LawnMaster LMDGJ260H-BC User manual

LMDGJ260H-BC

LMDGJ260H-BK

SAFETY AND OPERATING MANUAL

SPLIT SHAFT

BRUSH CUTTER

2

This manual explains how to operate the Split-Shaft Petrol Brush Cutter. Before operating the unit,

please ensure you read this manual carefully and acknowledge all safety elements before operating.

Understanding how to repair and maintain the unit will help you operate and complete the task safely.

SAFTY FIRST

Instructions in this manual marked with a danger/warning sign, are hazards or concerns that must be

taken into consideration when operating the unit to prevent possible serious injury. Please carefully

read all instructions and operate the unit accordingly.

IMPORTANT

The ‘!’ indicates instructions that must be followed, to prevent mechanical failure, breakdown, or

damage.

NOTE

The notebook indicates helpful tips, hints or directions when using the product.

PREFACE

TABLE OF CONTENTS

Preface 02

Table Of Contents 02

Parts Location 03

Specication 04

Unit Labels 05

For Safe Operations 05

Set-Up 08

Fuel & Chain Oil 10

Operation 11

Maintenance 18

Storage 22

Troubleshooting Guide 23

3

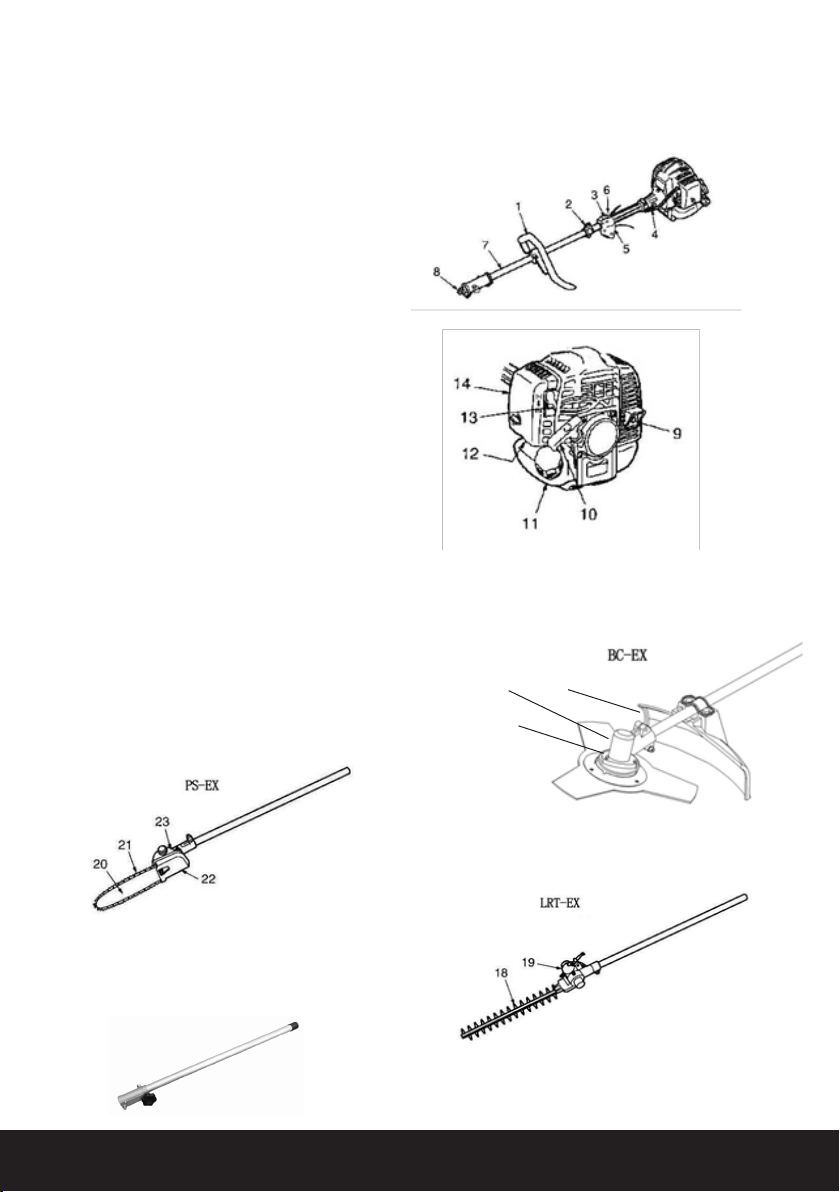

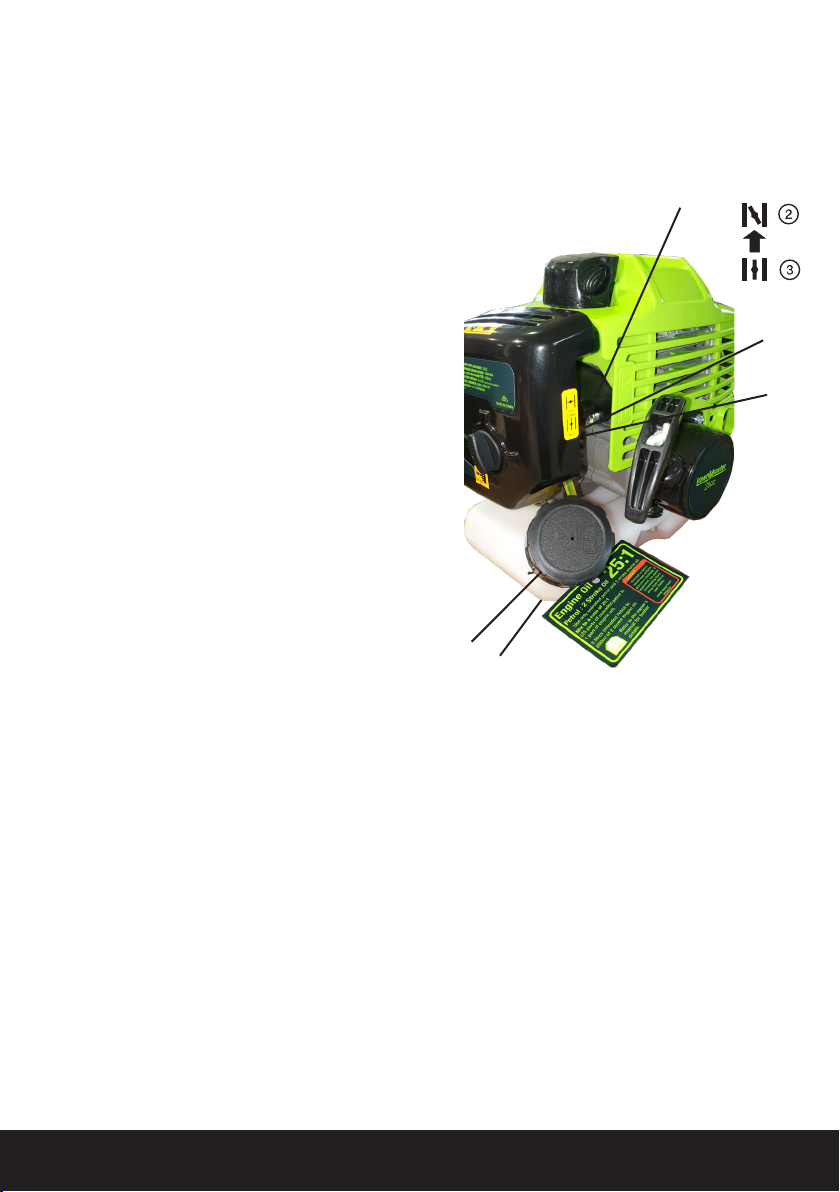

1. PARTS LOCATION

LMDCJ260H-BC

1. Loop handle

2. Shoulder strap hanger

3. On/Off switch

4. Throttle cable

5. Throttle Trigger

6. Throttle set button

7. Drive shaft housing

8. Connector Bolt

9. Spark arrester

10. Starter Handle

11. Fuel tank

12. Primer pump

13. Choke level

14. Air cleaner cover

15. Debris guard

16. Gear case

17. Cutting head

18. Blade

19. Gear case

20. Guide bar

21. Saw chain

22. Chain cover

23. Gear case

LMDCJ260H-HT

LMDCJ260H-PS

POLESAW

HEDGE TRIMMER

Additional Attachments

Can be bought separately or included with the Brush Cutter Kit

LMDCJ260H-BC

15

17

16

LMDCJ260H-E

EXTENSION

4

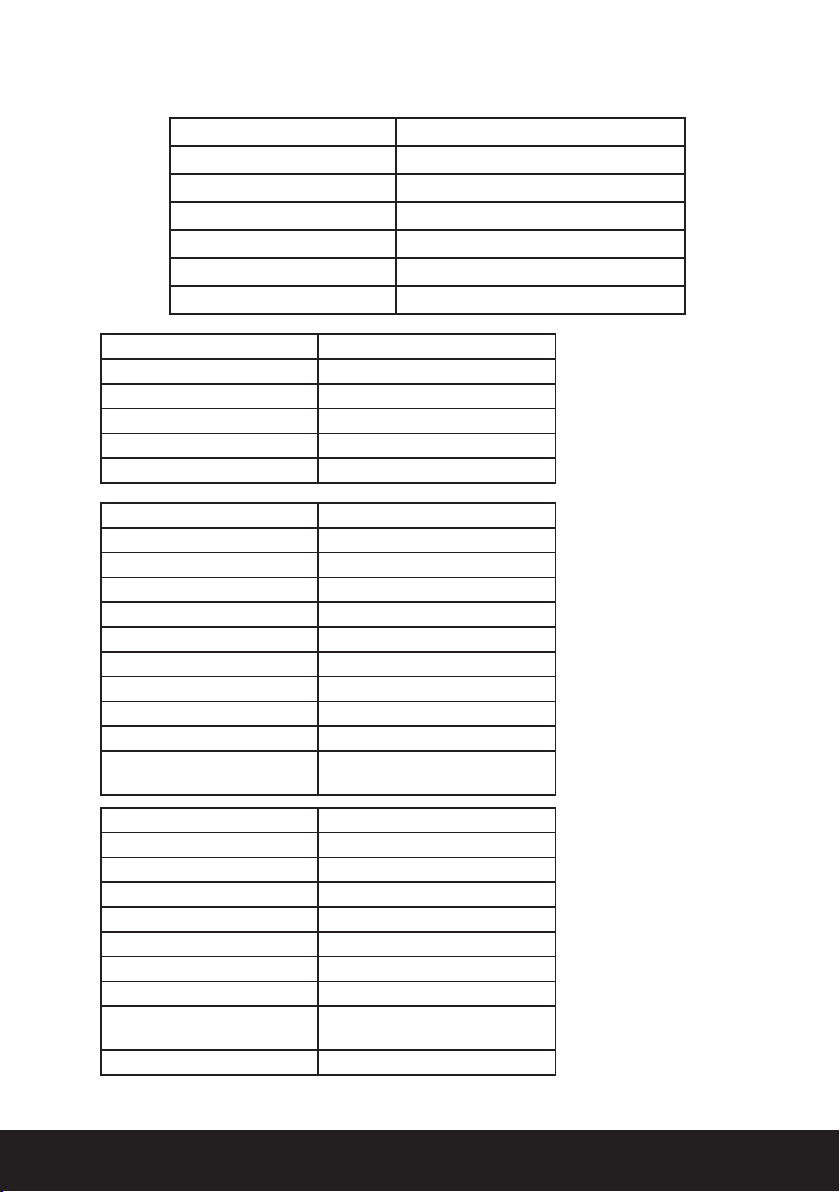

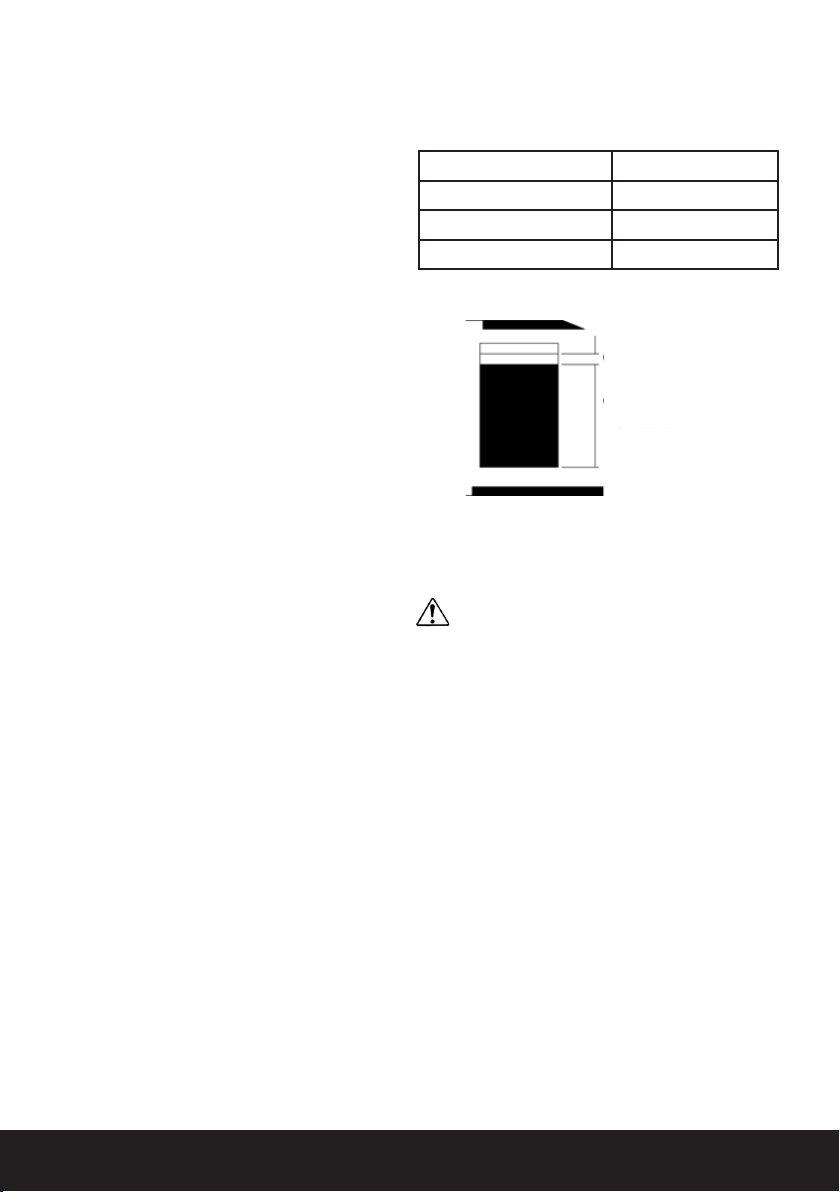

2. SPECIFICATIONS

MODEL LMDCJ260H-BC

Displacement: 26cc

Max Output: 0.9 kw,7000 r/min

Idle Speed: 2800 + - 200/min-1(rpm)

Fuel: Mixture (Petrol 40: Oil 1)

Spark Plug: Champion RCJ6Y

Fuel Tank Capacity: 0.7L

MODEL BC-EX (BRUSH CUTTER)

Overall Size(L×W×H): 1790×250×310mm

Dry Weight W/O Acc: 5.3kg

Transmission Centrifugal clutch, rigid drive shaft

Reduction Ratio: 1.294

Cutting Head Rotating Direction: Counter-clockwise (Operator view)

MODEL PS-EX (POLE SAW)

Overall Size(L×W×H): 2100×250×310mm

Dry Weight W/O Acc: 5.05kg

Transmission Centrifugal clutch, rigid drive shaft

Reduction Ratio: 0.94

Cutting Head: Counter-clockwise (Operator view)

Sprocket: 7T

Oil Pump: Plunger Type

Type of Chain: 40DL 3/8LP X 0.050”

(ProKut PPGAF20S040DL)

Bar Length: 254mm (10”)

MODEL LRT-EX (HEDGE TRIMMER)

Overall Size(L×W×H): 2300×250×310mm

Dry Weight W/O Acc: 6.1kg

Transmission Centrifugal clutch, rigid drive shaft

Reduction Ratio: 4.0

Cutting head:

Type: Reciprocating Double blade

Tooth: 28 Teeth

Pitch: 30mm

Effective Cut Width: 40mm

Angle Adjust Range: 90 degrees (45 from cutting head

position aligned shaft)

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

LMDCJ260H-HT

LMDCJ260H-PS

LMDCJ260H-BC

5

Read owner’s manual before

operating this unit.

Wear head, eye and ear protection.

Warning/Attention

Keep all children, bystanders and helpers 15

