LCM SYSTEMS CDIT-1 User manual

LCM SYSTEMS

Solutions in Load Cell TechnologySolutions in Load Cell Technology

Instruction Manual

LCM Systems Ltd

Unit 15, Newport Business Park

Barry Way, Newport

Isle of Wight PO30 5GY UK

Tel: +44 (0)1983 249264

Fax: +44 (0)1983 249266

www.lcmsystems.com

Operator Instructions

for Tension and Compression

Load Cells

Types: CDIT-1, CDIT-3, CPA, CPW, DCE, PTC-1, STA-2,

STA-4, STA-7, TCA, WAS

LCM SYSTEMS

Solutions in Load Cell TechnologySolutions in Load Cell Technology

Load Cell Instruction Manual

CONTENTS

3. CABLE INFORMATION

3.1

3.2

Cable Gland and Connector Configurations

Mating and De-mating a Connector Assembly

6

6

5. NOTICES

5.1

5.2

Copyright

About LCM Systems

8

8

2. OPERATING INSTRUCTIONS

2.1

2.2

2.3

2.4

2.5

2.6

2.7

Installation and Operation

Fixtures and Fittings

Separately Mounted Telemetry Enclosure

Wiring and Electrical Checks

Load Cell Output Options

Instrumentation and Display Set Up

Checks After Installation

2

4

4

4

4

5

6

1. GENERAL INFORMATION

1.1

1.2

1.3

1.4

1.5

Introduction

Markings

Electromagnetic Compatibility (EMC)

Load Cell Type/Model Number

Contact Details

1

1

1

1

1

4. ONGOING MAINTENANCE AND CARE

4.1

4.2

4.3

4.4

Warnings/Hazards

Calibration

Inspection and Repair

Storage

7

7

8

8

1

1. GENERAL INFORMATION

1.1 Introduction

This instruction manual refers to the LCM Systems range of tension and compression load cells and

includes instructions for both cabled and telemetry options. Before installing or operating any LCM Systems

load cells, this and any reference documents should be read and understood.

These load measuring devices were designed and manufactured to be installed as partly completed

machinery into a machine or partly completed machine.

These instructions must be retained and incorporated in the technical documentation for the machine or

partly completed machinery into which the load link is installed.

All LCM Systems load cells are designed and manufactured to LCM Systems Quality Management System

which is written in accordance with ISO 9001:2008

1.2 Markings

Each load cell will be marked with an individual serial number and the SWL (Safe Working Load).

1.3 Electromagnetic Compatibility (EMC)

The electromagnetic compatibility of the load cell device can only be assessed in conjunction with the

entire installation, including its control systems. The machine builder who installs this partly completed

machinery into a machine is responsible for compliance with the EMC directive.

1.4 Load Cell Type/Model Number

Load Cell: CDIT-1, CDIT-3, CPA, CPW, DCE, PTC-1, STA-2, STA-4, STA-7, TCA, WAS and LCMXXXX (custom

design)

All LCM Systems load cell designs are allocated a unique LCM number/model number. LCM Number =

LCMXXXX (where X= 0-9 i.e. LCM5203) or a model number (i.e. CPA-10). LCM Systems send a drawing to

the customer for approval prior to the manufacture of any custom designed load cell.

Load Cell Instruction Manual

Supplier/Manufacturer:

LCM Systems Ltd

Unit 15, Newport Business Park,

Barry Way, Newport

Isle of Wight PO30 5GY

United Kingdom

Tel: +44(0)1983 249264

e-mail: [email protected]

Service: (REPAIR, SUPPORT)

LCM Systems Ltd

Unit 15, Newport Business Park,

Barry Way, Newport

Isle of Wight PO30 5GY

United Kingdom

Tel: +44(0)1983 249264

e-mail: [email protected]

1.5 Contact Details

2.1 Installation and Operation

To ensure safe and trouble free installation of the load measuring device, the load cell must be properly

transported and stored, professionally installed and placed in operation.

Unpacking

Before removing the load cell, inspect the packaging for signs of damage and immediately inform the supplier

if any damage is found. Unpack the load cell carefully, taking special care with cables and be aware to the

possibility of damaging low range devices by mishandling. Ensure that calibration and instruction information

is not inadvertently discarded.

Checks Prior to Installation

If the load cell is fitted with a cable and gland, check that the cable is held securely by the gland.

