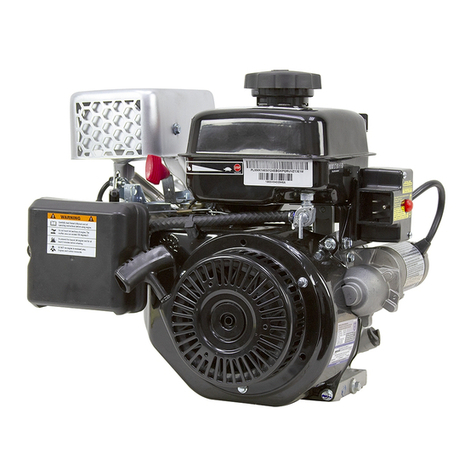

LCT 208cc SERIES User manual

LCT Engines

Online Service Manual

Table of Contents

Engine Model Number & Serial Numbering System 2-3

General Specications 4

General Troubleshooting 5-6

Advanced Troubleshooting (for authorized LCT technicians) 7-9

Spark Plug Service 9

Engine Oil Level Check 10

Engine Oil Change 10

Engine Oil Recommendations 10

Maintenance Schedule 11

Torque Specications 12

208cc Summer Engine Dimensions 13

291cc Summer Engine Dimensions 14

414cc Summer Engine Dimensions 15

208cc Snow Engine Dimensions 16

291cc Snow Engine Dimensions 17

414cc Snow Engine Dimensions 18

Exploded Parts Drawings 19-25

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 2

The rst two lines of an engine’s number is the model number. It is alphanumeric and engraved on the side of the block to the right of

the recoil. The third line is alphanumeric and is also the serial number.

Serial Number Definitions:

• Theengineserialnumberconsistsof11to12alphanumericcharacters.(example:0860H0203611)

• Firsttwodigits=yearproduced

• Nexttwotothreedigits=enginehorsepower

• Nexttwodigits=monthproduced

• Lastvedigits=sequencenumberofengine

Denitionofexample:Thisengineisthe3611th6HPengineproducedinFebruaryof2008

LCT Engine Model Numbering System Definition (see chart on page 3):

1. Preproduction - This column is coded and reserved for prototype engines only.

2. Plant - This column is coded and used for LCT internal use only.

3. Design Family - This column is used for emissions regulations and coded for LCT internal use only.

4. Crankshaft - This column indicated whether the PTO shaft (crankshaft) is congured in the engine horizontally or vertically.

5. Shaft - This column is used for the description of the PTO shaft. This will aid in determining what will be the engine’s primary use.

6. Shaft Detail - This column references a chart that designates which LCT engineering drawing corresponds to the PTO shaft.

This is for LCT internal use only.

7. Horsepower - This column is coded to designate the engine’s power output (horsepower) with its corresponding size

(cubic centimeters).

8. Paint Code - This column is coded to which color scheme the engine is equipped with.

9. Starter Type - This column is coded to which type of starting system the engine is equipped with.

10. Options - This column is coded to designate which equipment options the engine is equipped with.

11. Emissions Label - This column is coded for the emissions standards the engine meets.

12. Pack Code - This column is reserved for LCT Packaging Department only.

NOTE:

The LCT Engine Model and Serial Number Systems is subject to be changed or edited at any time

Engine Model Number & Serial Numbering System

08 60H 02 03611

year

produced

engineHP month

produced

sequence number

of engine

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 3

Preproduction Plant Design

Family Crankshaft Shaft Shaft

Detail HP Paint

Code

Starter

Type Options Emissions

Label

Pack

Code

x P LM Moderate H Horizontal T Threaded XX 150

1.5HP (63cc)

1

Black Recoil (Pantone

Black G Glossy)

E

Electric

Starter

A

Fixed Speed

E1

50 State

S

Single Pack

S LS Intermediate V Vertical K Straight-

Keyed

200

2HP (87cc)

