eqss JLG ES Series User manual

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

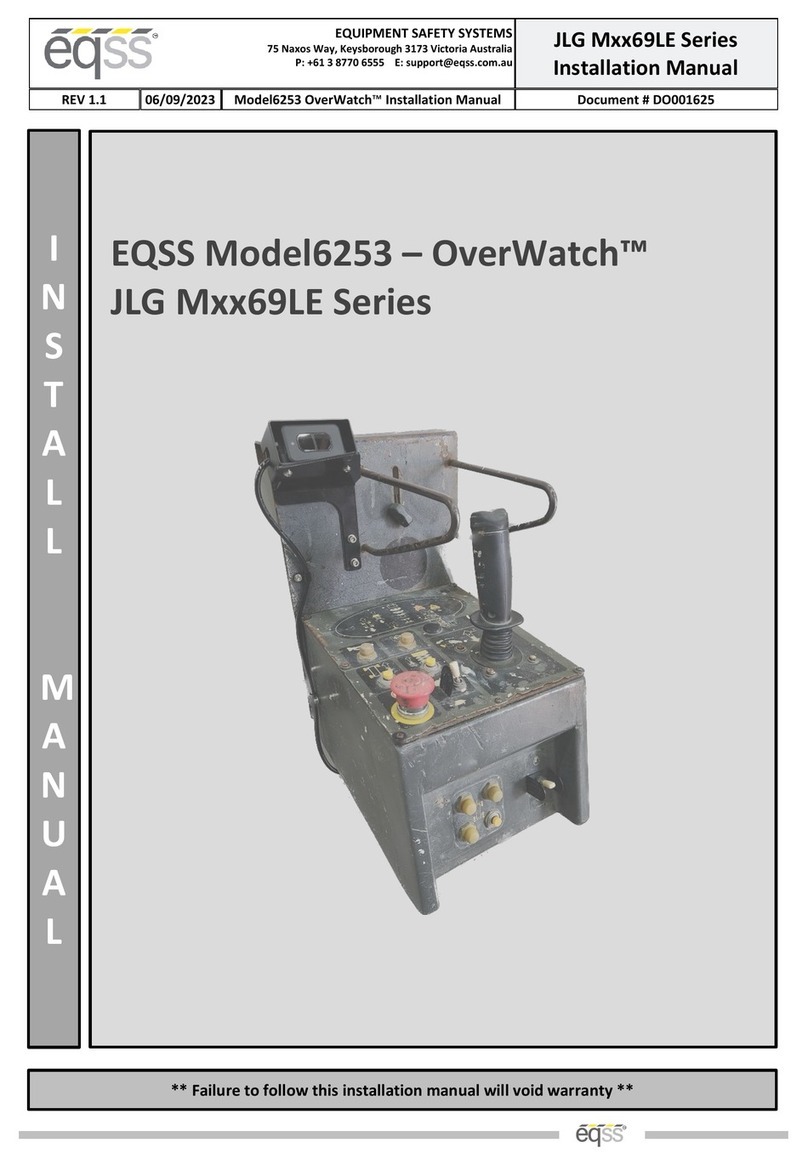

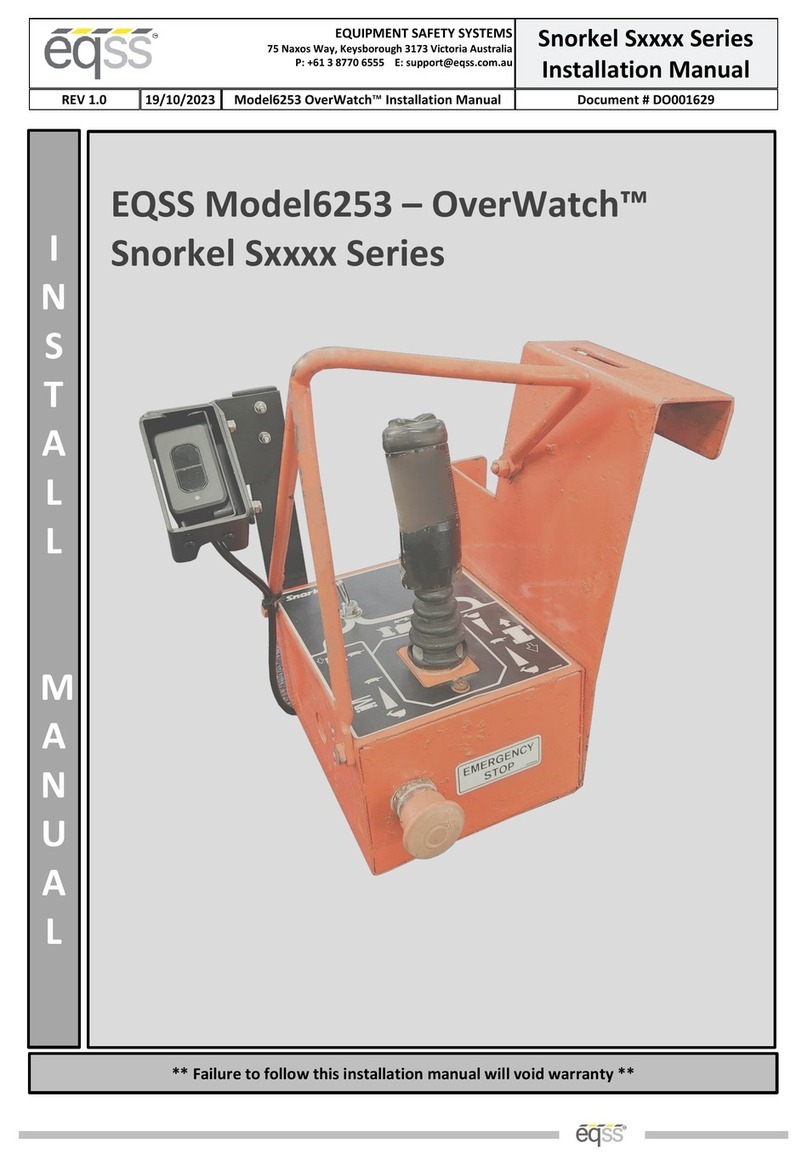

EQSS Model6253 –OverWatch™

JLG ES Series

I

N

S

T

A

L

L

M

A

N

U

A

L

** Failure to follow this installation manual will void warranty **

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|2 of 20|

AUTHORS:

Kieren Grogan, Truong Bui

AUTHORISED BY:

Kieren Grogan

CHECKED BY:

Andrew Donegan

DOCUMENT ABSTRACT:

This Installation Manual details the manufacturer’s installation instructions for installing the Model6253 OverWatch™ on a JLG

ES Series Scissor Lift using the plug and play loom.

PRODUCT NAME:

Model6253 OverWatch™ Operator Detection System

REFERENCE DOCUMENTS:

DO0001195 Model6253 OverWatch™ User Manual

CURRENT DOCUMENT REVISION:

1.4

REVISION INFORMATION:

•1.0 Initial Document Creation for system installation on a JLG ES Series Scissor Lift

•1.1 Update of wire connection and sensor mounting instructions

•1.2 Update of schematic

•1.3 Update to be suitable with quick connect harness installation.

•1.4 Update on installation procedures to use Plug and Play loom

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|3 of 20|

Important Information

Information contained in this publication regarding this device’s applications and the like, is provided only for your

convenience and may be superseded by updates. It is your responsibility to ensure that the application or our

equipment meets with your specifications.

EQUIPMENT SAFETY SYSTEMS MAKE NO REPRESENTATIONS OR WARRANTIES OF ANY KIND, WHETHER EXPRESSED OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR OTHERWISE, RELATED TO THE INFORMATION, INCLUDING, BUT NOT

LIMITED TO, IT’S CONDITION, QUALITY, PERFORMANCE, MERCHANTABILITY OR FITNESS FOR PURPOSE.

Equipment Safety Systems disclaims all liability arising from this information and its use. Use of Equipment Safety

Systems’ products as critical components in life support systems is not authorised except with express written

approval by Equipment Safety Systems. No licenses are conveyed, implicitly or otherwise, under any Equipment Safety

Systems intellectual property rights.

This is a class A product certified to AS/NZS CISPR 22:2006. In a domestic environment this product may

cause radio interference in which case the user may be required to take adequate measures.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|4 of 20|

Table of Contents

Preparation.........................................................................................................................................................................5

Required Tools ...............................................................................................................................................................5

Installation Time ............................................................................................................................................................ 5

Installation Instructions......................................................................................................................................................6

Operator Sensor............................................................................................................................................................. 6

