Lawrence Hardware LH3000 User manual

Not to Scale

e use of non-clutching impact drivers to install this hardware will automatically void the warranty.

All product specications are subject to change.

Phone: 1-800-267-1236 www.lawrencehardware.com Fax: 1-800-892-7026

LH3000

Instructions

and Template

676 Petrolia Road

Toronto, Ontario M3J 2V2

Installtion Instruction

1.Insert Plastichub

Into Door Hole Then

Insert The Latch.

2.Install Base Plate. 3.Insert Spindle

With Spring.

4.Install Lever Handle.

What is in the Box

Installation Instruction

January 2017 LH3000 series (2017)

What is in the Box

\

1 Allen Key

1 privacy

pin if

required

1 latchbolt

2 screws

1 D strike

2 screws

M4x12 4pcs

M4x25 2pcs

M4x40 2pcs

M4x30 2pcs

8X8X40mm 2pcs

Design

Drawn

Check by

Approved by

Customer

Title

Modle

Part No.

Drawing No.

3D Angle Projection

Quantity

Scale

Material

Weight

version

N/A

Sheet of

2276.78

GA

A0

M4x12 4pcs

M4x25 2pcs

M4x40 2pcs

M4x30 2pcs

8X8X40mm 2pcs

Design

Drawn

Check by

Approved by

Customer

Title

Modle

Part No.

Drawing No.

3D Angle Projection

Quantity

Scale

Material

Weight

version

N/A

Sheet of

2276.78

GA

A0

M4x12 4 each

M4x25 2 each

M4x30 2 each

M4x40 2 each

1 each

2 each

Save for

Emergency Release

Standard Latch Faceplate2⅜” Privacy Shown Standard “D” Strike2¾” Passage Shown

Privacy

Pin

5. Installation Complete.

1. Insert Plastic hub

Into Door Hole en

Insert e Latch.

2. Install Base Plate. 3. Insert Spindle

With Spring.

4. Install Lever Handle.

Not to Scale

e use of non-clutching impact drivers to install this hardware will automatically void the warranty.

All product specications are subject to change.

Phone: 1-800-267-1236 www.lawrencehardware.com Fax: 1-800-892-7026

676 Petrolia Road

Toronto, Ontario M3J 2V2

LH3000

Instructions

and Template

Template

Ø55

60/70

58

26

41.6

3.7

Ø3

Template

⁄ ⁄ ⁄ ⁄ ⁄

⁄”

2 ⁄”

1 ⁄”

⁄” 1”

2 ⁄ or 2⁄

Phone 1-800-435-9568 www.lawrencehardware.com Fax 1-800-892-7026

TQ2 TQ2

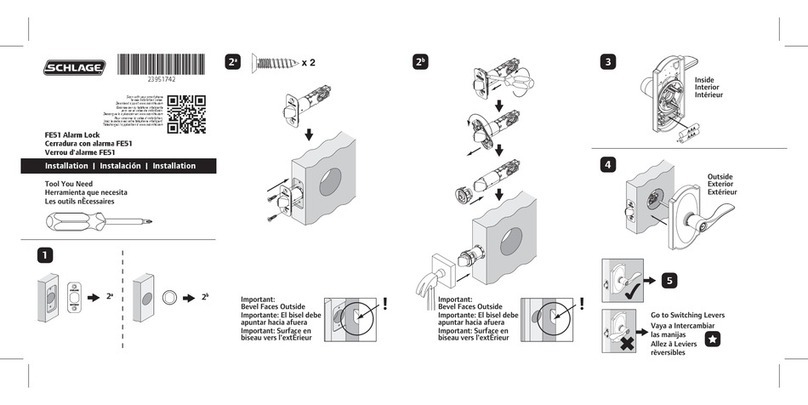

4. Reversible Levers

5. Install Outside Lever

Insert spindle through latch.

Press flush against door.

6. Install Inside Lever

Install inside lever and

tighten screws until lock is firm.

7. Install Strike

a. Close door to make horizontal

centre line of strike.

A.

B.

C.

c. Install strike and tighten screws.

b. Measure one half of door thickness

from door stop and mark vertical

centre line of strike.

Drill 1"(25.4mm) hole 1/2"(13mm)

deep at intersection of horizontal

and vertical line of strike.

Match screw holes on strike with

centre lines on jamb.

Mark outline and chisel 1/16"

(1.6mm)deep for strike.

Handle can be only

installed when the timing

of "emergency release"

is set in the position

shown below.

