5

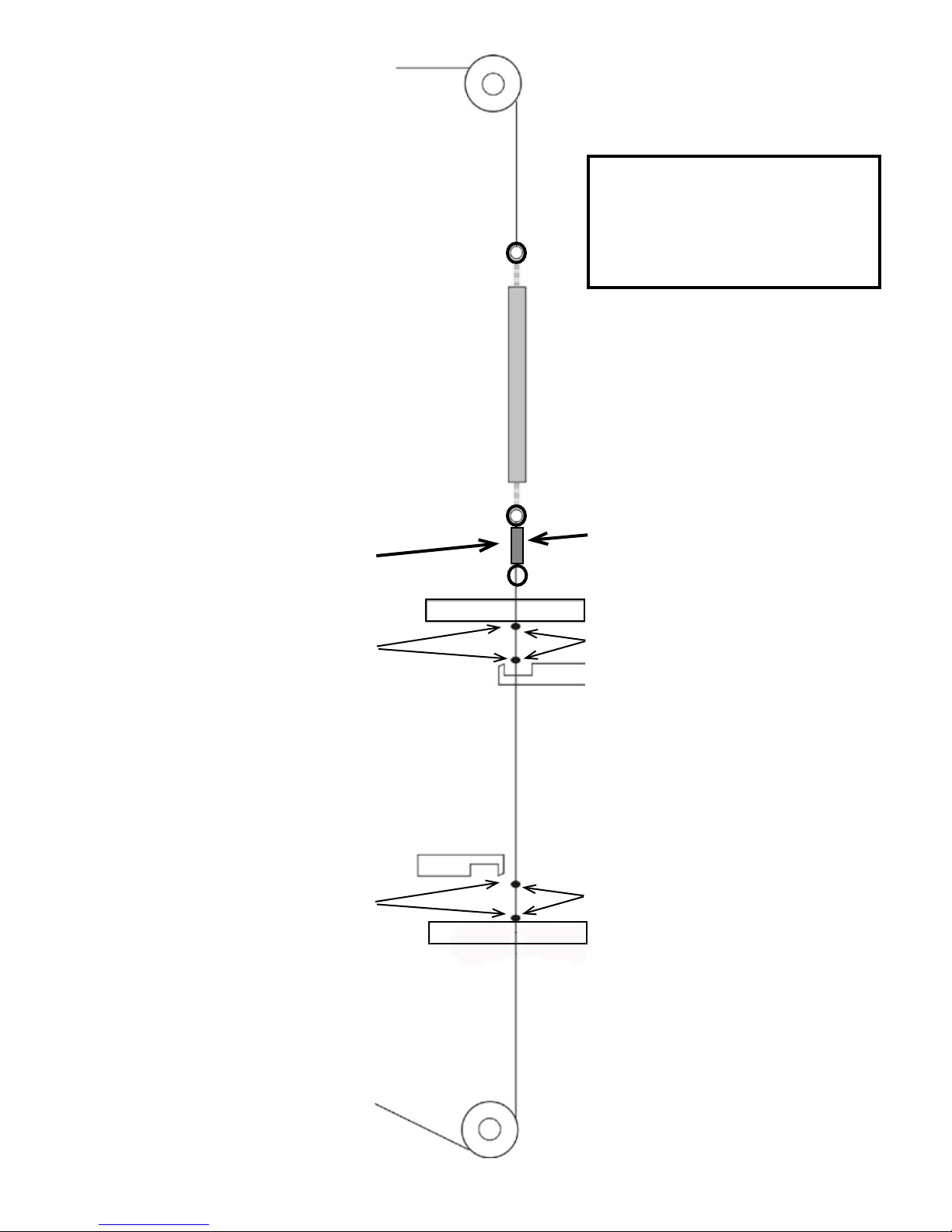