meters away from the unit.

Do not modify the unit, this will result in the

warranty being void.

Follow the instructions for changing the

accessories. The use of any other accessories

or attachments may cause a potential hazard or

injury to the user, damage to the unit and void this

warranty.

3. LABELS ON THE UNIT

4. SYMBOLS ON THE Unit

Read the manual before operating the unit and keep

the information for future reference to learn safe

operating techniques. For safe operation and

maintenance, symbols are helpful indications and

tips.

The direction to open the choke

Position: AIR CLEANER COVER

(PS-EX Only)

If you turn the rod by screwdriver follow the

MIN & MAX arrow to the “MAX” position,

the chain oil ow more, and if you turn to

the “MIN” position, less.

Position: Bottom of the GEAR CASE

The port to refuel the “MIX PETROL”

Position: FUEL TANK CAP

The direction to close the choke

Position: AIR CLEANER COVER

5. FOR SAFE OPERATION

Read the “Rules for Safe Operation “with care

and follow the instructions in the manual to

operate the unit safely. Read and be thorough

with the basic controls and functions of the unit. It is

important that you know how to stop and to shut off

the engine, and to unhook a harnessed unit quickly.

Do not allow anyone without proper instruction or

training to operate the unit. All operators of the unit

should wear appropriate foot, leg, eye, face and

hearing protection.

Do not rely on the debris shield on the unit to protect

your eyes from thrown objects. Keep the area clear

of bystanders, children and pets. Never allow chil-

dren to operate or play with the unit.

5.1 WORKING CONDITION

1. When using the unit, please ensure you wear

appropriate clothing and safety equipment as listed:

(1) Helmet

(2) Ear Muffs

(3) Protection goggles

(4) Thick work gloves

(5) Non-slip-sole work boots

2. Other important tools and resources to have with

you include:

a) Approved Brush Cutter Attachments

b) Reserve fuel

c) For commercial use, hazard signage and rope to

cordon working area.

d) Whistle (Collaboration or emergency).

3. In addition to head, eye, face and ear protection,

please wear appropriate footwear to protect your

feet and to improve footing on slippery surfaces. Do

not wear open-toed footwear, or go bare foot or bare

legged. Do not wear ties, jewelry, or loose, dangling

clothing which could be caught in the unit.

Do not allow anyone without proper instruction or

training to operate the unit. All operators of the unit

should wear appropriate foot, leg, eye, face and

hearing protection.

Do not rely on the debris shield on the unit to protect

your eyes from thrown objects. Keep the area clear of

6

NOTE

Check and follow local regulations regarding

appropriate sound levels and hours of operations

5.2 WORKING CIRCUMSTANCE

1. Never start the engine inside a closed room or

building. Exhaust fumes contain carbon monoxide

which is a health risk.

2. Never use the product:

(a) When the ground is slippery and you cannot

maintain a steady posture.

(b) At night, fog, or when your vision might be

limited so it becomes dicult to gain a clear view of

your working area.

(c) During storms, rainy weather, and or strong or

gale-force winds. Do not use the unit if the weather

conditions might make it unsafe to operate.