2

Black Tank (Pantone

Black G Glossy)

P

Pull Handle

B

Manual Choke

E2

49 State

M

Multi-Pack

LX Extended P Tapered 300

3HP (142cc)

3

Titan Yellow Blower

Housing

A

Alternator

Only

C

Catalytic Muffler

E4

California Preempt

LD Diesel 400

4HP (163cc)

4

Black Blower Housing

(Pantone Black G

Glossy)

D

Generator Air Filter

E5

California Exh Only

450

4.5HP

(173cc)

5

Yellow Recoil

(Pantone 1235C)

E

Generator Muffler

E7

(TBD)

650

6.5HP

(208cc)

6

Yellow Tank

(Pantone 1235C)

F

No Tank

E8

(TBD)

850

8.5HP

(291cc)

7

Black Tank (Pantone

Black M Matte)

G

High Oil Fill Tube

E9

(TBD)

1150

11.5HP

(414cc)

8

Black Blower Housing

(Pantone Black M

Matte)

H

Commercial Fuel Tank

(Large Fuel Tank)

E10

(TBD)

C1219A

4HP (219cc)

C1305

6HP (305cc)

9

Yellow Blower Housing

(Pantone 1235C )

I

AC Charging Coil Equipped

E11

(TBD)

C1305A

7HP (305cc)

1A

Titan Green Blower

Housing (Pantone

Green 364C)

J

DC Charging Coil Equipped

E12

(TBD)

C1418

8HP (418cc)

1B

Titan Green Recoil

(Pantone Green 364C)

K

Evaporative Emission

Equipped

E13

(TBD)

C1418A

9HP (418cc)

1D

Black Recoil (Pantone

Black M Matte)

L

High Output Air Filter - CA

E14

(TBD)

1C

Carmine Red Blower

Housing (RAL 3002)

M

Remote Throttle Control

E15

(TBD)

1E

Blue Recoil

(Pantone 1235C)

N

High Ouput Air Filter -

Non CA

1F

Blue Tank

(Pantone 294C)

O

Snow Engine Equipped

1G

Blue Blower Housing

(Pantone 294C)

P

Pleated Paper Air Filter

1H

(TBD)

Q

No Low Oil Sensor

1I

(TBD)

R

Low Temperature Muffler

1J

(TBD)

S

Atm. Vented Plastic Fuel

Cap w/ Tether Cord

T

Two Low Oil Fill Plugs

U

C&U Bearings

V

Viton Oil Seals

X

Single Coil DC Charging

System

Y

Dual Coil DC Charging

System

Z

(TBD)

Engine Model Number & Serial Numbering System

PLMHK14650124PBGPQRSE2

P Lister

LM Moderate Design Family

H Horizontal Crankshaft

K Keyed PTO design

14 #14 Crankshaft Drawing

650 6.5hp (208cc) engine

1 Black Recoil (Glossy)

2 Black Tank (Glossy)

4 Black Blower Housing (Glossy)

P Pull Start

B Manual Choke

G High Oil Fill Tube

P Pleated Paper Air Filter

Q No Low Oil Sensor

R Low Temperature Muffler

S Atmosphere Vented Plastic Fuel Cap w/ Tether Cord

E2 49 State Compliant

M Multi-Pack

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 4

General Specifications

Item 208cc 291cc 414cc

Maximum Speed 3850±50rpm 3850±50rpm 3850±50rpm

Idle Speed 2150+/-50rpm 2150+/-50rpm 2150+/-50rpm

Compression Ratio 8.5:1 8.2:1 8:1

Displacement 208cc 291cc 414cc

Compression Release yes yes yes

Cast Iron Sleeve yes yes yes

Bore x Stroke 2.76" x 2.13" (70mm x 54mm) 3.15" x 2.28" (80mm x 58mm) 3.54" x 2.56" (90mm x 65mm)

PTO Rotation CCW (measured from PTO side) CCW (measured from PTO side) CCW (measured from PTO side)

Fuel (DO NOT USE E85) regular unleaded gasoline regular unleaded gasoline regular unleaded gasoline

Low Oil Shutoff if equipped if equipped if equipped

Fuel Shutoff Valve yes yes yes

Oil Fill Capacity 16oz 32oz 38oz

Spark Plug Gap 0.7-0.8mm (.027-.030 in.) 0.7-0.8mm (.027-.030 in.) 0.7-0.8mm (.027-.030 in.)