RIGHT

HAND DOOR

LEFT

HAND DOOR

54mm (2-1/8")

FOR BACKSET ( )70mm 2-3/4"

FOR BACKSET ( )60mm 2-3/8"

Rev. 13/10/2011

45 40 35

1-3/4" 1-3/8"1-9/16" 2-1/4" (57mm)

5.5mm 7/32"

hole for metal

door only

( ) x 2

Make 1"(25.4mm)hole at center of door edge.

Fold on dotted line and fit on door edge

TEMPLATE

Fold on dotted line and fit on door edge

a. Please check the levers are unlocked(Entrance sets only).

Depressing lever catch with hand tool to release outside lever and pulling lever off.

Taking apart off the and cylinder from outside lever.

b. Reversing the levers from outside to inside/inside to out side, putting the cylinder

on the outside lever (Entrance sets only).

Please do the same procedures for inside lever.

c. Pushing handles in until catch clicks. Make sure levers are retained by lever.

Backset is a distance from the door edge to the centr of the hole on door face.

Some locks are supplied with adjustable latch which can fit 2-3/8"(60mm) or 2-3/4"(70mm) backset.

Just follow the steps shown below to change backset.

e

a. This latch is set for

2-3/8"(60mm)backset.

b. Keep spindle cam in correct

position as illustrated.

Pull spindle cam all the way

to right.

c. Your latch is now set for 2-3/4"(70mm) backset.

To reset 2-3/8"(60mm) backset, just push spindle

cam back to left side.

Please make sure that the cams are staying with

square shape.

Some locks are supplied with 4-way latch which can fit mortise in or drive in.

a. This latch is for mortise in. b. Rotate latch face clockwise 20°

and pull out latch face.

c. This latch is for drive in.

A. B. C.

22

33 88

// //

44

33

22

""

""

""""

22

33 44

//

//

88

33

22

A. B. C.

INSTRUCTIONS FOR INSTALLATION OF TUBULAR LEVERSETS

Latch Backset Adjustment

Latch Face Plate

1. Mark Door with Template

a. Start 36"(914mm) from floor, fold and apply template

from floor, mark centre of door edge.

b. Select 2-3/8"(60mm) or 2-3/4"(70mm) backset as

desired and mark centre of hole on door face.

2. Drill Holes

a. Drill 2-1/8"(54mm) hole on door face, from both sides to

avoid wood splitting.

b. Drill 1"(25.4mm) hole for latch.

(refer step 3c for drive-in latch)

3. Install Latch

a. Insert latch in hole, mark outline of faceplate and chisel 5/32"(4mm) deep.

b. Insert latch and tighten screws.

c. For drive in latch, drill 31/32"(24.6mm) hole and press latch until it is

flush with door edge.

A.

B. C.

TQ2 TQ2

TQ2 TQ2

Installation sheet for Tubular latchbolt (3000 series, October 2014)

1. Door face prep for either 2 3/8 or 2 ¾” backset

2. Door edge prep 1” x 2 ¼” 5/32” (4MM) 1” cross bore.

Phone 1-800-435-9568 www.lawrencehardware.com Fax 1-800-892-7026

Backset is a distance from the door edge to the centr of the hole on door face.

Some locks are supplied with adjustable latch which can fit 2-3/8"(60mm) or 2-3/4"(70mm) backset.

Just follow the steps shown below to change backset.

e

a. This latch is set for

2-3/8"(60mm)backset.

b. Keep spindle cam in correct

position as illustrated.

Pull spindle cam all the way

to right.

c. Your latch is now set for 2-3/4"(70mm) backset.

To reset 2-3/8"(60mm) backset, just push spindle

cam back to left side.

Please make sure that the cams are staying with

square shape.

Some locks are supplied with 4-way latch which can fit mortise in or drive in.

a. This latch is for mortise in. b. Rotate latch face clockwise 20°

and pull out latch face.

c. This latch is for drive in.

A. B. C.

22

33 88

// //

44

33

22

""

""

""""

22

33 44

//

//

88

33

22

A. B. C.

INSTRUCTIONS FOR INSTALLATION OF TUBULAR LEVERSETS

Latch Backset Adjustment

Latch Face Plate

1. Mark Door with Template

a. Start 36"(914mm) from floor, fold and apply template

from floor, mark centre of door edge.

b. Select 2-3/8"(60mm) or 2-3/4"(70mm) backset as

desired and mark centre of hole on door face.

2. Drill Holes

a. Drill 2-1/8"(54mm) hole on door face, from both sides to

avoid wood splitting.

b. Drill 1"(25.4mm) hole for latch.