If the load cell is fitted with a connector, check the connector is secure to the load cell, check the plug

and socket for any damage and check that the connector mates correctly.

Check the cable for damage, such as cuts or abrasions, especially where the cable enters the gland or

connector assembly.

Check that the load cell has been suitably selected for the environment it is being placed into. Any

adverse temperature, corrosive or potentially explosive environments may affect the operational life and

the safety of the product.

If the load cell is fitted with a telemetry module, check that the 2 off AAA batteries are correctly installed,

that the two RED clips on the telemetry housing are closed and that the battery cover is secure. See

figure 1 for details.

Installation

When installing a load cell, various factors need to be considered which can influence the performance and

accuracy of the load cell.

Tension and compression load cells are generally installed using threads or threaded fasteners, although

some compression only devises can be left free standing. Generally the load cell accuracy is not affected by

the tightening torque on the fasteners, but torque loading either during installation or use should be avoided.

Where specific torque value on fixings are required, these will be shown on the products general

arrangement drawing.

To avoid loss of accuracy during installation, the following point should be followed:

LCM SYSTEMS

Solutions in Load Cell TechnologySolutions in Load Cell Technology

2

Figure 1

Load Cell Instruction Manual

Battery Cover

2 x AAA Batteries Mounting Disc

Telemetry Housing

Battery Cover Clips

Battery Holder

When installing using threaded fasteners, always make use of any spanner flats provided to ensure that

the transducer sensing element is not subject to torsion, as this may result in irreparable damage being

caused.