5.3 WORKING PLAN

1. DO NOT use the Brush Cutter under the inuence

of alcohol, exhaustion or lack of sleep. Do not use

the unit if you are unwell or drowsy as a result of

taking medication.

2. When using the brush cutter, allow plenty of

time to rest. Limit your working sessions to 30-40

minutes, and take 10-20 minutes of rest in-between

each working session. Keep the total amount of

work performed in a single day to under 2 hours.

WARNING

1. If you don’t observe the working time, or

working manner when using the Brush Cutter

Repetitive Stress Injury (RSI) could occur.

2. If you feel discomfort, redness and swelling of

your ngers or any other part of your body, seek

medical advice as soon as possible.

3. To avoid noise complaints, in general, operate

product between 8 am and 5 pm on weekdays

and weekends.

5.4 BEFORE STARTING THE ENGINE

1. Do not allow anyone to enter the operating

DANGER ZONE with you. The danger zone is an

area 15 meters in radius (about 16 paces) or 50

feet. Insist that a person near the danger zone

wear eye protection from thrown objects.

2. If the unit must be used where there are unpro-

tected people, operate at a low throttle speed

to reduce the risk of thrown objects.

3. Check the working area to avoid any accidents

such as hitting hidden obstacles i.e., stumps,

stones, cans, or broken glass.

IMPORTANT

• Remove any obstacles before operating the

unit.

• Inspect the unit and check for loose parts and

fuel leakage.

• Make sure cutting attachments are properly

installed and securely fastened.

• Be sure to check whether the debris guard is

rmly attached and in place.

• Always use the shoulder strap. Adjust the

strap for comfort before starting the engine.

The strap should be adjusted so the left hand

can comfortably hold the handlebar grip,

approximately waist high

bystanders, children and pets. Never allow children

to operate or play with the unit.

5.5 STARTING THE ENGINE

1. Keep bystanders and animals at least 15m

away from the operating point. If you are

approached immediately stop the engine.

2. The product is equipped has a centrifugal

clutch mechanism; the cutting attachment

begins to rotate as soon as the engine is

started when the throttle is placed into the

‘start position’.

3. When starting the engine, rstly place the

product on the ground (at clear area). Hold it

rmly in place to ensure that neither the cutting

part nor the throttle comes into contact with

any obstacles when the engine starts.

WARNING

NEVER PLACE THE THROTTLE INTO THE

HIGH-SPEED POSITION WHEN STARTING THE

ENGINE.

7

5.6 USING THE PRODUCT

IMPORTANT

Cut only materials recommended by the

manufacturer to avoid any warranty concerns.

Only use the Brush Cutter on tasks explained in the

manual.

1. Grip the handles rmly with both hands. Place

your feet slightly further than your shoulder

width to distribute weight evenly across both

legs to maintain a steady posture when operat-

ing the unit.

2. Keep the Brush Cutter and the cutting attach-

ment waist low when operating the unit.

3. Maintain the speed of the engine at the level

required to perform cutting work, and never

raise the speed of the engine above the level

necessary.

4. If the unit starts to shake or vibrate. Turn off

the engine and thoroughly check the unit. Do

not use the unit until the trouble has been prop-

erly xed or take it to a service dealer for repair.

5. Keep all parts of your body away from the rotat-

ing cutting attachments and hot surfaces.

6. Never touch the muer, spark plug, or other

metallic parts of the engine while the engine is

in operation or immediately after shutting down

the engine. Doing so could result in serious

burns or electrical shock.

7. Be prepared at all times for any hazardous sit-

uations. Warn adults to keep pets and children

away from the working area. Be careful and

aware if you are being approached as an injury

would occur as a result of ying debris.

8. If someone calls out or otherwise interrupts

you while working, always be sure to turn off

the engine before giving them your attention.

5.7 MAINTENANCE

1. In order to maintain the Brush Cutter in proper

working order, perform regular servicing and

maintenance.

2. Always turn off the engine when performing

any servicing or maintenance.

WARNING

The metallic parts reach high temperatures immedi-

ately after stopping the engine.

3. When replacing cutting attachments or any

other unit parts, including oil or any lubricants,

be sure to use only authorized dealer products.

4. In the event any part must be replaced,

maintenance or repair work not described in

this manual must be performed, contact your

local service dealer for assistance.

5. Do Not use any other attachments other than

the attachments recommended with the unit.

6. Do Not take apart the product or alter it in any

way. Doing so will void warranty and might

result in having an unsafe product that does

not function properly.

5.8 HANDLING FUEL

1. The engine of product is designed to run on

mixed fuel which is highly ammable. Never

store fuel cans or rell the tank near a boiler,

stove, wood re, electrical sparks, welding

sparks, or any other source of heat or re which

might ignite the fuel.

2. Never smoke while operating the unit or

relling with fuel.

3. When relling with fuel, always turn off the

engine and allow it to cool down before

refueling.

4. Wipe spilled fuel completely using a dry rag if

spillage occurs.

5. After refueling, screw the fuel cap tightly and

carry the unit to a spot 3m away from where

it was initially refueled before turning on the

engine.

5.9 TRANSPORTATION

1. When hand-carrying the Brush Cutter, cover

the cutting blades if necessary. Lift the Brush

Cutter and carry it with attention to the blade.

4. After starting the engine, check to make sure

the cutting attachments stop rotating when

the throttle is moved fully back to its original

position. If the cutting attachment continues to

rotate even after the throttle has been moved

fully back, immediately turn off the engine and

take the unit to a service dealer for repair and

service.

8

2. Never transport the product over rough roads

or over long distances by vehicle without re-

moving all fuel from the fuel tank. In doing so,

might result in fuel leaks from the tank during

transport.

6. SET-UP

6.1 MOUNTING ENGINE

1. Push the drive shaft housing towards the clutch

housing and rotate it by hand to check that the

drive shaft is engaged with the gears.

2. Insert the drive shaft housing into the clutch

housing until it bottoms, and aligns the

positioning holes on the clutch housing and the

shaft tube and install the screw. When dicult

to engage, twist the engine slightly.

3. Fasten the clamp securely with two screws.

Tighten the screws gradually by turns.

IMPORTANT

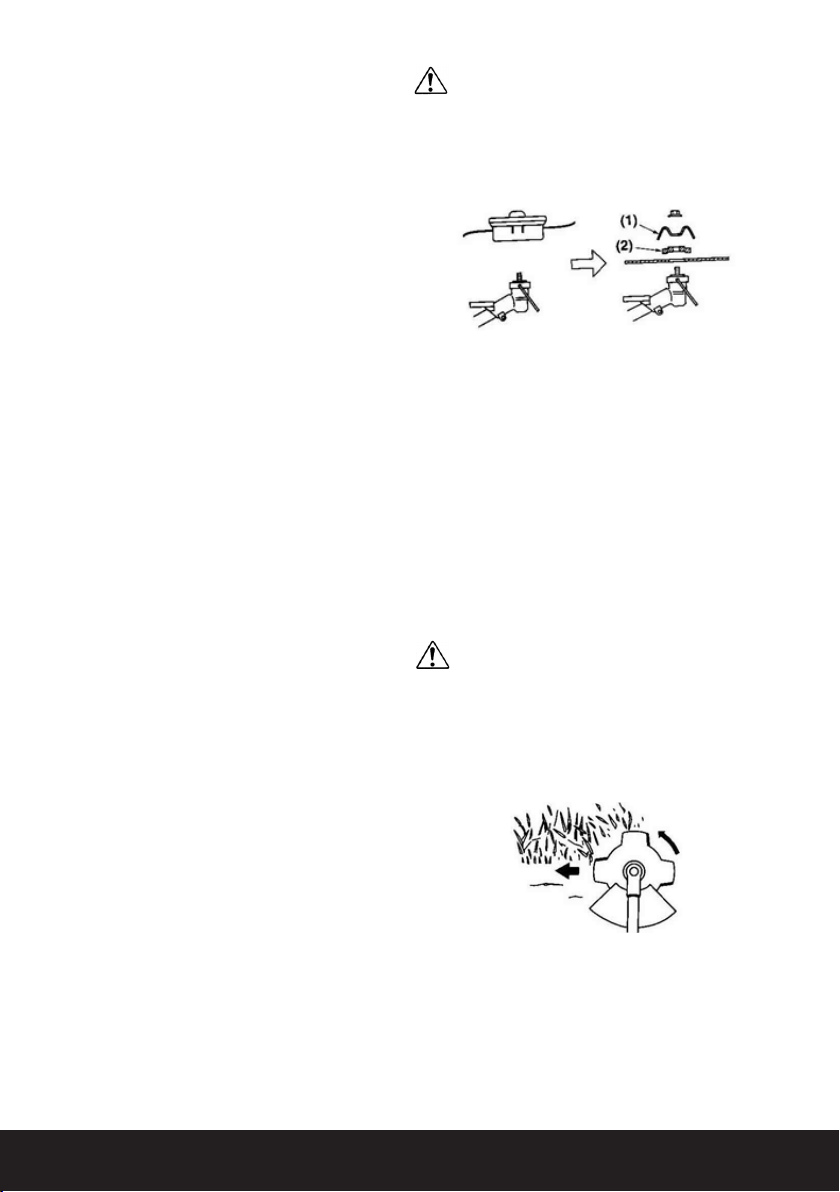

Connecting switch wires, connect the switch wires

between the engine and the main. Pair the wires of

the same colour.

6.2 INSTALLING HANDLE (BC-EX, LRT-EX)

•Install the handle to the shaft tube and clamp at the

location that is comfortable to you. (PS-EX only)

• Insert the grip to the shaft tube.

• Fasten the clamps with screws.

6.3 JOINT ATTACHMENT

• Insert the attachment to the main shaft.