Ignition Air Gap (At Flywheel) 0.4 +/- 0.2mm 0.4 +/- 0.2mm 0.4 +/- 0.2mm

Valve Adjustment (gap) Intake .15 +/- .02mm (.005-.007in) .15 +/- .02mm (.005-.007in) .15 +/- .02mm (.005-.007in)

Valve Adjustment (gap) Exhaust .20 +/- .02mm (.007-.009 in.) .20 +/- .02mm (.007-.009 in.) .20 +/- .02mm (.007-.009 in.)

Dry Weight (Summer Engines) 35lbs (16.6kg) 57.32lbs (26kg) 69.45lbs (31.5kg)

Dry Weight (Snow Engines) 38lbs (17.25kg) 61.5lbs (28.9kg) 75.5lbs (34.3kg)

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 5

General Troubleshooting

Engine will not start:

1.Checkoillevel-Doyouhavethecorrectamountofoil?(Ref:EngineOilService,pg.10)

Remedy:Oilshouldbevisibleandtothetop2threadsoftheLOWESToilllspout.

2. Is on/off switch on?

Remedy:Turntotheonposition.

3.SnowOnly:

a) Is the Run/Stop switch in the Run Position?

Remedy:PushswitchtotheRunPosition.

b) Is the snow safety key inserted into slot?

Remedy:Pushkeyintoslottofullyengage.

4. Do you have fuel in the fuel tank?

Remedy:Addfuel.

5. Is the fuel petcock turned to the on position?

Remedy:Turntotheonposition.

6.Wastheenginechoked?

Remedy:Whenstartingtheenginethechokelevershouldbepushedlefttotheonpositionand

after starting pushed right to the off position. If engine still does not start move to half choke and

pull twice.

7. Is the spark plug boot securely fastened to the spark plug?

Remedy:Slideoversparkplugandtsecurely.

8.Hasthefuelbeingusedbeenpurchasedwithinthelastthreemonthsandwasitstoredinaplasticcontainer?

Remedy:Replaceoldfuelwithnewfuel.

9. Is the engine ooded?

Remedy:RemovesparkplugandreplacewithanyofthesparkplugslistedunderSparkPlugService,pg.9.

• NOTICE

Using an incorrect spark plug may cause engine damage.

1 2 3 4

STA R T

ON

OFF

Snow Summer

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 6

General Troubleshooting

Engine stops running:

1.Hasthefuelbeingusedbeenpurchasedwithinthelastthreemonthsandwasitstoredinaplasticcontainer?

Remedy:Replaceoldfuelwithnewfuel.

2. Is the air lter dirty?

Remedy:Replaceairlterelementifdirty.Cleanprelterofanydirtordust.

3. Wastheenginechoked?

Remedy:Whenstartingtheenginethechokelevershouldbepushedlefttotheonposition

and after starting pushed right to the off position. If engine still does not start move to half

choke and pull twice.

4. Is the spark plug corroded?

Remedy:RemovesparkplugandreplacewithanyoftheplugslistedunderSparkPlugService,pg.9.

• NOTICE

Using an incorrect spark plug may cause engine damage.

5.Hastheenginerunoutoffuel?

Remedy:Refuelengine.

6. Is the fuel petcock turned to the on position?

Remedy:Turntotheonposition.

7. Is the throttle set too low (variable speed models only)?

Remedy:Increasethethrottle.

