LDS IGBT Series User manual

IGBT

SERIES

COMPACT INVERTER

1PHASE INVERTER

WITH 150% OVERLOAD PROTECTION

MODEL NO IGBT - K100 IGBT - K200

Motor Rating (maximum)

25W ~ 120W (1/6HP) 25W ~ 200W (1/4 HP)

Rated Output Capacity

0.4kVA 0.6kVA

Rated Output Current

1 Amp 1.5 Amp

Rated Output Voltage

AC 3 Phase 220V (3Ø220V)

Range of Output Frequency

0.1Hz ~ 400Hz

Power Source Voltage

AC 1 Phase 200V~240V (1Ø), 50Hz/60Hz

Input Current

2 Amp 3 Amp

Permissible AC Power Source Fluctuation

200V ~ 240V, 50Hz/60Hz, ±5%

Overload Protection

150% of rated output current for 1 minute

Cooling Method

Self-cooling

Protection Level

IP20

Dimension

Body 52 x 127 x 60mm • Mounting Frame: 60

x 100 x 3mm

Weight

0.4KG

Options

With Braking Transistor / Without Braking Transistor

Remark

Product dimension and mounting compatible with

US Type Speed Controller (US61-US62 / US71-US72)

The compact IGBT inverter is especially advantageous for standard application by

virtue of its user friendliness. It offers simple and safe operability, energy saving,

compact design as well as superior performance. The inverter is use in numerous

application such as conveyor drives, feeders, machining tool and door drives. It is

compactible with Unit Type AC Speed Controller (US series).

OPERATION PANEL

Start

Stop

• Reset

Up

• Down

Enter or Exit

the Function Mode

Set

• Switch

Monitor Mode

Switch Function

•

Group

• Number

Special Function

Key

Status Display I

Indicator : Frequency • Voltage •

Current • Operation

Status Display II

Power Indicator •

SPEC • START Key Indicator

Main LED Display (high brightness)

Display of Setting & Error Code

Potentiometer / Knob

Fast Setting and Input

Function Key

RUN

STOP

RESET

PROG

FUNC

DATA

<<

SPEC

P 1

Control

Method:

Voltage vector sinusoidal PWM control

(V/F control)

Switching frequency : 800~16kHz

Frequency

Range:

0.1Hz ~ 400.00Hz

Resolution:

Digital Command : 0.01Hz

•

Analogue Command: 0.06Hz / 60Hz

Overload

Protection:

150% of rated output current for 1

minute

DC Braking:

Start/Stop Braking Time:

0

~ 60.0 second •

Stop

Braking Frequency :

0.1Hz

~ 60Hz •

Braking

Ability: 0~150% of rated

current

Braking

Torque:

Approximately 20%

V/F Pattern:

Linear, Energy

-

Saving mode (automatic

adjusting V/F pattern according to the

load condition)

•

Square of 1.5, 1/7 and 2 curves.

•

V/F pattern (2 V/F points)

•

Output voltage adjustment of V/F

pattern

•

(Variable voltage adjustment of V/F

pattern for acceleration and

deceleration).

Other

Functions:

Automatic operation for energy

-saving •

Automatic torque compensation

•

Automatic adjustment for output voltage

stability

•

Automatic adjustment of switching

frequency

•

Slip compensation / Counter function

•

Restart after instantaneous power

failure

•

Modbus (RS

-485) communication •

Over

-torque detection • Jump frequency

•

Setting for upper

and lower limits of

output frequency

•

8

-preset speeds • S-curve acceleration &

deceleration

•

Temperature management

• Parameters

duplication

Frequency

Setting

Signal:

Operation panel (including KP

-601A

keypad):

Analogue Signal: (DC 0 ~ 10V) /

0~100%

Digital Signal: Jog speed, 8

-

preset speeds

Modbus (RS485) Communication

Operation

Signal:

Operation panel (including KP

-601A

keypad):

RUN / STOP

•

Digital Signal: FWD (forward) /

REV (reverse) rotation control

•

Modbus (RS

-485) communication

Multi

-

Function

Inputs:

3 programmable input terminal: X1~X3

•

Response time (1~255, unit 1ms)

•

Refer to the F5.19~F5.21 functions setting

description.