2. OPERATING INSTRUCTIONS

3

Load Cell Instruction Manual

Figure 2

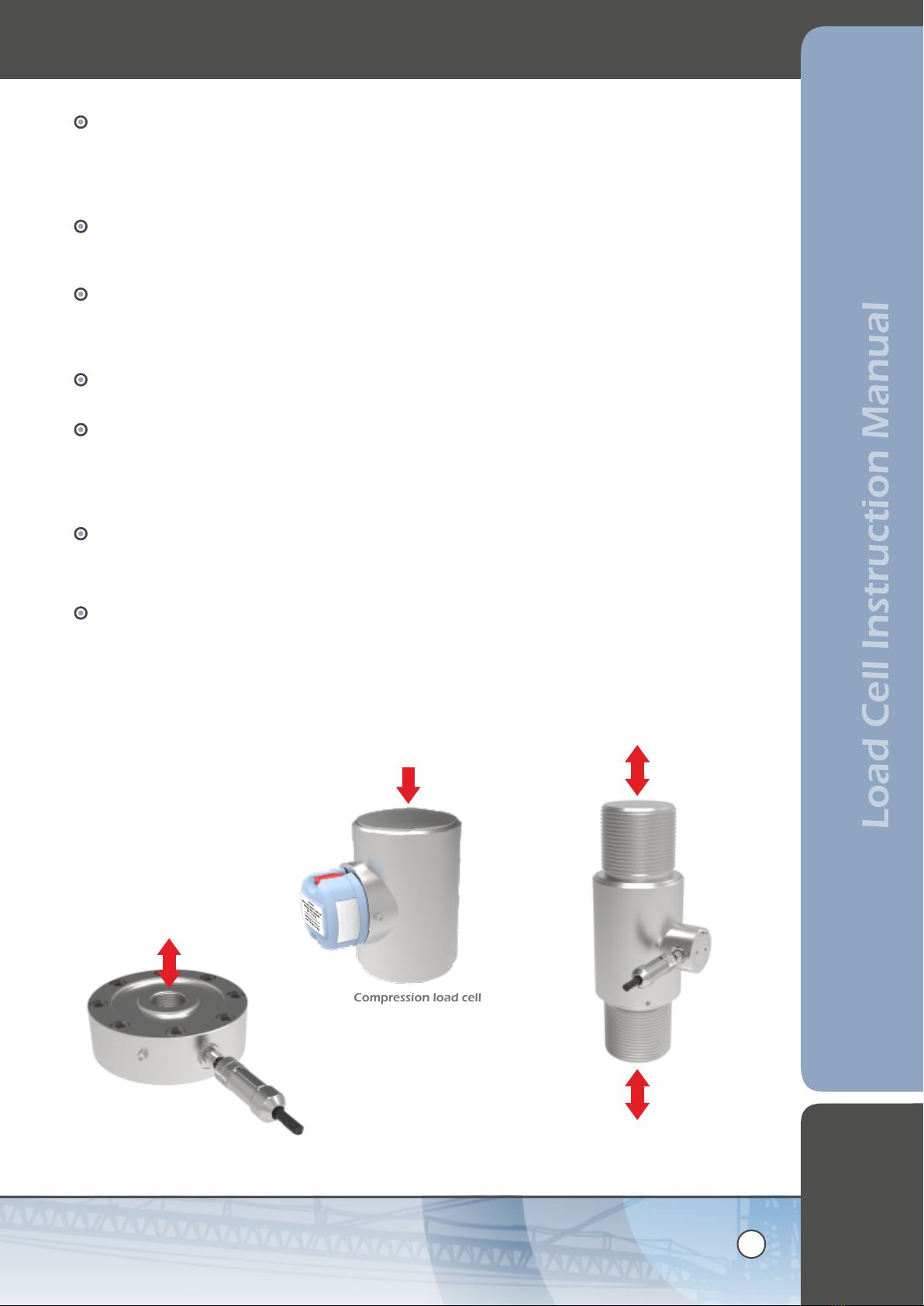

Ensure that the direction of load acting on the load cell is constant. In the case of compression cells

ensure that the load is applied centrally. Convex load buttons and caps are a convenient way of

ensuring this. In the case of tension load cells, swivel eyebolts at each end take out misalignment

during installation and service. The use of long loading rods in compression should be avoided, as

bending moment errors are magnified due to the long moment arm.

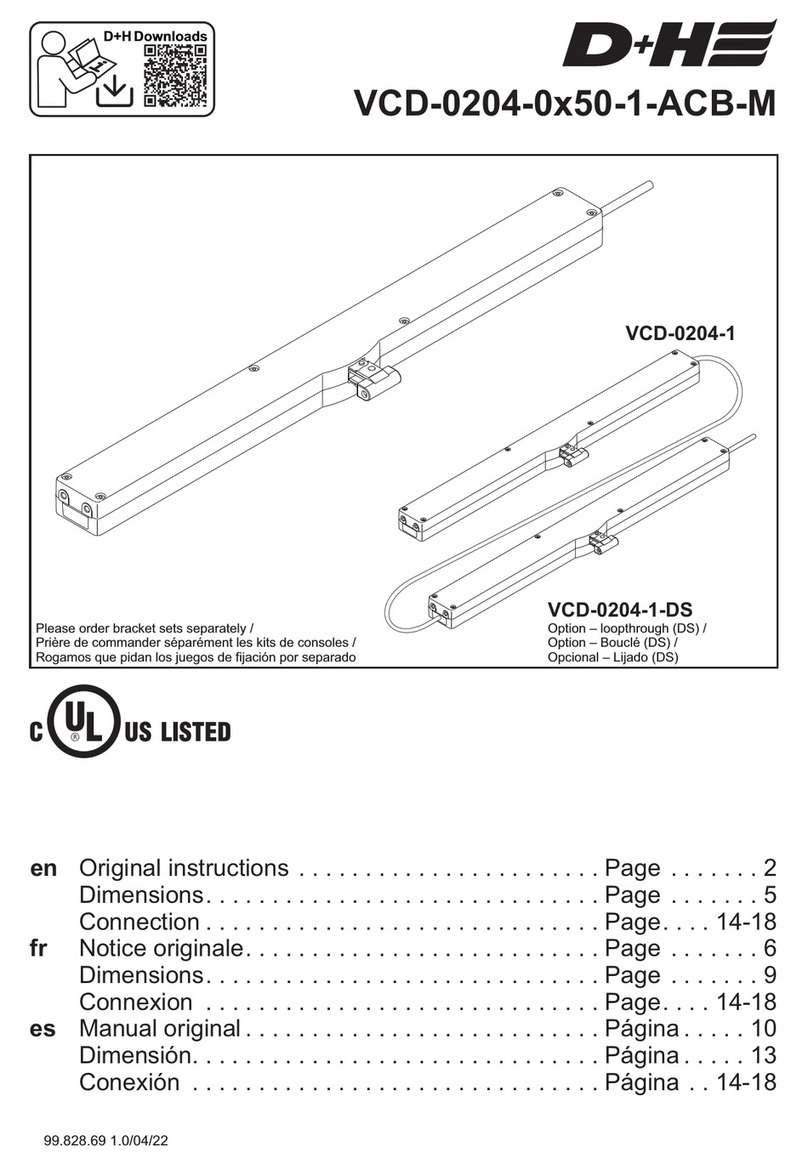

Tension and compression load cells should be loaded as shown below (Figure 2). In dynamic

applications the load cell rating should be de-rated by a factor of two, and care taken that bending is

not imposed on the transducer.

