LAWO mc296 User manual

Copyright

All rights reserved. Permission to reprint or electronically reproduce any document or graphic in whole

or in part for any reason is expressly prohibited, unless prior written consent is obtained fromthe Lawo

AG.

All trademarks and registered trademarks belong to their respective owners. It cannot be guaranteed that

all product names, products, trademarks, requisitions, regulations, guidelines, specifications and norms

are free from trade mark rights of third parties.

All entries in this document have been thoroughly checked; however no guarantee for correctness can

be given. Lawo AG cannot be held responsible for any misleading or incorrect information provided

throughout this manual.

Lawo AG reserves the right to change specifications at any time without notice.

© Lawo AG, 2021

3/65

Table of Contents

mc²96 Installation & Service Guide Version: 1.0/3

Table of Contents

1. Introduction ......................................................................................................................................... 5

2. Important Safety Instructions ................................................................................................................ 6

3. The Hardware ..................................................................................................................................... 7

Overview.................................................................................................................................... 73.1

Frame Variants .......................................................................................................................... 73.2

Mounting Options ....................................................................................................................... 83.3

Channel Controls ........................................................................................................................ 93.4

Centre Section Controls ............................................................................................................ 113.5

Central User Panel Options ....................................................................................................... 133.6

Overbridge Metering ................................................................................................................. 143.7

Console Rear Panel .................................................................................................................. 153.8

Ethernet Server Types .............................................................................................................. 163.9

Control Surface Wiring ............................................................................................................. 163.10

4. Installation ......................................................................................................................................... 20

Unpacking ............................................................................................................................... 204.1

Packing List ............................................................................................................................. 204.2

Mounting the Frame .................................................................................................................. 214.3

Dimensions and Weight ............................................................................................................ 214.4

Temperature and Cooling .......................................................................................................... 214.5

MinimumDistances for Control Surface Mounting ....................................................................... 224.6

Installing the Console Keyboard ................................................................................................. 234.7

Fitting the Script Tray ............................................................................................................... 244.8

Wiring from the Control Surface ................................................................................................ 254.9

Power ...................................................................................................................................... 264.10

Grounding ................................................................................................................................ 274.11

Control .................................................................................................................................... 284.12

Installing Extender Frames ........................................................................................................ 294.13

Local IO................................................................................................................................... 304.14

SFP Modules ........................................................................................................................... 334.15

Front Buffer Connections .......................................................................................................... 344.16

Connecting a Talkback Mic ....................................................................................................... 354.17

5. Service Procedures ........................................................................................................................... 36

mc²96 Installation & Service Guide

Table of Contents

4/65 Version: 1.0/3

Preparation .............................................................................................................................. 365.1

Restarting a Bayserver or Gateserver ......................................................................................... 375.2

Replacing a Panel .................................................................................................................... 385.3

Using the Hood Fastener ........................................................................................................... 425.4

Replacing a Fader .................................................................................................................... 435.5

Replacing a User Panel ............................................................................................................. 455.6

Replacing a TFT Display ........................................................................................................... 495.7

Calibrating a Touch-screen ....................................................................................................... 495.8

Bayserver & Gateserver Switch Settings ..................................................................................... 505.9

Replacing a Console Power Supply ............................................................................................ 525.10

Replacing the Local IO .............................................................................................................. 545.11

Replacing the Network Switch .................................................................................................... 565.12

Replacing the Monitoring Computer ............................................................................................ 585.13

6. Appendices ....................................................................................................................................... 60

Part Numbers ........................................................................................................................... 606.1

Wiring Diagrams ...................................................................................................................... 616.2

Connector Pin-Outs & IOSpecifications ..................................................................................... 626.3

SMPTE ST2022-7 (SPS) ........................................................................................................... 656.4

mc²96 Installation & Service Guide Version: 1.0/3 5/65

1. Introduction

1. Introduction

About this Manual

This document describes the hardware, installation and service procedures for the mc²96 control surface.

Look out for the following which indicate:

Notes - points of clarification.

Tips - useful tips and short cuts.

Attention - alert you when an action should always be observed.

Further Information

Mechanical drawings and data sheets (including weights and dimensions) are available from the Downloads

area at www.lawo.com (after Login)..

We also recommend that you carefully observe the release notes delivered with your system.