Analogue

Inputs:

1 set of analogue input: VI (DC 0 ~ 10V) •

Analogue filter (0~255, unit 5ms), the

dead band of analogue frequency, gain

and bias are adjustable

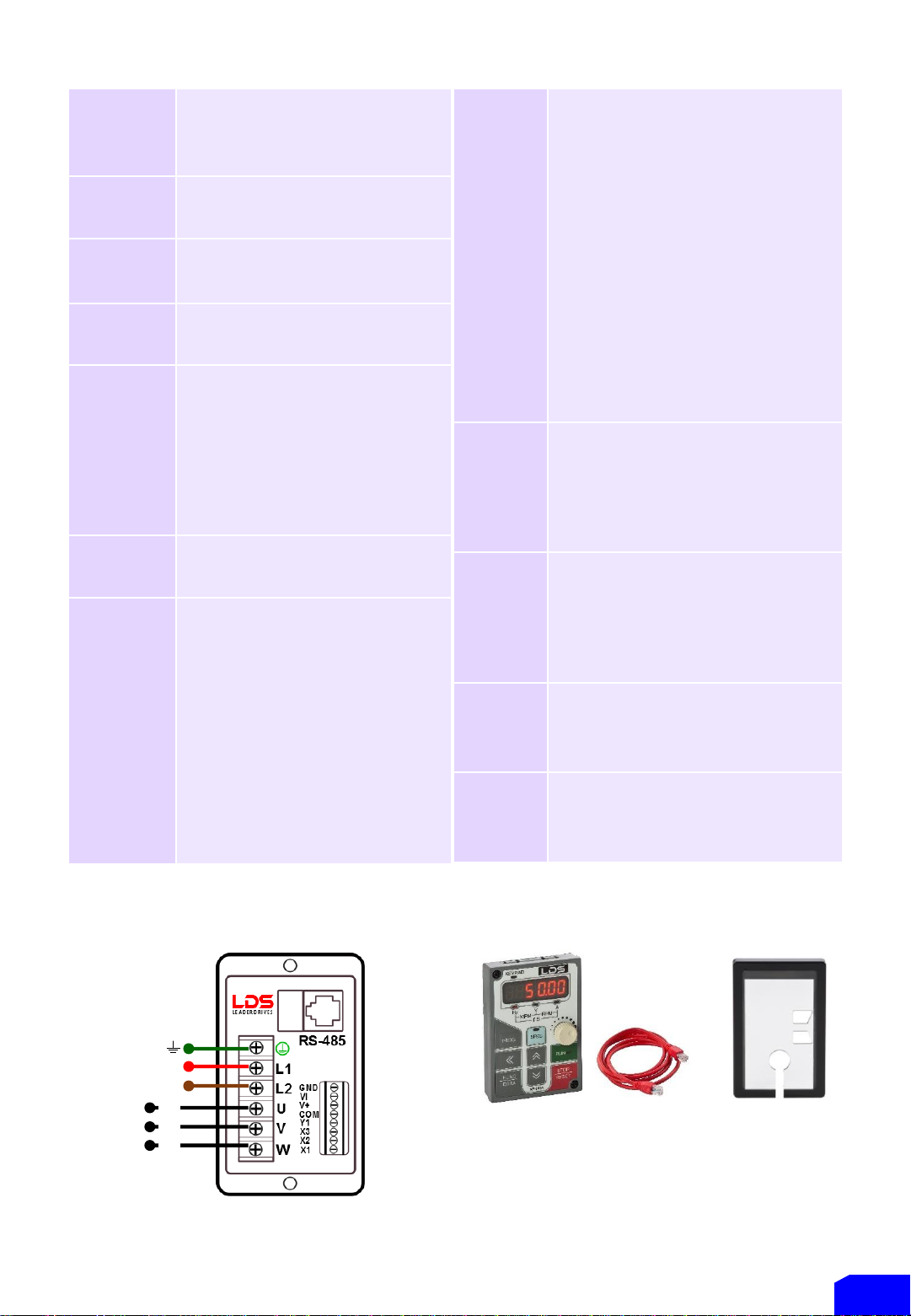

GENERAL SPECIFICATIONS / CONTROL CHARACTERISTICS

The keypad

Enable remote control of

the inverter via Modbus

(RS485) Communication.

Duplication of parameter

from Inverter to Inverter.