Snow Summer

1 2 3 4

STA R T

ON

OFF

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 7

Advanced Troubleshooting – For Authorized LCT Technicians

ENGINE

Complaint Symptom and possible causes Remedy

Engine will not start, or is

hard to start

Compression too low

1. Valves out of adjustment Adjust

2. Worn valve guides or poor seating of valves Repair or Replace

3. Mistiming valves Adjust

4. Excessively worn piston rings Replace

5. Worn-down cylinder bore Replace

6. Poor seating of spark plug Retighten

7. Failed head gasket Replace

Plug not sparking

1. Fouled spark plug Replace

2. Wet spark plug Dry off

3. Defective ignition coil Replace

4. Spark plug wire damaged Replace

5. Kill switch in “OFF” position Switch to “On”

6. Ignition coil air gap is too wide Reset

7. Ignition coil failure Replace

No fuel reaching the intake manifold

1. Clogged fuel filter or fuel line Replace

2. Dirty/gummed up carburetor Clean

3. Fuel petcock is turned off Turn on

4. Fuel tank is empty Fill

Engine idles poorly 1. Out of adjustment tappet clearance Adjust

2. Poor seating of valves Replace or Repair

3. Defective valve guides Replace

4. Worn down camshaft Replace

5. Too wide spark plug gap Adjust or replace

6. Defective ignition coil Replace

7. Ignition coil air gap too wide Adjust

8. Dirty/gummed up carburetor Clean

9. Stale fuel Replace

Engine stalls easily 1. Dirty/gummed up carburetor Clean

2. Fouled spark plug Replace

3. Clogged fuel line Replace

4. Valves out of adjustment Adjust

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 8

Noisy Engine Excessive Valve Chatter

1. Too large valve clearance Adjust

2. Weakened or broken valve spring Replace

3. Worn tappet or cam lobe Replace

4. Worn and burnt camshaft journal Replace

Noise seems to come from piston

1. Worn down piston or cylinder Replace

2. Fouled with carbon combustion chamber Clean

3. Worn piston pin or piston pin bore Replace

4. Worn piston rings or ring grooves Replace

Noise seems to come from crankshaft

1. Rattling bearings due to wear Replace

2. Worn and burnt main bearings Replace

3. Worn and burnt pin bearing Replace

4. Too large endplay Adjust

Noise seems to come from outside of engine

1. Loose trim item Tighten

Engine runs poorly in high

speed range

Defective engine internal/electrical parts

1. Weakened valve springs Replace

2. Worn camshaft Replace

3. Valve timing out of adjustment Adjust

4. Too narrow spark plug gaps Adjust

5. Defective ignition coil Replace

6. Clogged air cleaner element Replace

7. Clogged fuel line, resulting in inadequate fuel supply

to carburetor

Replace

8. Worn bearings Replace

9. Blown head gasket Replace

10. Ignition coil air gap too wide Adjust

11. Dirty/gummed up carburetor Clean

12. Stale fuel Replace

Defective air flow system

1. Carburetor gasket leak - sucking air causing engine to

run lean

Replace

Engine lacks power Defective engine internal/electrical parts

1. Loss of valve clearance Adjust

2. Weakened valve springs Replace

3. Out of adjustment valve timing Adjust

4. Worn piston ring or cylinder Replace

5. Poor seating of valves Replace

6. Fouled spark plug Replace

7. Incorrect spark plug Replace

8. Clogged air filter element Replace

9. Carburetor gasket leak - sucking air causing engine to

run lean

Replace

10. Too much engine oil Adjust

11. Air fins clogged on engine causing to overheat Remove debris

12. Not enough oil in engine Adjust

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 9

Dirty or heavy exhaust smoke 1. Too much engine oil in the engine Adjust

2. Worn piston rings or cylinder Replace

3. Worn valve guides Replace

4. Scored or scuffed cylinder wall Replace