Lawo User Registration

For access to the Downloads area and to receive regular product updates, please register at:

www.lawo.com/registration.

mc²96 Installation & Service GuideVersion: 1.0/36/65

2. Important Safety Instructions

2. Important Safety Instructions

Please observe all of the instructions provided in the "General Safety Information for Lawo Equipment" booklet

delivered with your devices. Double-click here to open the same information (as a pdf).

Please also observe the "Safety Information" included in the product data sheets. These are available from the

Downloads area at www.lawo.com (after Login).

mc²96 Installation & Service Guide Version: 1.0/3 7/65

3. The Hardware

3. The Hardware

This chapter describes the control surface hardware and options.

3.1 Overview

The mc296 comes in a range of flexible frame sizes and layouts. The control surface includes integrated local IO

and dual redundant power supplies. The frame is convection cooled and so there are no fans, except in the RTW

TM9.

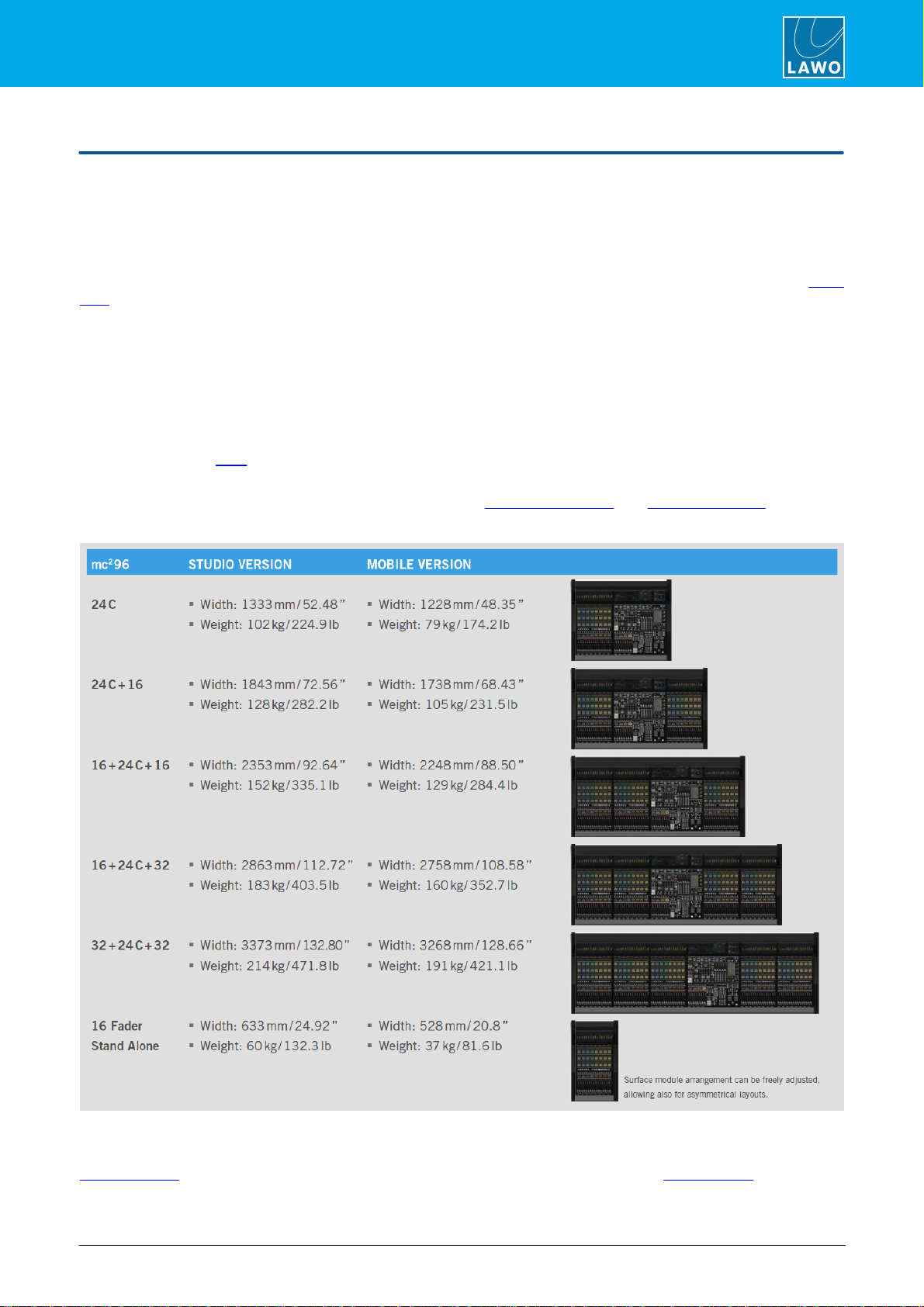

3.2 Frame Variants

The control surface can scale from 24 up to 120 faders. The five standard frame layouts are shown below.