PORTABLE KEYPAD

FG

AC Power Source

1Φ200V~240V

Motor

3Φ220VAC

L1

L2

U

V

W

MAIN CONTROL CIRCUIT

TERMINALS

Acrylic Protective

Cover

P 2

Main Circuit Terminals

Control Circuit Terminals

Modbus Port (RS-485)/ Keypad-601A

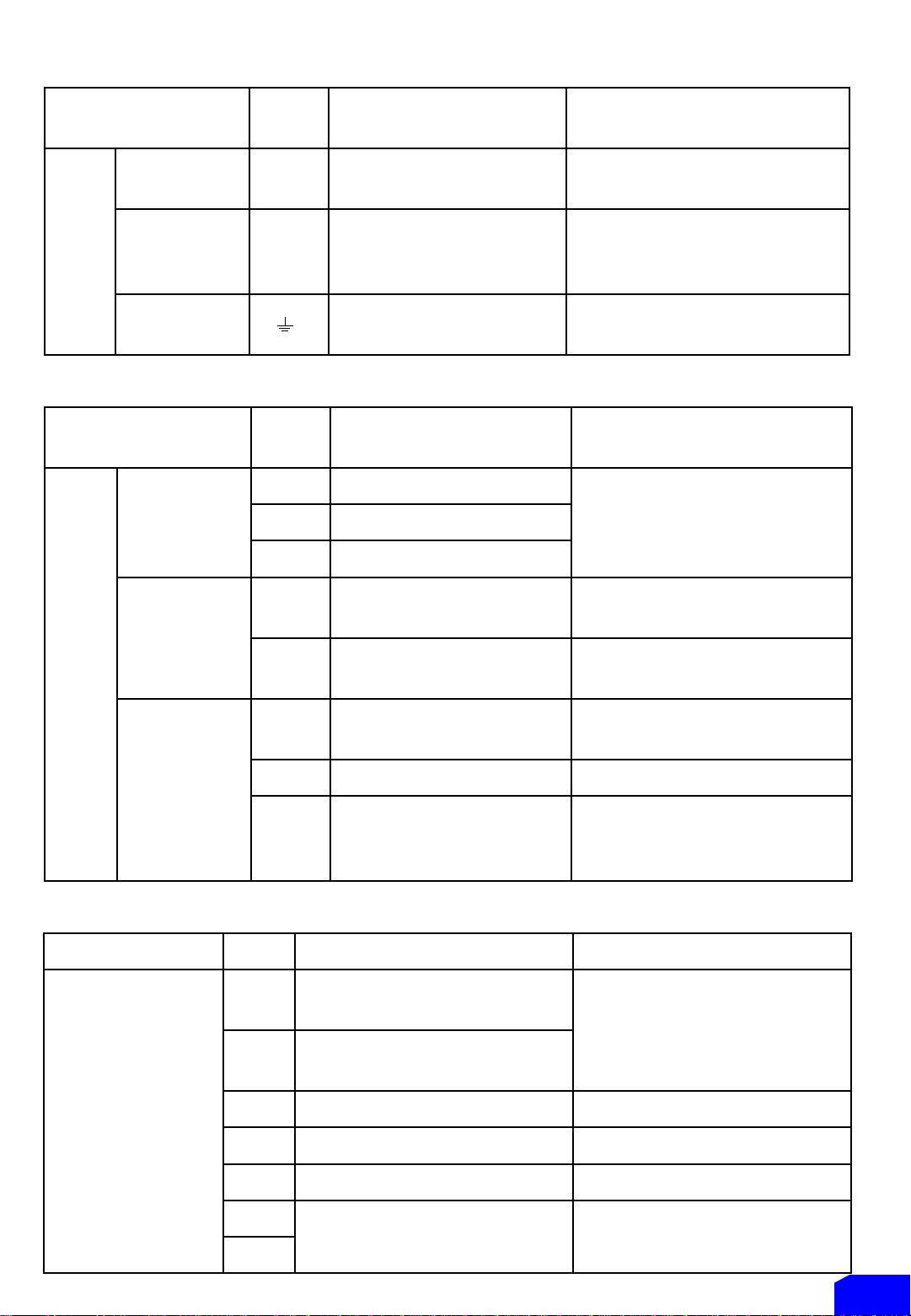

Type Symb

ol

Function Description

Terminal of Main

Circuit

Power

Source L1,L2 AC power source input

terminals

For the single-phase power

source AC 200~240V.

Motor U,V,W Drive outputs to motor

terminals

The terminals output three

phase variable frequency and

voltage to motor.

Grounding Grounding terminal Grounding resistance must be

below 100Ω

Type Sym-

bol Function Description

Control Circuit Terminal

Multi-

function

input

terminal

X1 Input terminal 1

The function is set by

F5.19~F5.21.

X2 Input terminal 2

X3 Input terminal 3

Multi-

function

output

terminal

Y1 Output terminal 1 Capacity: DC 48V, 50mA

The function is set by F5.26.

COM Input/output common

terminal

The common terminal of

input/output control signal

Control

Power

V+ Power terminal for

control signal

DC +12V output. Maximum

supplied current is 20mA.

