LawnMaster NPTBSP2609A User manual

SERVICE MANUAL

26cc 2-Cycle Brush Cutter

NPTBSP2609A

Read all safety rules and instructions carefully before servicing this tool.

601 Regent Park Court Greenville, SC 29607, 1-866-384-8432

2

Section Page

CONTENTS

CONTENTS 2

SPECIFICATIONS 3-4

GENERAL SAFETY RULES 5

PARTS AND FEATURES 6-11

WIRING DIAGRAM AND MANAGEMENT 12

GENERAL TROUBLESHOOTING 13-21

AIR & FUEL SYSTEM 22-29

THROTTLE AND STARTER SYSTEM 30-34

NOPULL™ STARTER SYSTEM 35-38

26CC 2-CYCLE ENGINE 39

GEAR HEAD AND BRUSH CUTTER BLADE 40

MANUFACTURER'S WARRANTY AND CONTACT 41

3

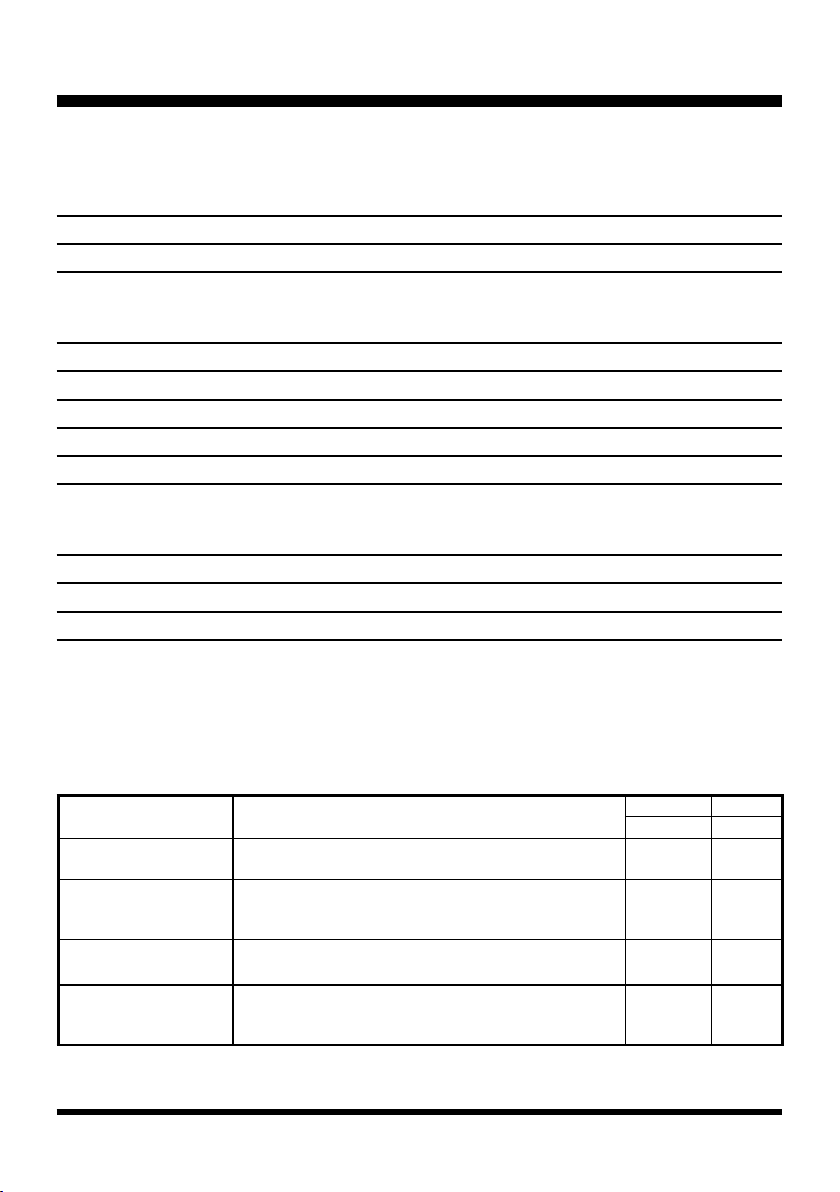

SPECIFICATIONS

TORQUE SPECIFICATIONS

Engine Size 2-Stroke / Full Crank

Engine Displacement Claimed / Rated 26cc / 25.4cm3

Ignition Capacitor Discharge Ignition (CDI)

Carburetor All Position Diaphragm Type With Primer Bulb

Air Filter Foam (Dry)

Engine Shut Off Auto-Reset

Throttle Control Variable Speed Trigger

Fuel / Oil Ratio 40 : 1

Fuel Tank Capacity 400 ml

Spark Plug Champion RCJ6Y

Rotor Air Gap 0.012”-0.015” (0.30-0.40 mm)

Spark Plug Gap 0.026” (0.65 mm)