The central bay (24C) houses the centre section with 8 main faders plus one 16-fader channel bay. Additional

channel bays may then be added as required. Each 16-fader channel bay adds 510mm to the width of the

console. The position of the central bay is flexible allowing for asymmetrical layouts which differ to those pictured

below. Double-click here to view all possible frame variants (as a pdf).

A frame can be expanded by adding 16-fader stand-alone extenders up to the maximum of 120 faders. The

number of faders in a frame can be increased by fitting the Fader Panel Upper and Xtra Main Faders options.

mc296 Standard Frame Layouts

The weights shown above for the "Studio Version" are for a console with no stand.

Mechanical drawings and data sheets for all frame variants are available from the Downloads area at

www.lawo.com (after Login). To help locate the correct data sheet, please refer to the part numbers appendix.

mc²96 Installation & Service GuideVersion: 1.0/38/65

3. The Hardware

To aid transportation, frames with up to three additional channel bays (72-fader) can be delivered either as a

single monolithic frame (978/50-xy) or as a spit frame (978/51-xy). Frames with four or more additional channel

bays (88-faders upwards) are always delivered as split frames (978/51-xy). Following transportation, split-frames

must be combined to form a single unit.

3.3 Mounting Options

mc296 Studio Version (with stand)

Each frame can be ordered for either Studio or OB-Van (Mobile) mounting.

The Studio version comes with wider side panels and a console stand (for a free-standing frame). The stand

comprises two detachable legs which are supplied with wooden mounting plates to attach the legs to the frame.

The OB-Van version is fitted with narrow aluminum side plates and is designed for crossbar mounting (i.e. no

feet or legs are supplied).

mc²96 Installation & Service Guide Version: 1.0/3 9/65

3. The Hardware

3.4 Channel Controls

Channel bays can be specified with either single or dual faders.

3.4.1 Single-Fader Bays

As standard, each channel bay is fitted with the following control panels.

1 x Channel Display (978/13)

A high resolution, touch-screen TFTdisplay.

1 x FC Panel (978/11)

with 112 rotary encoders, 24 mini TFTdisplays, 148 push-buttons.

1 x Fader Panel (978/10)

with 16 x100mm motorised faders, 8 mini TFT displays, 160 push-

buttons.

mc²96 Installation & Service GuideVersion: 1.0/310/65

3. The Hardware

3.4.2 Dual-Fader Bays

Optionally, the FC Panel (978/11) can be replaced by the Fader Panel Upper (978/12) to provide a second row

of short-scale fader strips at the expense of Free Controls 3 to 6. The 978/12 can be fitted to individual bays as

required, allowing you to combine single and dual-fader bays within the same surface.

1 x Channel Display (978/13)

Identical to a standard channel bay.

1 x Fader Panel Upper (978/12)

with 16 x60mm motorised faders, 48 rotary encoders, 16 mini TFT

displays, 214 push-buttons.

Replaces the 978/11.

1 x Fader Panel (978/10)

Identical to a standard channel bay.

3.4.3 Ethernet Bayserver

Internally, each channel bay is fitted with an Ethernet Bayserver mounted behind the display. This handles the

control data within the bay, and connects to the internal network.

3.4.4 Further Information

All faders and rotary encoders are touch-sensitive.

You can find more information about the individual panels and displays in their data sheets.

mc²96 Installation & Service Guide Version: 1.0/3 11/65

3. The Hardware

3.5 Centre Section Controls

The centre section can be specified with either 8 or 16 main faders.

3.5.1 Standard Centre Section

As standard, the centre section is fitted with the following control panels.

1 x Channel Display (978/13)

A high resolution, touch-screen TFT display

(identical to a channel bay). When fitted to the

centre section, the display is known as the

Central GUI.

1 x RTW Panel (978/27)

A special version of the RTW TM9 for Lawo

consoles.

1 x Central Panel Upper (978/21)

with 47 rotary encoders, 12 mini TFT displays, 1

touch-screen display, 1 motorised joystick, 1 XLR

connector, 130 push-buttons.

The panel includes a space for up to two user

panels. Unless otherwise specified, the console

ships with two blanking panels (978/28).