VI Analog input terminal DC 0~10V

GND Common terminal for

analog input control

Common terminal for control

power (V+) and analog input

terminal (AI)

Type Pin Function Description

Modbus (RS-485)/

KP-601A

Communication

1Communication transmission

terminal (DX+) Modbus (RS-485)

communication uses pin 1, 2.

2Communication transmission

terminal (DX-)

3 Power terminal of KP (+13V) Only for KP-601A linking

4 Auto-detect terminal of KP Only for KP-601A linking

5 ~ 6 Reversed Reversed

7Common ports terminal of KP

power (0V) Only for KP-601A linking

8

P 3

Preface

Thank you for using LDS Compact K-series Inverter drive. For proper operations and safety

purposes, please do read and follow the safety specific instructions in the manual before using the

product. To ensure proper operation of drive, the manual shall be placed on the top of the machine.

Furthermore, please download the completely safety information on LDS website

http://www.leaderdrives.com.

Safety Precaution

1.Don’t conduct any wiring during the system power ON to avoid the electric shock.

2.Please wait at least 5 minutes until the indicator light turn off.

3.The electronic components are sensitive to static electricity in the drive.

Please don’t put the any objects in the drives or touch the main circuit board.

4.PE terminal must be exactly grounded.

5.Don’t touch the heat sink because the temperature of heat sink may over 70°C.

6.The LDS inverter series outputs are designed to drive a three-phase motor.

Do not connect output terminals to the single-phase or use for other purpose.

7.U, V, W are the outputs of drive to the motor. Please do not connect these terminals to the power

source.

Ambient Conditions

Features

1.The drive has temperature management and setting pre-alarm level to forecast over temperature

2.RS-485 Modbus RTU communication function

3.Special function key (SPEC): Cable set (in parameter) to realize FWD/REV running, jog speed,

and other multifunction operation.

4.Built-in knob (Pot) for directly speed adjustment.

5.The switching frequency can be adjust between 800Hz ~16kHz.

6.Provide 8 sets of monitor displays. (frequency, speed, voltage, current and 13 kind of options

available)

7.Counter function.

8.To support external PTC for motor overheat protection.

9.User can connect KP-601A keypad (option) for remote control, parameters duplication and saving.

10.Detachable Buckles design for installation.

11.Six sets of fault record (fault record, current, voltage, frequency)

12.Simple parameter group and complete parameter group.

13.Parameter lock and parameter password functions.

Atmosphere Non-corrosive or non-conductive, or non-explosive gas or liquid, and non-dusty

Surrounding temperature: -10°C~+45°C (14°F~122°F) (Non-condensing and non-freezing)

Storage temperature: -20°C~+60°C (-4°F~140°F)

Relative humidity: 90% RH or less (No-condensing atmosphere)

Vibration: Less than 5.9m/sec²(0.6G)

Altitude: Less than 1000m (3280 ft.)

P 4

Chapter 1 Caution before Installation

The product has passed the strictest quality test before shipped out from the factory. However, the

product might possibly sustain minor damages due to the impact, shaking, vibration, and other

factors during the transportation. Please make sure to verify the following items after receiving this

product. If the product verification finds anything abnormal, please contact the agent immediately

for the further assistance.

(1)Check up appearance of the drive for any paint chipped off, smearing, deformation of shape, etc.

(2)Check up the operation manual whether it shortage or damage or not.

(3)Check up the drive model number is identical with the shipping label on the carton or not.

1-1 Confirmation of Appearance

Serial Number

IGBT-K200

LDS Compact IGBT Inverter 200W

OVLP 150% S/N : DM15A2V242

Input : 1Ø 200V~240V 50Hz/60Hz 3.0A

Output : 3Ø 220V 0.1Hz~400Hz 1.5A

PGM: 0201-001(AZ055891) ISO 9001 IP20

www.leaderdrives.com

Leader Mechanical

& Electrical Co., Ltd

Model Number

Product

Code

Power

(Watt)

Horse

Power

K100 125W 0.17HP

K200 200W 0.25HP

P 5

Input Power Voltage

Output Power Voltage

Control

Method:

Voltage vector sinusoidal PWM control

(V/F control)

Switching frequency : 800~16kHz

Frequency

Range:

0.1Hz ~ 400.00Hz

Resolution:

Digital Command : 0.01Hz

Analogue Command: 0.06Hz / 60Hz

Overload

Protection:

150% of rated output current for 1

minute

DC Braking:

Start/Stop Braking Time: 0 ~ 60.0 second

Stop Braking Frequency : 0.1Hz ~ 60Hz

Braking Ability: 0~150% of rated current

Braking Torque:

Approximately 20%

V/F Pattern:

Linear, Energy

-Saving mode (automatic

adjusting V/F pattern according to the

load condition)

Square of 1.5, 1/7 and 2 curves.