5. Worn valve stems Replace

6. Defective stem seal Replace

7. Worn oil ring side rails Replace

No spark or poor spark 1. Defective ignition coil Replace

2. Defective spark plug Replace

3. Open-circuit wiring connection Check and repair

Spark plug fouled with carbon 1. Incorrect gasoline Replace

2. Dirty air cleaner element Replace

3. Too cold spark plug Use hotter plug

Spark plug becomes fouled

too soon

1. Worn piston rings Replace

2. Worn piston or cylinder Replace

3. Excessive clearance of valve stems in valve guides Replace

4. Worn valve stem oil seal Replace

Spark plug electrode over-

heated or burnt

1. Too hot spark plug Use colder plug

2. Overheated the engine Tune up

3. Loose spark plug Tighten

4. Too lean fuel mixture Check for air leak

Spark Plug Service

Recommendedsparkplugs:TorchPlug:F6RTC

Cross References

•Champingplugcrossreferenceis:RN9YC(sometablesshowRN9YCC)

•NGKplugcrossreferenceis:BPR6ES

•BOSCHplugcrossreferenceis:WR6DC

• NOTICE

Using an incorrect spark plug may cause engine damage.

1. Whenengineiscool,disconnectthesparkplugcapandremoveanydebrisfromthesparkplugareawithhighpressureair.

2. Remove the spark plug with a 13/16-inch spark plug wrench.

3. Inspect the spark plug. Replace it if the electrodes are worn or if the insulator is cracked or chipped. Spark plug gap should

be set to 0.027 - 0.030 inches.

4. Install the spark plug carefully to avoid cross threading. Screw in spark plug by hand until it stops turning.

5. Tighten the spark plug with a 13/16-inch spark plug wrench. Tighten 1/4 turn after the spark plug seats.

• NOTICE

A loose spark plug can overheat and damage the engine. Over-tightening the spark plug can damage the threads in the

cylinder head.

6. Attach the spark plug cap. Ensure spark plug cap snaps into place securely.

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 10

Engine Oil Level Check

Check the engine oil level with the engine stopped and with the engine in a level position.

1. Remove either side mounted ller cap dipstick or high oil ll dipstick and wipe it clean.

2. Insert and remove the dipstick without screwing it into the ller neck. Check the oil level shown on the dipstick.

3. Iftheoillevelislow,lltotheedgeoftheoilllerholewiththerecommendedoil.

4. Securely screw in the ller cap/dipstick. Running the engine with a low oil level can cause engine damage.

Always check the engine oil before start up.

Engine Oil Change

Draintheusedoilwhiletheengineiswarm.Warmoildrainsquicklyandcompletely.

Avoid contact with hot oil.

1. Place a suitable container below the engine to catch the used oil then remove the

ller cap/dipstick and the drain plug.

2. Allowtheusedoiltodraincompletely,thenreinstallthedrainplug,andtighten

it securely. Do not over tighten. Dispose of used motor oil in a manner that is

compatiblewiththeenvironment.Wesuggestyoutakeusedoilinasealed

container to your local recycling center or service station for reclamation. Do not

throwusedoilinthetrash,pouritontheground,orpourdownadrain.

3. Withtheengineinalevelposition,lltotheouteredgeoftheoilllerholewiththe

recommended oil. (see ll limits right)

• NOTICE

Running the engine with a low oil level can cause engine damage.

4. Securely screw in the ller cap/dipstick.

Engine Oil

Recommendations

Engine oil affects performance and service life. Use 4-stroke automotive

detergent oil.

SAE10W-30isrecommendedforgeneraluse.Otherviscositiesshownin

the chart may be used when the average temperature in your area warrants.

The SAE oil viscosity and service classication are in the API label on the oil

container. The manufacturer recommends you use API SERVICE category

SJengineoil,orbetter.

