4

Marysville Michigan, USA and London, Ontario, Canada

1-800-637-5427

www.snugcottagehardware.com

Installation instructions:

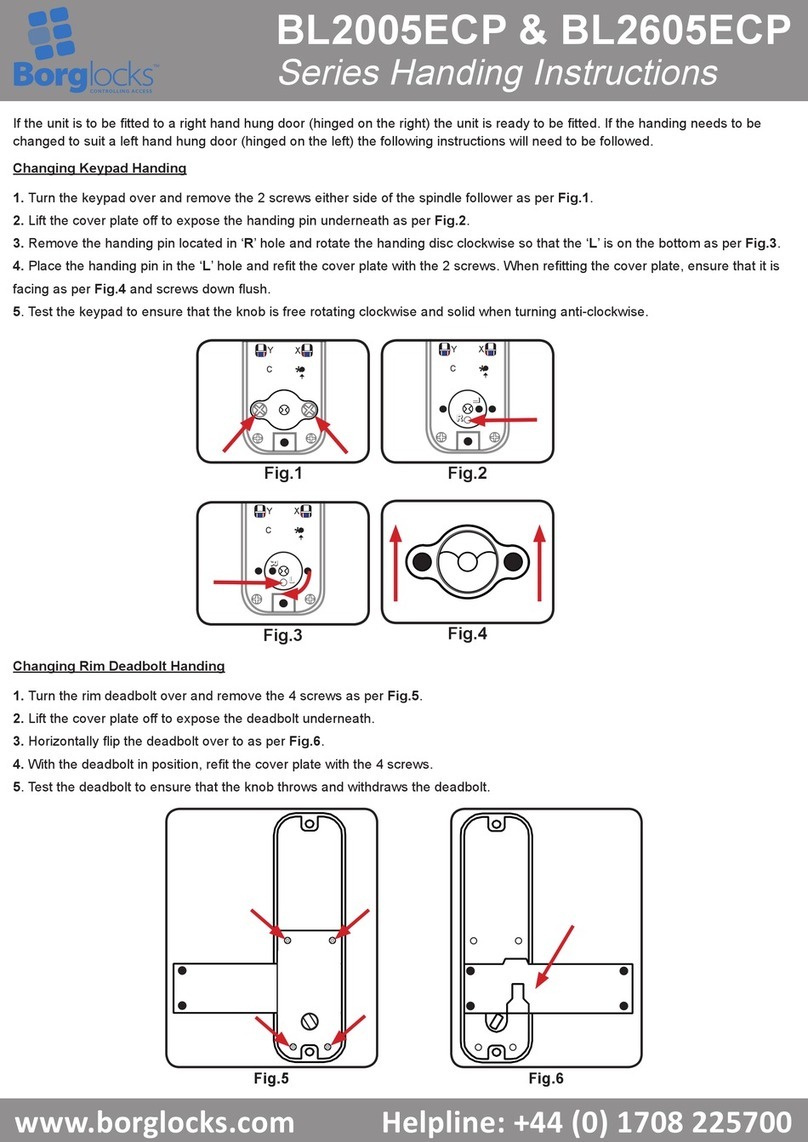

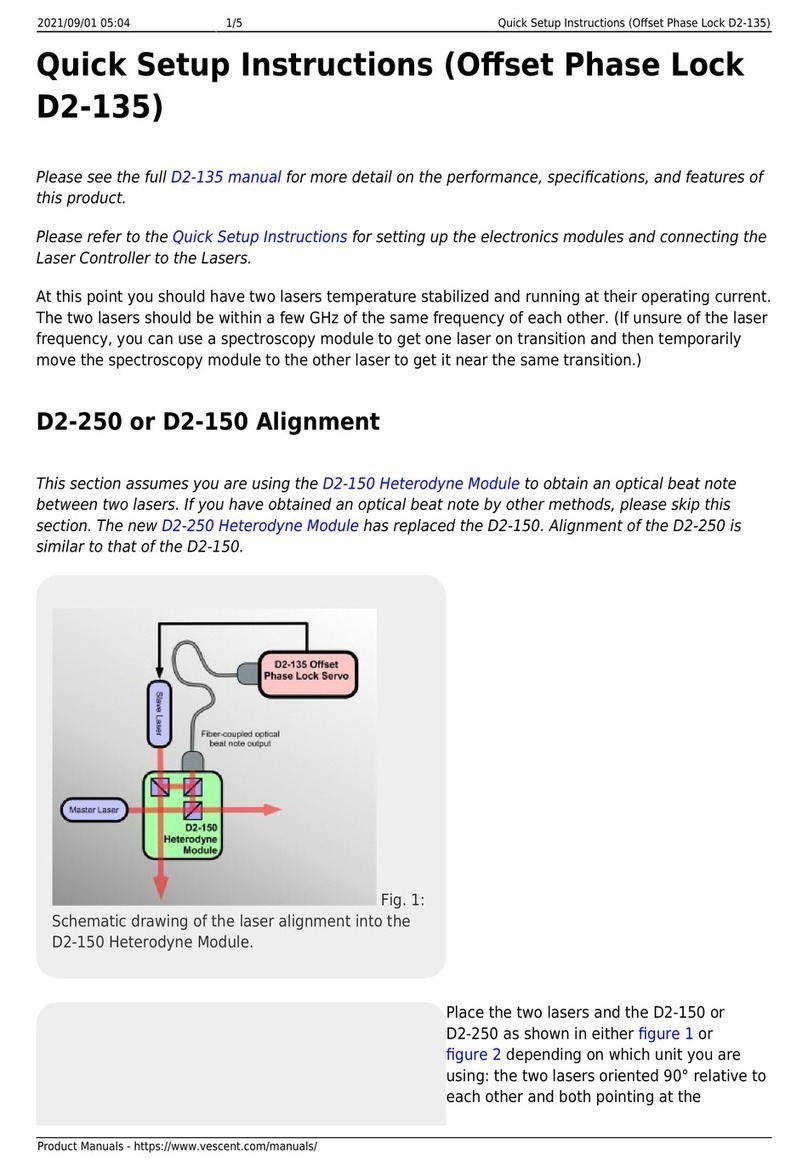

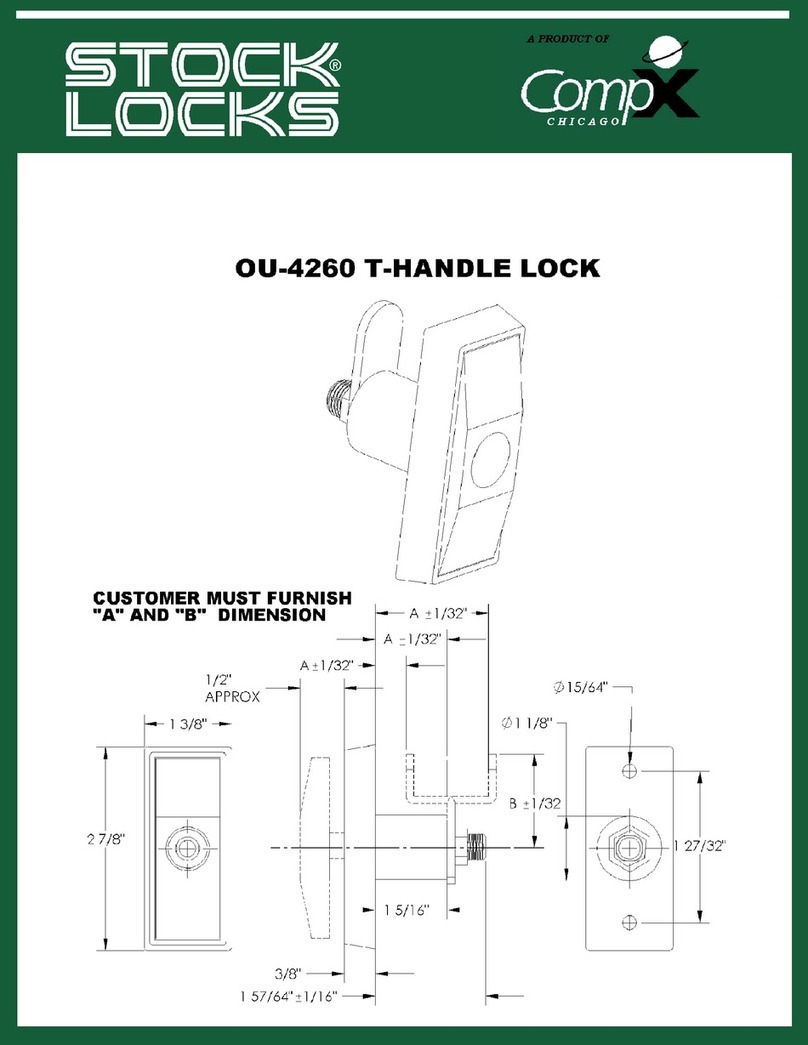

1. Using Diagram 3 determine which hand (left or right) lock you require for your specific application.

2. Using table 2A determine the length of the machine screws, hexagonal shaft and key stock spindle configuration

required for your gate or door thickness. This lock comes equipped to fit up to a 4 1/4” thick gate or door.

