Leclerc Looms COMPACT 8 SHAFTS User manual

Other Leclerc Looms Weaving manuals

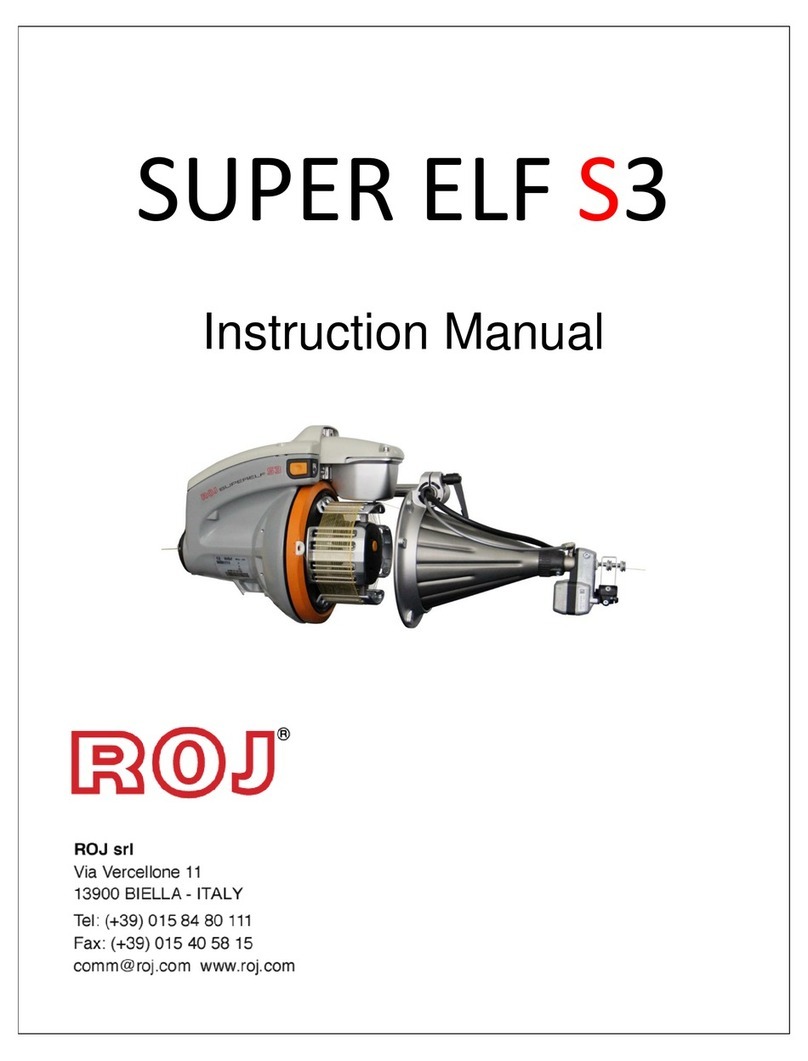

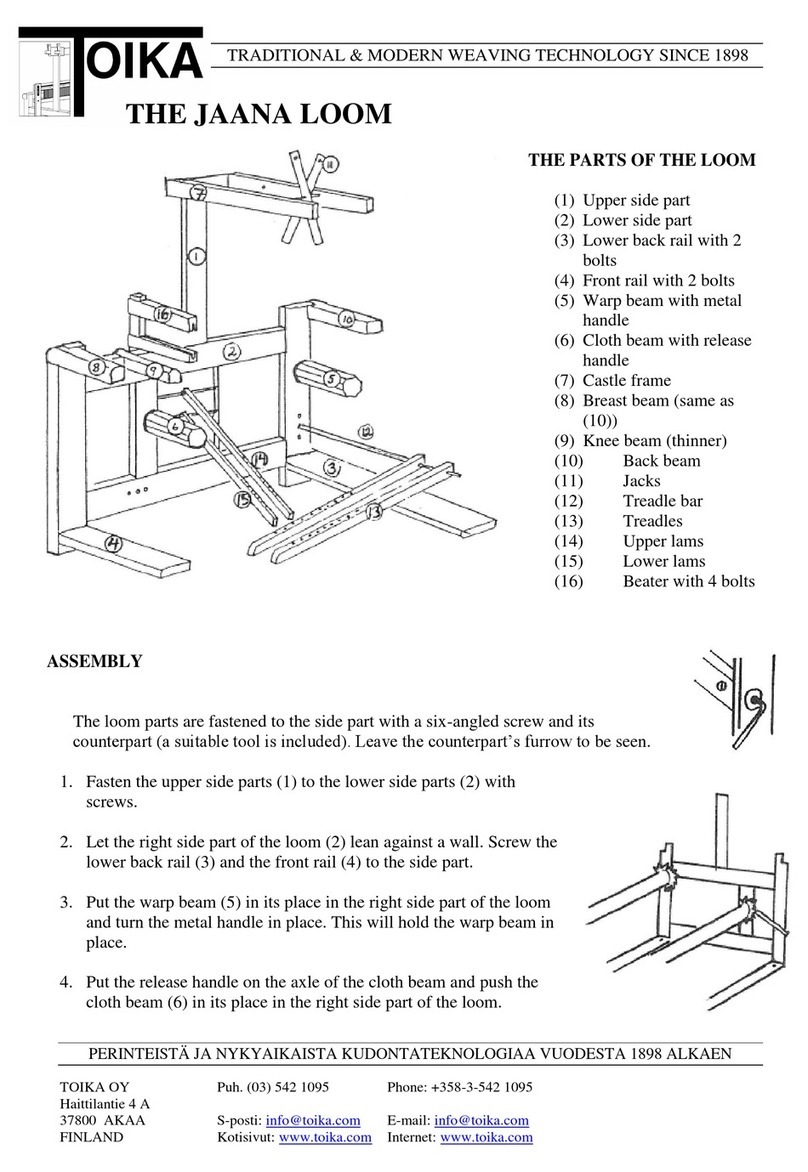

Popular Weaving manuals by other brands

Schacht