• Tighten the knob bolt securely Set up (BC-EX only)

6.4 INSTALLING DEBRIS GUARD

(1) Screw

(2) Plate

(3) Debris guard

Put the debris guard on the gearbox, attach it with

the 2 screws and hardware provided.

9

6.5.1 BALANCE UNIT

1. Put on the Brush Cutter strap and attach the

unit to the strap.

2. Slide clamp up or down until the unit balances

by slightly touching the ground. Set up (LRT-EX

only)

6.5 INSTALLING CUTTING HEAD

1. While locking the gear shaft, by inserting the

supplied tool into the upper holder on the

gearbox, loosen and remove the hexagon nut

(left-handed).

2. Then screw in the cutting head to the gear

shaft over the holders. Hand-tighten it securely.

6.6 ATTACHING THE TRIMMING

MECHANISM

(1) Main pipe

(2) Trimming mechanism

(3) Screw hole

(4) Screw

(5) Fastening bolt

1. Remove the screw that is screwed into the end

of the trimming mechanism.

2. Insert the end of the trimming mechanism into

the main pipe.

3. Line up the hole on the end of the trimming

mechanism to the screw to be inserted with the

hole on the main pipe - screw it in rmly.

4. Using a wrench, screw in the bolt provided to x

the trimming mechanism into place.

6.6.1 BALANCE UNIT

1. Put on the Brush Cutter strap and attach the

unit to the strap.

2. Depending on the working posture, slide clamp

up or down until the unit balances and the

straps comfortably to your body.

Set up (PS-EX only)

6.7 ATTACHING THE PRUNING

MECHANISM

(1) Main pipe

(2) Gear case

(3) Screw hole

(4) Fastening bolt

(5) Bolt

1. Remove the cap on the end of the main pipe.

2. Remove the screw that is screwed into the end

of the gear case.

10

3. Insert the end of the trimming mechanism into

the main pipe.

4. Line up the hole on the end of the gear case to

the screw that is to be inserted with the hole

on the main

6.7 ATTACHING THE PRUNING

MECHANISM

(1) Main pipe

(2) Gear case

(3) Screw hole

(4) Fastening bolt

(5) Bolt

1. Remove the cap on the end of the main pipe.

2. Remove the screw that is screwed into the end

of the gear case.

3. Insert the end of the trimming mechanism into

the main pipe.

4. Line up the hole on the end of the gear case to

the screw that is to be inserted with the hole on

the main pipe, and screw it in rmly.

5. Using a wrench, screw in the bolt provided to x

the mechanism into place.

7.1 FUEL

1. Petrol is very ammable. Avoid smoking or

bringing any ames or sparks near fuel.

2. Make sure to stop the engine and allow it cool

before refueling the unit.

3. Select outdoor bare ground for

fueling and move at least 3m (10ft) away from

the fueling point before starting the engine.

4. The engines are lubricated by oil specially

formulated for air-cool 2-cycle Petrol engine

use. If oil is not available, use an anti-oxidant

added quality oil expressly labeled for

air-cooled 2-cycle engine use.

5. Do not use BIA or TCW (2-stroke water-cooling

type) mixed oils.

7.1 SUMMARY

The engine uses two-stroke fuel. If you have

emission requirements, the mixture ratio of the

fuel to oil should be 40:1. If there are no emission

requirements, the mixture ratio can be 25:1.

7. FUEL AND CHAIN OIL

Petrol

Use 91 Unleaded Petrol.

Other Appropriate Fuel Mixtures

Petrol 2-Stroke Oil

1 Litre 25 ml

2 Litre 50 ml

5 Litre 125 ml

Oil - 1 Part

Gasoline - 40 Part

Emissions

7.2 HOW TO MIX FUEL

WARNING

Pay attention to agitation.

1. Measure out the quantities of petrol and oil to

be mixed.

2. Put some of the petrol into a clean, approved

fuel container.

3. Pour in all of the oil and agitate well.

4. Pour in the rest of the petrol and agitate again

for at least one minute. Some oils may be

dicult to agitate depending on oil ingredients,

sucient agitation is necessary for the engine

to last long. Be careful that, if the agitation is

insucient, there is an increased danger of

early piston seizing due to abnormally lean

mixture.

5. Put a clear indication on the outside of the

container to avoid mixing of petrol or other

containers.

6. Indicate and name the contents on the contain-

er for easy identication.

11

7.3 FUELING THE UNIT

1. Untwist and remove the fuel cap. Rest the cap

on a dustless area.

2. Put fuel into the fuel tank to roughly 80% of the

full capacity. Do not over ll.

3. Fasten the fuel cap securely and wipe any fuel

spillage around the unit.

WARNING

• When fueling, do it on a at and bare ground.

• Move at least 3m away from the fueling point

before starting the engine.

• Stop the engine before refueling the unit and be

sure to suciently agitate the mixed petrol in

the container.

7.4 PRESERVE ENGINE LIFE, AVOID:

1. FUEL WITH NO OIL (RAW PETROL)

Will cause severe engine damage to the inter-

nal engine parts very quickly.

2. OIL FOR 4-CYCLE ENGINE USE,

Can cause spark plug fouling, exhaust port

blocking, or piston ring sticking.

3. Mixed fuels that have been left unused for

a period of one month or more may clog the

carburettor and result in the engine failing to

operate properly.

4. When storing the product for a long period

of time, clean the fuel tank after rendering it

empty.

5. When scrapping used mixed oils, follow your

local council protocols and visit a repository

site.

NOTE

For details of quality assurance, read the description

in the section limited to warranty carefully.

Normal wear and tear of the product with no

functional inuence is not covered by warranty. Do

not make mistakes when mixing oil and petrol, follow

the instructions in the manual to avoid warranty

issues.

7.5 CHAIN OIL

NOTE

Do not use wasted or regenerated oil as this can

cause damage to the oil pump.

8. OPERATION

8.1 STARTING ENGINE

CAUTION

Do not pull the starter cord all the way out and do

not let go of the starter handle when the cord is

extended, this can damage the starter mechanism.

Before starting the engine, inspect the entire unit

for loose ttings or fuel leaks, and verify that the

cutting attachment is properly installed and securely

fastened.

AB

1110

CULTIVATOR EDGER PRUNING SAW HEDGE TRIMMER BRUSHCUTTER

the cords should stick out 15 cm each side,

8. Pull the cords to free them from the notches, refit the spool

cover.

Never use cutting device other than those supplied by the

manufacturer.

(Steel cord is never allowed).

Always use original spare parts in order to benefit from

continuous warranty.

Attaching The Tools To The Drive Shaft Assembly

• Rest the power unit/shaft assembly on a flat firm surface.

• Ensure that the clamping wing nut (2) is loose, pull out locator

pin (1).

• Carefully fit attachment drive shaft assembly (5) into coupler (3).

• After the attachment drive shaft is in the coupler, release the

locator pin (1).

• Turn the attachment drive shaft until the locator pin engages

with the locating hole (4) in the drive shaft, when this has

happened it will not be possible to twist the drive shaft.

• Secure the drive shaft by tightening the clamping wing nut (2).

Transportation

• Never transport the multi-tool with the engine running. An

engine that’s running could be accidently accelerated causing

the attachment to operate.

• When carrying by hand, the engine should be pointing forward.

Starting and Stopping the Engine

Starting the Engine

CAUTION

Do not pull the starter cord all the way out and do not let go of the

starter handle when the cord is extended, this can damage the

starter mechanism.

Before starting the engine, inspect the entire unit for loose fittings or

fuel leaks, and verify that the cutting attachment is properly installed

and securely fastened.

Place the unit on a flat, firm place. Keep

the cutting head clear of any obstructions.

1. Check that there is fuel in the tank

and that the fuel cap is screwed on

tightly.

(1) Cap

(2) Fuel tank

2. When starting a cold

engine move the choke

lever (behind the air cleaner

cover) to the closed

position.

(1) Choke lever

(2) Closed

(3) Open

3. If the engine has been running and is still warm, move the

choke lever to the open position.

4. Press the priming bulb under the carburettor repeatedly until

excess fuel can be seen returning to the tank through the clear

fuel return pipe.