Control Module..............................................................................................................................................................8

Post Installation Configuration .........................................................................................................................................13

Overview...................................................................................................................................................................... 13

Minimum system requirements .................................................................................................................................. 13

Wi-Fi Connection & Web Page Access ......................................................................................................................... 13

Machine Model Selection ............................................................................................................................................14

Installation Test............................................................................................................................................................ 15

Change Model Configuration.......................................................................................................................................16

System Settings.................................................................................................................................................................17

Default Settings............................................................................................................................................................17

Polarity and Input Style................................................................................................................................................ 19

Bypass .......................................................................................................................................................................... 19

Date and Time..............................................................................................................................................................19

Connection Schematics.....................................................................................................................................................20

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|5 of 20|

Preparation

Required Tools

The OverWatch™ has been designed to be fitted using basic workshop tools. Shown below is a list of tools required

to complete the installation

Item

Tool / Description

1

Electric Drill

2

Centre punch

3

Hammer

4

Side Cutters

5

Drill 3.2mm

6

Drill 5.0mm

7

Metric sockets or spanners

8

Needle nose pliers

9

Screw drivers

Installation Time

The suggested time required to install the OverWatch™ is as detailed below

Task

Estimated Time (Minutes)

Open the operator control box

5

Drilling of all mounting holes for the various components

15

Mechanical assembly

10

Electrical assembly

5

Post installation system tests

10

Close the operator control box

5

Total

50

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|6 of 20|

Installation Instructions

Operator Sensor

Step

Description

Diagram

1.

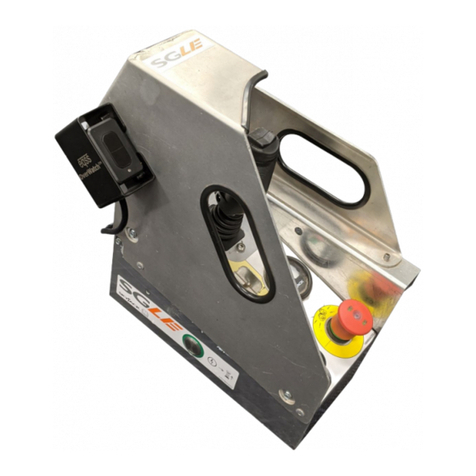

Mount the operator

sensor to the supplied

bracket, using the

supplied M4 washers

and security bolts, and

position the bracket in

the location shown in

the image.