Fillifoilis

belowletter

“L”onthe

llercap

Fillifoil

isbelow

“Add”

onthe

dipstick

Max Upper

Level

Max Lower

Level

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 11

NOTE

Followingpropermaintenanceiscriticalunderextreme

operatingconditions.

Maintenance Schedule

Normal Operating Conditions (less than 40 hrs. per year)

EACH USE FIRST

MONTH

EVERY

6 MONTHS

ONCE

A YEAR

Engine Oil Level Check

Engine Oil Replace Replace

Air Filter Check Clean / Replace

Spark Plug* Clean Replace

Cylinder/Head Fins Clean

Oil Leaks Check

Bolts Check

Fuel Hose Clamps Check

* Spark plug gap to be set to 0.027 - 0.030 inches.

Extreme Operating Conditions (greater than 40 hrs. per year)

EACH USE EVERY 40 HOURS

Engine Oil Level Check

Engine Oil Replace

Air Filter Check

Spark Plug* Replace

Cylinder/Head Fins Check Clean

Oil Leaks Check

Bolts Check

Fuel Hose Clamps Check

* Spark plug gap to be set to 0.027 - 0.030 inches.

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 12

Torque Specifications

208cc 291cc 414cc

Item Torque (N.M) Torque (N.M) Torque (N.M)

Drain bolt 12 24 24

Oil sensor 8 8 8

Oil level cap 3 3 3

Spark plug 20-25 20-25 20-25

Carburetor studs 10-12 20 20

Exhaust studs 20-24 20-24 20-24

Pivot bolt M8 22-25 22-25 22-25

Connecting rod bolt 12-14 20 20-24

Flange bolt 18-24 18-24 18-24

Distributor M6*27 10-12 10-12 10-12

Flange bolt of cylinder head M8*55 36 40-42 48

Pivot adjusting nut for intake, exhaust valve 10 10 10

Flange bolt for head cover 10-12 10-12 10-12

The bolt for crankcase cover M6*14 10-12 10-12 10-12

Side plate M6*12 8 8 8

Governor support 8 8 8

Carburetor nut M6 7 8 8

Muffler nut M8 24 24 24

Rocker bolt 20-25 20-25 20-25

Cylinder cover bolt (crankcase/ PTO cover) 24 24-26 24-26

Cylinder head bolt 36 40-42 48

Flywheel nut 75-80 96-102 96-102

Flange bolt for value cover (head cover) 7 12-13 12-13

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 13

208cc Summer Engine Dimensions

*Drawings do not accurately represent actual engine appearance.

6

4-5/16-24UNF

5/16-24UNF

16.250 in (412.75mm)

14.00 in (355.6mm)

11.625 in (295.275mm)

4.17 in [106mm]

3.78 in [96mm]

6.38 in [162mm]

3.625 in [92mm]

BOLT CIRCLE

5/16"-24 thread

3.190 in (81.026mm)

3.475 in (88.265mm)

13.45in (341.63mm)

10.110 in (256.79mm)

12.500" in (317.50mm)

3.05"(77.5mm)

.750 in (19.05mm)

2.4309 in (61.7mm)

Key width

3/16 in (4.76mm)

3.622

41.25+0.025

2.200"

4-5/16-24

7.28" (185mm)

4.09" (140mm)

1.97" (50mm)

3.05" (77.5mm)

.51" (13mm)

3.39" (86mm)

5.12" (130mm)

3.52" (89.5mm)

.20"

(5mm)

.67"

(17mm)

.49"

(12.5mm)

2.58" (65.5±0.05mm)

7.70" (195.5±0.05mm) 7.70" (195.5±0.05mm)

8.68" (220.5mm)

4.24" (105.75mm)

4.13" (105±0.05mm)

6.34" (162±0.05mm)

6.38" (162mm)

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 14

291cc Summer Engine Dimensions

*Drawings do not accurately represent actual engine appearance.

22.5

29

17

R13

R7

132

90

14

106

ø12

2-ø10.5

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 15

414cc Summer Engine Dimensions

*Drawings do not accurately represent actual engine appearance.