All tension and compression load cell should be installed so that side load is eliminated and generally

should not exceed 5% of the rated capacity, regardless of the rated maximum permissible value.

Depending on the design of the load cell, greater misalignments than this may lead to unacceptable

errors or damage to the load cell.

When installing tension load cells where vibration may be present, the use of thread locking

compounds or sprung vibration proofing devices (such as spring washers) is recommended.

If the load cell is fitted with a cable it must be installed in such a way as to avoid damage from impact,

abrasion or movement. The cable should be supported by cleats cable ties or in hose or conduit to

avoid flexing where possible. Ensure the cable is anchored on the ‘earth’ side of the load cell to

prevent the cable being part of the measurement loop. The installer must ensure that the cable meets

the operating requirements of the application.

Low profile load cells can be affected by both fastener torque and the quality and mechanical

stiffness of the mounting surface. For best results, the mounting surface should be flat to better than

0.03mm and be manufactured from hardened steel with a minimum hardness of 300 BHN. When

fixings are required, high tensile hexagon headed or socket cap bolts should be used, Grade 12.9.

If the load cell is fitted with a telemetry module there should be a clear line of sight between the

transmitter and receiver, and objects or structures must be kept a least one metre away from the

antenna (housed in the wireless enclosure) whenever possible. The installer should also first read the

T24 Telemetry User Manual, which can be found at the following web address:

http://www.lcmsystems.com/T24.

LOAD

Low profile tension &

compression load cell

LOAD

Tension & compression load cell

LOAD

Compression load cell

TYPE: CPW

LCM SYSTEMS

Solutions in Load Cell TechnologySolutions in Load Cell Technology

4

Load Cell Instruction Manual

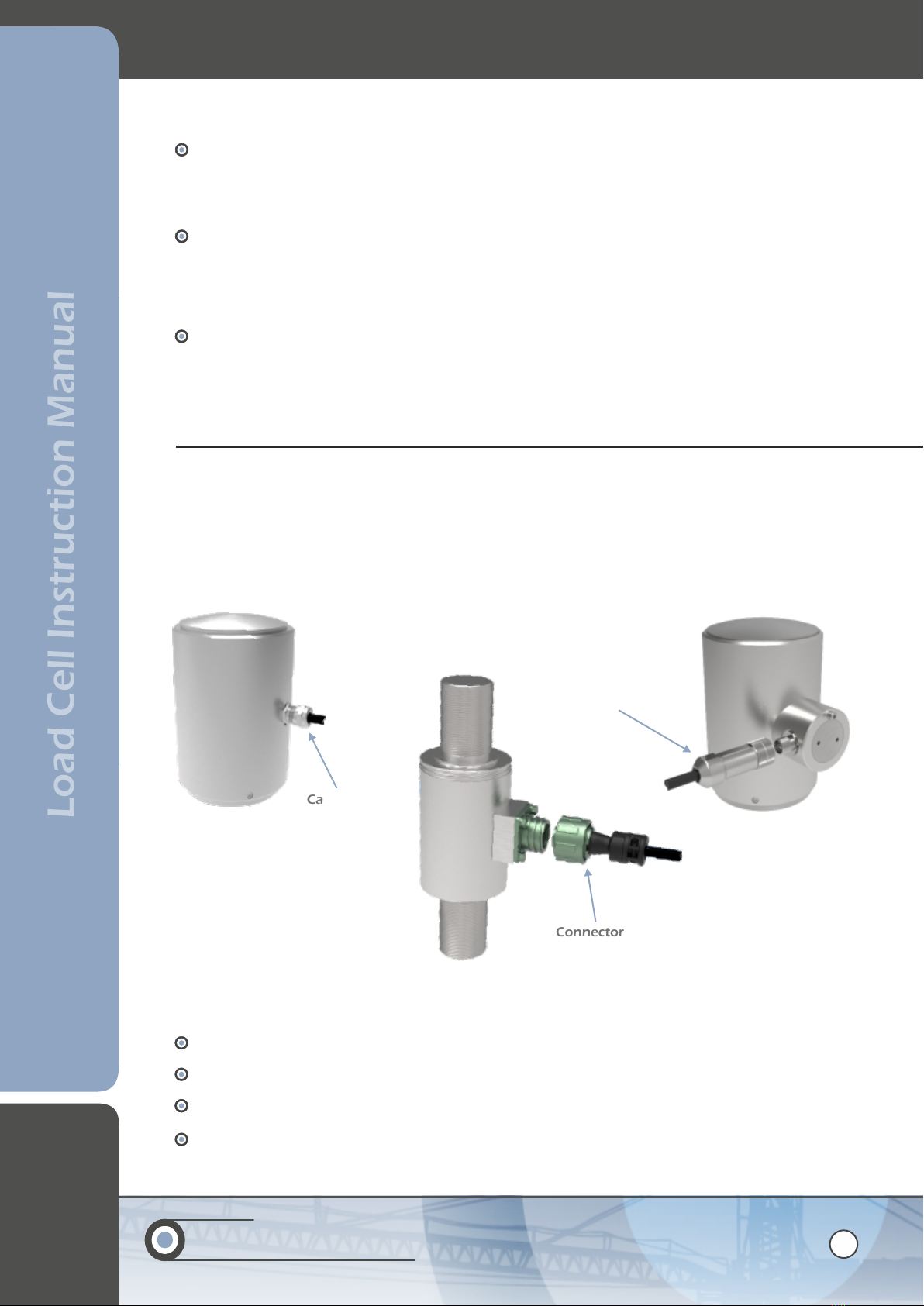

Each type of load cell can be supplied with a variety of fixtures and fittings that can be used to aid

installation. All fixtures and fittings should only be used in accordance with this manual, the load cells general

arrangement drawing (GA) and the manufacturers instructions.

2.2 Fixtures & Fittings

Load cap

Mounting base

Load cell Load cell

Spherical rod

end bearing

Base plate

Load fixture

Load cell

2.3 Separately mounted telemetry enclosure

Where the physical dimensions of a load cell are too small to accommodate the telemetry enclosure, or

where the location of the load cell means a clear line of site to the receiver is not possible, then a separately

mounted telemetry enclosure can be used. The maximum permissible cable length between the load cell and

the telemetry enclosure is 2.5 metres.

Checks to the cable gland or connector supplied with the telemetry enclosure should be performed in

accordance with the operator instructions for cabled load cells (refer to section 3.).

2.4 Wiring and Electrical Checks

The correct connection of a load cell to an instrument is critical to achieving and maintaining the performance

and reliability of the load cell.

Wiring connections are given on the calibration certificate supplied with each load cell.

Where a screened cable is fitted, that screen should be connected as indicated in the manual for the

instrument the load cell is connected to.

Cable length should not be added or removed from the load cell, as this could alter the calibration

figures.

Where junction boxes are used, check the connections are good quality and securely connected. Clean

the enclosure and check that it is free from moisture.

Load cell cabling must be kept away from high power cables and equipment, high output RF equipment

and inductive loads and generators. Cables must not be run alongside power cables.

2.5 Load Cell Output Options

The load cell can be fitted with a variety of built in (in-cell) signal conditioning boards, to offer either

analogue, voltage, current signals or RS485 digital signals (in various protocols). When a wireless signal is

required, the load pin can be fitted with a T24 Telemetry Module as shown in Figure 1.

DCELL

The DCELL Digital Signal Conditioning (amplifier) board offers high speed, RS485 and CANBus outputs in

several protocols.

DCELL Communication: RS485 Baud Rate

Protocols

See the DCELL Datasheet and Instruction Manual for further details:

5

Load Cell Instruction Manual

ICA

The ICA analogue signal conditioning (amplifier) board is available in six versions, offering a range of

current and voltage outputs. All amplifiers have a wide operating voltage range.

ICA1 - 3 wire, 0.1 to 10.1V

ICA2 - 3 wire, 0.1 to 5.1V

ICA3 - 4 wire, ±10V

ICA4 - 3 wire, 4 to 20mA

ICA5 - 2 wire, 4 to 20mA

ICA6, 3 wire , ±10V

See the ICA Datasheet and Instruction Manual for further details:

2400 Min to 230K Max

ASCII

MANTRABUS II

Modbus RTU

MANTRACAN

Telemetry

The T24 product range uses high performance two-way radio communication which operates on the 2.4

GHz licence free frequency. Each load cell fitted with the telemetry module requires either a T24 handheld

device, digital/analogue interface or a base station and PC to communicate with. See the T24 User Manual

for further details on the T24 range of products:

2.6 Instrumentation and Display Set Up

The electrical output of the load cell should be connected only to instrumentation with a high enough

input impedance, preferably 1Mohm or greater, in order to prevent loading effects on the output sensitivity

of the load cell. LCM Systems offers a wide range of digital and analogue instruments ensuring compatibility.