3. Using a hack saw cut the key stock spindle 1 5/8” longer than the thickness of your gate or door. Be careful the key

stock spindle is not cut too long as pinching it in between the two parts of the lock body when you install the

machine screws during assembly will possibly prevent free movement of the lock parts.

a. for gates or doors under the 1 ¾” thickness use the flat key stock spindle and cut to the appropriate length for

your application.

b. for gates or doors between 1 ¾ ” and 3” thick use the key stock spindle that is 135mm and has the heavier

“round” part in the middle – the heavier stock will resist twisting better at the longer lengths.

c. For gates or doors between 2 ¾” and 4 ¼” thick use the key stock spindle that is 160mm and has the heavier

“round” part in the middle – the heavier stock will resist twisting better at the longer lengths.

Note: Please take care in cutting the Keystock/Spindles that you cut the correct amount off each end. The Keystock/Spindle

seats into the back part of each half of the lock a different depth so you need to account for this when using the

Keystock/Spindles that are round in the middle – you will need to cut a little from both ends.

4. Using the supplied drilling template locate where the holes will be drilled in your gate or door by marking the

centres. NOTE: The horizontal placement of the lock does not have to match the “edge of door” reference on the

drilling template. As the latching bolt moves a full 1” in its action. If using in the mortised position for instance, it

may be advantageous to move the lock position backwards or forwards depending on your specific installation.

Please pay special attention to this step to ensure best results.

5. Once you have determined the locks most suitable position, mark the 3 hole centers for drilling, using the

appropriate sized bits. The template indicates 10mm (3/8”) and 13mm (½”) holes. Place a block on the opposite

side of the door or gate too minimize tear out while drilling.