When the sensor is

mounted on narrow

deck machines the

sensor should twist

towards the joystick. The

idea is to make sure that

the sensor is pointing

towards the operators

body centreline.

2.

Mount the module in the

located position using

the supplied M4

washers, nuts and

security bolts.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|7 of 20|

Step

Description

Diagram

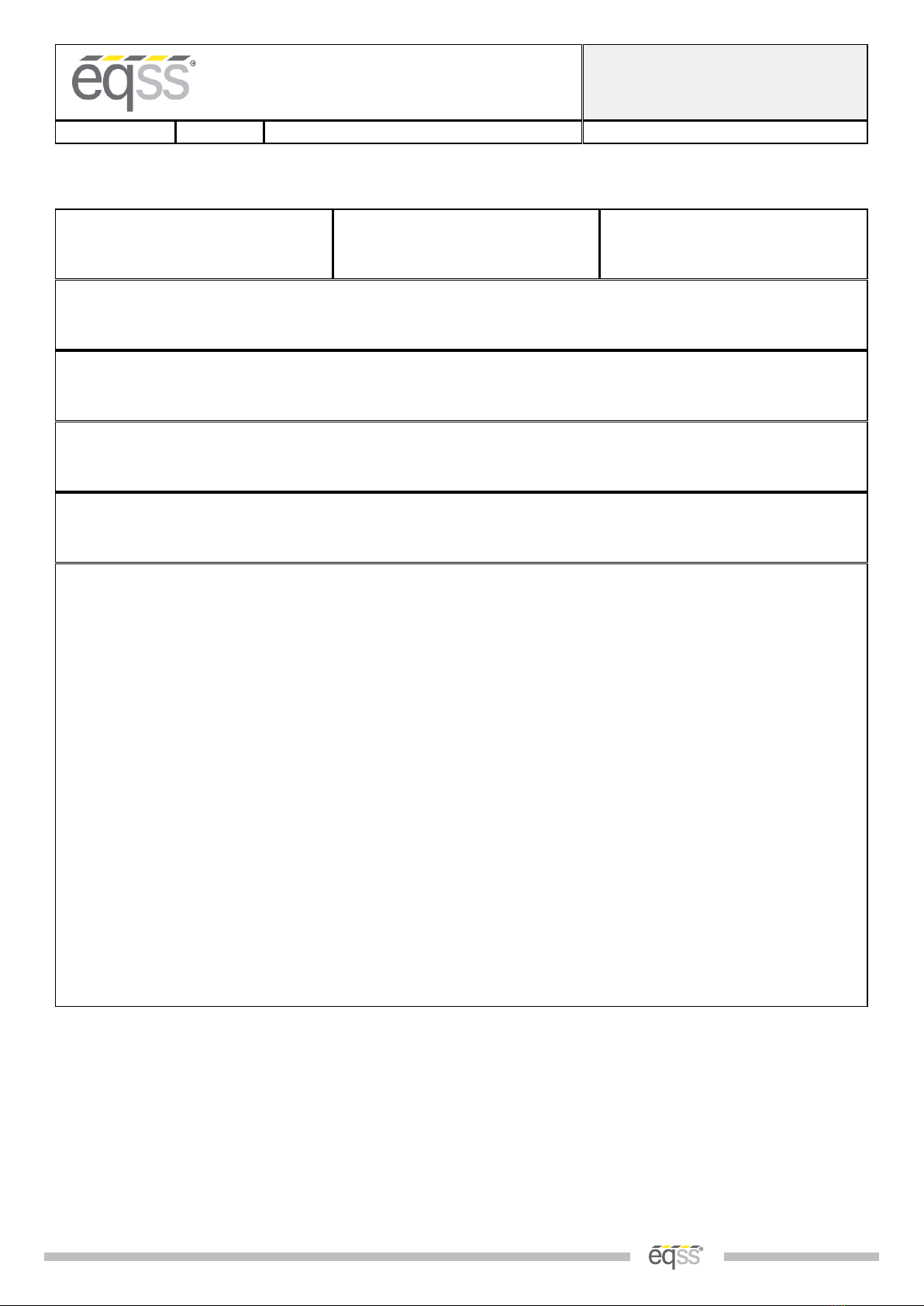

3.

Remove the outer

enclosure.

Install the supplied M20

cable glands in the

location shown in the

image and feed the wire

from the operator

sensor into the

enclosure.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|8 of 20|

Control Module

Step

Description

Diagram

1.

Wiring connections are

made by the Plug and Play

loom AS001937.

2.