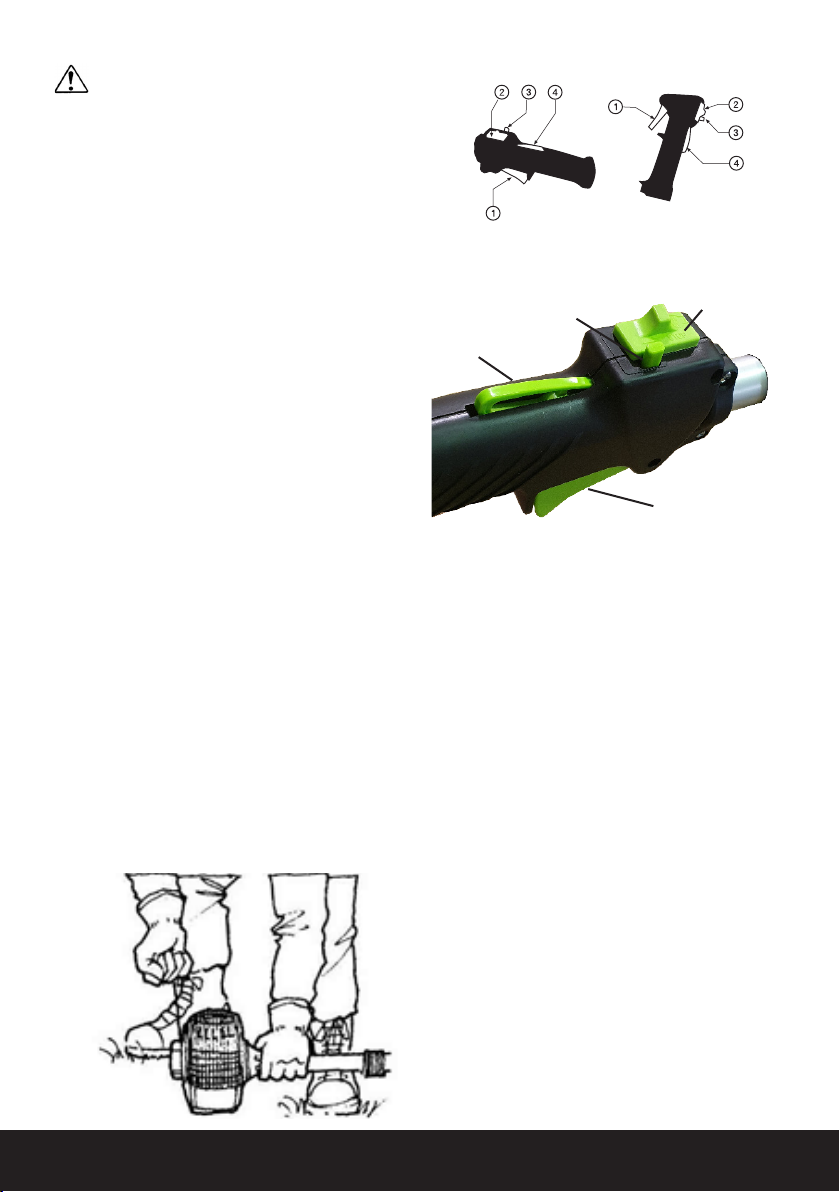

5. Slide the ignition switch (2) on the trigger grip away from the

STOP position (See Diagram .C on the next column).

6. To set the throttle in the start position.

- Depress the safety lever (4)

- Squeeze the throttle lever (1) fully.Hold down the starting

button (3) while releasing the throttle lever.

- The throttle lever will be held partly open until it is squeezed

again.

(1) Throttle lever

(2) Ignition Switch

(3) Starting button.

(4) Safety Lever

BC 230B S2, BC 260 S2 and

BC 260B S2

BC 325 S2

Diagram .C

7. While holding the unit firmly, pull out the

starter rope quickly.

8. After the engine has started, open the

choke gradually.

9. Allow the engine to run for 2 to 3 minutes

to warm up before starting work.

NOTE

Overchoking

• Should the engine become flooded due to over-choking set the

ignition switch to the STOP (O) position Fig 35, unscrew the

spark plug, wipe it dry or replace, pull the recoil starter several

times without the spark plug in place and with the choke in the

open position. This will help clean and ventilate the combustion

chamber.

STOPPING THE ENGINE

• Set the engine to idling by releasing the throttle lever.

• Set the ignition switch to the STOP (O) position.

• If the engine fails to stop, set the choke lever to the closed

position to stall the engine; do not use the machine until the

ignition switch is repaired.

RUNNING IN

• During the first ten hours of work, avoid running the engine

at maximum speed for a prolonged period until all the

components have bedded in. After the engine has been run-in,

it will reach its maximum power.

Wearing the Harness

The harness has a quick-release mechanism that allows

you to immediately release the machine from the harness

in an emergency.

Attaching the side hook

NOTE

If side hook (D) has disengaged from hook (B), engage it.

1. Insert hook (B) into side hook (D).

2. While holding hook (B) and side hook (D) in place,

insert stopper (C) into the hole on hook (B).

Adjusting the harness

1. As shown in the diagram, adjust the harness (A) so that

hip pad (E) is against your right hip. (Fig.7-2)

2. Before starting to work, attach the side hook (D) to the

suspension point (F) on the shaft tube. (Fig.7-3)

Recommended working position

CAUTION

If releasing both hands from the handle, use extreme care. Suddenly

Diagram .B

(1)

(2)

(3)

8. OPERATIONS

8.1 STARTING ENGINE

CAUTION

Do not pull the starter cord all the way

out and do not let go of the starter handle

when the cord is extended, this can

damage the starter mechanism.

Before starting the engine, inspect the

entire unit for loose ttings or fuel leaks,

and verify that the cutting attachment is

properly installed and securely fastened.

WARNING

The cutting head will start rotating upon

the engine starting.

Place the unit on a at, rm place. Keep

the cutting head clear of any obstructions.

1. Check that there is fuel in the tank and

that the fuel cap is screwed on tightly.

(See Image - Point 5 ).

(A) Cap

(B) Fuel tank

2. Fill fuel into the fuel tank and tighten

the cap securely.

3. Feed the chain oil into the oil tank and

tighten the cap securely. (PS-EX only)

4. Rest the unit on a at, rm area. Keep

the cutting head off the ground and clear

of surrounding objects, as it will start

rotating upon engine starting.

5. When Cold Starting, move the choke

lever to the closed position.

(1) Choke lever

(2) Close

(3) Open

6. If the engine has been running and is

still warm, move the choke lever to the

open position.

7. Press the priming bulb under the

carburettor repeatedly until excess fuel

can be seen returning to the tank through

the clear fuel return pipe.

AB

1110

CULTIVATOR EDGER PRUNING SAW HEDGE TRIMMER BRUSHCUTTER

the cords should stick out 15 cm each side,

8. Pull the cords to free them from the notches, refit the spool

cover.

Never use cutting device other than those supplied by the

manufacturer.

(Steel cord is never allowed).

Always use original spare parts in order to benefit from

continuous warranty.

Attaching The Tools To The Drive Shaft Assembly

• Rest the power unit/shaft assembly on a flat firm surface.

• Ensure that the clamping wing nut (2) is loose, pull out locator

pin (1).

• Carefully fit attachment drive shaft assembly (5) into coupler (3).

• After the attachment drive shaft is in the coupler, release the

locator pin (1).

• Turn the attachment drive shaft until the locator pin engages

with the locating hole (4) in the drive shaft, when this has

happened it will not be possible to twist the drive shaft.

• Secure the drive shaft by tightening the clamping wing nut (2).

Transportation

• Never transport the multi-tool with the engine running. An

engine that’s running could be accidently accelerated causing

the attachment to operate.

• When carrying by hand, the engine should be pointing forward.

Starting and Stopping the Engine

Starting the Engine

CAUTION

Do not pull the starter cord all the way out and do not let go of the

starter handle when the cord is extended, this can damage the

starter mechanism.

Before starting the engine, inspect the entire unit for loose fittings or

fuel leaks, and verify that the cutting attachment is properly installed

and securely fastened.

Place the unit on a flat, firm place. Keep

the cutting head clear of any obstructions.

1. Check that there is fuel in the tank

and that the fuel cap is screwed on

tightly.

(1) Cap

(2) Fuel tank

2. When starting a cold

engine move the choke

lever (behind the air cleaner

cover) to the closed

position.

(1) Choke lever

(2) Closed

(3) Open

3. If the engine has been running and is still warm, move the

choke lever to the open position.

4. Press the priming bulb under the carburettor repeatedly until

excess fuel can be seen returning to the tank through the clear

fuel return pipe.

5. Slide the ignition switch (2) on the trigger grip away from the

STOP position (See Diagram .C on the next column).

6. To set the throttle in the start position.

- Depress the safety lever (4)

- Squeeze the throttle lever (1) fully.Hold down the starting

button (3) while releasing the throttle lever.

- The throttle lever will be held partly open until it is squeezed

again.

(1) Throttle lever

(2) Ignition Switch

(3) Starting button.

(4) Safety Lever

BC 230B S2, BC 260 S2 and

BC 260B S2

BC 325 S2

Diagram .C

7. While holding the unit firmly, pull out the

starter rope quickly.

8. After the engine has started, open the

choke gradually.

9. Allow the engine to run for 2 to 3 minutes

to warm up before starting work.

NOTE

Overchoking

• Should the engine become flooded due to over-choking set the

ignition switch to the STOP (O) position Fig 35, unscrew the

spark plug, wipe it dry or replace, pull the recoil starter several

times without the spark plug in place and with the choke in the

open position. This will help clean and ventilate the combustion

chamber.

STOPPING THE ENGINE

• Set the engine to idling by releasing the throttle lever.

• Set the ignition switch to the STOP (O) position.

• If the engine fails to stop, set the choke lever to the closed

position to stall the engine; do not use the machine until the

ignition switch is repaired.

RUNNING IN

• During the first ten hours of work, avoid running the engine

at maximum speed for a prolonged period until all the

components have bedded in. After the engine has been run-in,

it will reach its maximum power.

Wearing the Harness

The harness has a quick-release mechanism that allows

you to immediately release the machine from the harness

in an emergency.

Attaching the side hook

NOTE

If side hook (D) has disengaged from hook (B), engage it.

1. Insert hook (B) into side hook (D).

2. While holding hook (B) and side hook (D) in place,

insert stopper (C) into the hole on hook (B).

Adjusting the harness

1. As shown in the diagram, adjust the harness (A) so that

hip pad (E) is against your right hip. (Fig.7-2)

2. Before starting to work, attach the side hook (D) to the

suspension point (F) on the shaft tube. (Fig.7-3)

Recommended working position

CAUTION

If releasing both hands from the handle, use extreme care. Suddenly

Diagram .B

(1)

(2)

(3)

8. Slide the ignition switch (2) on the

trigger grip away from the STOP position

9. To set the throttle in the start position.

- Depress the safety lever (4) and squeeze

the throttle lever (1) fully. Hold down the

starting button (3). Releasing the throttle

lever and then the starting button.

- The throttle lever will be held partly open

until it is squeezed again.

(1) Throttle lever

(2) Ignition Switch

(3) Starting button.

(4) Safety Lever

10. While holding the unit rmly, pull out

the starter rope quickly.

11. After the engine has started, open the

choke gradually.

12. Allow the engine to run for 2 to 3

minutes to warm up before starting work.

NOTE - OVERCHOKING

• Should the engine become ooded due

to over-choking set the ignition switch

to the STOP (2), unscrew the spark plug,

wipe it dry or replace, pull the recoil

starter several times without the spark

plug in place and with the choke in the

open position. This will help clean and

ventilate the combustion chamber.