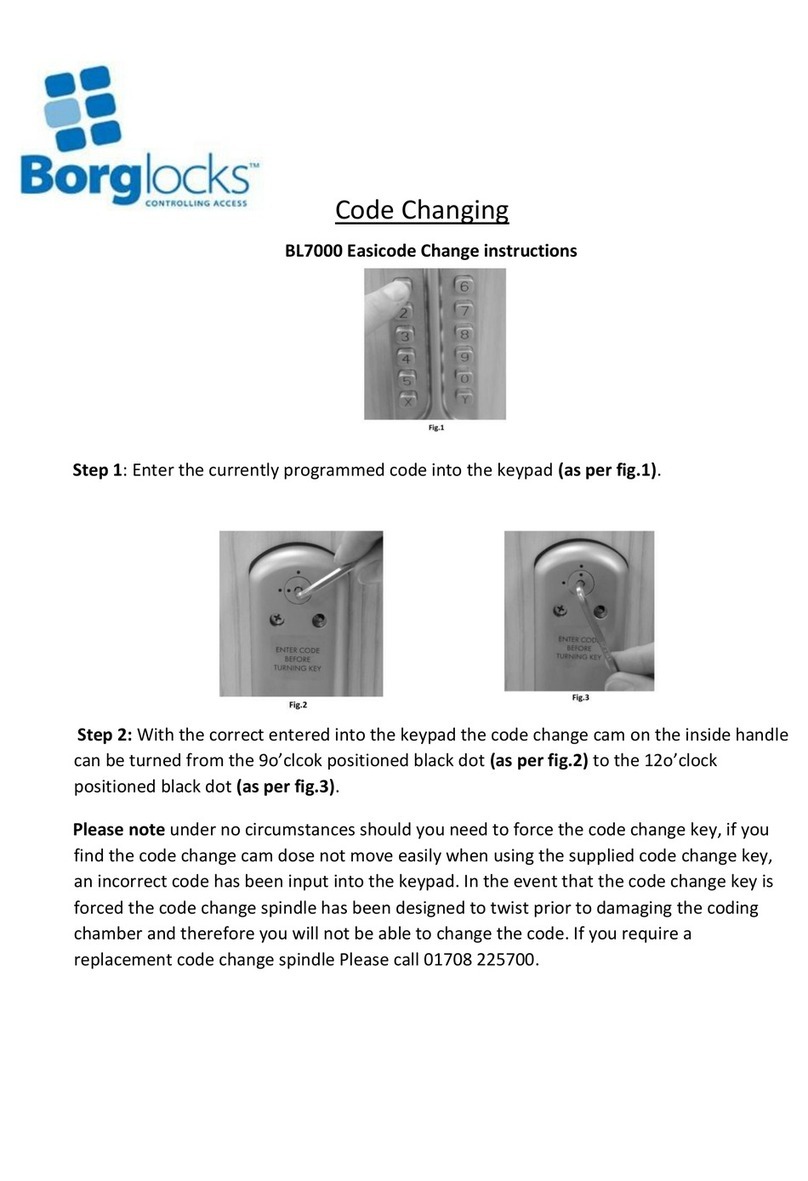

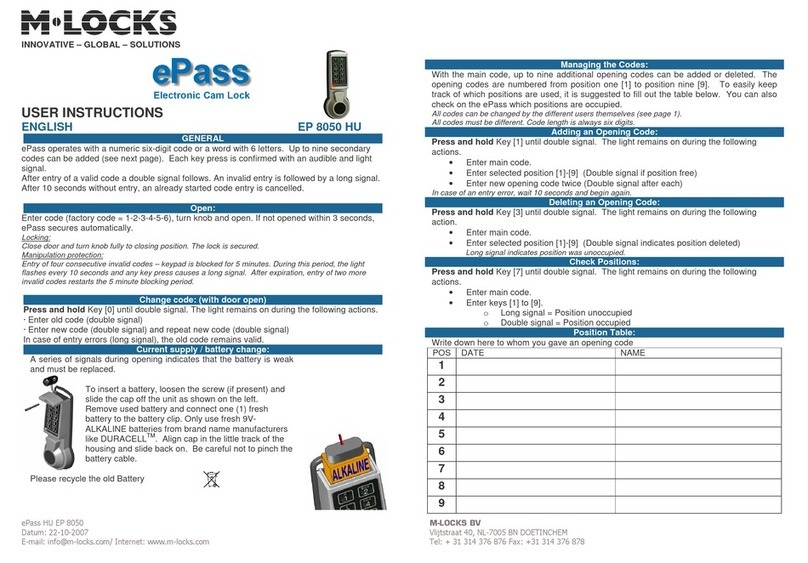

6. If you haven’t already changed the code or the handing, but wish to change the code or the handing, Please

refer to “How to Change Your Code” and “How to Change the Handing (Table 4A)” and do so now.

7. Add the black rubber lock base gaskets to each of the lock pieces at this time.

8. After reviewing the exploded view Table 5A - Carefully affix the lock to the door or gate using the appropriate sized

machine screws as determined in step 2. Be sure to install your key stock spindle at this time. NOTE: take great care

when starting the threads in the hexagonal shaft not to cross thread them. The threads are very fine- it is easy to

make a mistake. Tighten gently, do not overtighten.

9. Now the lock position is set you can install surface lock keeps for flush mount applications, or one surface lock keep

and one mortise lock keep for mortised installations. Both have elongated receiver slots to allow for some post

movement and settling.

10. Test the lock for accurate operation once complete

Maintenance Instructions

Monthly:

Clean the surface of the lock with a silicon based lubricant, remove any excess with a soft cloth. Do NOT use an oil based spray like

WD40 as this will attract dirt and debris.

Annually:

