CAUTION: If Pilot hole is used with the wood thread

hook, the pilot hole should be drilled no larger than

the minor diameter of the screw threads on the hook.

Do not put lubricant on the “J” hook. At least 11/2”of

the screw threads should be secured Into the

structural wood joist.When the threaded bolt hook is

used, be careful to secure tightly with supplied

lockwashers and nuts. Attach the hook as instructed

and hang the fan.

CAUTION: Make sure that blades are attached as

shown.

9. This fan is eq ipped with the req ired “secondary

s pport” cable. This cable m st-be affixed to the

beam str ct res and sec rely clamped in s ch a ma-

ner to s pport the weight of the fan in the event the

mo nting hook or other parts fail. After wrapping cable

aro nd a str ct ral member that will s pport 300

lbs., sec re cable with s pplied cable clamps as

ill strated in Fig re 3. (Note: Any additional materials

needed for specific installations may be p rchased

from yo r local distrib tor.)

NOTICE: Leave approximately 3” b t no more than 5” of

slack on this safety cable to allow for possible fan

movement. Do not exceed more than 5” total slack.

IMPORTANT CAUTION:The safety cable must not be

placed between the rubber roller and hook but as

illustrated in Figure 3.

Assembly

This fan incl des a “secondary s pport” safety cable fea-

t re that complies with existing C.S.A. (Canadian

Standards Association) req irements and all other

proposed safety reg lations for overhead air movement

eq ipment. To ins re proper installation of this important

safety feat re, please read and follow these instr ctions

caref lly.

1. Caref lly nwrap the coiled safety cable and motor

lead wires.

2. At the motor yoke assembly (A), remove the cotter pin

and loosen the hexagon n t. Caref lly remove spring

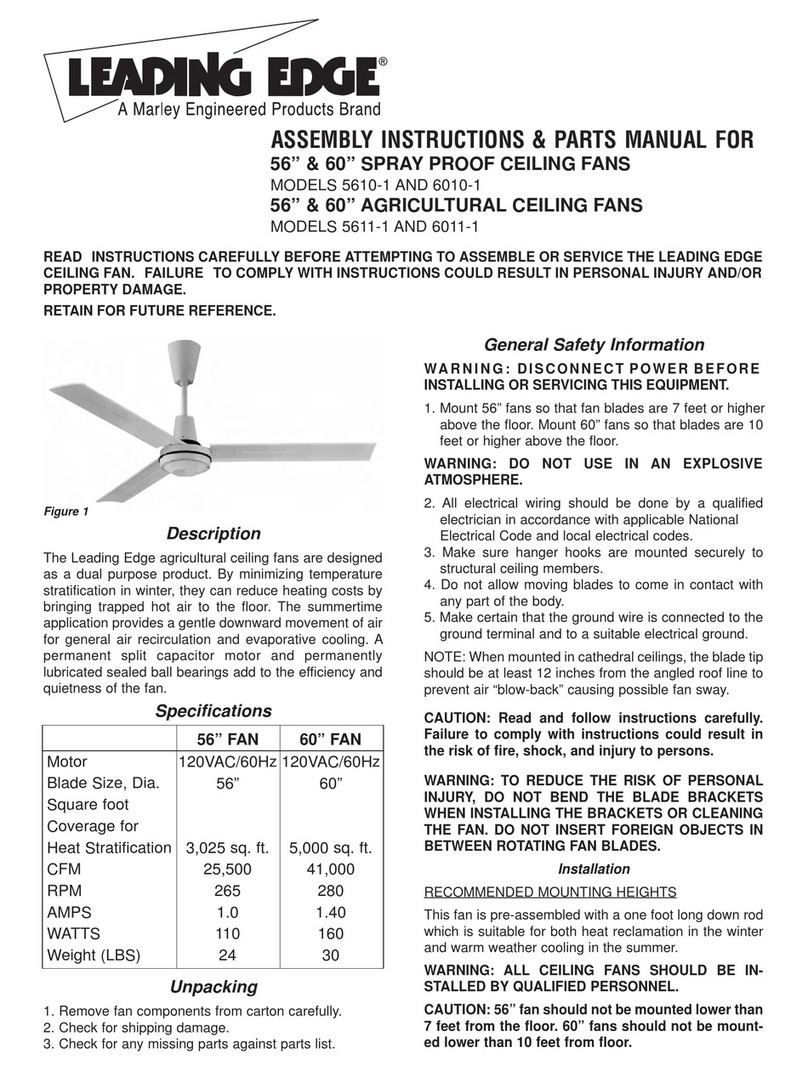

washer and the hexagon screw (E). (See Figure 1)

3. Slide the pper canopy cover (B) (bell shaped) p the

rod. Slide the lower canopy cover (C) p to rod.

4. Feed the five wires and the safety cable thro gh the

center hole in the steel yoke connecting piece above

the motor (A) and then contin e feeding wires and

cable thro gh the downrod ntil the wires and cable

come o t at the pper (shackle) end.

5. Mo nt the downrod to the yoke (A) and replace the

hexagon screw. Sec re the spring washer hexagon

n t and spread the coffer pin.

NOTICE: The safety cable sho ld be taped to one side

of the yoke with electrical tape to prevent the cable from

resting on top of motor d ring r nning operation.

(See Figure 2)

6. Slide the lower canopy (C) to be a 1/4” minim m

height above the motor.

CAUTION: Do not allow the permanently installed

lower canopy to touch the revolving motor as dam-

age will occur. Make sure all wires are securely

placed to avoid rubbing against the motor.

7. Attach the three blades, c rved side down to the motor

with the ins lation pad mo nted between the blade

and the motor. Make s re blade holder is flat against

motor platform when tightening blade n ts for sec re

fit.

CAUTION: Blades must be fastened to the motor as

shown in Figure 1. DO NOT reverse blades when

installing.

NOTE: Blades are weight balanced per set. DO NOT mix

on m ltiple fan installations.

NOTE:Do not bend fan blade brackets.

WARNING: DISCONNECT CIRCUIT POWER BEFORE

MAKING ANY ELECTRICAL CONNECTIONS.

CAUTION: To reduce the risk of personal injury,

install the primary mounting directly from building

structure and use only the hardware provided with

the fan.

8. Before attaching the appropriate “J” hook to the

b ilding str ct re member note the following:

IMPORTANT. WHEN MOUNTING THIS FAN, THE

SUPPORT BEAM MUST BE SUITABLE FOR A 50

POUND LOAD LIMIT.

Figure 1 - Assembly

WOOD JOIST METAL BEAM

STYLES

HOOK

WIRE

RUBBER

ROLLER

(D) UPPER SHACKLE ASSEMBLY

CAUTION: Leave 1/4” clearance

between upper canopy

and ceiling.

(F) SET SCREW

(B) UPPER CANOPY COVER

DOWNROD

(C) LOWER CANOPY COVER

CAUTION: Leave 1/4” clearance

between lower canopy

and motor housing.

(E) MOUNTING HEX BOLT SET

HEX BOLT

PLASTIC PAD

MOTOR HOUSING

LOCKWASHER

BLADE

CAUTION: Never adjust the

lower shaft bolt assembly which

is precision secured during the

manufacture of this fan.

STEEL YOKE

CAPACITOR

2

COTTER PIN

MOTOR YOKE

ASSEMBLY