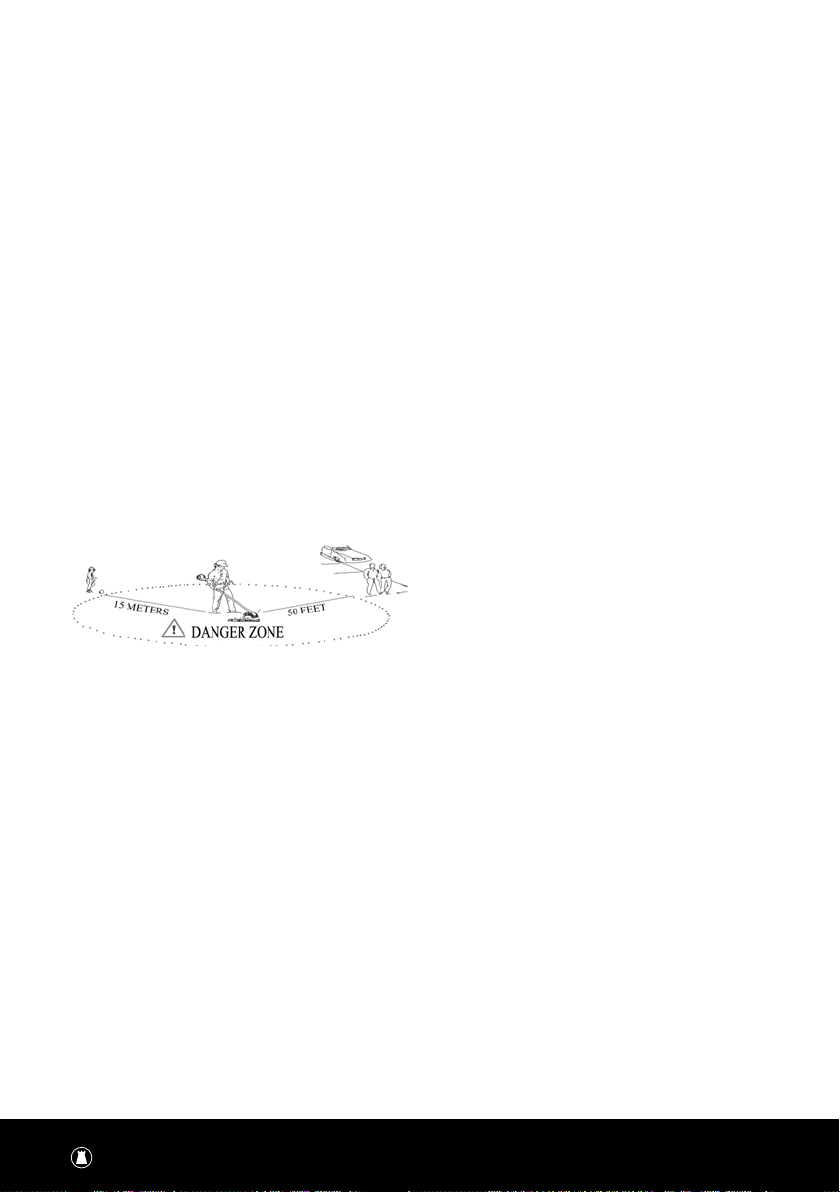

Do not allow anyone to enter the operating DANGER

ZONE with you. The danger zone is an area 15 meters

in radius (about 16 paces) or 50 feet.

Insist that persons in the RISK ZONE beyond the

danger zone wear eye protection from thrown

objects. If the unit must be used where there are

unprotected people, operate at a low throttle speed

to reduce the risk of thrown objects.

Move the stop switch to “stop” position when the

engine idles, insure it reliable before cutting. Only

may continue to operate the unit when stop switch is

in good condition.

Routines for checking that the cutting attachment

stops turning when the engine idles.