When setting up your load cell the following points should be acknowledged:

The zero load output given on the calibration certificate is the output of the load cell when no load is

applied.

Check the calibration certificate for details of the load cell output.

http://www.lcmsystems.com/ICA_In-Cell_Analogue_Strain_Gauge_Amplifier

http://www.lcmsystems.com/DCELL_In-Cell_Digital_Strain_Gauge_to_Data_Converter

http://www.lcmsystems.com/T24

LCM SYSTEMS

Solutions in Load Cell TechnologySolutions in Load Cell Technology

6

Load Cell Instruction Manual

2.7 Checks After Installation

With the load cell installed, check that when a load is applied the output is in the correct direction in

accordance with the calibration certificate. Incorrect positive or negative outputs could be a result of

incorrect electrical connections or a side force is being applied to the load cell. Refer back to section 1.5

and figure 2 for details on correct loading.

When applying load to the load cell use the calibration certificate for reference as to the output observed

at certain loads. If this is not the same then check the following:

a. All electrical connections are correct i.e. to an instrument or junction box.

b. If a connector is fitted, check that it is fully mated.

For wireless load cells, check the receiver communicates with the load cell at the desired operating

range. Signal obstruction or reflection can significantly reduce transmission range and even cause signal

loss.

3. CABLE INFORMATION

All non wireless load cells are fitted with either a cable gland or connector assembly. Cable exits are either

perpendicular to the load direction or mounted radially from a boss. See below for examples. All wiring

colours and connector pin details are shown on the calibration certificate supplied with each load cell. The

removal or replacing of the cable gland or bulkhead connector is not recommended, and any adjustment or

repair should either be preformed by LCM systems or by a suitably qualified engineer.

Connector

Cable gland

Connector

3.1 Cable gland and connector configurations

3.2 Mating and de-mating a connector assembly

Check both halves of the connector for any damage or obstructions.

Align the connector assembly and mate the two halves. Press firmly to ensure they are fully engaged.

Tighten the locking sleeve (finger tight only) to complete the mating process.

Always fully disengage the locking sleeve before attempting to un-mate the connector.

7

Load Cell Instruction Manual

4. ONGOING MAINTENANCE AND CARE

4.1 Warnings/Hazards

Tension and compression load cells are highly stressed devices and commonly have safety factors between

three and five times the rated capacity under static conditions. Fatigue applications and environmental

factors can contribute to reducing this margin.

The user should determine media effects on the exposed load cell materials. Where a corrosive environment

is present, load cells can often be manufactured from corrosion resistant materials or alternatively, isolation

barriers can be employed between the corrosive environment and the load cell. The following points should

be followed to avoid potentially dangerous situations and/or damaging the load cell:

Check for excessive wear on the load cell which could compromise performance or the IP rating.

Tension and compression load cells are sealed units which should not be dismantled. When an

amplifier is fitted, removing the cap is permitted, but only to adjust the span and zero when performing

a calibration. This should only be done by a competent person. Damaged load cells should be returned

to LCM Systems for repair and re-calibration.

The accuracy of the system is dependent upon correct installation of the load cell.

Tension and compression load cells must not be subjected to shock loads, such as using a hammer to

force the load cell into position.

Load cell material and any applied treatments (heat treatments etc.) should be verified as suitable for

the environment before the load cell is installed. Some heat treatments which LCM use are not suitable

for marine environments/high chloride (for example, 17-4PH heat treated to H900).

Fixing methods (high tensile bolts, rod end fittings or mounting bases) must always be installed as to

the general arrangement (GA) drawing or to the manufacturers instructions.

Avoid use within 20 to 30 minutes of rapid changes in temperature, for example moving the device

from a cold vehicle to a warm room. The change in temperature can affect the accuracy of the device.

The operating temperature is -20 to +70ºC or -4 to 158ºF.

Do not weld near to installed load cells, as leakage currents may destroy the load cells electric circuits.

Load cells should not be handled or carried by means of the cable.