1 x Central Panel Lower (978/20)

with 8 x 100mm motorised faders, 1 rotary

encoder, 13 mini TFT displays, 1 trackball, 207

push-buttons.

mc²96 Installation & Service GuideVersion: 1.0/312/65

3. The Hardware

3.5.2 Xtra Main Faders

Optionally, the Central Panel Lower (978/20) can be replaced by the Xtra Central Panel Lower (978/22) to

increase the number of main faders from8 to 16. To support this option, the Central Panel Upper (978/21) must

be fitted with the Xtra User Panel (978/23) to provide access to the following functions: FC PRESETS, LINK,

ISO, STRIP ASSIGNMENT, FADER USER BUTTON and BUS ASSIGNMENT. This option can be retrofitted to

existing consoles.

1 x Channel Display (978/13)

Identical to standard centre section.

1 x RTW Panel (978/27)

Identical to standard centre section.

1 x Central Panel Upper (978/21)

Identical to standard centre section.

1 x Xtra User Panel (978/23)

with 35 push-buttons.

1 x Xtra Central Panel Lower (978/22)

with 16 x 100mm motorised faders, 1 rotary

encoder, 12 mini TFT displays, 1 trackball, 210

push-buttons.

Replaces the 978/20.

3.5.3 Ethernet Server

Internally, the central bay is fitted with an Ethernet server (mounted behind the display). This can be either a

Bayserver or Gateserver. The differences are described later.

3.5.4 Further Information

All faders and rotary encoders are touch-sensitive.

You can find more information about the individual panels and displays in their data sheets.

mc²96 Installation & Service Guide Version: 1.0/3 13/65

3. The Hardware

3.6 Central User Panel Options

The Central Panel Upper (978/21) can be fitted with up to two Lawo User Panels. If the console is fitted with the

Xtra Main Faders option, then the lower slot must be used for the XTRA USER PANEL (978/23). In all other

cases, the two slots are freely configurable. Unless otherwise specified, the console ships with two blanking

panels (978/28).

User Panel Options

Part No

User Panel Name

Description

978/23

XTRA USER PANEL

Must be fitted to an Xtra Main Faders console.

978/24

40 KEY USER PANEL

40 user-programmable buttons. Two panels can be fitted to provide 80

buttons.

978/25

REVEAL FADER

5 dedicated faders for revealing surround slaves.

978/26

AUTOMATION

Controls for the timecode automation system.

978/28

BLANKING PLATE

Single slot blanking panel.

XTRA USER PANEL

40 KEY USER PANEL

REVEAL FADER

AUTOMATION

mc²96 Installation & Service GuideVersion: 1.0/314/65

3. The Hardware

3.7 Overbridge Metering

The console comes as standard with an RTW TM9 meter. This is a special version of the TM9, designed

specifically for Lawo consoles. If the meter is removed, then a blanking panel (978/29) should be installed.

The meter provides 4 x AES3 inputs for multi-channel metering and 5 x GPI for external control. These are

wired internally to the console's local IO. The default configuration sets the AES3 inputs to follow the MON 1

monitor source selector. Alternatively, signals can be routed directly to the meter using the console GUI.

All other functions are operated via the meter's touch-screen display. Please refer to the documentation from

RTW.

Note that meter includes a temperature-controlled fan to provide cooling at extreme temperatures (>70°C).

Under normal operating conditions, the fan is inactive. When the meter boots up, the fan is tested. This means

that you will hear the fan, momentarily, whenever the control surface power is applied.