WARNING

In addition to head, eye, face and ear protection,

please wear appropriate footwear to protect your

feet and to improve footing on slippery surfaces.

Do not wear open-toed footwear, or go bare foot or

barefeet.

3. PREPARING FOR OPERATION

IMPORTANT

Failure to follow proper fuel mix instructions may

cause damage to the engine.

When preparing fuel mixture, mix only the amount

needed for the job you intend to do. Do not use fuel

that has been stored longer than two months. Fuel

mixture stored longer than this will cause hard start-

ing and poor performance. If fuel mix has been stored

longer than this time, it should be removed and lled

with a fresh mixture.

WARNING

• Never ll the fuel tank to the brim. (Under 3/4

of the tank)

• Never add fuel to the tank in a closed non-ven-

tilated area.

• Do not add fuel to this unit close to an open re

or sparks.

• Be sure to wipe spilled fuel before attempting

to start the engine

• Do not attempt to refuel a hot engine.

CHECK POINTS BEFORE OPERATION

• Check for loose bolts, nuts and ttings.

• Check the air lter for dirt. Clean before

operation.

• Check to be sure that protector is securely in

place.

• Check that fuel isnt leaking.

STARTING THE BRUSH CUTTER

STARTING THE ENGINE

WARNING

The cutting attachment may start to move when the

engine is started. Make sure the attachment can not

come into contact with any object.

Make sure that no unauthorised persons are in the

working area, otherwise there is a risk of serious

personal injury.

12 A STEELFORT PRODUCT

1. Press the fuel pump several times until it lls

with fuel. (Fig.12)

2. Turn the engine switch to the ”I “position.

(Fig.13) Press the throttle trigger, throttle

trigger lockout and lock pin together to lock the

trigger .

WARNING

the switch is auto-returned switch, it would always

stays in “I” position, press it to “O” manually if needed.

3. In Res.13, Press the trigger lock to activate the

trigger, then press the trigger lock pin together

to make the trigger half open. This is for easier

starting.

4. Move the choke lever to position. (Fig.14)

5. Close the choke: Start Position

WARNING

Ensure the cutting attachment stops when the engine

is idling. Note that initial engine startup may require

multiple attempts for the fuel to reach the motor.

6. Turn the choke lever to the run position. (Fig.16)

7. Pull the starter quickly until the engine starts.

8. Press the trigger (in Res.13) to release the

trigger lock pin.

9. After starting, let the engine run for 2 to 3

minutes before subjecting it to any load.

HOT START

When the machine is hot, keep the choke level in

“Start position”, the user can start the machine by

repeating steps of 1,2,6,7.

WARNING

Under the following conditions the machine MUST be

stopped.

• When the motor rotary speed changes

• When sparks occur

• When blades are damaged

• In case of misre

• In case of high vibration

• When ames or smoke appear

• In rain or stormy weather

Check the cutting attachment always stops when the

engine is idling.