Schacht CRICKET LOOM Assembly and Weaving Instructions

Schacht

Schacht FL3109 Assembly instructions

Schacht

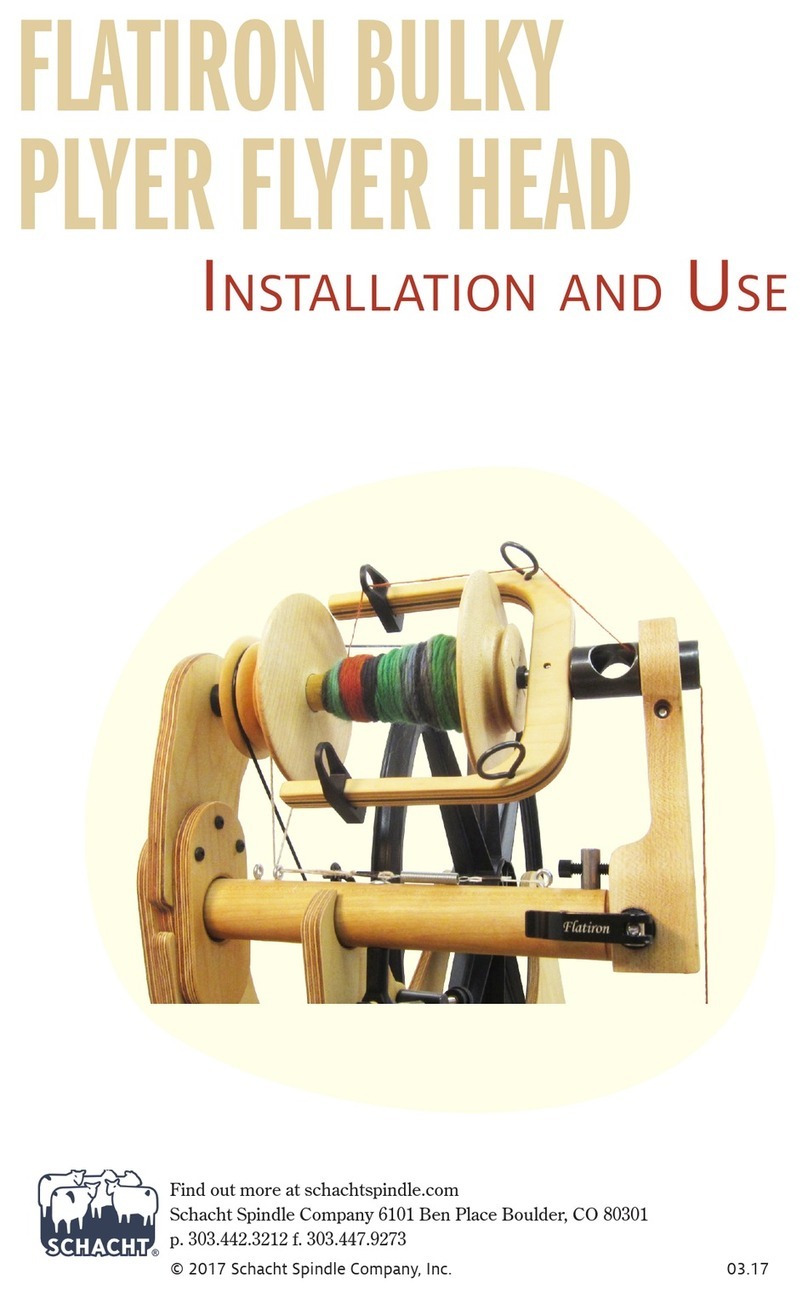

Schacht FLATIRON BULKY PLYER FLYER HEAD Installation and use