8.2 STOPPING THE ENGINE

• Set the engine to idling by

releasing the throttle lever.

• Set the ignition switch to the STOP (2)

position.

• If the engine fails to stop, set the choke

lever to the closed position to stall the

engine; do not use the machine until the

ignition switch is repaired.

RUNNING IN

• During the rst ten hours of work, avoid

running the engine at maximum speed for

a prolonged period until all the

components have bedded in. After the

engine has been run-in, it will reach its

maximum power.

(1)

(3) (2)

(4)

1110

CULTIVATOR EDGER PRUNING SAW HEDGE TRIMMER BRUSHCUTTER

the cords should stick out 15 cm each side,

8. Pull the cords to free them from the notches, refit the spool

cover.

Never use cutting device other than those supplied by the

manufacturer.

(Steel cord is never allowed).

Always use original spare parts in order to benefit from

continuous warranty.

Attaching The Tools To The Drive Shaft Assembly

• Rest the power unit/shaft assembly on a flat firm surface.

• Ensure that the clamping wing nut (2) is loose, pull out locator

pin (1).

• Carefully fit attachment drive shaft assembly (5) into coupler (3).

• After the attachment drive shaft is in the coupler, release the

locator pin (1).

• Turn the attachment drive shaft until the locator pin engages

with the locating hole (4) in the drive shaft, when this has

happened it will not be possible to twist the drive shaft.

• Secure the drive shaft by tightening the clamping wing nut (2).

Transportation

• Never transport the multi-tool with the engine running. An

engine that’s running could be accidently accelerated causing

the attachment to operate.

• When carrying by hand, the engine should be pointing forward.

Starting and Stopping the Engine

Starting the Engine

CAUTION

Do not pull the starter cord all the way out and do not let go of the

starter handle when the cord is extended, this can damage the

starter mechanism.

Before starting the engine, inspect the entire unit for loose fittings or

fuel leaks, and verify that the cutting attachment is properly installed

and securely fastened.

Place the unit on a flat, firm place. Keep

the cutting head clear of any obstructions.

1. Check that there is fuel in the tank

and that the fuel cap is screwed on

tightly.

(1) Cap

(2) Fuel tank

2. When starting a cold

engine move the choke

lever (behind the air cleaner

cover) to the closed

position.

(1) Choke lever

(2) Closed

(3) Open

3. If the engine has been running and is still warm, move the

choke lever to the open position.

4. Press the priming bulb under the carburettor repeatedly until

excess fuel can be seen returning to the tank through the clear

fuel return pipe.

5. Slide the ignition switch (2) on the trigger grip away from the

STOP position (See Diagram .C on the next column).

6. To set the throttle in the start position.

- Depress the safety lever (4)

- Squeeze the throttle lever (1) fully.Hold down the starting

button (3) while releasing the throttle lever.

- The throttle lever will be held partly open until it is squeezed

again.

(1) Throttle lever

(2) Ignition Switch

(3) Starting button.

(4) Safety Lever

BC 230B S2, BC 260 S2 and

BC 260B S2

BC 325 S2

Diagram .C

7. While holding the unit firmly, pull out the

starter rope quickly.

8. After the engine has started, open the

choke gradually.

9. Allow the engine to run for 2 to 3 minutes

to warm up before starting work.

NOTE

Overchoking

• Should the engine become flooded due to over-choking set the

ignition switch to the STOP (O) position Fig 35, unscrew the

spark plug, wipe it dry or replace, pull the recoil starter several

times without the spark plug in place and with the choke in the

open position. This will help clean and ventilate the combustion

chamber.

STOPPING THE ENGINE

• Set the engine to idling by releasing the throttle lever.

• Set the ignition switch to the STOP (O) position.

• If the engine fails to stop, set the choke lever to the closed

position to stall the engine; do not use the machine until the

ignition switch is repaired.

RUNNING IN

• During the first ten hours of work, avoid running the engine

at maximum speed for a prolonged period until all the

components have bedded in. After the engine has been run-in,

it will reach its maximum power.

Wearing the Harness

The harness has a quick-release mechanism that allows

you to immediately release the machine from the harness

in an emergency.

Attaching the side hook

NOTE

If side hook (D) has disengaged from hook (B), engage it.

1. Insert hook (B) into side hook (D).

2. While holding hook (B) and side hook (D) in place,

insert stopper (C) into the hole on hook (B).

Adjusting the harness

1. As shown in the diagram, adjust the harness (A) so that

hip pad (E) is against your right hip. (Fig.7-2)

2. Before starting to work, attach the side hook (D) to the

suspension point (F) on the shaft tube. (Fig.7-3)

Recommended working position

CAUTION

If releasing both hands from the handle, use extreme care. Suddenly

Diagram .B

12

WARNING

The cutting head will start rotating upon the engine

starting.

Place the unit on a at, rm place. Keep the cutting

head clear of any obstructions.

1. Check that there is fuel in the tank and that the

fuel cap is screwed on tightly. (See Image - Point 5 ).

(A) Cap

(B) Fuel tank

2. Fill fuel into the fuel tank and tighten the cap

securely.

3. Feed the chain oil into the oil tank and tighten the

cap securely. (PS-EX only)

4. Rest the unit on a at, rm area. Keep the cutting

head off the ground and clear of surrounding ob-

jects, as it will start rotating upon engine starting.

5. When Cold Starting, move the choke lever to the

closed position.

(1) Choke lever

(2) Close

(3) Open

6. If the engine has been running and is still warm,

move the choke lever to the open position.

7. Press the priming bulb under the

carburettor repeatedly until excess fuel can be seen

returning to the tank through the clear fuel return

pipe.

1110

CULTIVATOR EDGER PRUNING SAW HEDGE TRIMMER BRUSHCUTTER

the cords should stick out 15 cm each side,

8. Pull the cords to free them from the notches, refit the spool

cover.

Never use cutting device other than those supplied by the

manufacturer.

(Steel cord is never allowed).

Always use original spare parts in order to benefit from

continuous warranty.

Attaching The Tools To The Drive Shaft Assembly

• Rest the power unit/shaft assembly on a flat firm surface.

• Ensure that the clamping wing nut (2) is loose, pull out locator

pin (1).

• Carefully fit attachment drive shaft assembly (5) into coupler (3).

• After the attachment drive shaft is in the coupler, release the

locator pin (1).

• Turn the attachment drive shaft until the locator pin engages

with the locating hole (4) in the drive shaft, when this has

happened it will not be possible to twist the drive shaft.

• Secure the drive shaft by tightening the clamping wing nut (2).

Transportation

• Never transport the multi-tool with the engine running. An

engine that’s running could be accidently accelerated causing

the attachment to operate.

• When carrying by hand, the engine should be pointing forward.

Starting and Stopping the Engine

Starting the Engine

CAUTION

Do not pull the starter cord all the way out and do not let go of the

starter handle when the cord is extended, this can damage the

starter mechanism.

Before starting the engine, inspect the entire unit for loose fittings or

fuel leaks, and verify that the cutting attachment is properly installed

and securely fastened.

Place the unit on a flat, firm place. Keep

the cutting head clear of any obstructions.

1. Check that there is fuel in the tank

and that the fuel cap is screwed on

tightly.

(1) Cap

(2) Fuel tank

2. When starting a cold

engine move the choke

lever (behind the air cleaner

cover) to the closed

position.

(1) Choke lever

(2) Closed

(3) Open

3. If the engine has been running and is still warm, move the

choke lever to the open position.

4. Press the priming bulb under the carburettor repeatedly until

excess fuel can be seen returning to the tank through the clear

fuel return pipe.

5. Slide the ignition switch (2) on the trigger grip away from the

STOP position (See Diagram .C on the next column).

6. To set the throttle in the start position.

- Depress the safety lever (4)

- Squeeze the throttle lever (1) fully.Hold down the starting

button (3) while releasing the throttle lever.

- The throttle lever will be held partly open until it is squeezed

again.

(1) Throttle lever

(2) Ignition Switch

(3) Starting button.

(4) Safety Lever

BC 230B S2, BC 260 S2 and

BC 260B S2

BC 325 S2

Diagram .C

7. While holding the unit firmly, pull out the

starter rope quickly.

8. After the engine has started, open the

choke gradually.

9. Allow the engine to run for 2 to 3 minutes

to warm up before starting work.

NOTE

Overchoking

• Should the engine become flooded due to over-choking set the

ignition switch to the STOP (O) position Fig 35, unscrew the

spark plug, wipe it dry or replace, pull the recoil starter several

times without the spark plug in place and with the choke in the

open position. This will help clean and ventilate the combustion

chamber.

STOPPING THE ENGINE

• Set the engine to idling by releasing the throttle lever.

• Set the ignition switch to the STOP (O) position.

• If the engine fails to stop, set the choke lever to the closed

position to stall the engine; do not use the machine until the

ignition switch is repaired.

RUNNING IN

• During the first ten hours of work, avoid running the engine

at maximum speed for a prolonged period until all the

components have bedded in. After the engine has been run-in,

it will reach its maximum power.

Wearing the Harness

The harness has a quick-release mechanism that allows

you to immediately release the machine from the harness

in an emergency.

Attaching the side hook

NOTE

If side hook (D) has disengaged from hook (B), engage it.

1. Insert hook (B) into side hook (D).

2. While holding hook (B) and side hook (D) in place,

insert stopper (C) into the hole on hook (B).

Adjusting the harness

1. As shown in the diagram, adjust the harness (A) so that

hip pad (E) is against your right hip. (Fig.7-2)

2. Before starting to work, attach the side hook (D) to the

suspension point (F) on the shaft tube. (Fig.7-3)

Recommended working position

CAUTION

If releasing both hands from the handle, use extreme care. Suddenly

Diagram .B

(1)

(3) (2)

(4)

8. Slide the ignition switch (2) on the trigger grip

away from the STOP position

9. To set the throttle in the start position.

- Depress the safety lever (4) and squeeze the

throttle lever (1) fully. Hold down the starting button

(3). Releasing the throttle lever and then the starting

button.