Run Time on Full Tank 30 Minutes

UNIT SPECIFICATIONS

Engine

Fuel System

General

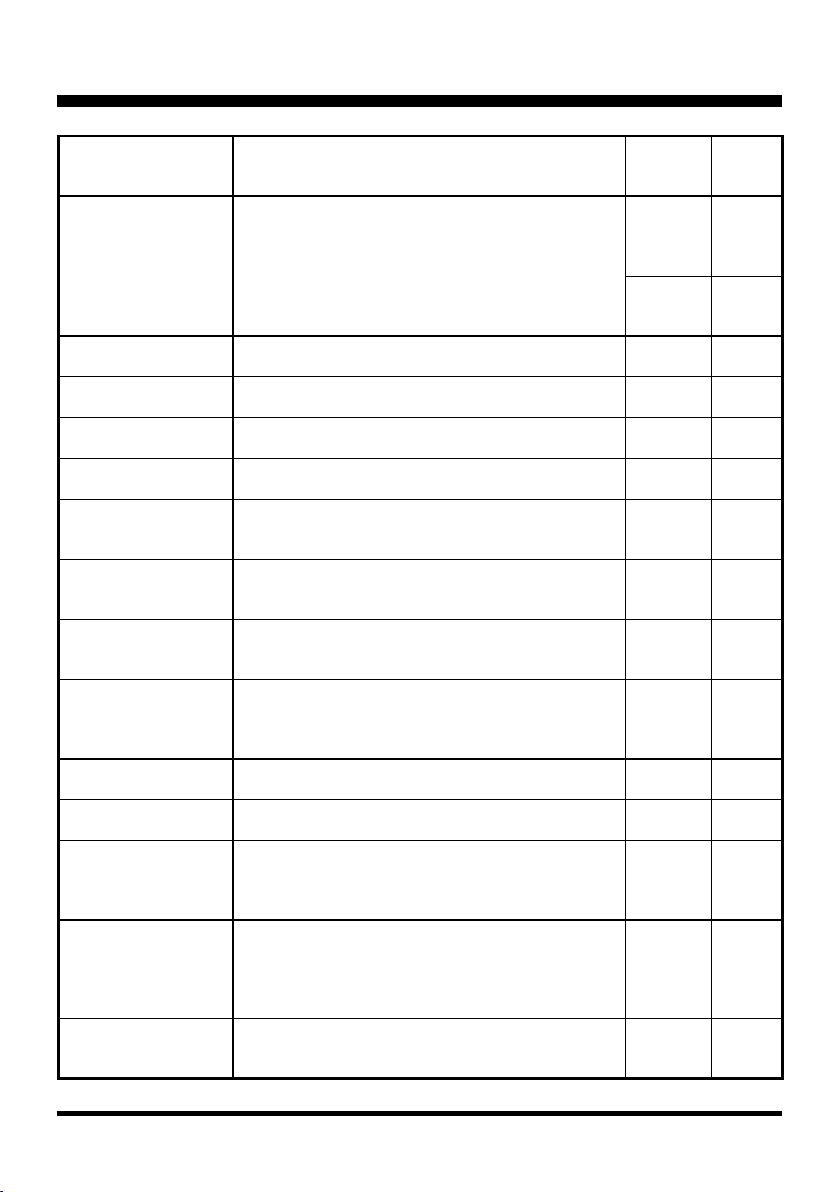

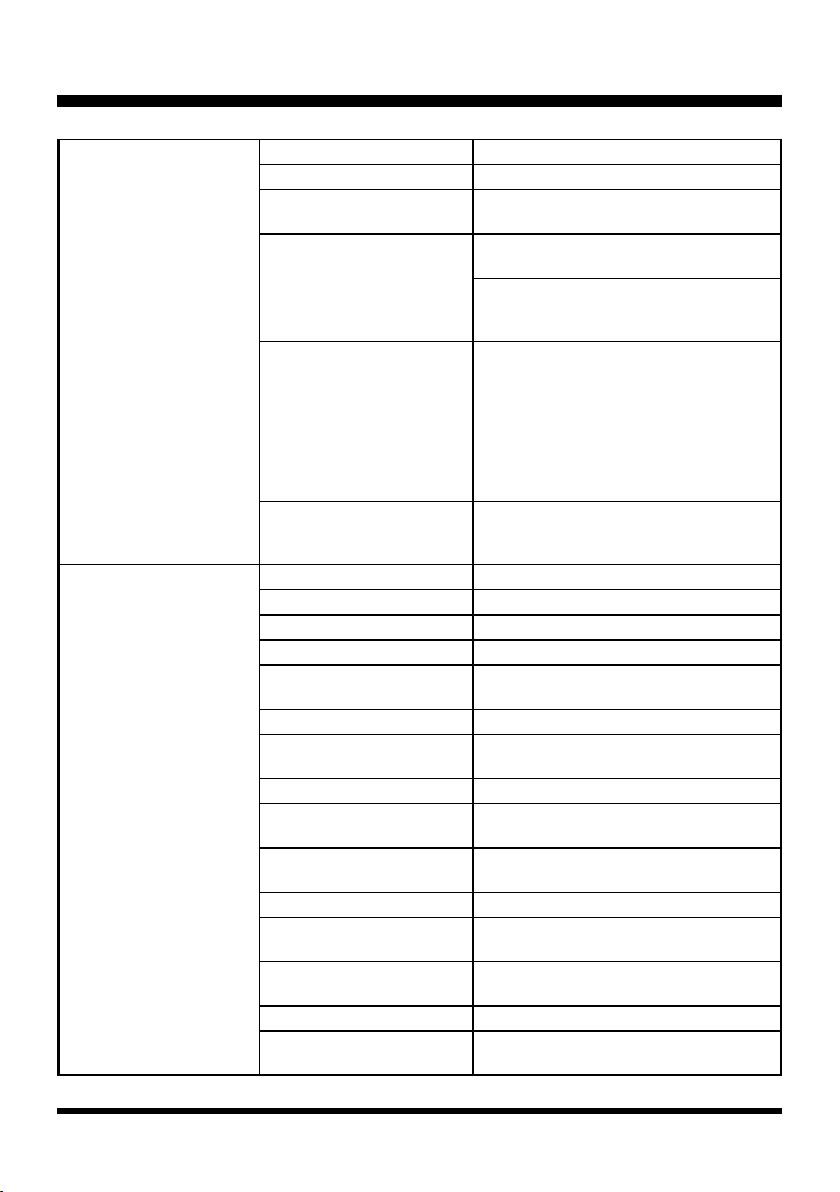

Application Description Torque Torque

(IN.LBS) (N.m)

Crankcase Apply a thermostable screw-thread glue onto the 4

screws (M5X30) and then x the crankcase cover. 53-62 6-7

Cylinder to crankcase

Apply a thermostable screw-thread glue onto the 4

screws (M5X20) and then tighten the screws securing

the cylinder to crankcase.

53-62 6-7

Spark plug to cylinder Pre-screw the spark plug to the cylinder, and then

tighten with a torque spanner. 115-137 13-15.5

Carburetor mount to

cylinder

Apply a thermostable screw-thread glue onto the 2

screws (M5X20) and tighten the screws securing the

carburetor mount to the cylinder.

35-44 4-5

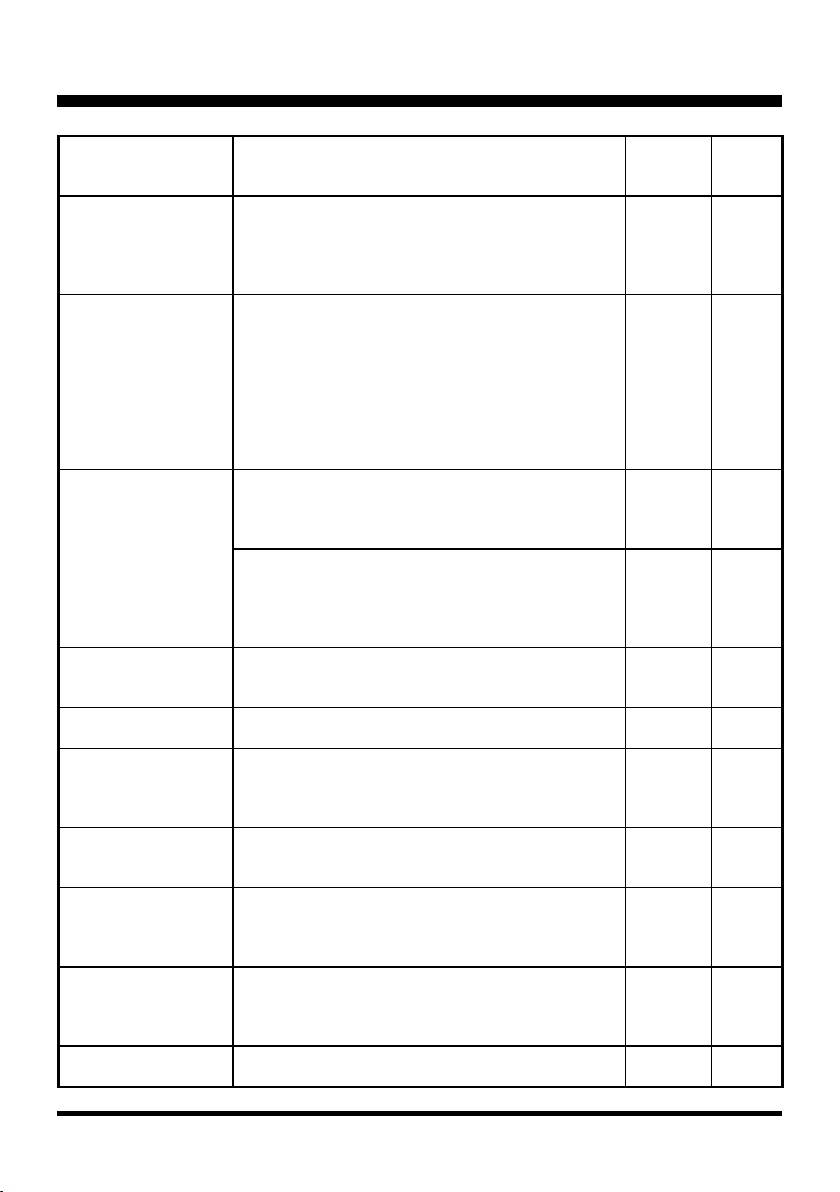

4

SPECIFICATIONS

Flywheel to crankshaft

Apply a thermostable screw-thread glue onto the

crankshaft thread. Pre-screw the ange hexagon nut

(M8) and then tighten.

89-133 10-15

Clutch to ywheel

Slide the corrugated washers onto the clutch bolts

(M6X21.5). Apply a thermostable screw-thread glue

onto the bolt thread head section. Install the bolts into

the clutch and tighten the bolts securing the clutch to

ywheel.

71-89 8-10

Ignition coil to cylinder

Put the 2 screws (M5X20) through the ignition coil

and two spacers respectively. Apply a thermostable

screw-thread glue into the cylinder holes and then pre-

screw the 2 screws (M5X20). Insert a feeler gauge

of 0.014 in. (0.35mm) between the ywheel and the

ignition coil. Press down the ignition coil ush against

the feeler gauge. Tighten the screws with a torque

spanner securing the ignition coil. Remove the feeler

gauge.

27-35 3-4

Mufer to crankcase

Put the 2 bolts (M5X50) through the mufer assembly.

Apply a thermostable screw-thread glue onto the 2

bolts and secure the mufer to the crankcase using

the torque wrench.