mc²96 Installation & Service Guide Version: 1.0/3 15/65

3. The Hardware

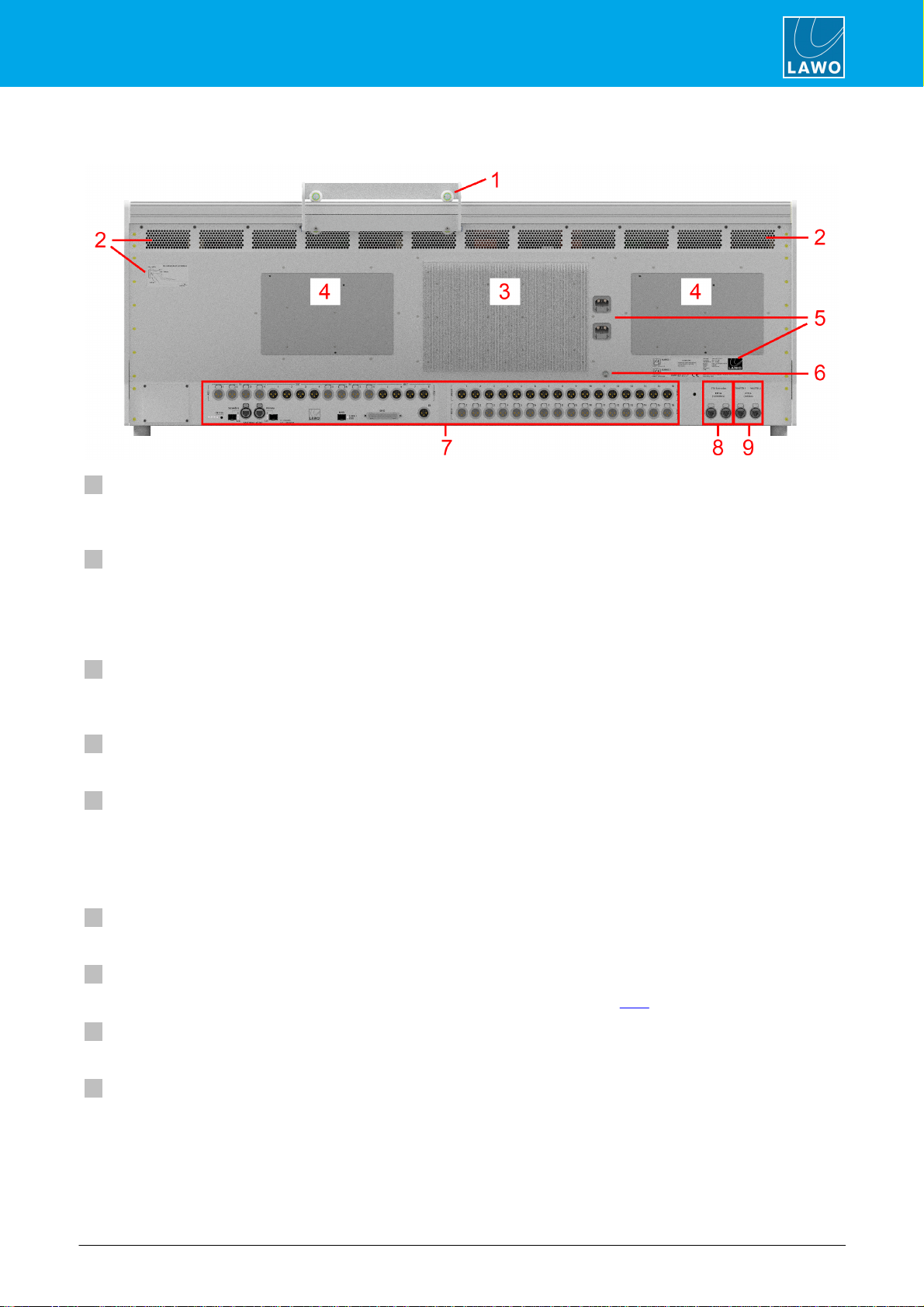

3.8 Console Rear Panel

1 Removable Script Tray (optional)

One or more removable script trays may be ordered. The script tray glides across the top of the frame, and can

be lifted on or off for removal.

2 Ventilation Holes & Sticker

The sticker shows the direction of airflow (required for convection cooling) and the minimum distance

requirements (for installing the frame). It is important that cold air is taken in underneath the console, near the

armrest, and that cold air flows externally upwards across the whole of the rear panel. This is because both the

PSU heat sink (3) and Bayserver back plates (4) will dissipate heat during operation.

3 PSU Heat Sink

Radiates heat from the internal power supplies. The heat sink indicates the location of each PSU block within

the frame.

4 Ethernet Server Back Plates

Radiates heat from the internal Ethernet servers. The back plates indicate their location within the frame.

5 MAINS 1 & 2

The MAINS 1 & MAINS 2 connectors supply AC mains power to the frame. The sticker states the AC mains

requirements.

Depending on the frame size, one or more PSU "blocks" may be installed, each providing main and redundant

power supplies. Therefore, in larger frames you will see more than one set of MAINS connectors.

6 CASE

The CASE grounding screw (M5 x 12mm) should be used to ground the frame.

7 Local IO Connector Panel

Here you will find the connections for the built-in local IO. These are described later.