(refer step 3c for drive-in latch)

3. Install Latch

a. Insert latch in hole, mark outline of faceplate and chisel 5/32"(4mm) deep.

b. Insert latch and tighten screws.

c. For drive in latch, drill 31/32"(24.6mm) hole and press latch until it is

flush with door edge.

A.

B. C.

TQ2 TQ2

TQ2 TQ2

3. Handing of latch-bolt, turn faceplate approximately 20 degree and remove, turn latch-bolt

over and reinstall faceplate. Note this change may not be required.

4. handing privacy button if required. Move screw in privacy button from the inside of the door to

the outside of the door if needed. Note; this change may not be needed.

3. To change hand if required, hold latch tube with one hand and rotate faceplate 180

degrees, take care to ensure both tabs stay engaged between the latchtube and faceplate

tabs holding the faceplate to the latchtube stay engaged.

1. Door face prep for either

2 3/8” or 2 ¾” backset

2. Dooredge prep

1” X 2 1/4” X 5/32”

3. To change hand if required,

simply hold latch tube with one

hand and rotate latch bolt with

other hand .

4. readed portion of latch bolt

must be on the inside of the door

5. Emergency release hole on

outside rose

6. In emergency push small object

into outside hole to release privacy

function and gain entry

Popular Lock manuals by other brands

BEST ACCESS SYSTEMS

BEST ACCESS SYSTEMS 6K Series Service manual

Hama

Hama 00086516 operating instructions

Safety 1st

Safety 1st HS162 user guide

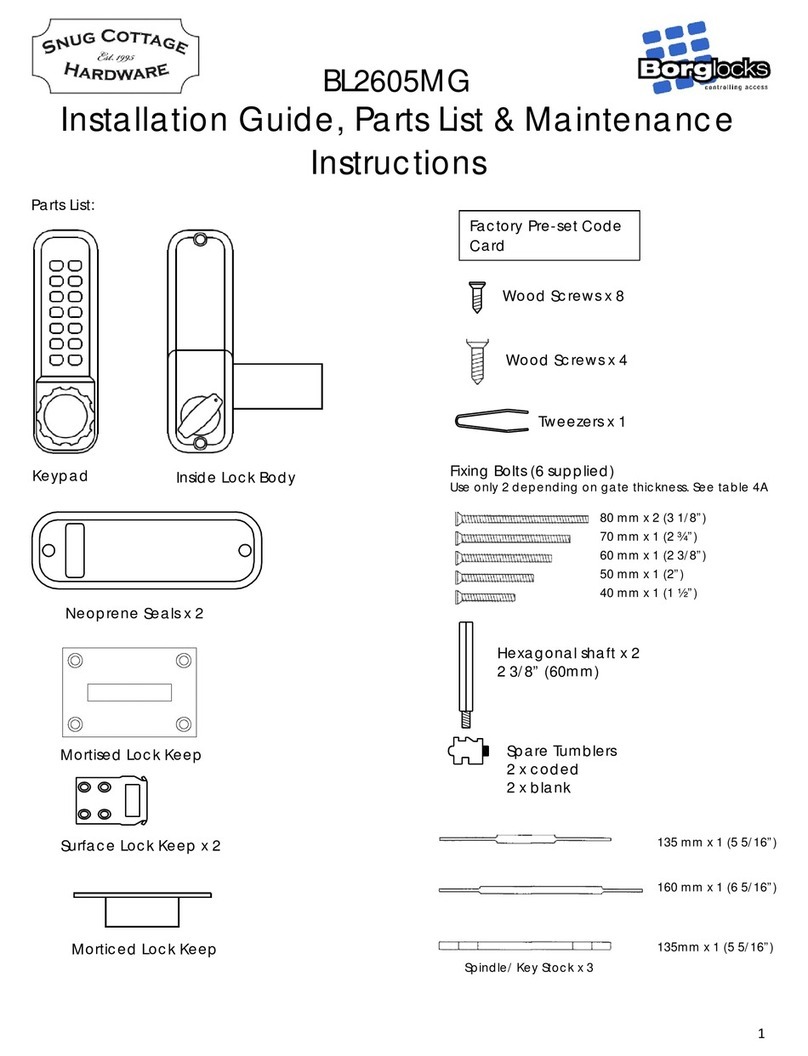

Borglocks

Borglocks BL2605MG Installation Guide, Parts List & Maintenance Instructions

Hornbill

Hornbill SB-122 Troubleshooting

Assa Abloy

Assa Abloy KESO eCLIQ N0.001 BA3 operating instructions