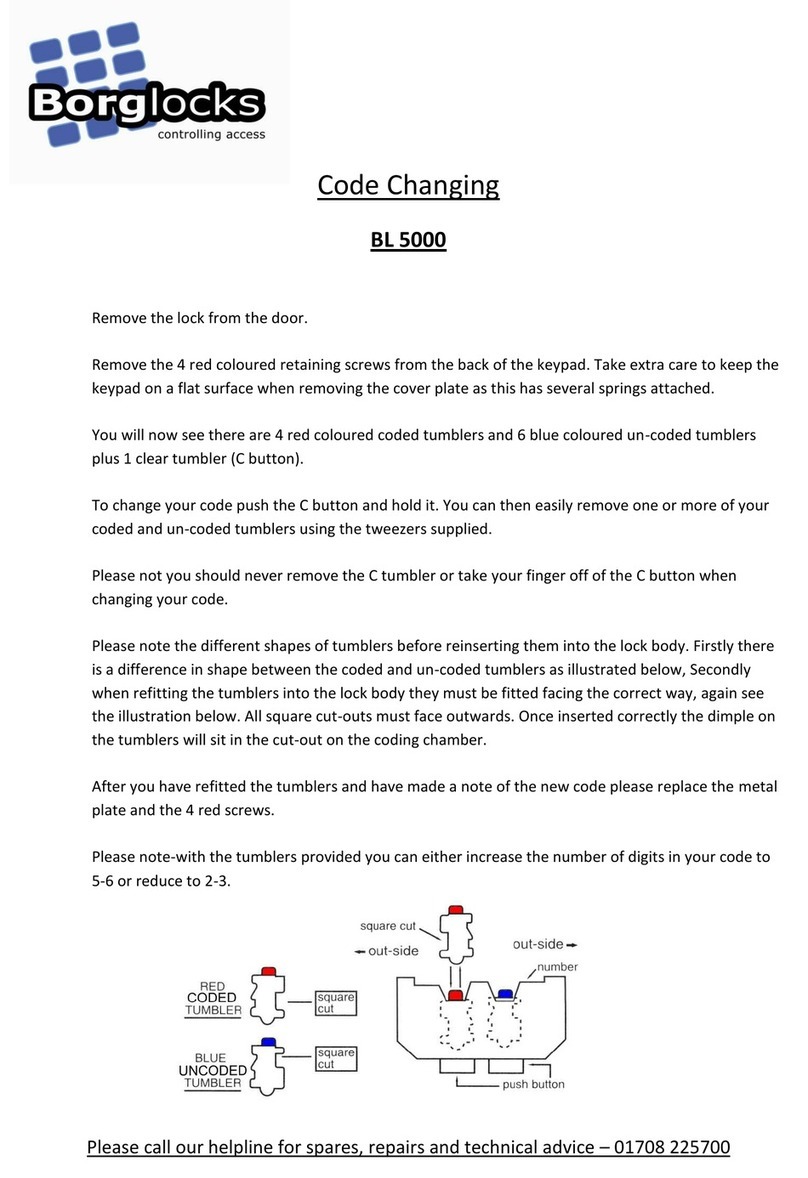

Remove the lock from the door.

Spray the inside of the lock thoroughly with a silicon based lubricant, through the tumbler holes at the back of the lock.

Spray all the fixing accessories and the latch with a silicon based lubricant.

Push each of the buttons and rotate the knob several times to ensure that the lock is working smoothly and the lubricant has

penetrated the lock appropriately. These procedures can be carried out as needed when lock is sticky or code is accepted

intermittently.

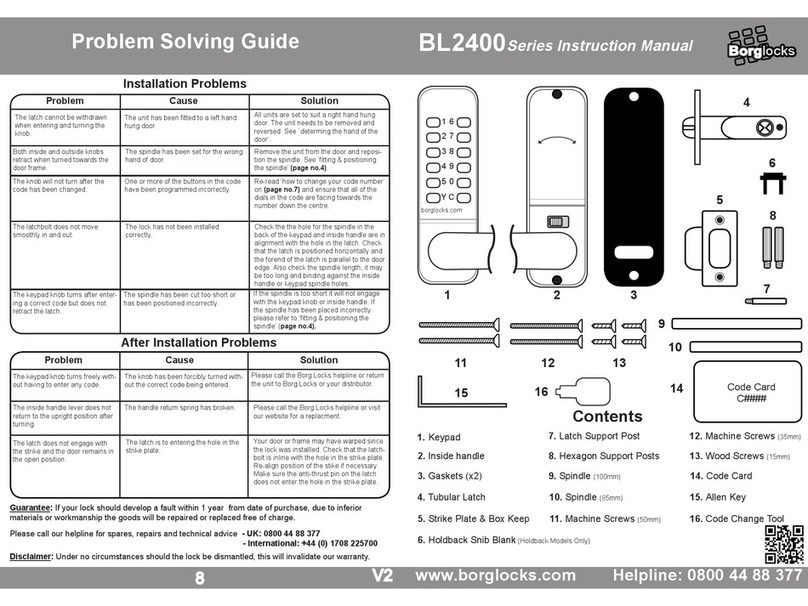

If you experience any problems when installing this lock, or changing the code please contact: