3

monoxide fumes can collect

b) Keep the machine free of oil, dirt and

other impurities.

c) Please always place the appliance on

even and stable surfaces.

d) Never operate the appliance inside

buildings or in an environment without

proper ventilation. Pay attention to air

flow and temperature.

e) Do not operate or store the appliance

in wet or humid surroundings.

f) Ensure the sound absorber and air

filter work properly. These parts serve

as flame protection in case of misfire.

g) To avoid possible burn injuries, do not

touch the exhaust system or other

parts that become hot during operation.

Pay attention to the warnings on the

machine.

h) The engine must not be operated with

excessive rotary speed. The operation

of the engine with excessive rotary

speed raises the risk of injury. Parts

which affect the rotary speed must not

be altered or replaced.

i) Regularly check for leakage or traces

of abrasion in the fuel system, such as

porous pipes, loose or missing clamps

and damage to the tank or tank cap.

Before use all defects must be repaired.

j) Work only in daylight or in good

artificial light.

k) Never pick up or carry a machine while

the engine is running

l) Stop the engine:

-whenever you leave the machine

-before refuelling

m) Before checking or adjusting the

machine, the ignition plug and the

ignition wire respectively must be

removed to prevent accidental starting.

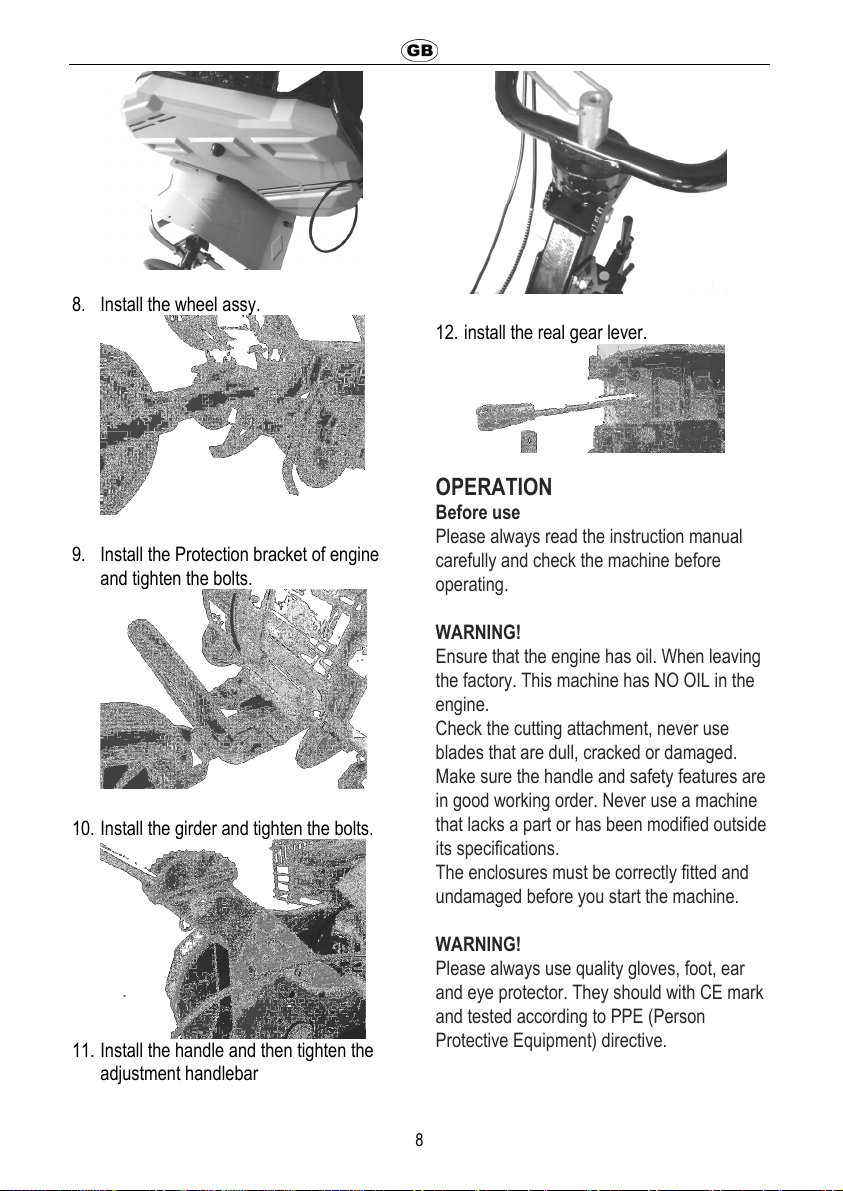

4). Maintenance and storage

a) Keep all nuts and screws tight to be

sure the equipment is in safe working

condition.

b) Never store the equipment with petrol

in the tank inside a building where

fumes can reach an open flame or

spark.

c) Allow the engine to cool before storing

in any enclosure.

d) To reduce the fire hazard, keep the

engine, silencer and petrol storage

area free of vegetative material and

excessive grease.

e) Replace worn or damaged parts for

safety.

f) If the fuel tank has to be drained, this

should be done outdoors.

g) Always clean and maintenance before

storage.

h) Never disassembly the guards for

cutting attachments.

i) Always store the metal blade in cool

and dry place, never use rusted blade.

It may cause serous injure during

working.

SPECIAL SAFETY WARNINGS FOR

TILLER

1) While using the machine, always wear

sturdy shoes and long pants. Never

use the machine being barefoot or

wearing open sandals.

2) Thoroughly inspect the area where the

tiller will be used and remove all

objects that could be launched by the

machine.

3) Before using the appliance, always

check visually that the tools are not

worn or damaged. Replace teeth and

bolts, worn or damaged lots to

preserve the balance.

4) The engine shall be stopped when

carrying out maintenance and cleaning

operations, when changing tools and

when being transported by means

other than under its own power.