4.2 Calibration

All LCM Systems load cells are calibrated in UKAS traceable test machines to best simulate normal loading

conditions.

We endeavour to match the loading conditions that would be experienced in service but it is not possible

to totally simulate the on-site structure for every load cell manufactured. It is for this reason that for

optimum system accuracy, a calibration in the final assembly is recommended. On-site calibration should be

performed in accordance with the manual for the instrument the load cell is connected to.

As all load cells are subject to deterioration due to use, mistreatment, drift or ageing, calibration at regular

intervals should to be carried out to establish how the load cell is currently performing. Load cells can also

become less reliable due to electrical influence, mechanical effects and instrumentation faults. Unless

calibrations are routinely carried out, load measurement readings can become less accurate, with the user

potentially being unaware that they are using compromised data.

Annual calibration is recommended as the standard interval to ensure that measurements are always as

accurate as possible, which is particularly important if being used for safety critical applications. However,

more frequently than one year may be advisable if the load cell is being used in a particularly harsh

environment or arduous operational conditions (high vibration levels, excessive cyclic loading).

LCM SYSTEMS

Solutions in Load Cell TechnologySolutions in Load Cell Technology

8

Load Cell Instruction Manual

4.3 Inspection and Repair

Repair

Only LCM Systems personnel are authorised to carry out a repair to or service their products. All repairs or

servicing will be carried out in the premises of LCM Systems. The unit is not serviceable outside of LCM

Systems premises.

Inspection

All LCM Systems load cells should be subject to periodic inspection, which should include, but is not

exclusive to the following checks:

Completion of the checks after installation, see section 2.7 (Checks After Installation).

Check output at zero load (shift in zero offset). Verify against calibration certificate.

Inspect to see if the load cell has been damaged/worn or chemically attacked (from a corrosive

environment or lubricants etc.).

For cabled versions, verify the integrity of the cable.

For wireless versions, inspect the batteries to ensure they are the correct type and have been installed

correctly. The battery holder shows pictorially the correct orientation. Check for any signs of water

ingress in the battery compartment and for any signs of battery corrosion.

After any serious operating incident, repeat first five checks above.

4.4 Storage

When not in use load links should be stored undercover in a dry environment (max humidity 95% non-

condensing) at a storage temperature of -40ºC to +85ºC.

5. NOTICES

The copyright and all rights of a like nature in respect of this document in any part of the world are the

property of LCM Systems Ltd.

No part of this document may be reproduced or transmitted in any form or by any means, whether

electronic, mechanical, photocopying, recording or otherwise, nor used for tendering or manufacturing, nor

communicated to any other person without the written permission of LCM Systems Ltd.

The recipient of this document, as its registered holder, must exercise due diligence in ensuring that the

above conditions are observed. (errors and omissions excepted). Any enquires relating to this document or

its contents should be addressed, in writing, in the first instance to LCM Systems Ltd.

LCM Systems Ltd reserve the right to make changes to its products and specifications without notice.

5.1 Copyright

LCM Systems is a specialist provider of standard and bespoke load cells, load pins, load shackles, load links

and associated instrumentation, with over 30 years' experience in supplying innovative load measurement

solutions to many different industries worldwide. Whatever the application and however demanding the

environment, we can provide a system to meet your needs.

5.2 About LCM Systems

9

Load Cell Instruction Manual

IF IN DOUBT ABOUT ANY ASPECT OF THE SELECTION,

INSTALLATION OR USE OF A TENSION & COMPRESSION

LOAD CELL, CONTACT LCM SYSTEMS FOR ADVICE

BEFORE INSTALLING

LCM Systems Ltd

Unit 15, Newport Business Park

Barry Way, Newport

Isle of Wight PO30 5GY UK

Tel: +44 (0)1983 249264

Fax: +44 (0)1983 249266

www.lcmsystems.com

www.lcmsystems.com

Issue 1

Issue date: /0 /2027 5 22

APPROVED

(Unapproved if printed)

This manual suits for next models

7

Table of contents

Other LCM SYSTEMS Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

STIEBEL ELTRON

STIEBEL ELTRON HSBC 225 S Operation and installation manual

EPPINGER

EPPINGER PSC SVC Product information

Texas Automation Products

Texas Automation Products DES-42 C4 manual

eqss

eqss JLG ES Series installation manual

Omron

Omron V460-H Network Connection Guide

Lincoln Electric

Lincoln Electric Statiflex 6000-MS Operator's manual