62-71 7-8

Apply a thermostable screw-thread glue onto the

head section of 1 screw (M5X10). Pass the screw

through the positioning hole on the mufer assembly

holder and tighten the screw securing the mufer to

crankcase.

62-71 7-8

Pawl assembly to

crankshaft

Apply a thermostable screw-thread glue onto the

crankshaft thread. Pre-screw the pawl assembly to

crankshaft, and then tighten using the torque wrench.

62-80 7-9

Air lter base to

carburetor

Pre-screw the nuts (M5) with washers, and then

tighten using the pneumatic tool. 27-35 3-4

Fuel tank bracket to

crankcase

Apply a thermostable screw-thread glue onto the

screw (M5X10) and pass it through the hole on fuel

tank bracket. Tighten the screw securing the fuel tank

bracket to crankcase.

27-35 3-4

Fuel tank to crankcase

Apply a thermostable screw-thread glue onto the

screw (M5X12). Pass it through the fuel tank hole.

Tighten the screw securing the fuel tank to crankcase.

27-35 3-4

Cylinder pressure plate

Apply a thermostable screw-thread glue onto the

screw (M5X10). Pass the screw through the cylinder

pressure plate hole and then tighten it onto the

cylinder.

27-35 3-4

Electric starter

assembly to crankcase

Align the 2 screw holes on the electric starter

assembly with the screw holes on crankcase. Tighten

the 2 screws (M5X60) securing the electric starter

assembly to crankcase.

27-35 3-4

Rear engine cover

assembly

Tighten the 2 screws (ST3.9X30F) to secure the rear

engine cover. 12-13 1.3-1.5

5

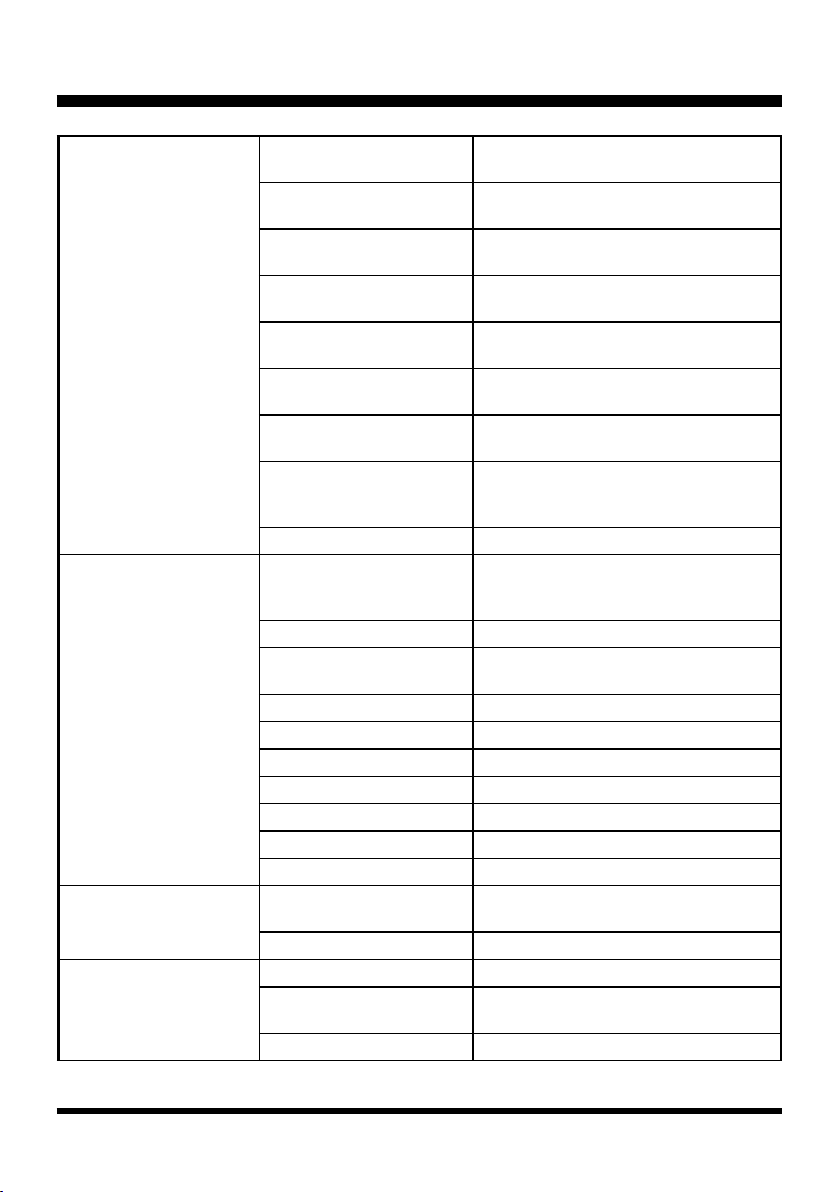

SPECIFICATIONS

Flywheel cover to

crankcase

Apply a thermostable screw-thread glue into the two

holes on crankcase. Tighten the 2 screws (M5X15)

securing the ywheel cover to crankcase.

53-64 6-7.2

Lower engine cover

assembly

Place the lower engine cover onto crankcase. Tighten

the 3 screws (1*ST3.9X8, 2*M5X10) securing the

lower engine cover.

10-12

1.1-1.3 (for

1*ST3.9X8)

27-35

3-4 (for

2*M5X10)

Upper engine cover

assembly

Tighten the 3 screws (M5X35) securing the upper

engine cover. 27-35 3-4

Spark plug cover to

upper engine cover

Tighten the screw (M5X10) securing the spark plug

cover to upper engine cover. 27-35 3-4

Lower engine cover to

upper engine cover

Tighten the screw (ST3.9X12) to secure the upper and

lower engine covers (on mufer side). 10-12 1.1-1.3

Right handle cover to

left handle cover

Tighten the screws (ST3.9X16) to secure the right and

left parts of the main handle. 10-12 1.1-1.3

Transmission yoke to

ywheel cover

Apply a thermostable screw-thread glue into the four

screw holes on ywheel cover. Tighten the screws

(M5X20) securing the transmission yoke.

53-62 6-7

Shaft connection sleeve

to upper shaft

Align the shaft connection sleeve with the screw holes

on upper shaft. Tighten the screws (M5X25 & M5X12)

securing the shaft connection sleeve to upper shaft.

53-62 6-7

Gear box to lower shaft

Align the screw holes on the gear box with the lower

shaft. Tighten the screws (M5X12, M6X25, M6X10)

securing the gear box to lower shaft.

53-62 6-7

Transmission yoke

assembly

Align the screw holes on the transmission yoke with

the screw holes on upper shaft. Tighten the screws

(M5X12 & M6X25) securing the transmission yoke to

upper shaft.

53-62 6-7

Shoulder strap clasp

assembly

Adjust the position of the shoulder strap clasp and

tighten the screw (M5X16). 27-35 3-4

Trimming line cutting

blade assembly

Tighten the screws (ST3.9X16) with washers to secure

the trimming line cutting blade to the debris guard. 10-12 1.1-1.3

Ratchet to electric

starter assembly

Attach the ratchet to the electric starter lower cover.

Apply a thermostable screw-thread glue onto the head

section of the screw (M5X10) and tighten the screw

(M5X10) securing the ratchet.

27-35 3-4

Electric starter motor

assembly

Align the electric starter motor with the screw holes on

the electric starter upper cover. Apply a thermostable

screw-thread glue onto the head section of the screws

(M3X8) and tighten the screw securing the electric

motor.

4-6 0.5-0.7

Electric starter lower

and upper covers

assembly

Tighten the two screws (ST2.9X12F) securing the

lower and upper covers of the electric starter. 4-5 0.4-0.6

6

GENERAL SAFETY RULES

SAFETY

To protect the eyes from loose objects that could be thrown from the brush cutter, always wear eye

protection with side shields marked to comply with ANSI Z87.1 when operating the brush cutter.

Use only genuine manufacturer’s replacement parts for this product. Failure to do so may cause poor

t, poor function and possible injury.

Scarfs, neckties, jewelry, jackets or other loose clothing and accessories should be avoided as they

can be caught on or become entangled in the brush cutter. Secure hair so it is above shoulder level. To

protect your legs and feet, long pants and closed toed shoes should be worn.

To improve your grip and protect your hands, wear heavy-duty nonslip gloves.

The sound level exceeds 85 dB(A). To prevent hearing damage, always wear sound barriers (ear plugs

or ear mufers).

GENERAL BRUSH CUTTER SAFETY

Never operate the brush cutter with a damaged guard or without the guard in place.

Avoid getting into direct contact with the brush cutter blade.

Always remember to keep both hands on the control handles when the engine is running.

Do not operate the brush cutter if there is a fuel leak as it is a re hazard. The fuel leak must be xed

prior to operating the brush cutter.

Empty the fuel tank before storing if the brush cutter will not be used for a few days.

Make sure the control handles have not accumulated oil and fuel and are clean and dry.

Beware of blade kickback:

- Blade kickback may occur when the spinning blade contacts an object that it does not immediately

cut.

- Blade kickback can be violent enough to cause the unit and/or operator to be propelled in any

direction, and possibly lose control of the unit.

- Blade kickback can occur without warning if the blade snags, stalls or binds.

- Blade kickback is more likely to occur in areas where it is difcult to see the brush or vegetation being

cut.

A coasting blade can cause injury while it continues to spin after the engine is stopped or throttle

trigger is released. Maintain proper control until the blade has completely stopped rotating.

See Operator’s Manual for additional safety precautions.

WORK AREA

Operate only in well ventilated areas.

Observe all safety regulations for the safe handling of fuel. Mix and handle fuel in a container approved

for storing gasoline. Wipe the brush cutter dry if fuel is spilled on it. Always move away from the fueling

area before starting the engine.

Fuel the brush cutter at least 10 ft. (3 m) from the place where you start the engine and operate the

brush cutter.

NOTE: The brush cutter blade will rotate during carburetor adjustment. Wear protective equipment and

observe all safety instructions.

7

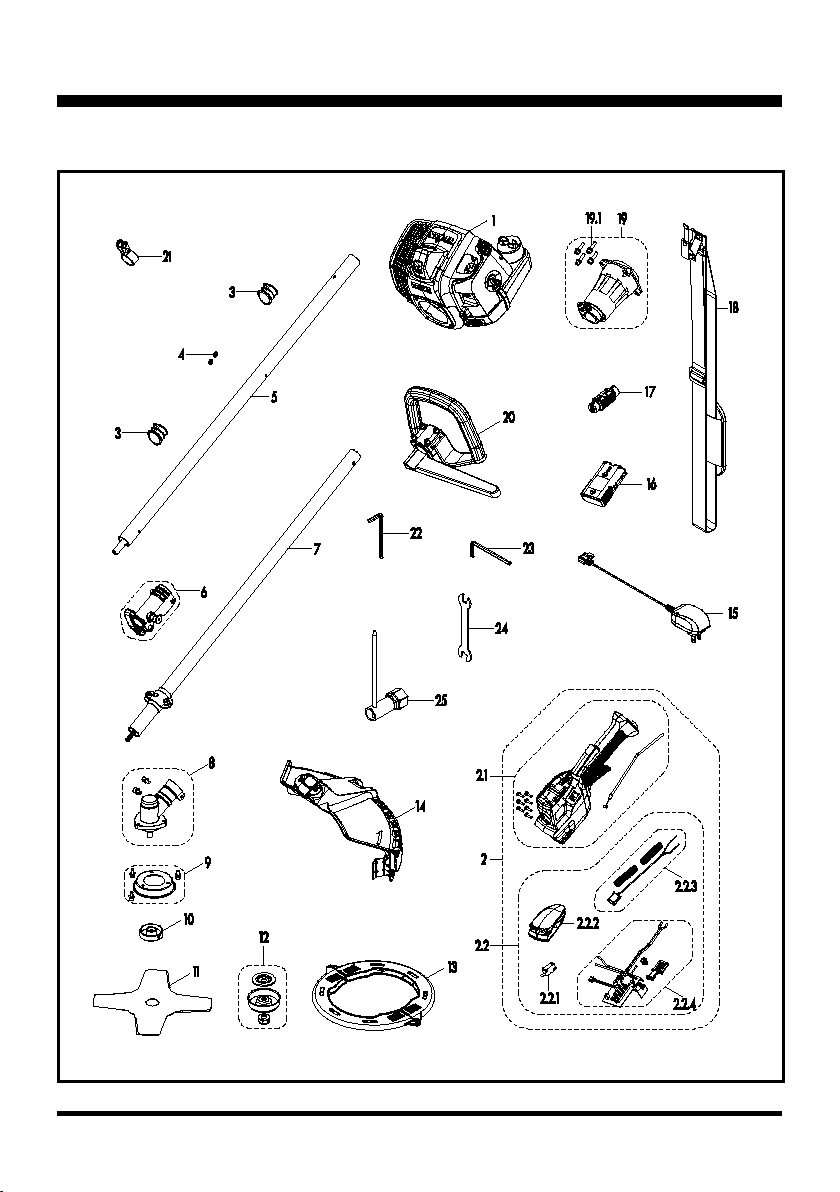

PARTS AND FEATURES

NPTBSP2609A EXPLODED VIEW

8

PARTS AND FEATURES

NPTBSP2609A PARTS LIST

Key

Number Application Description Quantity

1 641002101 Cleva 26cc 2-Cycle Engine 1

2 321001102 Throttle-body & Start Set 1

2.1 321001103 Throttle-body Set 1

2.2 321001104 Starter Set 1

2.2.1 321001105 Micro Switch 1

2.2.2 321001106 Starter Switch Assembly 1

2.2.3 321001107 Stop Switch Set 1

2.2.4 321001108 PCB Assembly 1

3 321001109 Handle Spacer 2

5 641001104 Aluminum Upper Shaft 1

4 141004102 Cable Clamp 2

6 641001105 Shaft Connection Sleeve 1

7 641001106 Aluminum Lower Shaft 1

8 641001107 Gear Box 1

9 641001108 Blade Guard Assembly 1

10 221003105 Cover Plate 1

11 RBB2609A 9" Blade 1

12 641001111 Blade Clamp Assembly 1

13 641001112 Saw Blade Sheath 2

14 641001113 Debris Guard 1

15 321001127 Charger 1

16 321001114 7.2V Lithium-Ion Battery 1

17 321001113 Wire Lock 1

18 221003102 Shoulder Strap 1

19 641001115 Clutch Assembly 1

19.1 321005103 Screw 4

20 641001116 P-Handle 1

21 321001128 Shoulder Strap Clasp 1

22 321004122 M5 Hexagon Socket Wrench 1

23 321004121 M6 Hexagon Socket Wrench 1

24 321004123 Open End Wrench 1

25 321004124 Socket Wrench 1

9

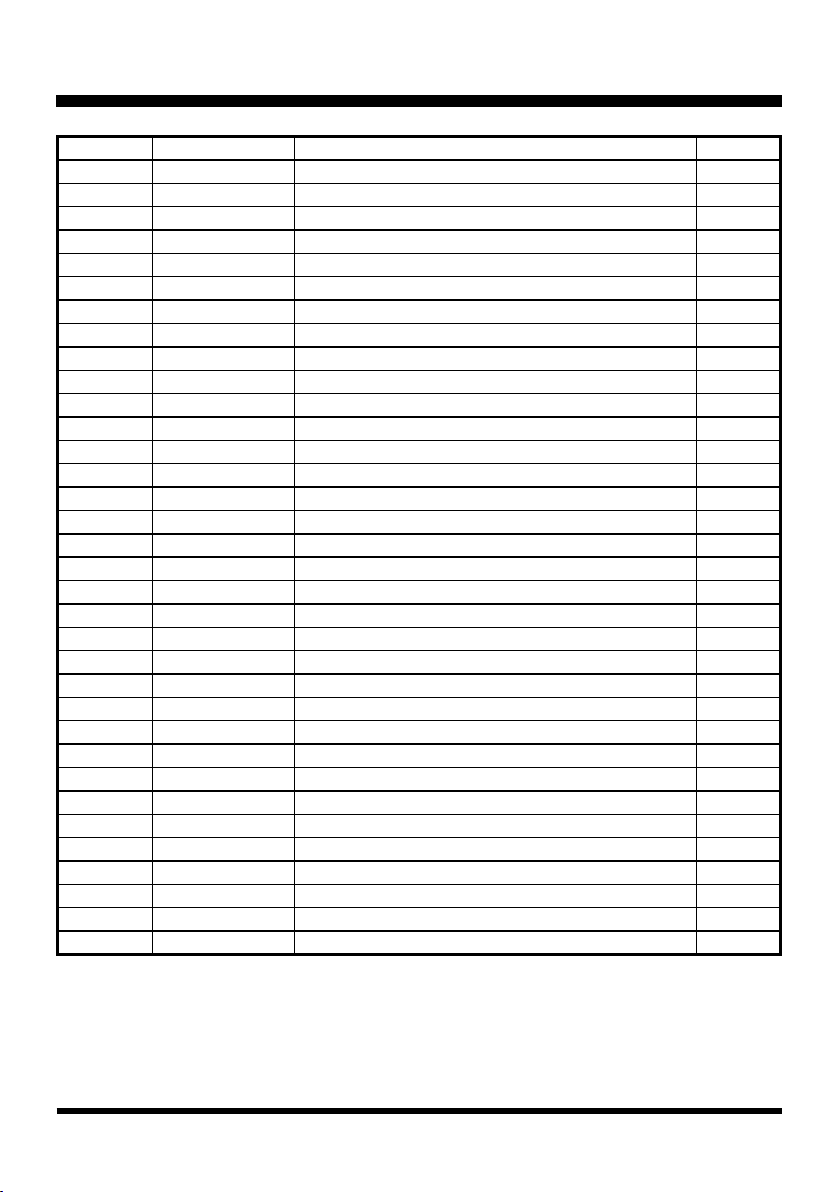

PARTS AND FEATURES

EXPLODED VIEW 26CC 2-CYCLE ENGINE

10

PARTS AND FEATURES

NPTBSP2609A PARTS LIST

Key

Number Application Description Quantity

1 321001130 Spark Plug Cover 1

2 321001131 Nut 1

3 321001132 Upper Engine Cover 1

4 321001133 Logo 1

5 321001134 Air Deector 1

6 321002109 Cylinder Air Damper 1

7 321001136 Mufer Cover 1

8 321001137 Mufer 1

9 321001138 Insulation Sheet 1

10 321001139 Spark Plug 1

11 321002110 Gasket 1

12 641002103 Ignition Coil Assembly 1

13 321002112 Positive Stop Switch Cable 1

14 321002113 Spacer Set 4

15 321002114 Cylinder 1

16 321002115 Gasket 1

17 321001143 Pawl Assembly 1

18 321002116 Electric Starter Assembly 1

19 321002117 Rear Engine Cover 1

20 321002118 Carburetor Mount Assembly 1

21 321002119 Washer 1

22 321002120 Carburetor 1

23 321001147 Air Filter Base 1

24 321001148 Air Filter 1

25 321001149 Air Filter Cover 1

26 321001150 Rotary Knob 1

27 321001151 Choke Lever 1

28 321001152 Fuel Cap Assembly 1

29 321002121 Fuel Tank Grommet 1

30 321002122 Fuel Tank 1

31 321002123 Fuel Tube 1

32 321002124 Fuel Tube 1

33 321002125 Fuel Line Filter 1

34 321001154 Rubber Pad 1

35 321001155 Fuel Tank Bracket 1

36 321002126 Negative Stop Switch Cable 1

37 321001156 Lower Engine Cover 1

11

38 321002127 Crankshaft Set 1

39 321002128 Piston Ring 2

40 321002129 Piston 1

41 321002130 Retainer Ring 2

42 321002131 Retainer Ring 2

43 321002132 Needle bearing 1

44 321002133 Piston Pin 1

45 321002134 Crankcase Assembly 1

46 641001126 Flywheel 1

47 321002143 Flange Nut M8 1

48 311014125 Flat Key 1

49 321002145 Clutch Assembly 1

50 321002146 Washer 2

51 321002147 Corrugated Washer 2

52 321002148 Bolt 2

53 321002149 Flywheel Cover 1

54 321002150 Round Ring 2

55 321002151 Screw 2

56 321002152 Screw 3

57 321002153 Self-Tapping Screw 2

58 321002154 Screw 2

59 321002155 Lower Rear Engine Cover Plate 1

60 321002156 Heat Resistant Grommet 1

61 321001160 Screw 6

62 321001161 Self-Tapping Screw 2

63 321002157 Screw 2

64 321002158 Screw 4

65 321002159 Screw 6

66 321001163 Screw 2

67 321001164 Rubber Plug 1

68 321001165 Nut 2

69 321001166 Washer 5

70 321001162 Self-Tapping Screw 1

71 321001210 Screw 1

72 321005103 Screw 2

PARTS AND FEATURES

12

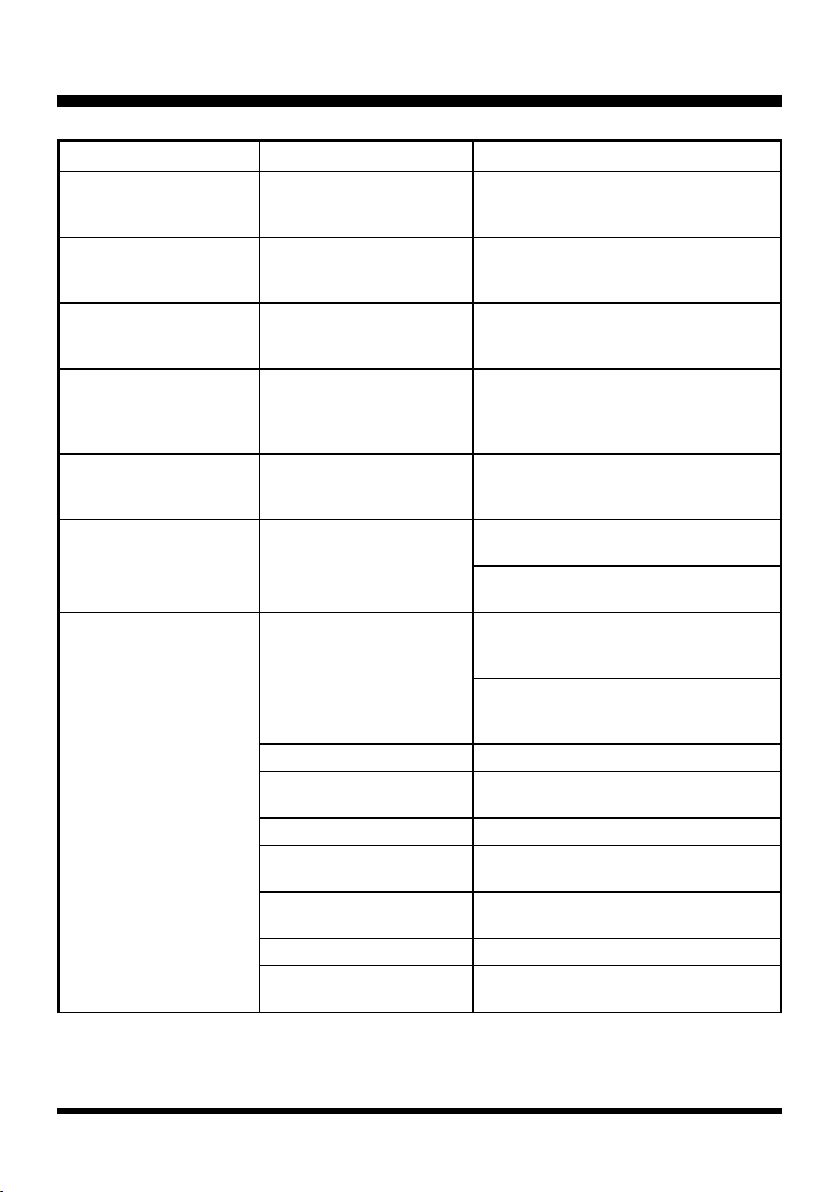

WIRING DIAGRAM AND MANAGEMENT

- IGNITION AND STARTING

2S Battery Pack Starter Switch (Self-reset)

Stop Switch (Self-reset)

3.5 Bullet Terminal

Ignition Coil

Spark Plug

Engine

Engine Body Engine Body

3.5 Bullet Terminal

NTC

NTC

RD

RD

BK

BK BK

BK BK

BK

RD

Bullet Terminal(BL)

Bullet Terminal(BL)

Electric

Motor

EngineHandle

lgnition

Handle

M

RD

J10 J9

J8

GND M+

M-

Battery

Connector

LED

Panel

Battery Connector

PCB ASSEMBLY

VCC’

Push-Start

Ignition

13

GENERAL TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

The electric motor does

not start, and the battery

indicator LED ashes red.

The battery is not fully

charged or not inserted

correctly.

Charge the battery fully and insert it

correctly.

The motor does not start,

and the battery indicator

LED ashes yellow.

The battery is overheated.

Allow the battery to cool to room

temperature. Re-start the tool after about

30 minutes.

The motor does not start,

and the battery indicator

LED ashes green.

Possible short circuit in the

electric motor or the motor

drive lines.

Check if there is a short circuit in the

electric motor or the motor drive lines

referring to page 36.

The motor does not start,

and the battery indicator

LED ashes alternatively

red and green.

The starting current is

excessive - the engine or

electric motor may be seized

or cannot rotate smoothly.

Check if the engine or the electric motor is

stuck and cannot rotate smoothly referring

to page 36.

The motor does not start,

and the battery indicator

LED is continuously on.

There is an open circuit from

the PCB output to the motor

connecting line.

Check if there is an open circuit occurs

from the PCB output to the motor

connecting line referring to page 36.

The motor starts, but the

engine does not start.

The starter drive system is

broken.

Remove the electric starter. Replace the

drive system.

If drive system of the starter is in good

condition, the engine may be broken.

The engine does not start.

No spark or weak spark.

Clean or replace the spark plug. Reset the

spark plug gap 0.026”±0.002” (0.65±0.05

mm).

Check the gap between ignition coil and

ywheel. Make sure the gap is 0.012’’-

0.015’’ (0.30-0.40mm).

The air lter is blocked. Clean the air lter.

The fuel tank valve is

blocked. Remove the blockage or replace.

Incorrect lubricant/fuel. Use correct lubricant/fuel.

The fuel tube is blocked or

broken. Clean or replace.

Incorrect carburetor

adjustment. Re-adjust the carburetor.

The carburetor is blocked. Remove the blockage.

Excessive oil in carburetor. Tighten the carburetor nut or replace the

carburetor washer.

14

GENERAL TROUBLESHOOTING

The engine stops during

operation.

No fuel. Add fuel to the fuel tank.

The fuel tube is blocked. Remove the blockage.

The carburetor nut loosens

and has air leakage.

Tighten the carburetor nut or replace the

carburetor washer.

No spark or weak spark.

Clean or replace the spark plug. Reset the

spark plug gap.

Check the gap between ignition coil and

ywheel. Make sure the gap is 0.012’’-

0.015’’ (0.30-0.40mm).

Abnormal engine

compression.

Check if the piston ring sinters and the

piston and piston ring wear status. Check

the carbon deposit status in combustor.

Check the wear status inside cylinder.

Check if the spark plug loosens. Check

the gap between ignition coil and ywheel.

Make sure the gap is 0.012’’-0.015’’ (0.30-

0.40mm).

The engine is ooded.

Remove the spark plug. Clip the fuel tube

for fuel entering. Press the start button to

remove the fuel inside the cylinder.

The engine has less power.

The choke lever is closed. Open the choke lever.

The air lter is blocked. Clean the air lter.

The fuel lter is blocked. Remove the blockage or replace.

Incorrect lubricant/fuel. Use correct lubricant/fuel.

Incorrect carburetor

adjustment. Re-adjust the carburetor.

Carburetor washer hardens. Replace.

The main nozzle of the

carburetor is blocked.

Clean or replace the carburetor if

necessary.

The spark plug is worn out. Replace with new spark plug.

The carburetor has air

leakage. Tighten the carburetor.

The fuel has been

contaminated with water. Empty tank and replace with clean fuel.

Mufer has carbon deposit. Remove the carbon deposit.

Exhaust port has carbon

deposit. Remove the carbon deposit.

Piston ring sinters. Clean the ring groove or replace the piston

ring.

Cylinder worn. Replace the cylinder.

Piston and piston ring are

worn out. Replace.

15

GENERAL TROUBLESHOOTING

No spark.

Electrode of the spark plug

is wet. Dry the spark plug.

Spark plug has carbon

deposit. Remove the carbon deposit.

Spark plug insulation is

broken. Replace the spark plug.

Spark plug gap is too big/

small. Adjust to 0.026”±0.002” (0.65±0.05 mm).

Electrode of the spark plug

is burnt out. Replace the spark plug.

High voltage line of the

ignition coil is broken. Replace the high voltage line.

Stator of the ignition coil is

broken or burnt out. Replace the stator.

Poor contact of the high

voltage line and the jump

ring.

Amend.

Spark plug cap is broken. Replace.

Engine will not start but

spark plug res.

Excess fuel inside spark

plug.

Remove the spark plug. Clip the fuel tube

for fuel entering. Press the start button to

remove the fuel inside the cylinder.

Fuel is not clean, with water. Replace the fuel.

Cylinder and piston ring

wear. Replace.

The spark plug loosens. Tighten.

Crankcase has air leakage. Replace the gasket.

Cylinder has air leakage. Replace the gasket.

No fuel. Add fuel.

No fuel in primer bulb. Prime the bulb.

Engine is not choked. Engage the choke.

Fuel tank valve is blocked. Remove the blockage.

The engine cannot be

stopped.

The switch wire does not

connect. Connect the wire.

The switch is broken. Replace.

The clutch engages during

idle speed.

Clutch is damaged. Replace.

The free length of the clutch

spring is too long. Replace.

Clutch is off center. Replace.

16

GENERAL TROUBLESHOOTING

No load speed is not

stable/consistent.

Incorrect carburetor

adjustment. Re-adjust the carburetor.

The carburetor has an air

leakage. Replace or re-tighten.

Fuel tube is broken. Replace.

Crankcase washer has air

leakage. Replace.

Fuel seal has air leakage. Replace.

After release the throttle

lever, the brush cutter

blade remains rotating.

Idle speed is too high. Adjust the engine.

Clutch spring is broken. Replace.

Clutch friction plate is

broken. Replace.

The engine accelerates,

but the brush cutter blade

does not rotate.

Spline of the axle of

rotation or the spline of the

transmission yoke is worn

out.

Replace.

Irregular vibration.

Brush cutter blade is not

installed tightly. Secure the brush cutter blade into place.

Brush cutter blade is bent. Repair or replace.

Brush cutter blade is worn

out. Replace.

The drive shaft is bent. Replace.

Worn bearings. Replace.

Clutch is off center. Replace.

17

GENERAL TROUBLESHOOTING

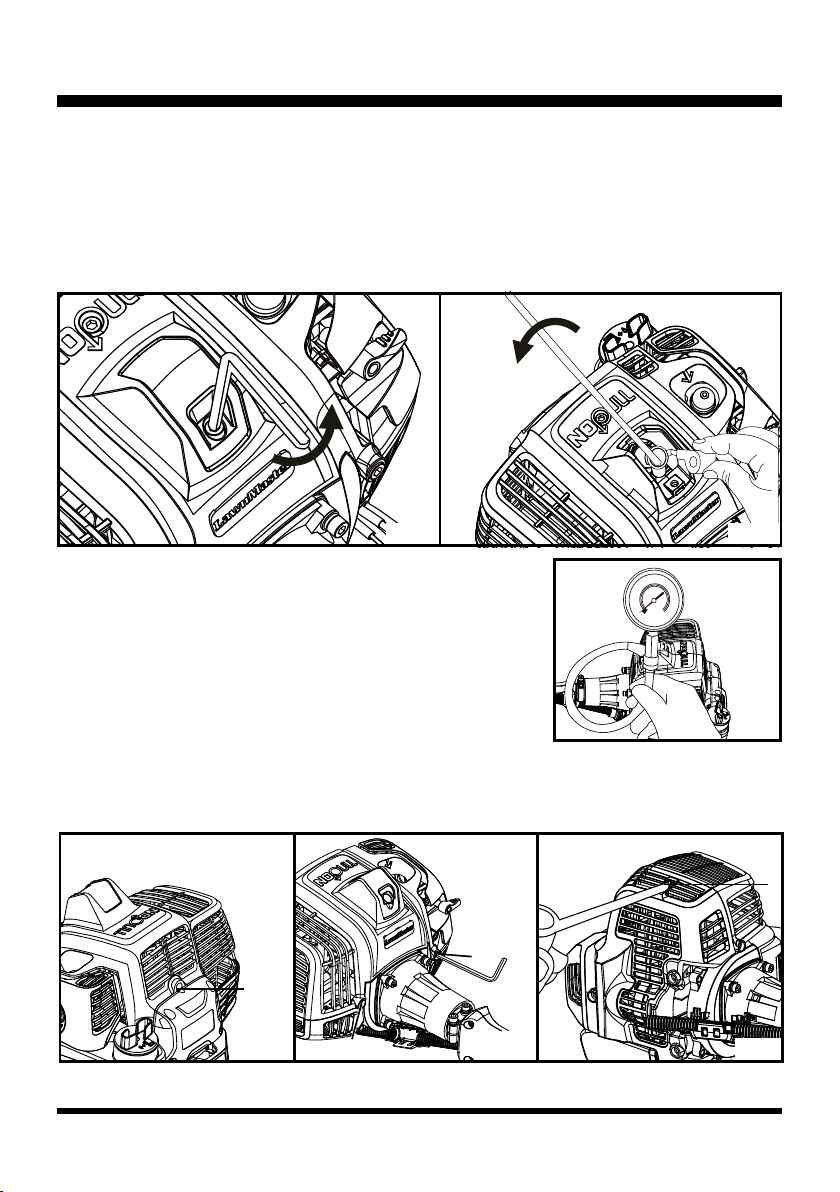

■ Rotate a compression gauge into the spark plug hole (Fig. 3).

Place the choke lever in the RUN position. Engage the throttle

safety and throttle trigger together to open the throttle and the

choke lever in the on position. Lift the start button cover and

press the start button 3-5 times until the gauge needle reaches its

peak (stops moving). Engine compression should be >0.6MPa.

Ignition System (See Figs. 4-9)

■ Remove the upper engine cover by removing the 4 screws with the provided hex wrench and

screwdriver (Fig. 4 - 6)

1

4

2

3

Fig. 5Fig. 4

Fig. 2Fig. 1

Engine Compression (See Figs. 1-3)

Low compression will cause erratic idling, low power, and hard starting when hot. To test the engine

compression:

■ Remove the spark plug cover using the provided hex wrench (Fig. 1).

■ Remove the spark plug cap. Fully cover the spark plug using the provided socket wrench. Rotate

the wrench counter-clockwise to remove the spark plug (Fig. 2).

Fig. 6

0

30

60

90

120 150 180

210

240

270

300

Fig. 3

18

GENERAL TROUBLESHOOTING

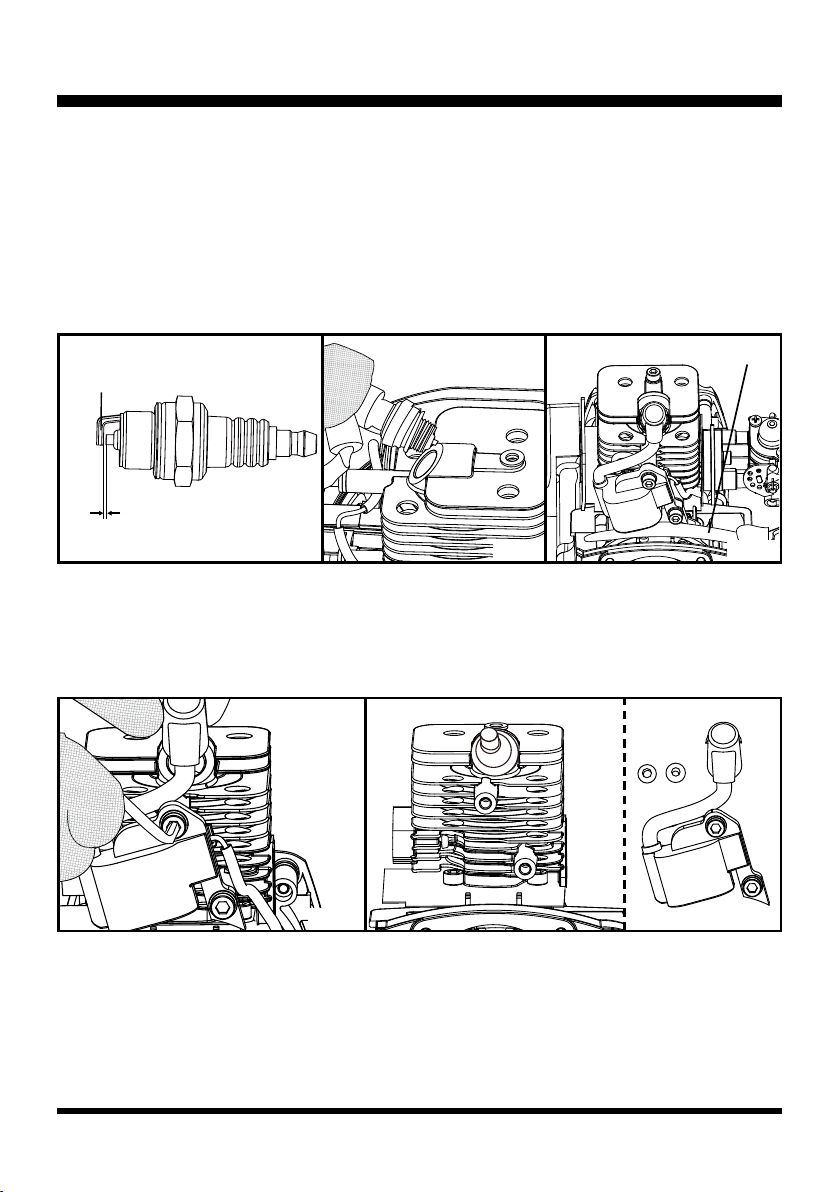

Feeler Gauge

■ Remove the spark plug cover. Remove the spark plug cap and the spark plug. Check and remove

the carbon deposit in the spark plug. The spark plug gap should be 0.65±0.05mm. Inspect the

electrodes for wear and deposits (Fig. 7).

■ Install the spark plug into the spark plug cap. Contact the negative electrode to the aluminum part

(Fig. 8).

■ Press the start button to check if the spark plug sparks.

■ Check the gap between the rotor and the ignition coil. Make sure the gap is between 0.012 and 0.015

in. (0.30-0.40 mm) as instructed in step 3 of the Ignition Coil Replacement section (Fig. 9).

Fig. 8Fig. 7

Ignition Coil Replacement (See Figs. 10-11)

■ Remove the upper engine cover.

■ Remove the spark plug cover and the spark plug cap. Remove the 2 screws. Remove the ignition

coil and the washers (Fig. 10 - 11).

Fig. 11Fig. 10

■ Replace with a new ignition coil.

■ To adjust the gap between the rotor and the ignition coil, rst insert a feeler gauge of 0.014 in.

(0.35mm) between the rotor and the ignition coil, then rotate the rotor and align the magnetic pole

of the rotor with the ignition coil. Press down the ignition coil ush against the feeler gauge. Tighten

the screws to x the ignition coil. Rotate the rotor counter-clockwise to remove the feeler gauge. Re-

check to ensure the gap is 0.012-0.015 in. (0.30-0.40 mm) (Fig. 9).

Outer Electrode

0.026 in. (0.65 mm)

Fig. 9

19

GENERAL TROUBLESHOOTING

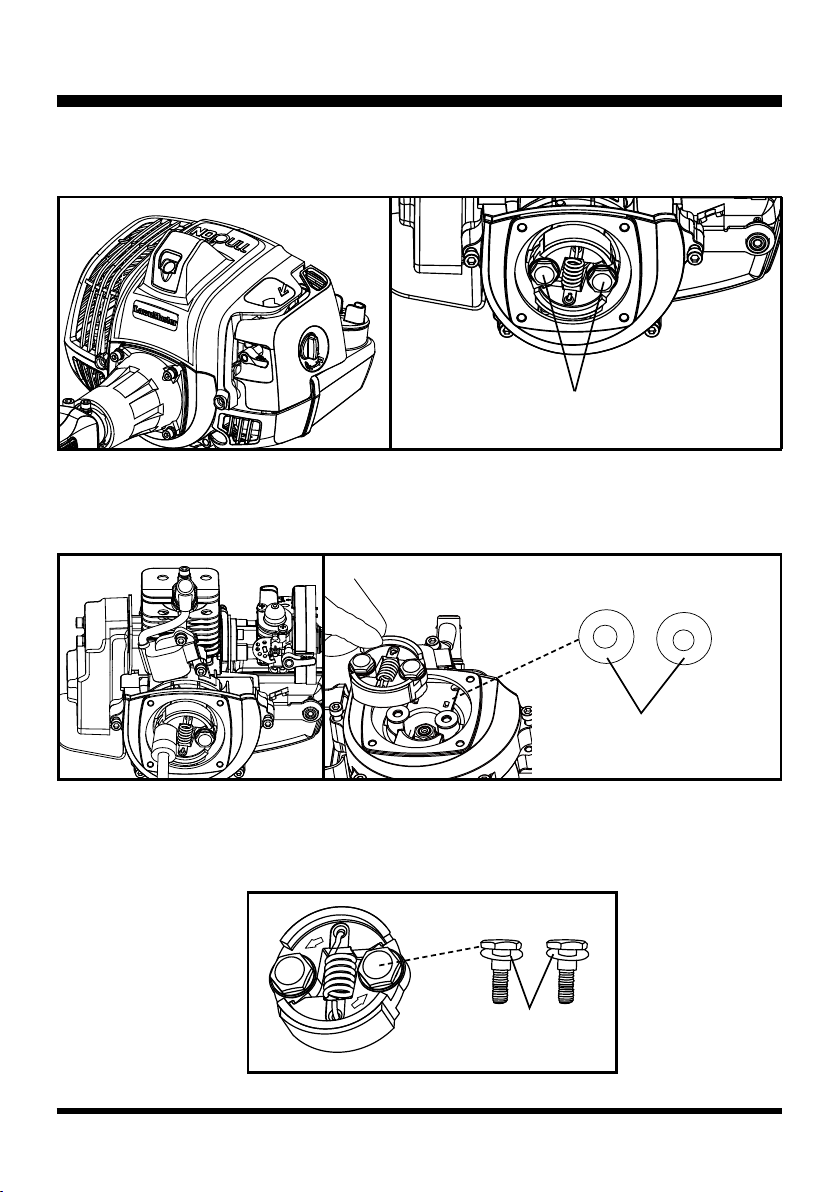

Clutch Replacement (See Figs. 12-18)

■ Remove the 4 screws to remove the transmission yoke (Fig. 12 & 13).

■ Remove the upper engine cover.

■ Unscrew the bolts on the clutch assembly using an impact driver or wrench (Fig. 14).

■ Remove the 2 bolts and corrugated washers. Then remove the clutch and at washers (Fig. 15).

■ Replace with a new clutch.

■ Slide the corrugated washers onto the bolts. Then install the bolts together with the corrugated

washers into the clutch, with the side of the clutch marked with the direction of rotation facing

upwards (Fig. 16).

Fig. 13

Fig. 15

Fig. 12

Fig. 14

Fig. 16

Bolts

Flat Washers

Corrugated Washers

20

GENERAL TROUBLESHOOTING

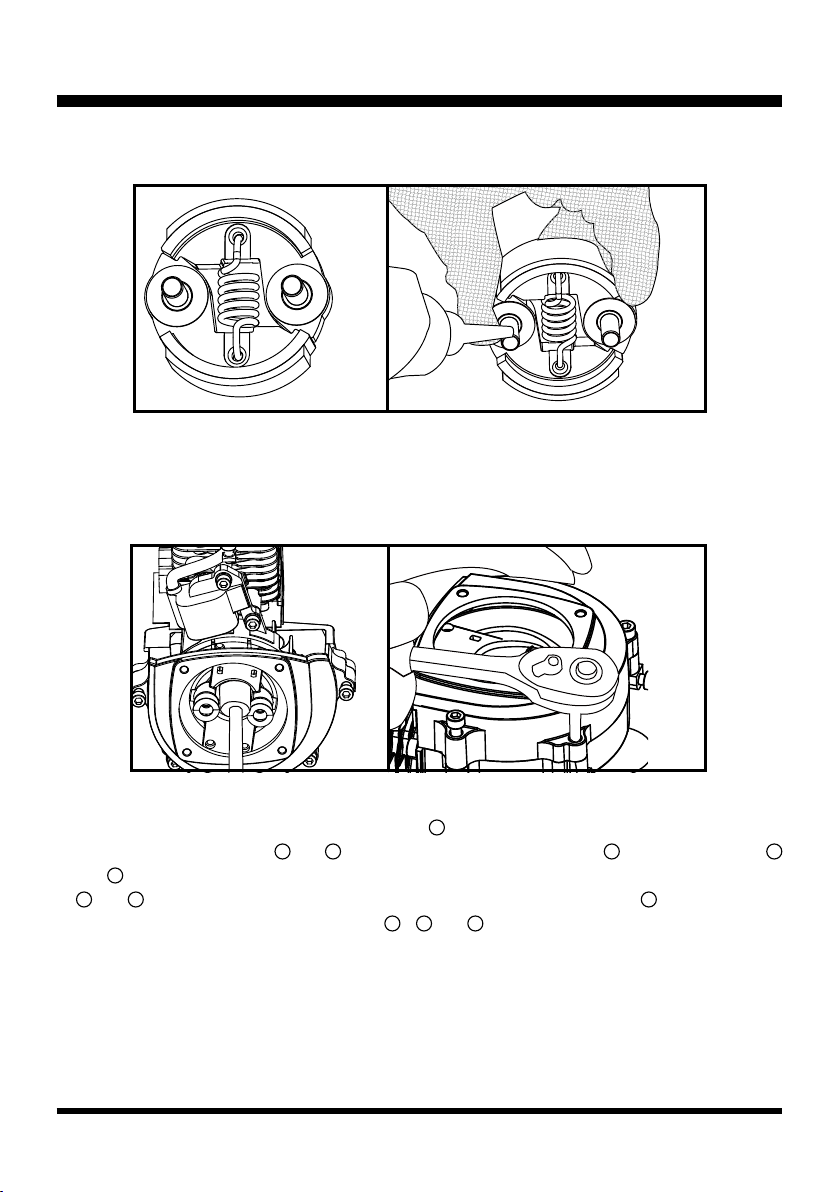

Flywheel (Rotor) Replacement (See Figs. 19-22)

■ Remove the clutch.

■ Remove the nut using an impact driver (Fig. 19).

■ Remove the 2 screws to remove the ywheel cover (Fig. 20).

■ The ywheel can be removed by a puller (Fig. 21). Choose an appropriate puller to remove the

ywheel. Before using the puller, rotate screw rod

1

counter-clockwise till it is 1/4 to 1/2 its length

through. Ensure screw rods

2

and

3

are protruded longer than screw rod

1

. Rotate screw rods

2

and

3

clockwise into the corresponding threaded holes as shown in Fig. 21. Make sure screw rods

2

and

3

are level and in same length. Then use a spanner to rotate screw rod

1

clockwise until

the ywheel is removed. Rotate screw rods

1

,

2

and

3

counter-clockwise to remove the puller

from the ywheel.

■ Turn the clutch upside down and slide the at washers onto the bolts. Apply the thread-locking glue

for 3-5 screw threads and then re-install the clutch (Fig. 17 & 18).

Fig. 18Fig. 17

Fig. 19 Fig. 20

Other manuals for NPTBSP2609A

2

Table of contents

Other LawnMaster Brush Cutter manuals