8 ETH Extension

The first pair of network ports can be used to connect Extender frames.

9 Control Data to/from the Core

The second pair of network ports connect the control surface to the Core.

mc²96 Installation & Service GuideVersion: 1.0/316/65

3. The Hardware

3.9 Ethernet Server Types

Internally, each channel and central bay is fitted with an Ethernet server. In channel bays, the server type is

always the same: a Bayserver. For the central bay, there are two possibilities: either a Bayserver or Gateserver

(supported fromV6.4.0 onwards). This option determines how the control surface connects to the Core and, as

a result, where it can be installed.

·

Bayserver consoles connect directly to the ETHERNET A ports on the Nova73. Since the connection

must be directly-wired, this limits the maximumdistance between the surface and Core.

·

Gateserver consoles connect to the Core via the Management Network. Since this supports Layer 3

routing, this allows the surface to be installed remotely fromthe Core.

The internal and external wiring for each variant are described later.

Externally, there are two ways to determine the central server type: via the start-up screens on the Central GUI,

or the Ethernet connector panel at the rear of the frame.

Start-up Screen (for Central Bayserver)

Start-up Screen (for Central Gateserver)

Rear Connector Panel (if Central Bayserver)

Rear Connector Panel (if Central Gateserver)

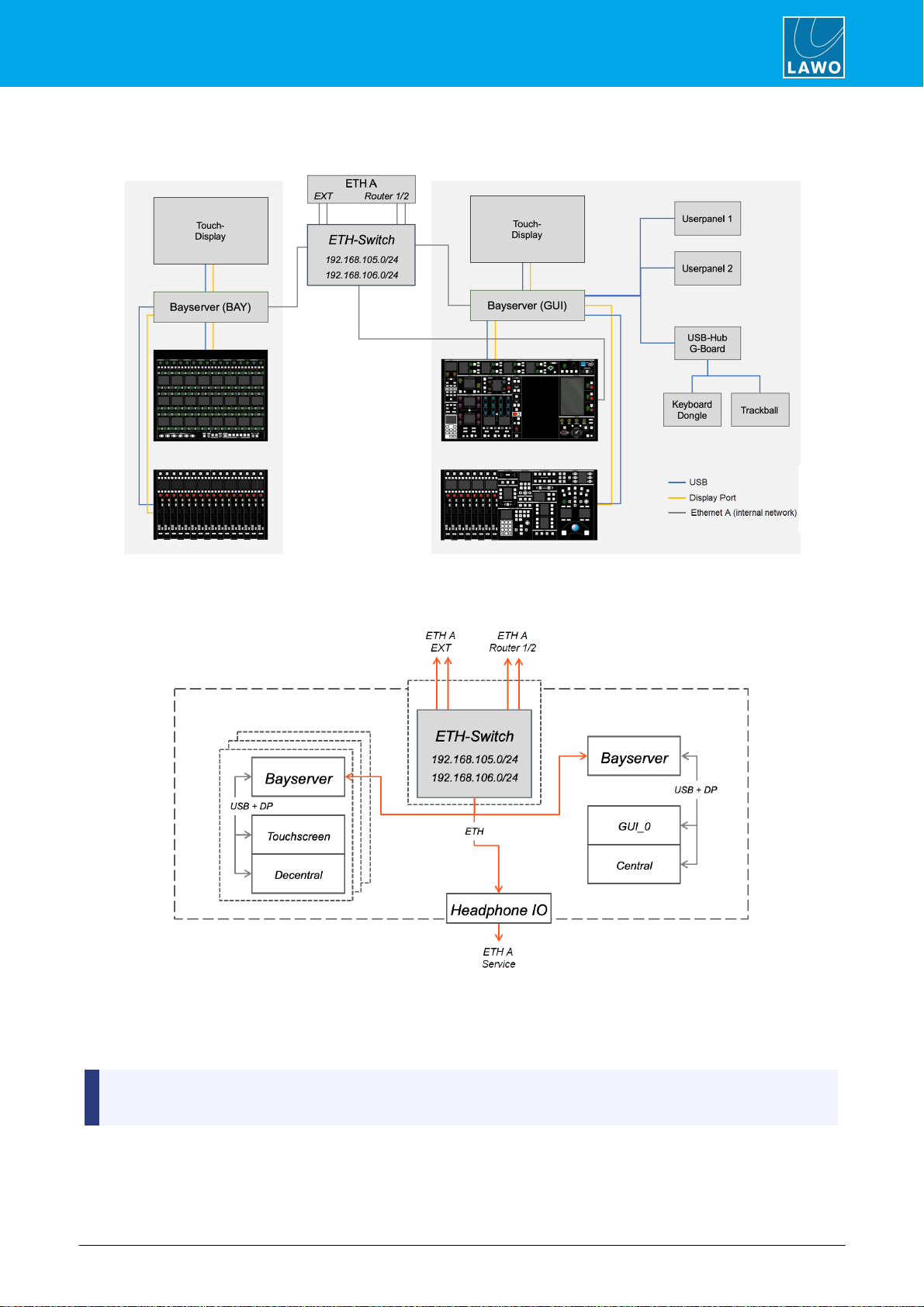

3.10 Control Surface Wiring

Internally, the control surface uses point-to-point connections, within each bay, to provide fault tolerance and