- The throttle lever will be held partly open until it is

squeezed again.

(1) Throttle lever

(2) Ignition Switch

(3) Starting button.

(4) Safety Lever

10. While holding the unit rmly, pull out the starter

rope quickly.

11. After the engine has started, open the choke

gradually.

12. Allow the engine to run for 2 to 3 minutes to

warm up before starting work.

13

8.3 ADJUSTING IDLING SPEED

1. When the engine tends to stop frequently at

idling mode, turn the adjusting screw

clockwise.

2. When the cutting head keeps rotating after

releasing the trigger, turn the adjusting screw

counter-clockwise.

NOTE

Warm up the engine before adjusting the idling

speed.

NOTE

OVERCHOKING

• Should the engine become ooded due to

over-choking set the ignition switch to the STOP (2),

unscrew the spark plug, wipe it dry or replace, pull

the recoil starter several times without the spark

plug in place and with the choke in the open position.

This will help clean and ventilate the combustion

chamber.

8.2 STOPPING THE ENGINE

• Set the engine to idling by releasing the throttle

lever.

• Set the ignition switch to the STOP (2) position.

• If the engine fails to stop, set the choke lever to the

closed position to stall the engine; do not use the

unit until the ignition switch is repaired.

RUNNING IN

• During the rst ten hours of work, avoid running the

engine at maximum speed for a prolonged period

until all the components have bedded in. After the

engine has been run-in, it will reach its maximum

power.

IMPORTANT

Except for an emergency, avoid stopping the engine

while pulling the throttle lever.

8.3 OPERATION (BC-EX ONLY)

8.3.1 CUTTING WORK (LINE HEAD USE)

• Always wear eye protection such as safety

goggles.

• Never lean over and look at the rotating

cutting head. Rocks and or other debris could

be thrown at the eyes/face and cause serious

injury.

• Keep the debris guard in place at all times

when the unit is operated

WARNING

• Always wear eye protection such as safety

goggles.

• Never lean over and look at the rotating cutting

head. Rocks and or other debris could be

thrown at the eyes/face and cause serious

injury.

• Keep the debris guard in place at all times

when the unit is operated

14

8.3.2 TRIMMING GRASS AND WEEDS

Always remember that the TIP of the line does the

cutting. You will achieve better results by not crowd-

ing the line into the cutting area and allowing the unit

to trim at its own pace.

1. Hold the unit so the head is off the ground

and is tilted about 20 degrees towards the

sweeping direction.

2. To avoid thrown debris, move the Brush Cutter

in a sweeping movement from left to the right.

3. Use a slow, deliberate action to cut heavy

growth. The rate of cutting motion will depend

on what is being cut. Heavy growth will require

a slower action in comparison to light growth.

4. Never swing the unit in an extreme motion or

with physical force, this is extremely dangerous

as you may lose balance or control of the unit.

5. Control the cutting motion with your hips rather

than placing the full workload on the arms and

hands.

6. Take extra care to avoid wires, dead or dry

grass, long-stem weeds from wrapping around

the head shaft. Such materials can stall the

head and cause the clutch to slip, resulting

in damage to the clutch system if repeated

frequently.

8.3.3 ADJUSTING THE LINE LENGTH

• The brush cutter is equipped with a semi-auto

type nylon line head that allows the oper-

ator to advance the line without stopping the

engine. When the line becomes short, lightly

tap the head on the ground while running the

engine at full throttle to extend it. Each time the

head is bumped, the line advances about 1 inch

(25.4mm).

• For better effect, tap the head on bear ground

or hard soil. Avoid bumping in thick, tall grass

as the engine may stall by overload.

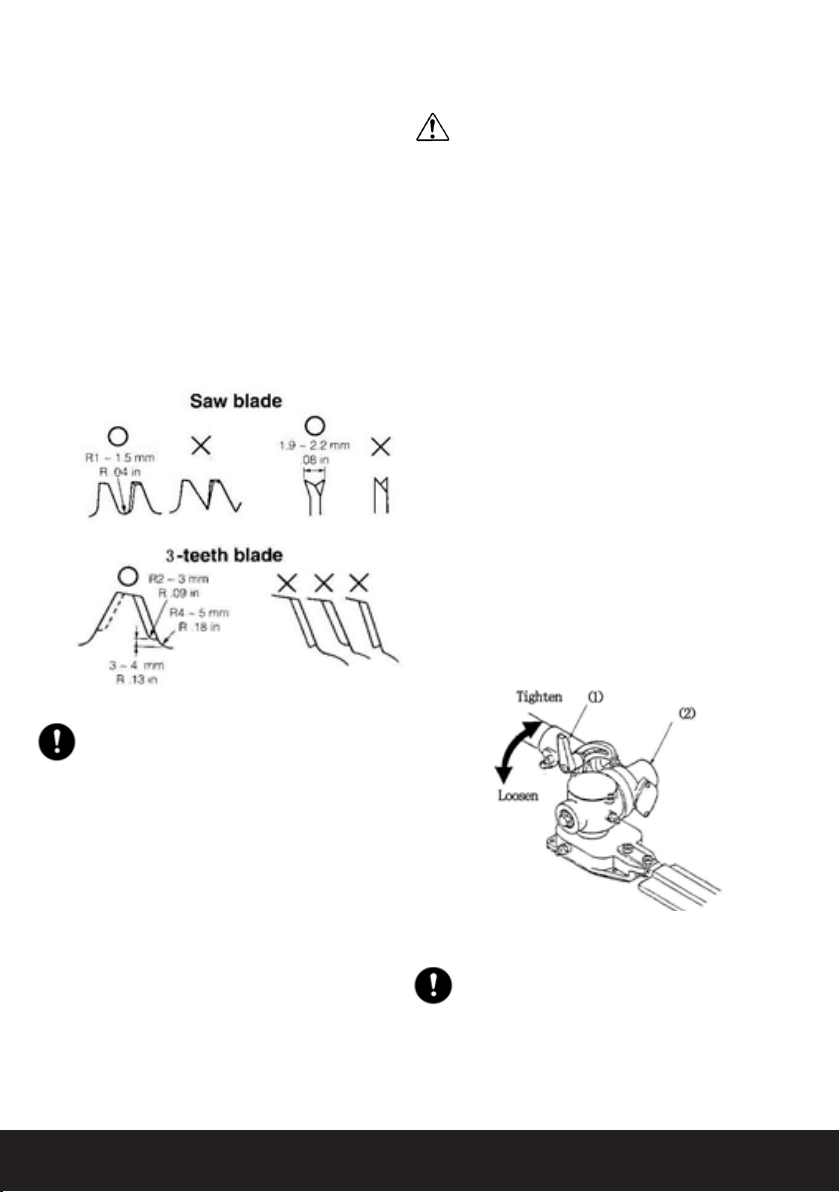

8.3.4 CHOOSE THE BLADE

• Choose a suitable recommended cutting

attachment according to the object to be cut.

• When replacing the blade always be sure to use

products, which have been certied.

WARNING

When sharpening, removing, or reattaching the

blade, be sure to wear thick, sturdy gloves and use

only proper tools and equipment to prevent injury.

8.3.5 SET UP

(1) Cover

(2) Holder

1. Detach the line head assembly completely.

2. Put on the blade, making the marked side face

the holder, put on the outer holders and fasten

the blade with the blade nut.

8.3.6 STARTING THE ENGINE

Please refer to the manual for safe operation.

WARNING

This product is equipped with a centrifugal clutch

mechanism, so the cutting attachment begins to

rotate as soon as the engine is started by putting

the throttle into the start position.

8.3.7 CUTTING METHOD

1. Use the front left side cutting.

2. Guide the blade from your right to left with it

tilted slightly to your left.

3. When mowing a wide area, start working from

your left to avoid interference of cut grass.

4. The blade could be seized by weeds if the

15

engine speed is too low, or the blade cuts too

deep into weeds. It is important to adjust the

engine speed and cutting depth accordingly to

the challenge.

WARNING

If the grass or any other object gets caught on

the blade, or if the unit starts to shake, vibrate or

the engine turns off. Thoroughly check the unit

before using it again and change the blade if it has

been damaged. Always turn off the engine before

attempting to check the blade and removing any

objects that are caught or entangled on the blade.

8.4 OPERATION

1. Check the bolt to fasten the blade and be sure

the bolt has no fault, and no abrasion.

2. Be sure that the blade and the holder have been

fastened according to instruction and that the

blade turns smoothly without abnormal noise.

3. To use the shoulder strap, hang the unit on your

right side. Adjust the strap length so the cutting

head becomes parallel to the ground

WARNING

8.4.1 CONTROLLING BLADE BOUNCE

Kick out can cause serious personal injury. Read this

section carefully to manage and understand what

causes kick outs, and how you can reduce it from

happening to remain in control of the unit if it does

occur.

8.4.2 WHAT CAUSES KICK OUT:

Kick out occurs when the moving blade makes con-

tact with an object that cannot be cut. The contact

causes the blade to stop for an instant and suddenly

move or “bounce” away from the object that was hit.

8.4.3 HOW YOU CAN REDUCE THE

CHANCE OF KICK OUT:

1. Recognize that kick out can happen by

understanding and knowing about bounce to

eliminate the element of surprise.

2. Cut brous weeds and grass only. Do not let the

blade make contact with materials it cannot cut

such as hard, woody vines and bushes or rocks,

fences, metal, etc.

3. Be prepared for bounce if you must cut where

you cannot see the blade making contact such

as in areas of dense growth.

4. Keep the blade sharp. A blunt blade increases

the chance of bounce.