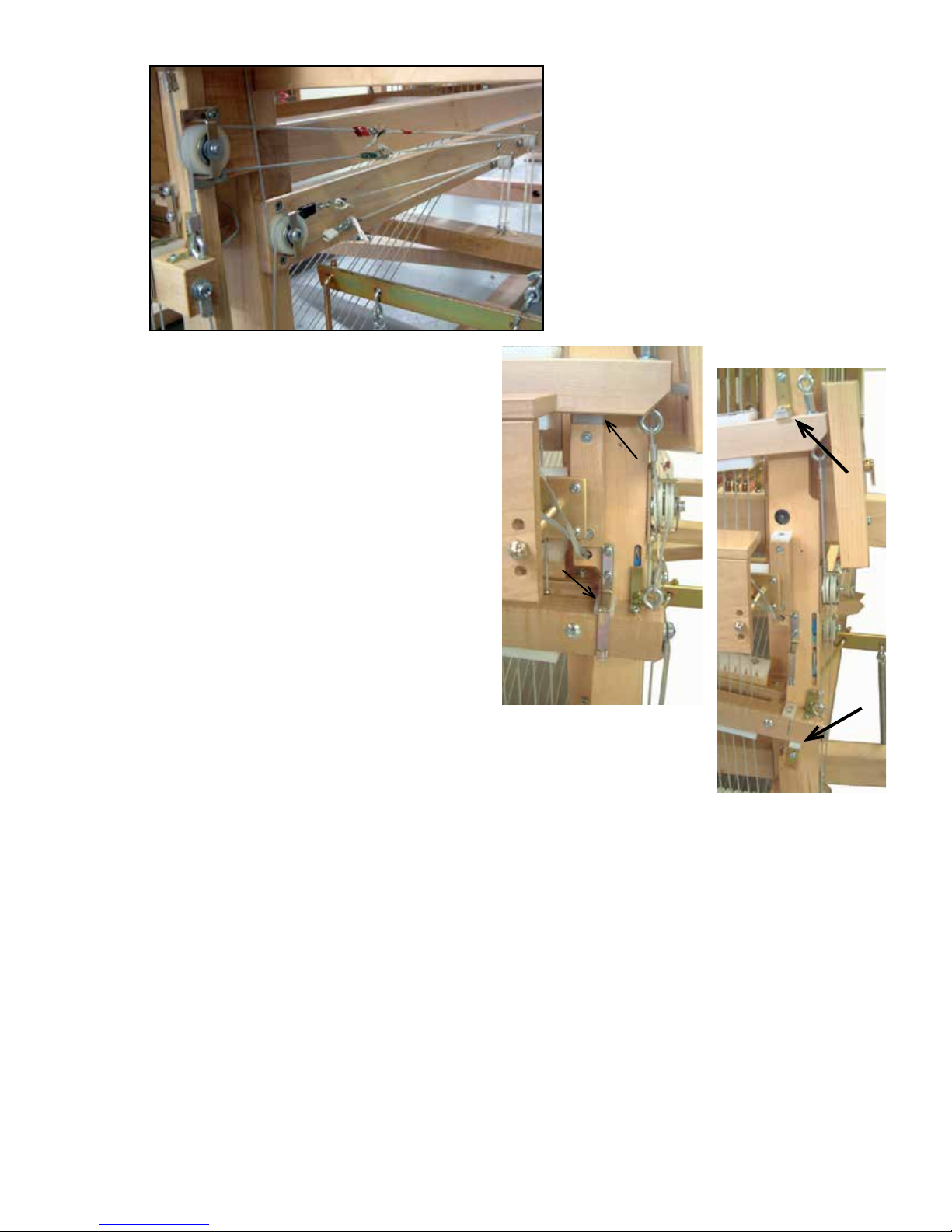

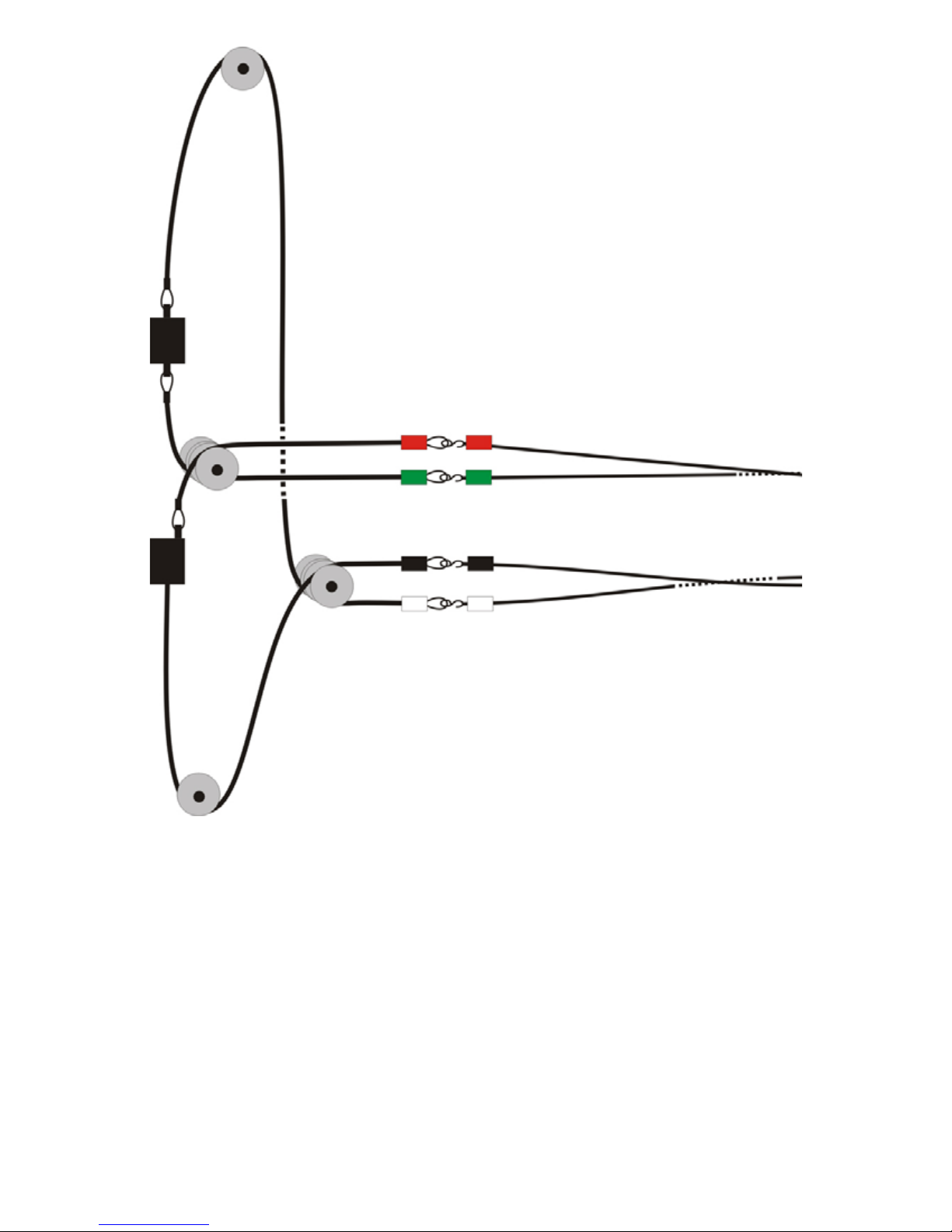

- Make sure that the left treadle is com-

pletely down.