V/F pattern (2 V/F points)

Output voltage adjustment of V/F

pattern.

(Variable voltage adjustment of V/F

pattern for acceleration and

deceleration).

Other

Functions:

Automatic operation for energy

-saving •

Automatic torque compensation

•

Automatic adjustment for output voltage

stability

•

Automatic adjustment of switching frequency •

Slip compensation / Counter function

•

Restart after instantaneous power

failure •

Modbus (RS

-485) communication •

Over

-torque detection • Jump frequency •

Setting for upper

and lower limits of output

frequency

•

8

-preset speeds • S-curve acceleration &

deceleration

•

Temperature management

• Parameters

duplication

Frequency

Setting

Signal:

Operation panel (including KP

-601A keypad):

Analogue Signal: (DC 0 ~ 10V) / 0~100%

Digital Signal: Jog speed, 8

-preset speeds

Modbus (RS485) Communication

Operation

Signal:

Operation panel (including KP

-601A keypad):

RUN / STOP

Digital Signal: FWD (forward) / REV (reverse)

rotation control

Modbus (RS

-485) communication

Multi

-

Function

Inputs:

3 programmable input terminal: X1~X3

Response time (1~255, unit 1ms)

Refer to the F5.19~F5.21 functions setting

description.

Analogue

Inputs:

1 set of analogue input: VI (DC 0 ~ 10V)

Analogue filter (0~255, unit 5ms), the dead

band of analogue frequency, gain and bias are

adjustable

GENERAL SPECIFICATIONS / CONTROL CHARACTERISTICS

Chapter 2 Installation and Confirmation

2-1 Basic Equipment

•Correct installation can extend the lifespan of the inverter, please follow the installation

precaution.

•Do not place the drive next to the heating substance or exposure to sunlight. Due to the heat

dissipating requirement during the drive operation, the drive must keep enough space for heat

dissipation.

•Environment temperature -10°C~+45°C (14°F~122°F)

•Please install the drive with clearance space around the drive and the location of installation

shall be arrange as follow :

P 6

2-2-2 Main Circuit Terminals

2-2-3 Control Circuit Terminals

Type Symb

ol

Function Description

Terminal of Main

Circuit

Power

Source L1,L2 AC power source input

terminals

For the single-phase power

source AC 200~240V.

Motor U,V,W Drive outputs to motor

terminals

The terminals output three

phase variable frequency and

voltage to motor.

Grounding Grounding terminal Grounding resistance must be

below 100Ω

Chapter 3 Characteristics and Instructions

2-1 The Features of Control and Operation

General Specifications : Control Characteristics

Control Method: Voltage vector sinusoidal PWM control (V/F control); Switching frequency :

800~16kHz

Frequency Range: 0.1Hz ~ 400.00Hz

Resolution: Digital Command : 0.01Hz

Analogue Command: 0.06Hz / 60Hz

Overload Protection: 150% of rated output current for 1 minute

DC Braking: Start/Stop Braking Time: 0 ~ 60.0 second

Stop Braking Frequency : 0.1Hz ~ 60Hz

Braking Ability: 0~150% of rated current

Braking Torque: Approximately 20%

V/F Pattern: Linear, Energy-

Saving mode (automatic adjusting V/F pattern according to the

load condition)

Square of 1.5, 1/7 and 2 curves.

V/F pattern (2 V/F points)

Output voltage adjustment of V/F pattern.

(Variable voltage adjustment of V/F pattern for acceleration and deceleration).

Other Functions: Slip compensation / Counter function / Automatic torque compensation /

Automatic adjustment for output voltage stability / Automatic operation for

energy-saving /

Automatic adjustment of switching frequency / Restart after instantaneous

power failure /

Modbus (RS-485) communication / Over-torque detection / Jump frequency /

Setting for upper and lower limits of output frequency / 8-preset speeds /

S-curve acceleration and deceleration / Temperature management /

Parameters duplication

Frequency Setting

Signal:

Operation panel (including KP-601A keypad):

Analogue Signal: (DC 0 ~ 10V) / 0~100%

Digital Signal: Jog speed, 8-preset speeds

Modbus (RS485) Communication

Operation Signal: Operation panel (including KP-601A keypad): RUN / STOP

Digital Signal: FWD (forward) / REV (reverse) rotation control

Modbus (RS-485) communication

Multi-

Function Inputs:

3 programmable input terminal: X1~X3

Response time (1~255, unit 1ms)

Refer to the F5.19~F5.21 functions setting description.