5. Avoid feeding the blade too rapidly. The blade

can bounce away from material being cut if the

blade is fed faster than its cutting capability.

6. Cut only from your right to your left.

7. Keep your path in advance clear of material

that has been cut and other debris.

8.4.4 HOW YOU CAN MAINTAIN THE

BEST CONTROL:

1. Keep a good rm grip on the unit with both

hands. A rm grip can neutralize bounce and

keep your right and left hands completely

around their respective handles.

2. Keep both feet spread apart in a comfortable

stance and yet braced for the possibility that

the unit could bounce. Do not overreach. Keep

rm footing and balance.

16

8.4.5 MAINTENANCE

BLADE

• Check the blade and the fasteners for loose-

ness cracking, or bending.

• Check the cutting edges and reform with s at

le.

Point:

1. Keep the end corner sharp.

2. Round the root of the edge, using a round le.

3. Do not use water when using a grinder.

IMPORTANT

It is recommended that all ling be completed by

professionals at service dealerships as this may

result in warranty being void if the unit or trimming

attachments are damaged.

8.4.6 TRANSPORTING THE UNIT

• Turn off the engine every time when

transporting the Brush Cutter from one location

to the next paying close attention to the blade.

• Once you are nished with the unit, always

remember to place the protective cover over

the blades.

• If you are transporting the unit over long

distances, detach the blade and fasten the unit

by ropes.

8.5 OPERATION (LRT-EX ONLY)

WARNING

This product is equipped with extremely sharp

blades! If incorrectly used or handled, these blades

can be very dangerous and can cause accidents that

lead to serious injury or death.

For this reason, it is recommended that you take

an extremely cautious approach, follow all safety

procedures and instructions when using the Brush

Cutter with the Hedge Trimmer attachment.

1. Do not point the hedge trimmer blades towards

anyone.

2. Do not allow the blades to come into close

proximity with you or anyone else when

running.

3. Turn off the engine before changing the angle

of the blades or having to touch the blade.

4. Always wear work gloves made of leather or

other sturdy material when running the unit.

5. Always use the blade cover on the blade that is

provided when not in use.

6. Wear safety equipment to protect yourself from

falling trees, branches, sharp steams or ying

objects. It is advised that a face protector,

helmet, gloves and covered shoes are worn at

all times.

8.5.1 WHEN USING THE HEDGE TRIMMER

IMPORTANT

When using the hedge trimmer attachment, the

maximum cutting thickness of branches maybe

limited to approximately 3/16″ (5mm). Do not try to

cut branches thicker than this, as this may result in

damage to the trimmer.

17

ADJUSTING THE ANGLE OF THE CUTTING

BLADES

(1) Clamp lever

(2) Trimming mechanism

1. Stop the engine.

2. Turn the bolt located on the top of the trimming

mechanism counterclockwise to loosen it.

3. Adjust the angle of the blades to the desired

angle, and x the bolt rmly back into place.

8.6 OPERATION (PS-EX ONLY)

8.6.1 CHECKING OIL SUPPLY

When using the Pole Saw attachment, after starting

the engine, run the chain at medium speed and see if

chain oil splatters off in a forward direction as shown

in the gure.

The oil reservoir has the capacity to provide 40

minutes of cutting time (based on minimum ow

rate, or from a tank of fuel). Be sure to regularly rell

oil when refueling the saw and use Genuine Chain

Bar Oil.

8.6.2 ADJUSTING OIL FLOW RATE

WARNING

Do not ll the oil reservoir or adjust the

oiler when the engine is in operation or

running.

IMPORTANT

An increase in bar oil ow rate will speed up oil

consumption thus resulting in more frequent checks

on the oil reservoir. To ensure sucient lubrication, it

may be necessary to check oil levels more regularly

in comparison to fuel tank rells.

The guide bar and chain are lubricated automatically

by a pump that operates when the chain rotates. The

pump is set at the factory to deliver a minimum ow

rate, but this can be adjusted. A temporary increase

in oil ow is often desirable when cutting dense

material such as hardwood or wood with a lot of

pitch.

8.6.3 ADJUST THE PUMP AS FOLLOWS:

1. Stop the engine and make sure the stop switch

is in the OFF position.

2. Place the unit on its side with the oil reservoir

up.

IMPORTANT

The oil ow adjusting screw must be pressed in

slightly in order to turn. Failure to do so could

damage the pump and screw.

3. With a screwdriver, push-in on the oil ow rate

adjusting screw and turn-in on the desired

direction (there are three incremental settings):

(a) Clockwise-decrease lubrication

(b) Counter clockwise-increase lubrication

(c) Middle

18

WARNING

Make sure the engine has stopped and has cooled

down before performing any servicing to the unit.

Contact with moving cutting head or hot muer may

result in a personal injury.

9.1 AIR FILTER

The air lter, if clogged, will reduce engine perfor-

mance. Check and clean the lter element in warm

soapy water as required and dry completely before

installing. If the element is broken or shrunk, replace

with a new one.

9.2 FUEL FILTER

When the engine runs short of fuel supply, check the

fuel cap and the fuel lter for blockage

.

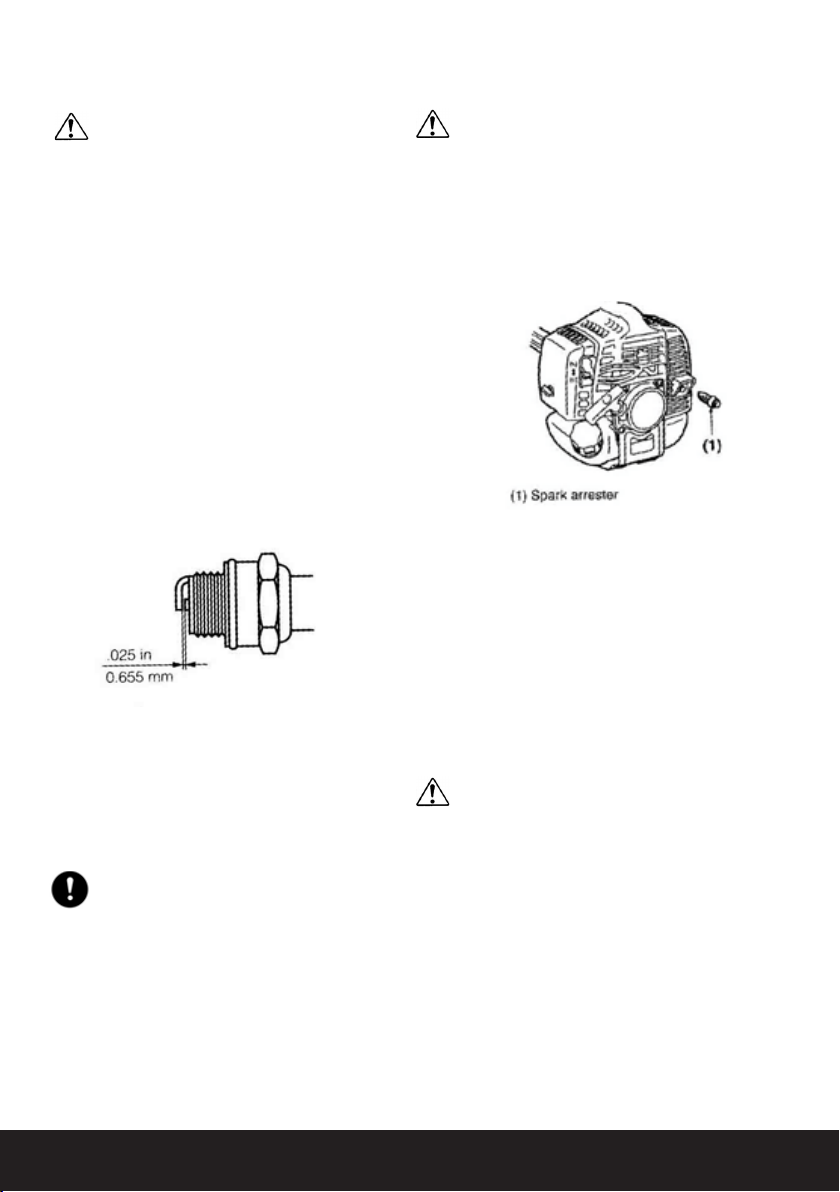

9.3 SPARK PLUG

Starting failures and misring are often caused

by fouled spark plugs. Clean the spark plug and

check that the plug gap is in the correct range. For a

replacement plug, use the correct type specied.

IMPORTANT

Using any spark plug other than those designated

may result in the engine failing to operate properly or

becoming overheated and damaged.

To install the spark plug, rst turn the plug until it is

nger tight, then tighten it a quarter turn more with a

socket wrench.

TIGHTENING TORQUE: (9.8-11.8N.m.).

9. MAINTENANCE 9.4 MUFFLER

WARNING

Periodically inspect the muer for loose fasteners,

damage or corrosion.

If any sign of exhaust leakage is found, stop using

the unit and have it repaired immediately with a

Service Dealer. Failing to do so may result in the

engine catching on re.

9.5 SPARK ARRESTER

The muer is equipped with a spark arrester to

prevent red hot carbon from ying out of the exhaust

outlet.

Periodically inspect and clean as necessary with a

wire brush.

9.6 INTAKE AIR COOLING VENT

WARNING

• Do not touch the cylinder, muer, or spark

plugs with your bare hands immediately after

using the unit when the engine is hot. The

engine can become very hot during operation,

and doing so could result in severe burns.

• Before a working session, thoroughly inspect

the unit before use. Check specic areas

around the muer and remove any wood chips

or leaves which have become attached. Failing

to do so could result in the muer overheating

and in turn could cause the engine to catch

on re.

• After every 25 hours of use, check the intake air

cooling vent and the area around the cylinder

This manual suits for next models

1

Table of contents

Other LawnMaster Brush Cutter manuals