Schacht

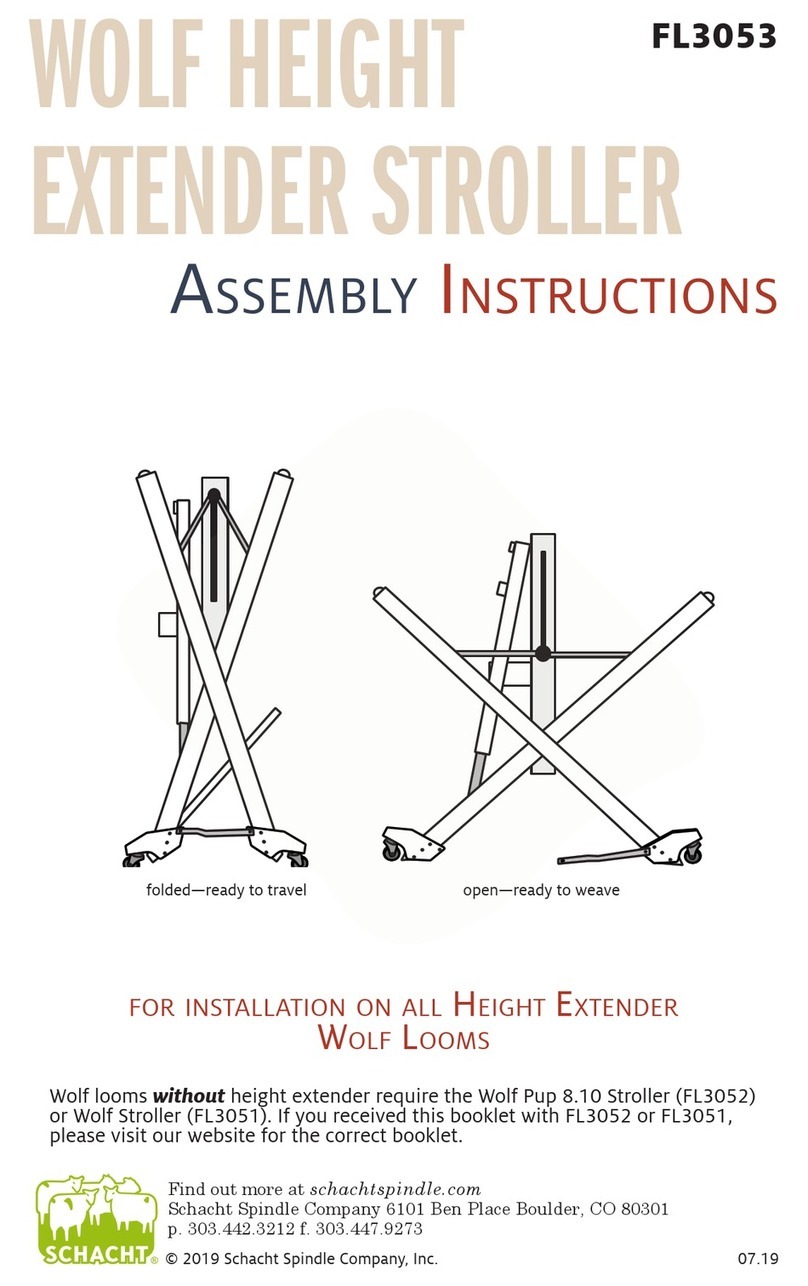

Schacht FL3053 Assembly instructions

Schacht

Schacht WOLF PUP 8.10 HEIGHT EXTENDER Assembly instructions

Schacht

Schacht SL2225 Assembly instructions