convenient servicing. Any bay or panel can be isolated from the rest of the console, allowing panels and

displays to be replaced during operation.

Firstly, within each bay, individual panels and displays connect to the Ethernet server (mounted behind the

display). In channel bays, the connections are made using both USB and Display Port. In the centre section,

the optional user panels connect via USB only, and there is also a USB hub which connects to the console

keyboard and trackball.

Each server then connects to an Ethernet switch to form what is known as the internal network or ETHERNET

A. On the mc296, the switch also connects to the Central Panel Upper to drive the touch-screen MONITORING

display.

Externally, the following connections are wired from the internal network switch (on all consoles):

·

ETH Extension (rear panel) - to connect extender frames.

·

ETH A (front buffer) - to connect a service computer.

The remaining connections vary, depending on whether the central bay is fitted with a Bayserver or Gateserver.

mc²96 Installation & Service Guide Version: 1.0/3 17/65

3. The Hardware

3.10.1 Internal Wiring for Bayserver Console

Schematics (Bayserver Console)

On a Bayserver console, there are a further two connections from the internal network switch: ROUTER 1 and

ROUTER 2. These must connect directly to the ETHERNET A ports on the Nova73 Router Modules. Only one

connection is essential for operation. If a second Router Module is fitted, then a second connection should be

made to support redundancy.

The control surface must be connected to the mc2control system (via ETHERNETA) in order to boot.

Therefore, to start the system, both the control surface and Nova73 must be powered.

