9

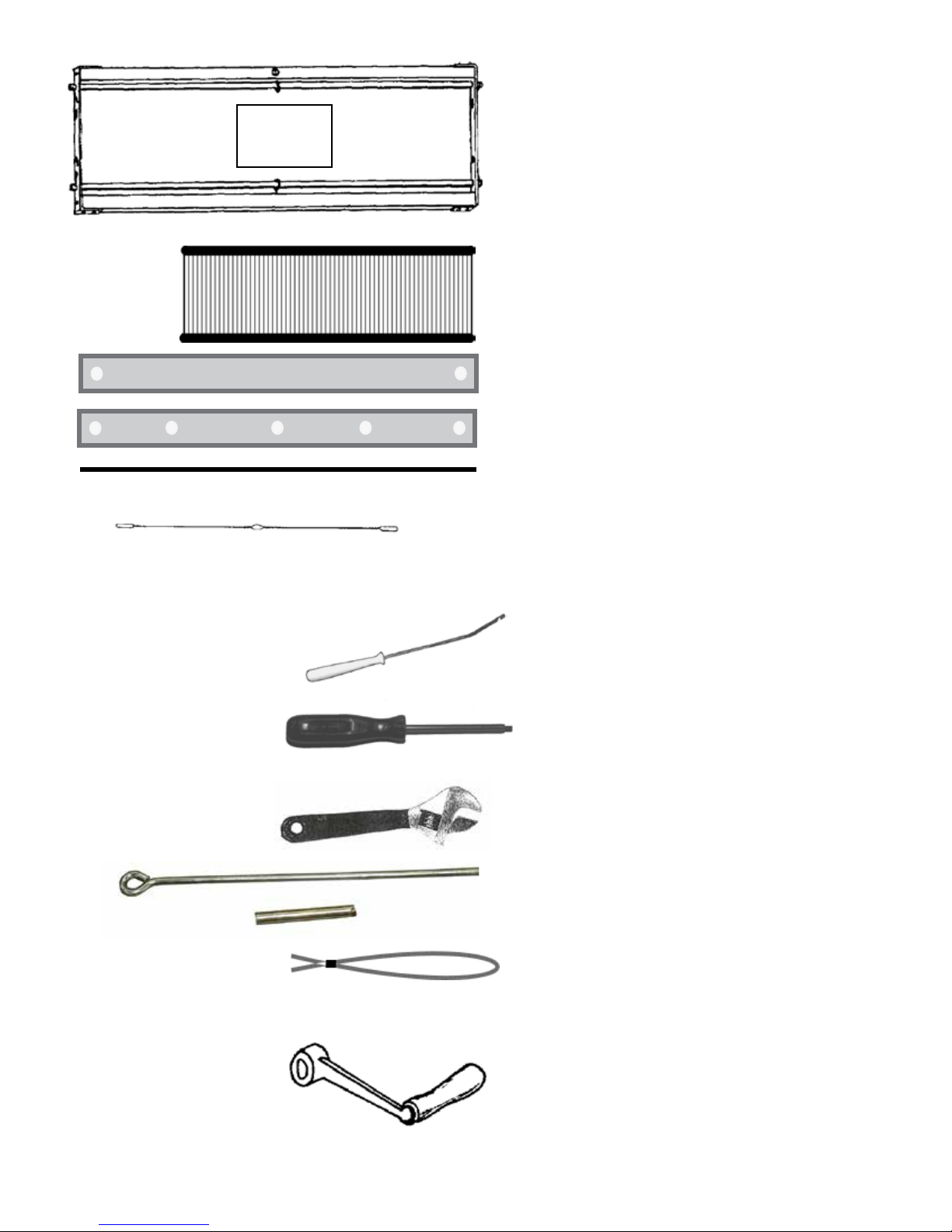

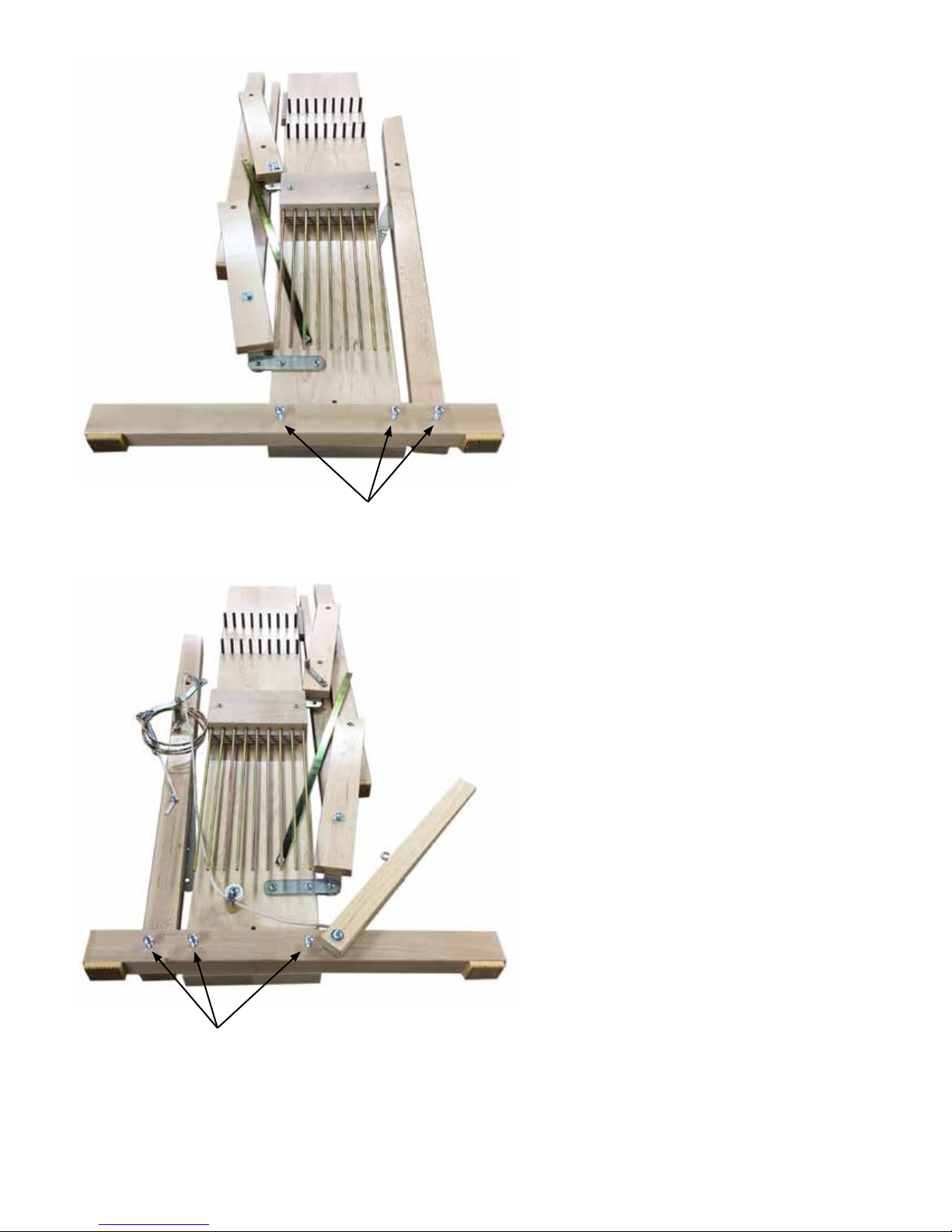

Place the take-up motion handle E, with a

9/16” steel

washer, on the right-hand side end of cloth

beam F.

Note: The ratchet gear is on the right-hand

side beam end.

The ratchet pawl afxed to the take-up mo-

tion handle must be lifted up.

Insert the end of cloth beam F into the holes

in upper front cross-members G and G` The

hole in lower middle cross-member B must

be right beside the hole at the bottom of

right-hand side A`

Using a 2” (50 mm) round-headed screw

no. 14, afx right-hand side A` to lower

middle cross-member B.

Using two 2” (50 mm) round-headed screws

no. 14, afx one of the two breast beams to

the top of the front posts B and B`

The rounded edge must be towards the out-

side of the loom.