22.5

29

17

R13

R7

132

ø12

2-ø10.5

90

400

485

14

106

432

133±0.03

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 16

208cc Snow Engine Dimensions

*Drawings do not accurately represent actual engine appearance.

D-D

D

D

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 17

291cc Snow Engine Dimensions

*Drawings do not accurately represent actual engine appearance.

317

70.8 182

145

182

297

260

35

349

100

73 81 0.1

+

-

317

70.8 182

145

182

297

260

35

349

100

73 81 0.1

+

-

+

-

+

-

+

-

+

-

+

-+

-

59+1

0

4.5

3/8-24UNF-2B

60˚

ø/10.5

73.03

+1

0

34

133.5 0.05

65

28 R2

R2 R3

ø30-0.04

-0.06

369.03 296

446

424

133.5 0.05

3º

2º

402

90 0.1 105.5 0.1

ø113 0.15 ø92 0.15

8x5/16-24

9.12-0.13

0

6.4-0.05

0

ø25.4

-0.025

0

2120

118

3781 0.1

+

-

4xø8.9 0

-0.1

N

N

+

-

90 0.1

+

-

90 0.1 +

-

105.5 0.1

+

-

105.5 0.1

208.3

640

220.9

195

Rev:072409 Copyright © 2009 Liquid Combustion Technology, LLC LCT Engine Service Manual: 208cc, 291cc & 414cc 18

414cc Snow Engine Dimensions

*Drawings do not accurately represent actual engine appearance.

70.8

322

35

359

100

73 103

270

70.8 183

103

225

35

100

73

+

-

+

-

+

-

+

-

+

-+

-

59+1

0

4.5

3/8-24UNF-2B

60˚

ø/10.5

73.03

+1

0

34

133.5 0.05

65

28 R2

R2 R3

ø30-0.04

-0.06

387.03 314

465

249

118

431

133.5 0.05

3º

2º

412

90 0.1 105.5 0.1

ø113 0.15 ø92 0.15

8x5/16-24

9.12-0.13

0

6.4-0.05

0

ø25.4

-0.025

0

22.5

223.2

640

132

236.85

195

29103 0.1

+

-

4xø8.9 0

-0.1

N

N

+

-

90 0.1

+

-

90 0.1 +

-

105.5 0.1

+

-

105.5 0.1

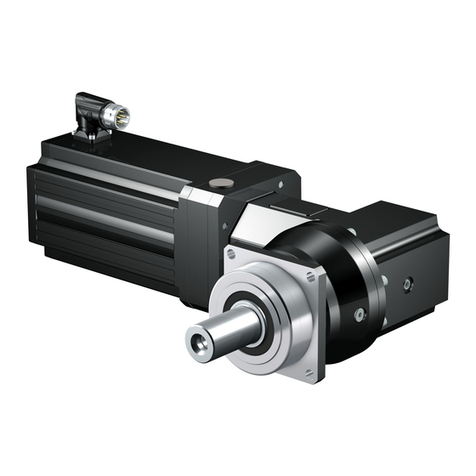

32

31

33

12

38

30

47

27

29

22

21

45

10

26

19

17

20

18

28

3

7

15

42

44

40

41

40*

*Included

with part# 40

39

6

1

23

2

13

46

48

8

11

5

4

34

16

37

36

25

49

This manual suits for next models

2

Table of contents

Other LCT Engine manuals

Popular Engine manuals by other brands

Audion Elektro

Audion Elektro MAGNETA MGM 321 Instructions for use

Evolution

Evolution EVO200 Original manual

Henderson

Henderson Prometheus instruction manual

Chicago Pneumatic

Chicago Pneumatic M3901-70-SQ Safety information

Assun

Assun AM-CL4071GAE Series product manual

Onan

Onan NHC Series Operator's/Service Manual and Parts Catalog