The following connections

will need to be done in the

bottom module.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|9 of 20|

Step

Description

Diagram

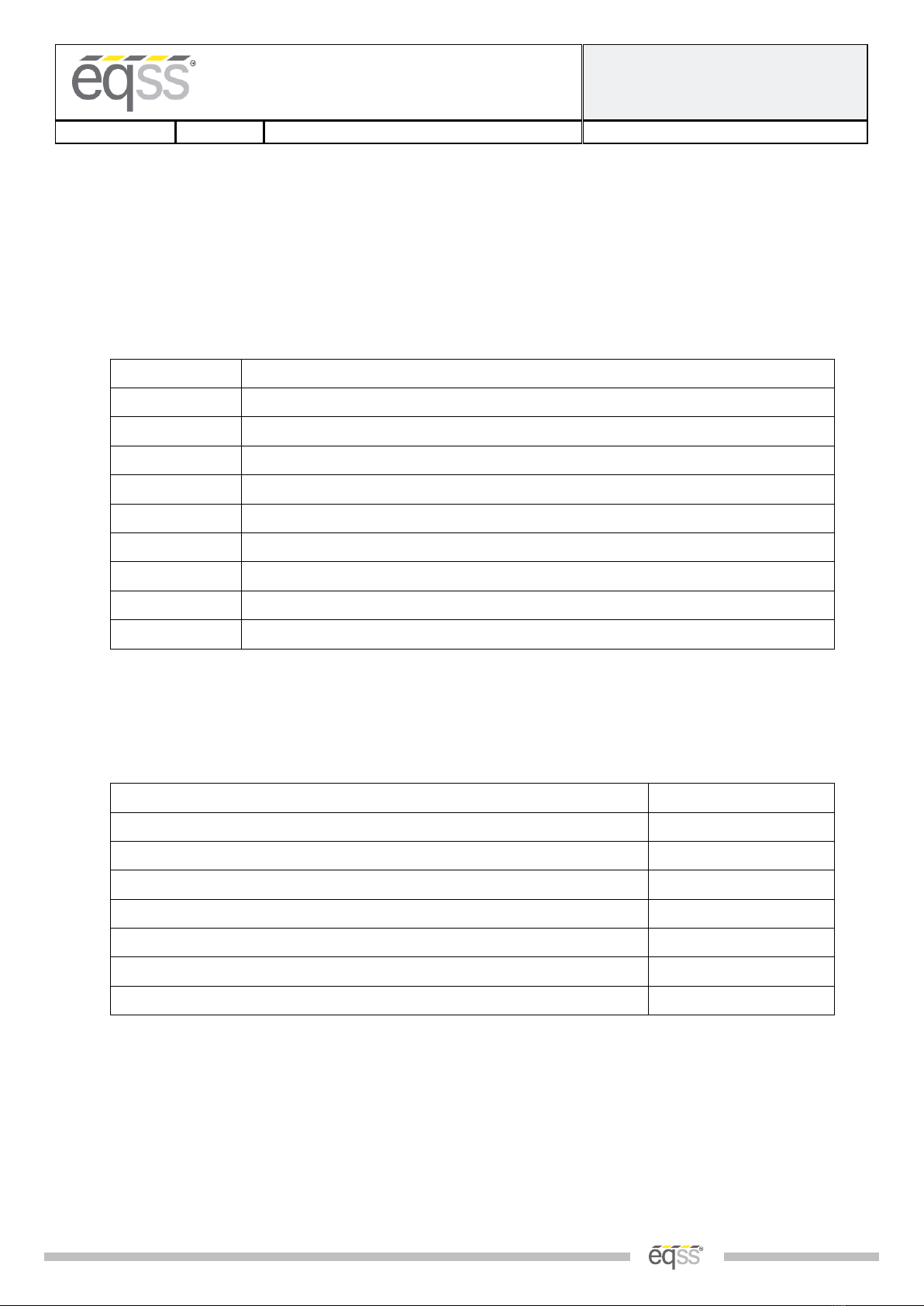

3.

Joystick and power:

Disconnect the 9-pin

connector from the JLG

joystick and install the

OverWatch™ Harness in

series.

4.

Buzzer:

At the back the buzzer,

disconnect the orange cable

on the Negative side and

install the OverWatch™

harness white cable.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|10 of 20|