Analogue Inputs: 1 set of analogue input: VI (DC 0 ~ 10V)

Analogue filter (0~255, unit 5ms), the dead band of analogue frequency, gain

and bias are adjustable

P 7

P 8

2-2-1 Function of Operation Panel

2-2-1 Function of Operation Panel

Light color represents for lights flashing.

•2-2-3 The description of monitor mode

* To check the complete parameter list and communication instruction, please consult authorized distributor whom

you have bought the product from.

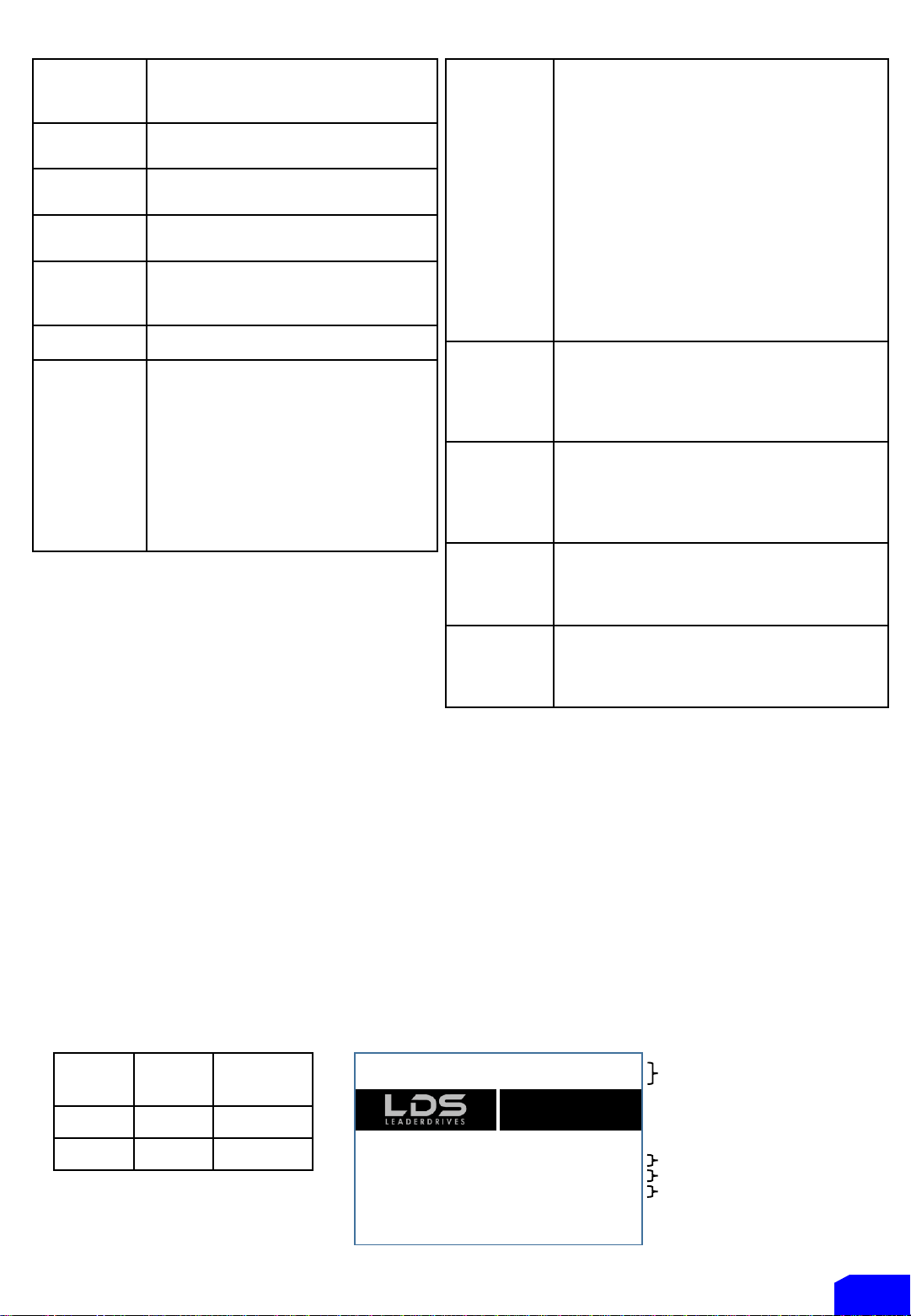

SIMPLE PARAMETER GROUP

(F0.18 = 0) COMPLETE PARAMETER GROUP LIST

(F0.18 = 1)