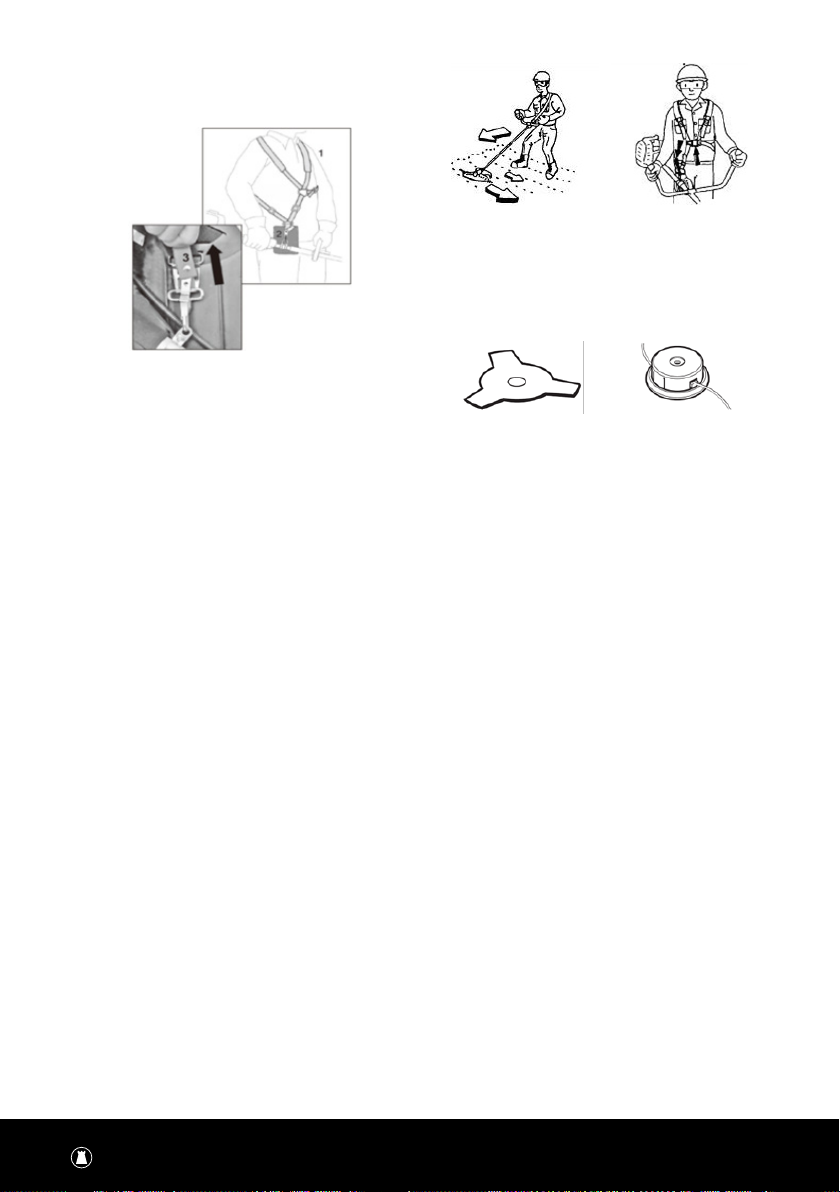

FITTING THE FULL VEST HARNESS

(FIG.17)

FIG.12

FIG.13

FIG.14

FIG.15

FIG.16

13

A STEELFORT PRODUCT

Fit the harness well. Stretch the harness as below pic,

and then t on shoulder.

The design and type of carry strap may vary.

1. Place the full vest harness over your shoulders

and clip in the middle.

2. Adjust to suit as so the harness is comfortable

to wear.

3. Clip the BC451 on to the harness

4. Adjust the full vest harness if required to

balance the BC451 on the harness.

WARNING

This carry strap has a safety device allowing you to

immediately disconnect the strap from the machine

in an emergency. To do so, pull forcefully on the red

pull tab (3) on the strap. This disconnects the strap

from the holding xture immediately. NOTE: Never

start the motor with the carry strap attached to the

machine!

CUTTING WITH THE BRUSH CUTTER

Avoid operating the cutting tool at a speed just above

clutch engagement to prevent premature clutch

wear. Additionally, it is not recommended to continu-

ously run the engine at maximum speed after cutting,

as this can shorten the engine’s lifespan.

WARNING

In an emergency, stop the engine by moving the

engine switch to the stop position.

After the cutting attachment hits stone or debris,

stop the engine and inspect for any damage or loose

attachment. If the cutting attachment retains wet

grass or branches, stop the engine and remove them.

CUTTING ATTACHMENTS

Only use orginal cutting devices from the

manufacturer

WARNING

The user assumes responsibility for any damages

resulting from the selection, application, and usage

of the accessory. When unsure or lacking knowledge

about specic accessories, it is advised to contact

your LawnMaster Sercie Dealer.

KICKBACK

Kickback occurs when a rotating blade is pinched or

snagged, causing the power tool to forcefully move

in the opposite direction of the blade’s rotation at the

binding point. The blade can jump towards or away

from the operator, depending on its movement during

pinching.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as given

below.

• Maintain a rm grip on the tool and position

your body and arm to allow you to resist kick

back forces.

• Never place your hand near the rotating acces-

sory. Accessory may kick back over your hand.

• Exercise caution when working near corners,

sharp edges, or during bouncing to prevent

snagging the accessory. Snagging can lead to

loss of control or kickback.

EXTENDING THE CUTTING LINE

FIG.17.1

FIG.18

FIG.19

14 A STEELFORT PRODUCT

WARNING

Avoid metal wire or wire encased in plastic in the

cutting head to prevent injuries. To extend the line,

run the motor at full speed and tap the cutting head

on the ground. This will automatically lengthen the

line, with the cord cutter trimming it to the proper

length (Fig. 20).

FIG.20

MAINTENANCE & STORAGE

It is the operator’s responsibility to complete all scheduled maintenance and or servicing in a timely manner.

Always correct any issues before operating the brush cutter. Follow all inspection and

maintenance recommendations that are listed in the manual.

WARNING

Improper maintenance and or failure to correct problems prior to operating the unit may cause the unit to

malfunction and result in property damage and or serious personal injury. Improper maintenance and servicing

may void warranty.

During maintenance operations:

• Remove the spark plug cap.

• Wait until the engine is suciently cold.

• Never dispose of oils, fuel or other polluting materials in unauthorized places.

Before performing any maintenance or cleaning work, always turn off the engine.

1. Do not spray the unit with water. Ingress of water may damage the engine and electrical connection.

2. Clean the unit with a cloth, hand brush, etc.

MAINTENANCE SCHEDULE

STOPPING THE ENGINE

1. Release the throttle trigger and let it run idling

for a few minutes.

2. Switch off the engine by moving the engine

switch to the stop position.

Ensure the cutting attachment has completely

stopped turning before setting down the unit to

prevent potential accidents.

MAINTENANCE DAILY

MAINTENANCE

WEEKLY

MAINTENANCE

MONTHLY

MAINTENANCE

Clean the outside of the machine.

Make sure the throttle trigger lock and

the throttle function correctly from a

safety point of view.

Check that the engine switch works

correctly.

15

A STEELFORT PRODUCT

MAINTENANCE DAILY

MAINTENANCE

WEEKLY

MAINTENANCE

MONTHLY

MAINTENANCE

Clean the outside of the machine.

Make sure the throttle trigger lock and

the throttle function correctly from a

safety point of view.

Check that the engine switch works

correctly.

MAINTENANCE DAILY

MAINTENANCE

WEEKLY

MAINTENANCE

MONTHLY

MAINTENANCE

Check that the blades do not move when

the engine is idling or when the choke is

in the start throttle position.

Check that the blades are undamaged

and show no signs of cracking or other

damage. Replace the blades if necessary.

Check that the blade guard is not

damaged or distorted. Replace the blade

guard if it is bent or damaged.

Clean the air lter. Replace if necessary.

Check that nuts and screws are tight.

Check that there are no fuel leaks from

the engine, tank or fuel lines.

Check the starter and starter cord.

Clean the outside of the spark plug.

Remove it and check the electrode gap.

Adjust the gap to 0.6-0.7 mm or replace

the spark plug. Check that the spark plug

is tted with a spark plug cap.

Clean the machine’s cooling system.

Clean the outside of the carburetor and

the space around it.

Check the ange, cap and nut are assem-

bled correctly and tightened

Clean the fuel tank.

Check all cables and connections.

Check the clutch, clutch springs and

the clutch drum for wear. Replace if

necessary by an authorised LawnMaster

Service Agent.

Replace the spark plug. Check that the

spark plug is tted with a spark plug cap.

To reduce the re hazard, clean dirt,

leaves and surplus lubricant, etc from the

muer and engine.

16 A STEELFORT PRODUCT

MAINTENANCE

Should be carried out at REGULAR

INTERVALS in each of the indicated

months or after a certain number of

hours of operation (whichever comes

rst). (1)

BEFORE USE

EVERY TIME

MONTHLY OR

AFTER 25

HOURS

EVERY THREE

MONTHS OR

AFTER 50

HOURS

EVERY SIX

MONTHS OR

AFTER 100

HOURS

Air Filter Clean

Fuel Tank & Filter Clean

(1)

(2)

Fuel Feed Line Check (replace

if necessary)

Every three years

(2)

(1) If operated in dusty areas carry out maintenance more frequently.

(2) A specialist technician should carry out this maintenance if the owner does not have the appropriate tools or

mechanical knowledge.

AIR FILTER

(FIG.21)

WARNING

Cleaning the air lter is essential to guarantee the

eciency and duration of the machine. Do not work

with a damaged lter or without a lter, as this could

permanently damage the engine.

Clean the lter as follows:

• Loosen the knob (3), remove the cover (1) and

the lter element (2).

• Wash the lter element (2) with soap water. Do

not use petrol or other solvents.

• Leave the lter to dry in the open air.

• Fit the lter element (2) and the cover (1) back

on, tightening the knob (3) again.

•

WARNING

The use of petrol or combustible solvents for

cleaning can cause re or explosion. Therefore only

use soap water or non-combustible solvent. Never

operate the machine without the air lter.

SPARK PLUG

RECOMMENDED SPARK PLUG: NGK BPMR7A / BOSCH

WSR6F To ensure proper engine operation, the spark

plug must be properly gapped and free of deposits.

1. Remove the spark plug cap.

2. Clean any dirt around the spark plug base.

3. Use the socket spanner which provided to

remove the spark plug.

4. Visually inspect the spark plug. Remove carbon

deposits using a wire brush.

5. Check for discoloration on the top of the spark

plug. The standard color should be a tan color.

6. The acceptable spark plug gap should be

between 0.6 - 0.7mm.

FIG.21

17

A STEELFORT PRODUCT

7. Install /reinstall the spark plug carefully by

hand.

8. Once the spark plug has been seated, tighten it

with a socket spanner.

9. Reinstall the spark plug cap on top of the spark

plug

FIG.22

CLEANING

1. To keep your machine clean, use a damp cloth

with mild detergent for the exterior—avoid

water to prevent internal damage.

2. Some maintenance products and solvents may

damage the plastic parts, these include prod-

ucts containing benzene. Trichloroethylene,

chloride and ammonia.

3. Keep ventilation inlets/outlets clear. Use a

soft brush and compressed air for internal

cleanliness.

4. Wear eye protection when carrying out clean-

ing.

ANGLE TRANSMISSON

(FIG.22)

Lubricate with lithium-based grease.

Remove the screw (1) and put in the grease, turning

the shaft manually until grease emerges, then

replace the screw (1).

STORAGE

At the end of each working session, carefully clean

the machine of dust and debris, and make sure

that there are no damaged parts, replacing any faulty

parts. The machine must be stored in a dry

place away from the elements and with the cover

correctly tted.

• Keep all nuts and screws tight to be sure the

equipment is in safe working condition.

• Never store the equipment with petrol in the

tank inside a building where fumes can reach

an open ame or spark.

• Allow the engine to cool before storing in any

enclosure.

• To reduce the re hazard, keep the engine,

silencer and petrol storage area free of vegeta-

tive material and excessive grease.

• Replace worn or damaged parts for safety.

• If the fuel tank has to be drained, this should be

done outdoors.

• Always clean and maintenance before storage.

• Never disassembly the guards for cutting

attachments.

• Always store the metal blade in cool and dry

place, never use rusted blade. It may cause

serous injure during working.