Step

Description

Diagram

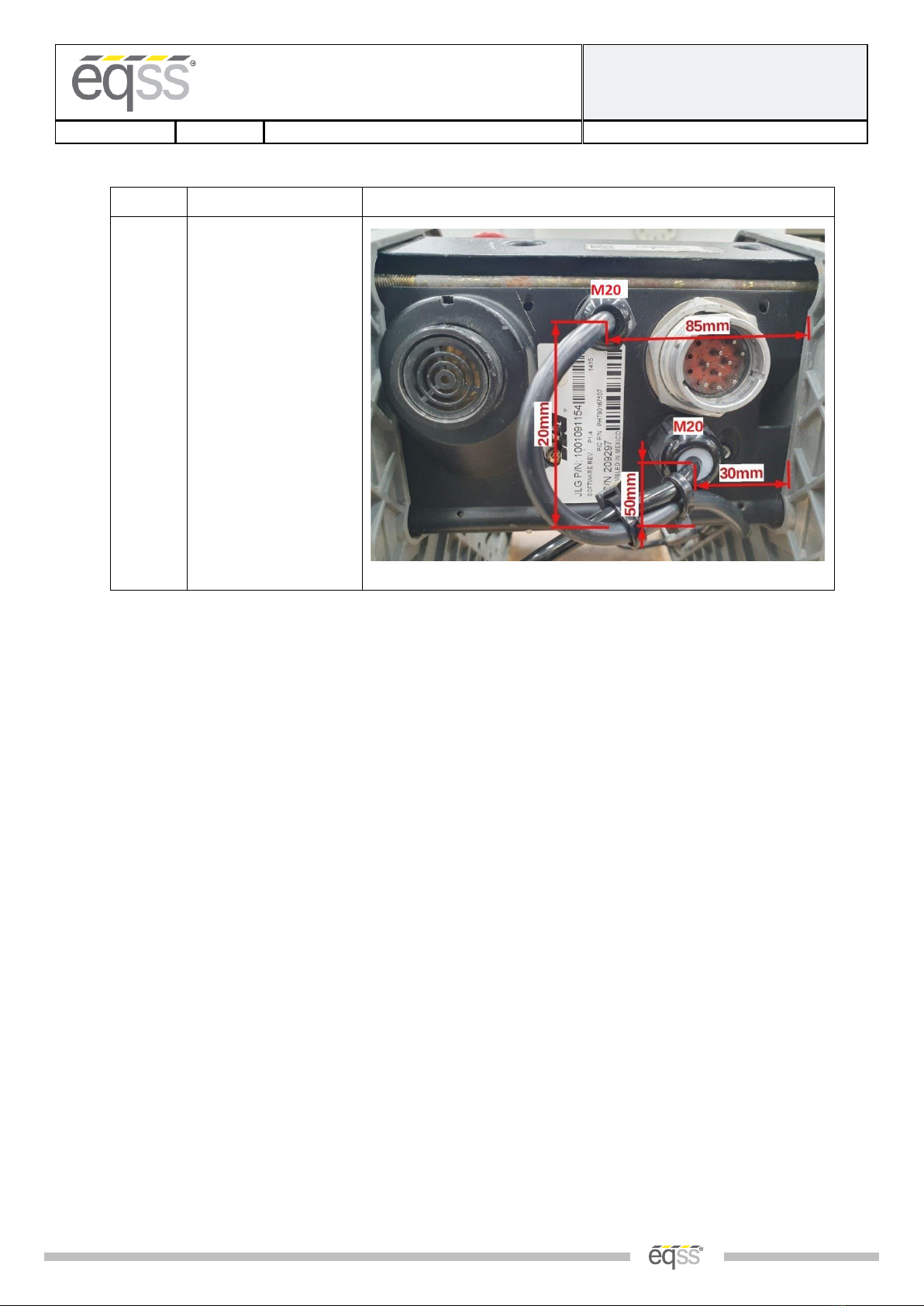

5.

Install the OverWatch™ ECU

module in the location

shown in the image and

neatly manage the cables.

Making sure the joystick

connectors are positioned

as shown.

6.

The following connections

will need to be done in the

top module.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|11 of 20|

Step

Description

Diagram

7.

Install the M20 cable gland

in the top unit of the control

box in the location shown.

8.

Run the 2-core upper panel

cable from the bottom unit

to the top unit, through the

two M20 glands installed.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|12 of 20|

Step

Description

Diagram

9.

Drive Select and Elevate

Select piggyback:

At the back the

Drive/Elevate switch:

Disconnect the existing

black Molex 3 pin connector

and install the Drive/Elevate

Select piggyback cable in

between. Refer to the photo

shown on the right.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|13 of 20|

Post Installation Configuration

Overview

After the OverWatch™ has been installed it must be configured with the parameters to suit the machine. Follow

the instructions below to configure the OverWatch™.

Minimum system requirements

Any smart phone, tablet or laptop that meets the following requirements:

•The device can connect to a Wi-Fi access point supporting 802.11 b/g/n (2.4GHz) protocol

•The device has an up to date web browser installed (2019 onwards). Firefox or Chrome are

recommended. Note: Microsoft Internet Explorer is not supported.

Wi-Fi Connection & Web Page Access

To enable the Wi-Fi connection on the OverWatch™ to complete the configuration follow the steps below.