P 9

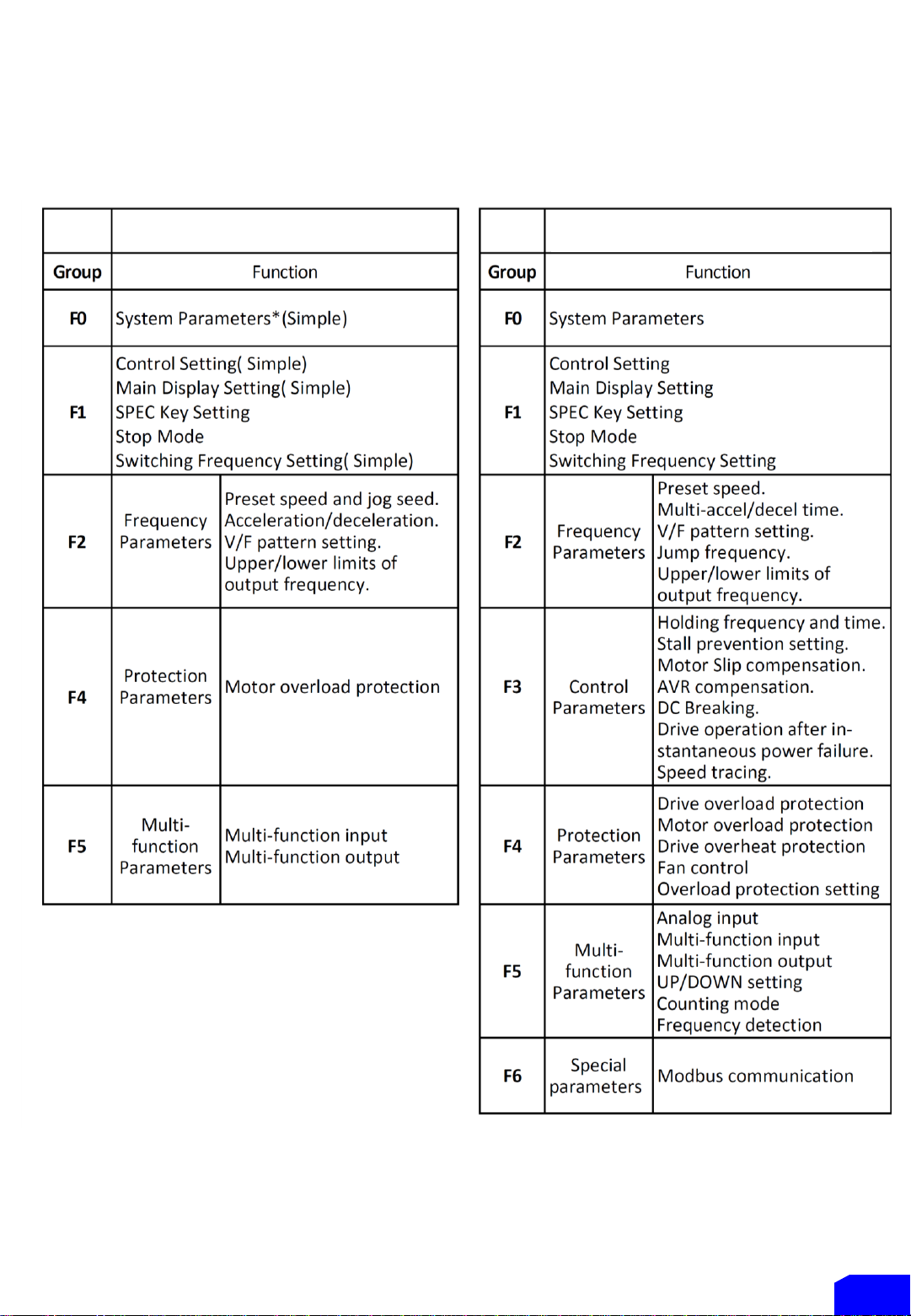

CHAPTER 3 : PARAMETER LIST

The Default Setting is Simple Parameter

P 10

(4)