mc²96 Installation & Service GuideVersion: 1.0/318/65

3. The Hardware

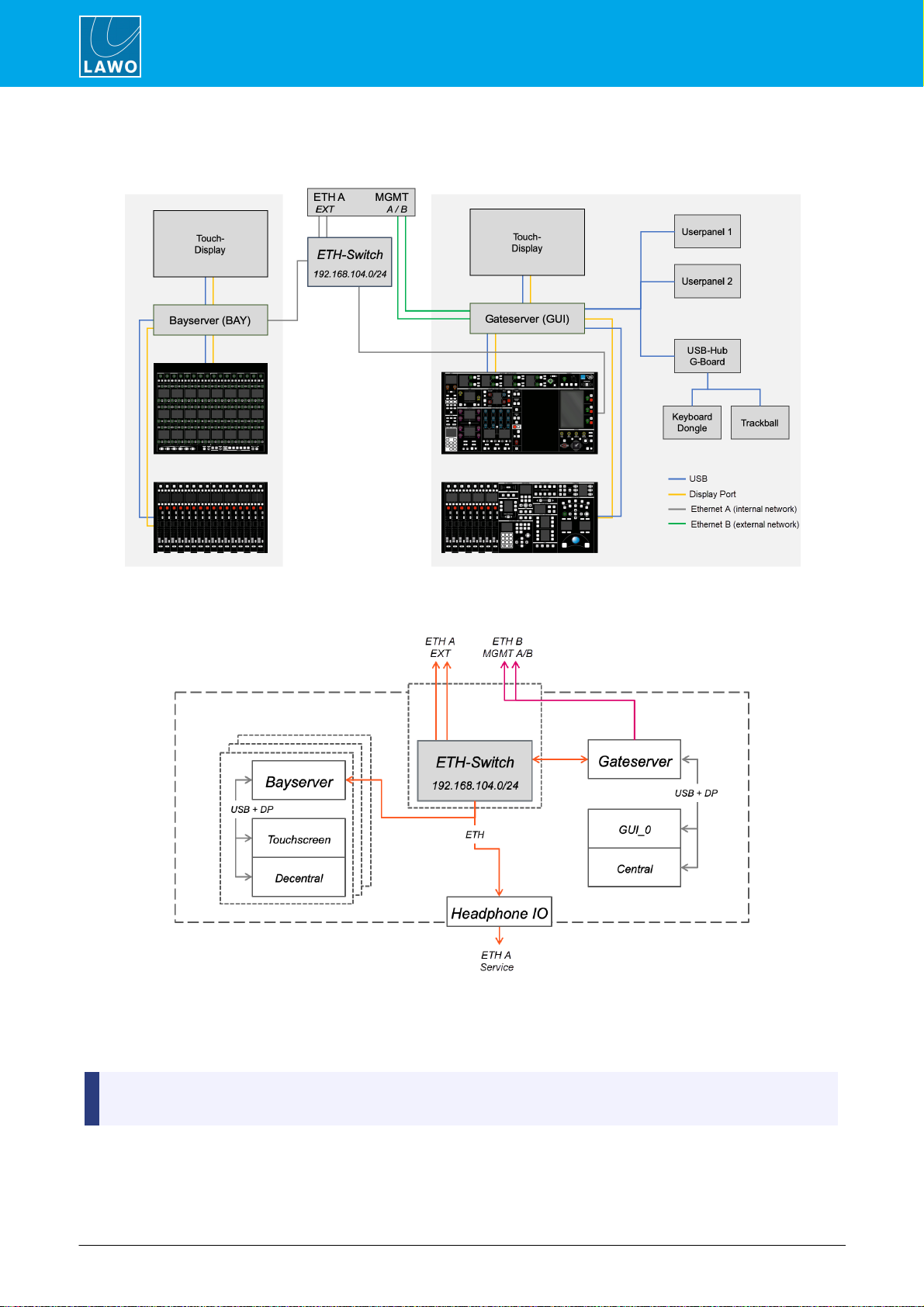

3.10.2 Internal Wiring for Gateserver Console

Schematics (Gateserver Console)

On a Gateserver console, there are a further two connections which come from the Gateserver: MGMT A and

MGMT B. These must connect to the same Management Network as the Core's control ports (e.g. ETHERNET

B if the Core is a Nova73). Only one connection is essential for operation. A second connection can be

installed to support redundancy.

A Gateserver console can boot on its own once power is supplied to the control surface. To become fully

operational, there must also be a valid network connection to the Core.

mc²96 Installation & Service Guide Version: 1.0/3 19/65

3. The Hardware

3.10.3 Additional Notes for Gateserver Consoles

The Gateserver provides a more sophisticated computing engine that can boot on its own once power is supplied

to the control surface. To achieve this, the Gateserver has its own SSD storage containing the boot image. This

must be updated separately using the mxUpdater utility (included with mxGUI).

After a successful boot, the Gateserver connects automatically to its partnered Core (by creating a VPN

connection between the Gateserver and mc2control system). If there is no connection available, then the

console will show "disconnected" screens. Once a valid network connection is established, the screens update to

their "connected" state. This indicates that the console is ready for operation.

For the console to become fully operational, there must be a valid network connection between the

Gateserver and mc2control system.

mc²96 Installation & Service GuideVersion: 1.0/320/65

4. Installation

4. Installation

This chapter describes how to install the control surface.

4.1 Unpacking

If the control surface comprises more than one frame, then each frame is delivered separately. All included

accessories are shipped in the "Accessories" box. Any optional components are delivered in their own packing

boxes.

Please check the contents of the shipping boxes, and in the event of any transport damage, contact your local

Lawo representative or email support@lawo.com.

4.2 Packing List

Included

The following items are included with the control surface (in the "Accessories" box):

·

2 x 2m IEC power cables (country-specific) - to connect mains power to the frame. If the surface

contains more than one PSU block, then additional IEC power cables are supplied.

·

1 x Logitech wireless keyboard + USB dongle - to be installed as the console keyboard. The USB

cable is included for charging purposes.

·

1 x dust-cover - to protect the console when not in use.

·

1 x tool case + tools - for performing service procedures.

·

1 x USB memory card - containing the latest software and configuration files.

If you have ordered the studio version, then this comes with the console stand: 2 x detachable legs + mounting

plates.

Optional

The following items must be ordered separately.

·

SFP modules - for the MADI and RAVENNA/AES67 ports.

·

Removable Script Tray (978/68).

Table of contents

Other LAWO Dj Equipment manuals