1. Power down the platform control box with the ESTOP

2. Wait 10 seconds

3. Power up the platform control box with the ESTOP

4. While standing in the operator position, switch on the OverWatch™

5. As the welcome chime starts to play, cover the sensor. The LED will flash white then black to acknowledge.

6. Remove your hand from the sensor. The LED will flash white then black to acknowledge.

7. After covering then uncovering the sensor this way 2 more times, "Wi-Fi On" will be announced

8. On your Wi-Fi enabled device (laptop, tablet, smartphone, etc), show the available wireless networks

9. Select the wireless network (starts with “overwatch”) to connect to the OverWatch™

10. When prompted, enter the password “12345678”

11. Open your preferred web browser (Chrome, Firefox)

12. Enter the following into the address bar http://192.168.4.1 to open the OverWatch™ main page

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|14 of 20|

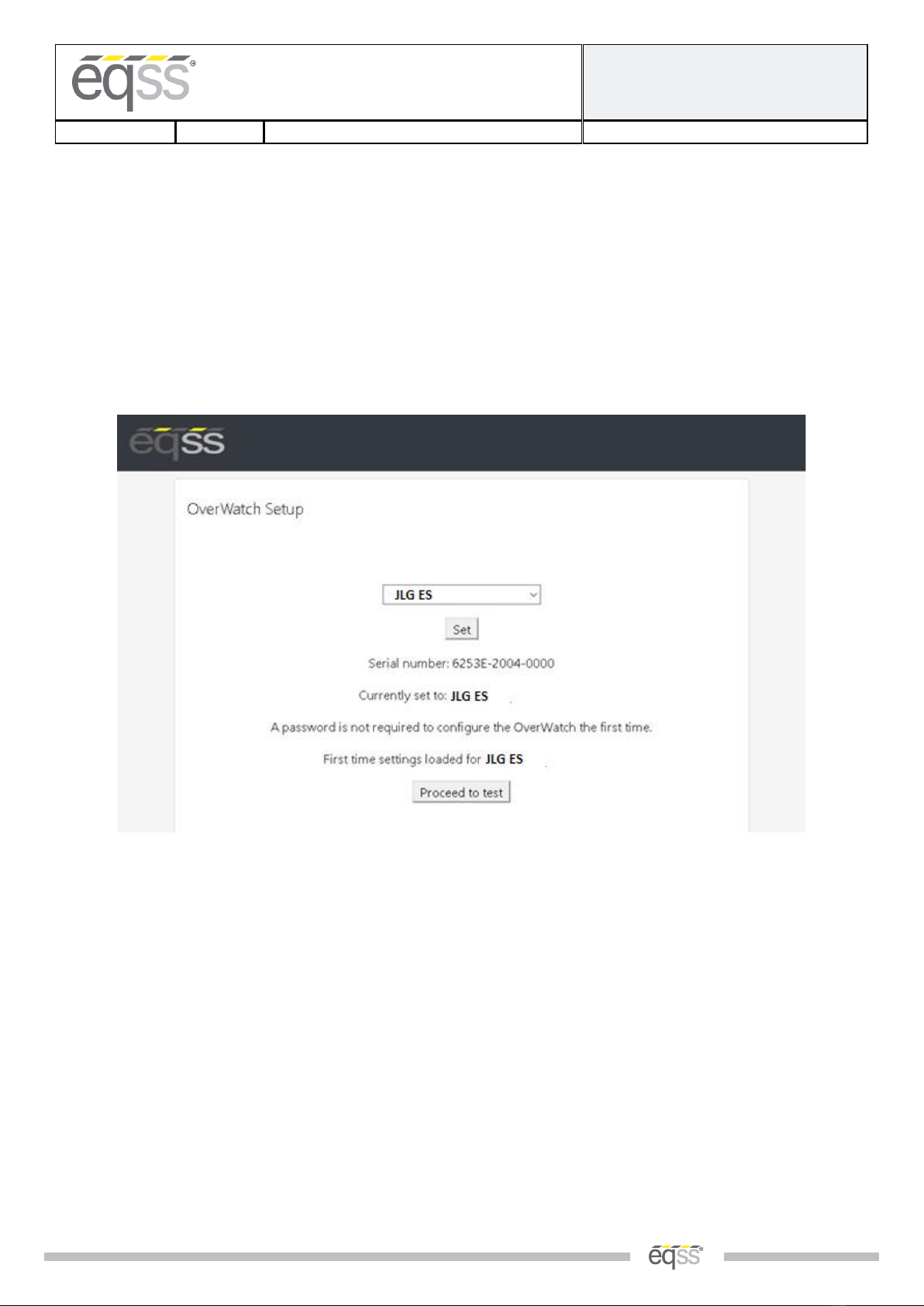

Machine Model Selection

Follow the instructions below to configure the OverWatch™.