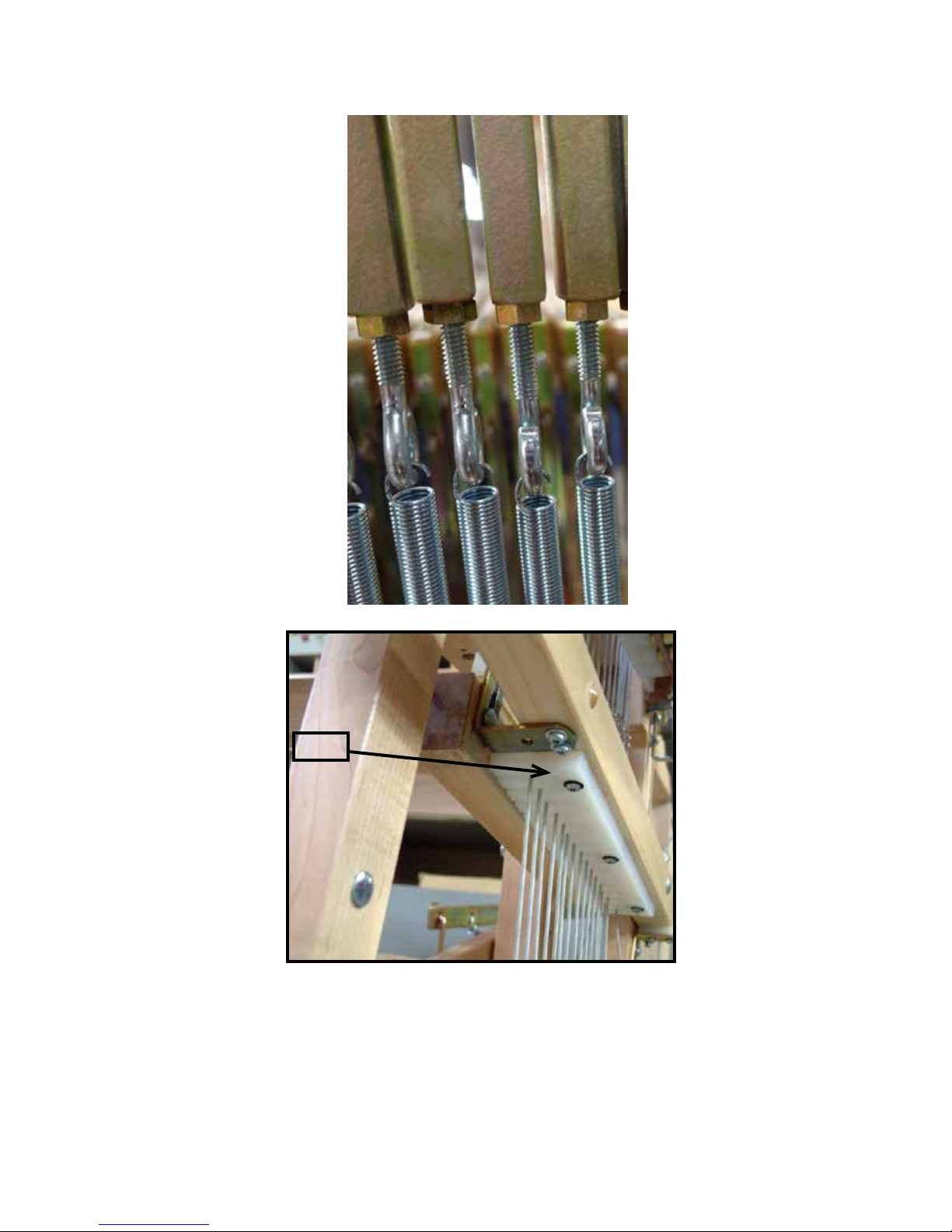

- Connect the spring to the eyebolt

- adjust the eyebolt height so the distance

between the top of the cable and the bottom

of the spring is approx 3/8" with the weight

at the lowest position.

- Connect the spring to the bottom cable

by stretching the spring a little.

The bottom cable should now be straight

and have a small amount of tension on it.

CABLE TENSION ADJUSTMENT

for the lower cables with springs

"If necessary"

1/8"

Ajustement de la tension sur les ressorts.

"Si nécessaire"

- Assurez-vous que la pédale de gauche soit bien enfoncée

- Joindre le ressort à l'oeillet

- Ajuster l'oeillet pour avoir environ 3/8" entre l'extrémité du

câble du bas et le bas du ressort

- Joindre le câble du bas au ressort en étirant un peu le res-

sort. Le cable du bas doit maintenant être droit et avoir une

petite tension.