P 11

P 12

P 13

P 14

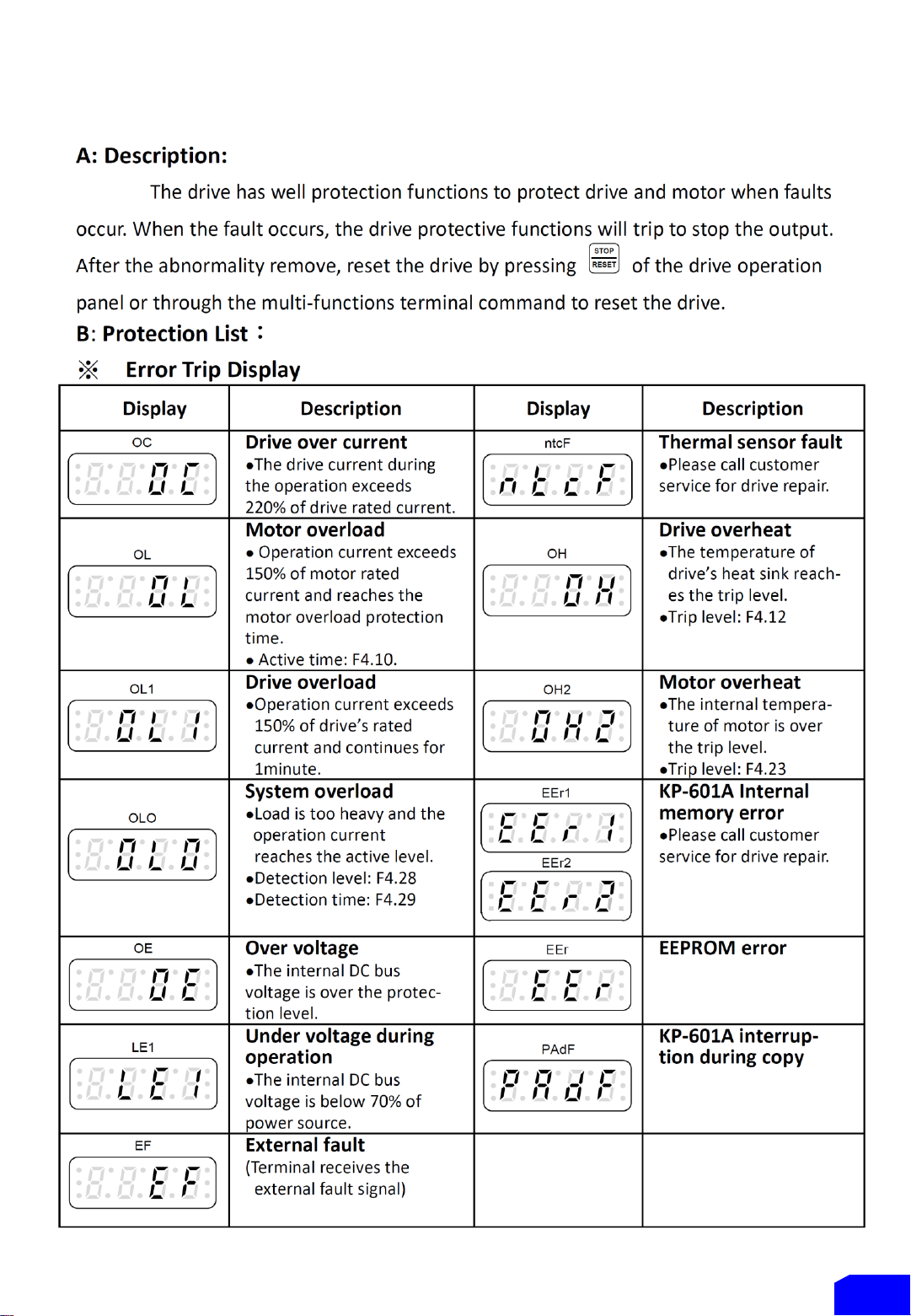

CHAPTER 4 : FAULT PROTECTION DISPLAY

P 15

CHAPTER 5 : INSTLLATION DIMENSION OF DRIVE

5-1 Outline Dimension of Drive

Purchase Accessories

1. KP-601A Keypad

2. Protection Cover for Drive

3. Inverter Mounting Bracket –Type H

(Made in Stainless Steel 304)

Please consult any LDS authorized distributor for

the accessories and specification.

Log on: www.leaderdrives.com

P 16

5-2 Installation Dimension

This manual suits for next models

2

Table of contents

Popular Inverter manuals by other brands

Lenze

Lenze 8600 series operating instructions

SMA

SMA SUNNY BOY 3600TL operating manual

Champion Global Power Equipment

Champion Global Power Equipment 200953 Operator's manual

Mastervolt

Mastervolt WHISPER 3 installation manual

Mayty

Mayty PS028 user guide

Power One

Power One AURORA Installation and operation guide