Transporting the machine in a car, please empty the

fuel tank completely rst to avoid the leakage.

Store the machine, operating instructions and where

necessary the accessories in the original packaging

.In this way you will always have all the information

and parts ready to hand.

Pack the device well or use the original packaging in

order to avoid transit damage. Use protective gloves

when handling the blades. Keep the blade protection

device on, except when intervening directly on the

blade.

Store the machine in dry and well ventilated sur-

roundings and with the fuel tank empty. Do not store

fuel next to the machine.

18 A STEELFORT PRODUCT

TROUBLESHOOTING

The engine stalls, is

dicult to start or

doesn’t start

Fuel at the

carburetor

The fuel does

not arrive at the

cylinder

Fuel at the

cylinder

The fuel does

not arrive at the

carburetor

Fuel lter blocked

Fuel supply

blocked

Carburetor

Clean or replace

Clean or replace

Ask your LM

dealer for advice

Carburetor

There is fuel

in the exhaust

The fuel

mixture is too

rich

Open the throttle

valve

Clean or replace

the air lter

Sparks at the

spark plug

electrodes

There is no

spark

Set the switch to

the ON position

(Run)

Switch in “O”

position

Electrical

problem

Locked switch

Sparks at the

spark plug There is no

spark

Bad spacing of

the electrodes

Electrodes

contaminated

Electrodes

contaminated

with fuel

PROBLEM CHECK CONDITION CAUSE SOLUTION

Defective

spark plug

Adjust the gap to

0.6-0.7 mm

Clean or replace

Clean or replace

Replace the

spark plug

The engine turns,

but stalls or does not

accelerate correctly

Air lter

Fuel lter

Spark plug

Dirty air lter

Dirty fuel lter

Dirt or worn

spark plug

Fair wear

and tear

Dirt or residue in

the fuel

Fair wear

and tear

Clean or replace

Replace

Clean, adjust

or replace

The engine does not

engage N/A Internal engine

problem

N/A

Ask your LM

dealer for advice

Ask your LM

dealer for advice

Ask your LM

dealer for advice

Ask your LM

dealer for advice

19

A STEELFORT PRODUCT

WARRANTY

Subject to the following conditions, this unit is covered by a comprehensive two-year warranty.

The unit is designed for domestic purposes only, issues and faults due to commercial use may not by covered

by warranty. The warranty covers all manufacturing faults but excludes normal wear and tear, misuse, neglect,

accidental damage or defects arising from failure to comply with instructions as outlined in this owners manu-

al. Only genuine spare parts can be used for repairs and this must be carried out by an authorised LawnMaster

Services Dealer to maintain warranty.

Warranty does not cover the cost of transportation of any part(s) but does cover the labour/parts cost

incurred in repairing or replacing any defective part(s) consequential or special damages and / or expenses

resulting from any defect.

If the unit requires further repairs or services please visit www.lawnmaster.co.nz to nd your local

LawnMaster Service Dealer.

For all other enquries contact Steelfort Customer Services +64 6 350 1350

Steelfort

500 Rangitikei Street, Private Bag 11045

Palmerston North, 4412, New Zealand

06 350 1350

Steelfort Auckland

880 Great South Road, Penrose

Auckland, 1061, New Zealand

09 573 1324

lawnmasternz

FIND US

www.lawnmaster.co.nz

Table of contents

Other LawnMaster Brush Cutter manuals

Popular Brush Cutter manuals by other brands

Brush Wolf

Brush Wolf 4200 Instruction & maintenance manual

Husqvarna

Husqvarna 555FX Operator's manual

Land Pride

Land Pride RC5010 parts manual

Blue Diamond

Blue Diamond Extreme Duty 2 Series Operation and maintenance manual

BLACK DECKER

BLACK DECKER SEASONMASTER BCASK861D Original instructions

Blue Diamond

Blue Diamond Rototiller Operation and maintenance manual