1. Select the Setup option

2. If there is a password field at the bottom of the page, follow the instructions in Change Model Configuration

to obtain the password and enter the password field

3. Select the EWP Model from the drop-down list and click Set

4. Click on Proceed to test to begin the installation test

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|15 of 20|

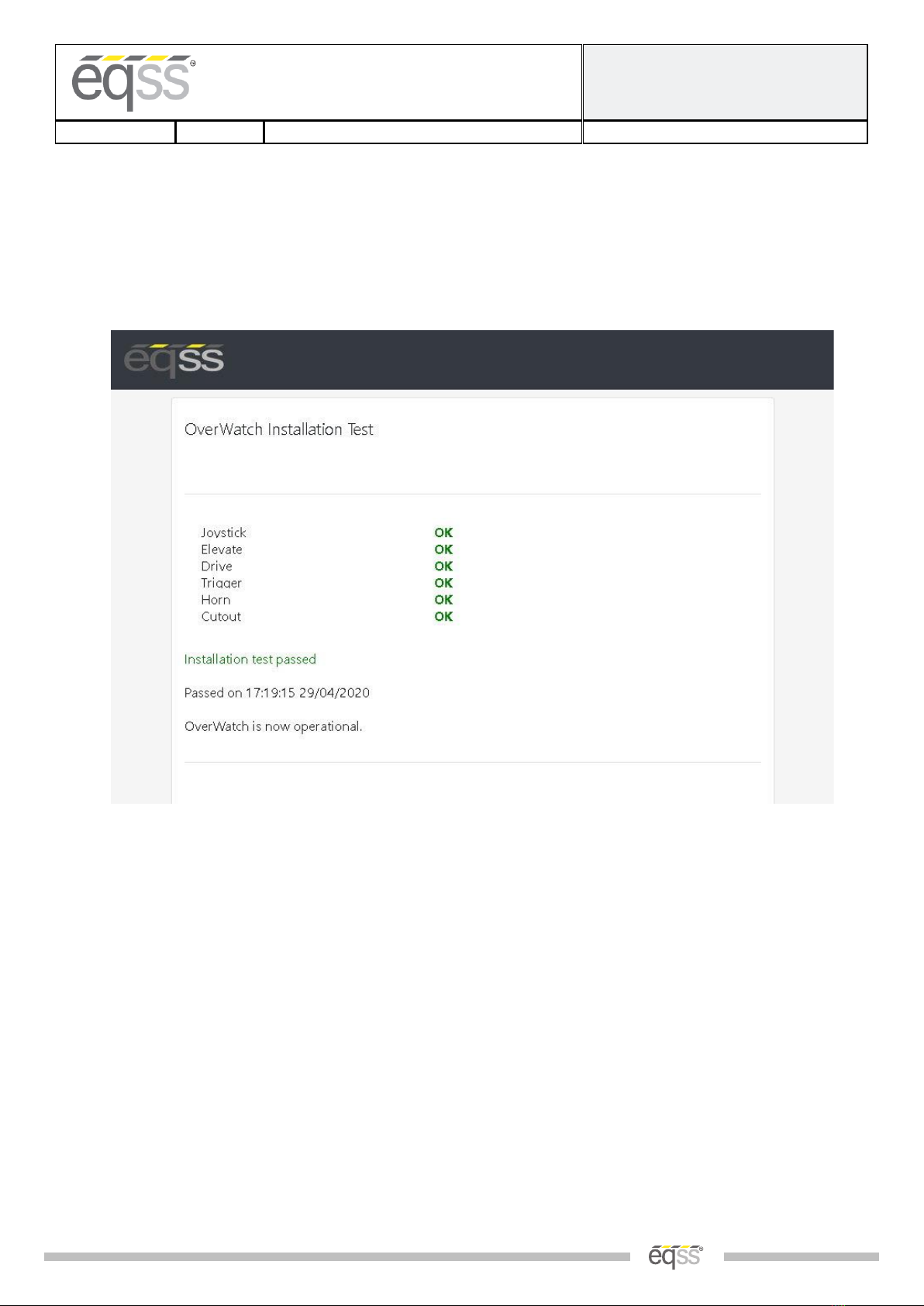

Installation Test

After the model configuration has been set or updated an Installation Test must be performed. This will ensure the

installation has been correctly performed and the OverWatch™is functioning correctly.

Follow the instructions on the web page to complete the Installation Test.

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|16 of 20|

Change Model Configuration

To reconfigure the OverWatch™for a different model requires an authorisation password to be supplied by a

service manager. The authorisation password is generated from the EQSS website. The EQSS website requires a

login username and password. If you are a service manager and don’t have a username and password, contact

EQSS to register. Follow the instructions below to obtain an authorisation password.

1. Open your preferred web and enter the following into the address bar http://www.eqss.com.au/overwatch

to open the Login page

2. Select Customer

3. Enter your username and password

4. Ask the service technician for the serial number shown on the Setup page or on the ECU module along with

the owner details of the EWP and complete the details form then click Generate Hash

5. Provide the 5-digit hash password to the service technician

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|17 of 20|

System Settings

Default Settings

See the sections below for details on each of the JLG ES Series OverWatch™default system settings.

Setting Name

Description

Default

deltaseek

This specifies which of the previous lidar reading to

compare against the current one to calculate the speed.

20

max_safe_velocity

This is the velocity threshold for the cutout in cm/s. for

drive mode.

100

max_safe_displacement

This is the maximum permitted distance in cm the operator

may be away from the calibration position in drive mode.

50

max_safe_velocity_elevate

This is the velocity threshold for the cutout in cm/s. in

elevate mode.

80

max_safe_displacement_elevate

This is the maximum permitted distance in cm the operator

may be away from the calibration position in elevate mode.

50

max_safe_velocity_neutral

This is the velocity threshold for the cutout in cm/s. in

neutral mode.

60

max_safe_displacement_neutral

This is the maximum permitted distance in cm the operator

may be away from the calibration position in neutral mode.

40

fwddispadj

The coefficient to apply to the displacement when the

displacement is toward the sensor.

-0.8

fwdveladj

The coefficient to apply to the velocity when the

displacement is toward the sensor.

-1.0

zone_obstruction

If the lidar sensor reading is below this, the lidar is

considered to be obstructed (with paint or thick coat of

dust) and the system is cutout until the obstruction is

cleared.

5

zone_minimum

Any lidar reading below this will trigger a cutout with the

message: “Operator Zone”

15

zone_maximum

Any lidar reading above this will trigger a cutout with the

message: “Operator Zone”

120

horn_count_max

The number of times the horn will sound when alerting the

operator if the deadman remains pressed during the

cutout.

2

horn_time_ms

The amount of time in milliseconds each individual horn

should play.

200

adc_elevate_threshold

For the elevate ADC input, a reading above this indicates

the EWP is in elevate mode.

300

adc_drive_threshold

For the drive ADC input, a reading above this indicates the

EWP is in drive mode.

300

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|18 of 20|

Setting Name

Description

Default

adc_trigger_threshold (not

applicable)

For the deadman ADC input, a reading above this indicates

the trigger is pressed.

2000

adc_joystick_fwd_threshold

For the joystick ADC input, a reading above this indicates

the joystick has been pushed forward.

1250

adc_joystick_bwd_threshold

For the joystick ADC input, a reading below this indicates

the joystick has been pulled backward.

1450

override_cooldown

The amount of time in milliseconds the system will wait

before accepting another override request.

20000

override_time

The amount of time in milliseconds the override will last

before it expires, and normal operation is resumed.

15000

override_listening_time

The amount of time in milliseconds the system will wait

while the deadman is held down before considering it not

to be part of the triple click override request.

300

override_reset_time

The amount of time in milliseconds the override system will

wait before resuming listening after the deadman has been

released at the end of an override period.

500

override_triple_click_time

The amount of time in milliseconds 3 clicks of the deadman

needs to occur in order to trigger the override.

2000

lidar_fault_timeout

The amount of time in milliseconds of silence from the

sensor module before a fault condition is triggered.

1000

cutout_fault_timeout

The amount of time in milliseconds a discrepancy between

the cutout and the cutout sensor is permitted before a fault

condition is triggered.

3000

throttle_time

Period after the trigger is pressed, the system does not

track velocity.

2000

stuck_time

Period, after cutout to determine if the operator is not

moving and is trapped

5000

time_before_welcome

Time after power on before welcome audio is played

250

stuck_time_long

After the stuck time this is the interval between horn alerts

10000

stuck_displacement

How much movement is considered to be non operator

movement / trapped

20

wifi_on_clicks_count

The number of times the deadman trigger is pressed to

enter Wi-Fi mode.

10

wifi_on_clicks_time

The amount of time in milliseconds after power on to enter

Wi-Fi mode.

10000

wifi_on_gesture_count

The number of times to cover and uncover the sensor to

enter Wi-Fi mode.

3

wifi_on_gesture_time

The timeout before OverWatch stops waiting for the next

part of the gesture in milliseconds

3000

wifi_on_gesture_initial_time

The timeout after startup before OverWatch stops waiting

for start of the gesture in milliseconds

10000

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|19 of 20|

Setting Name

Description

Default

driving_state_timeout

Mode selection switch timeout

7000

Polarity and Input Style

The table below describes each setting

Setting Name

Description

Default

joystick_drive_forward

Direction of joystick to move machine forward

forward

joystick_elevate_upward

Direction of joystick to move machine upwards

backward

joystick_neutral_move

Which direction requires monitoring when in neutral

forward

elevate_polarity

Direction of signal logic

high

drive_polarity

Direction of signal logic

low

trigger_polarity

Direction of signal logic

high

joystick_polarity

Direction of signal logic

low

driving_state_input

Direct or timer based

direct

neutral_safe

Safe or not safe

yes

Bypass

Setting Name

Description

test_cutout_state

Test channel enabled for primary cutout

bypassed

Date and Time

Setting Name

Description

Date

Enter the current date to be saved into the OverWatch™

Time

Enter the current time to be saved into the OverWatch™

Set date and time

Press to store the displayed date and time into the OverWatch™

Read OverWatch date and time

Press to display the current date and time stored in the OverWatch™

EQUIPMENT SAFETY SYSTEMS

75 Naxos Way, Keysborough 3173 Victoria Australia

P: +61 3 8770 6555 E: support@eqss.com.au

JLG ES Series

Installation Manual

REV 1.4

04/09/2020

Model6253 OverWatch™Installation Manual

Document # DO001203

|20 of 20|

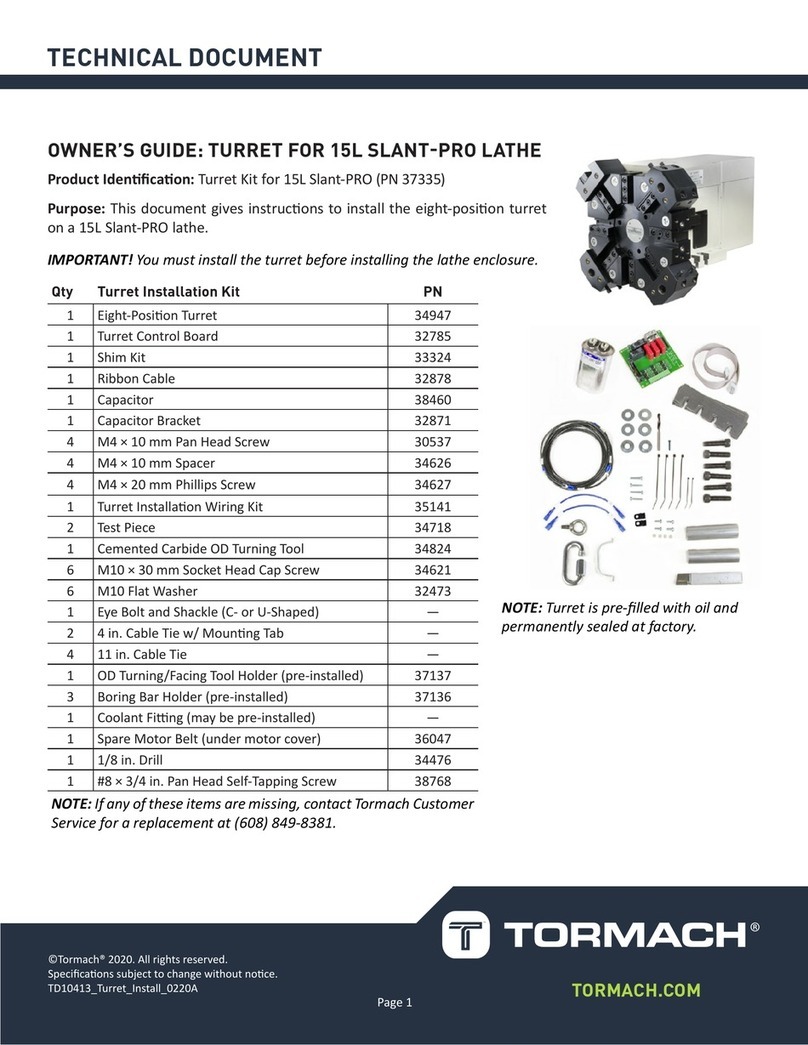

Connection Schematics

This manual suits for next models

1

Table of contents

Other eqss Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Grundfos

Grundfos SMD Installation and operating instructions

Expleco

Expleco GLAFS MAXI instruction manual

TapFlo

TapFlo DT Series Original instruction

Virutex

Virutex EB140PLC Premilling quick start guide

schmersal

schmersal AZM300 operating instructions

Schenker

Schenker Modular 100 230V Electron digital Operation and maintenance manual