Power Wiring

- Please follow the PSU selection guidelines below in order to

select the correct Power Supply.

- Use at least 18 AWG (0.75mm2) for DC Power In connection.

- It is highly recommended to connect all 4 terminals of the

Power In screw terminal block.

Important

Maintain correct polarity when connecting the Power Supply.

Failure to do so may cause damage to the Unit.

PSU selection guidelines

The PSU must be selected while considering the maximal num-

ber of serried LEDs per channel in the application, output cable

type/length and the power rating needed to drive the LEDs at

the desired current.

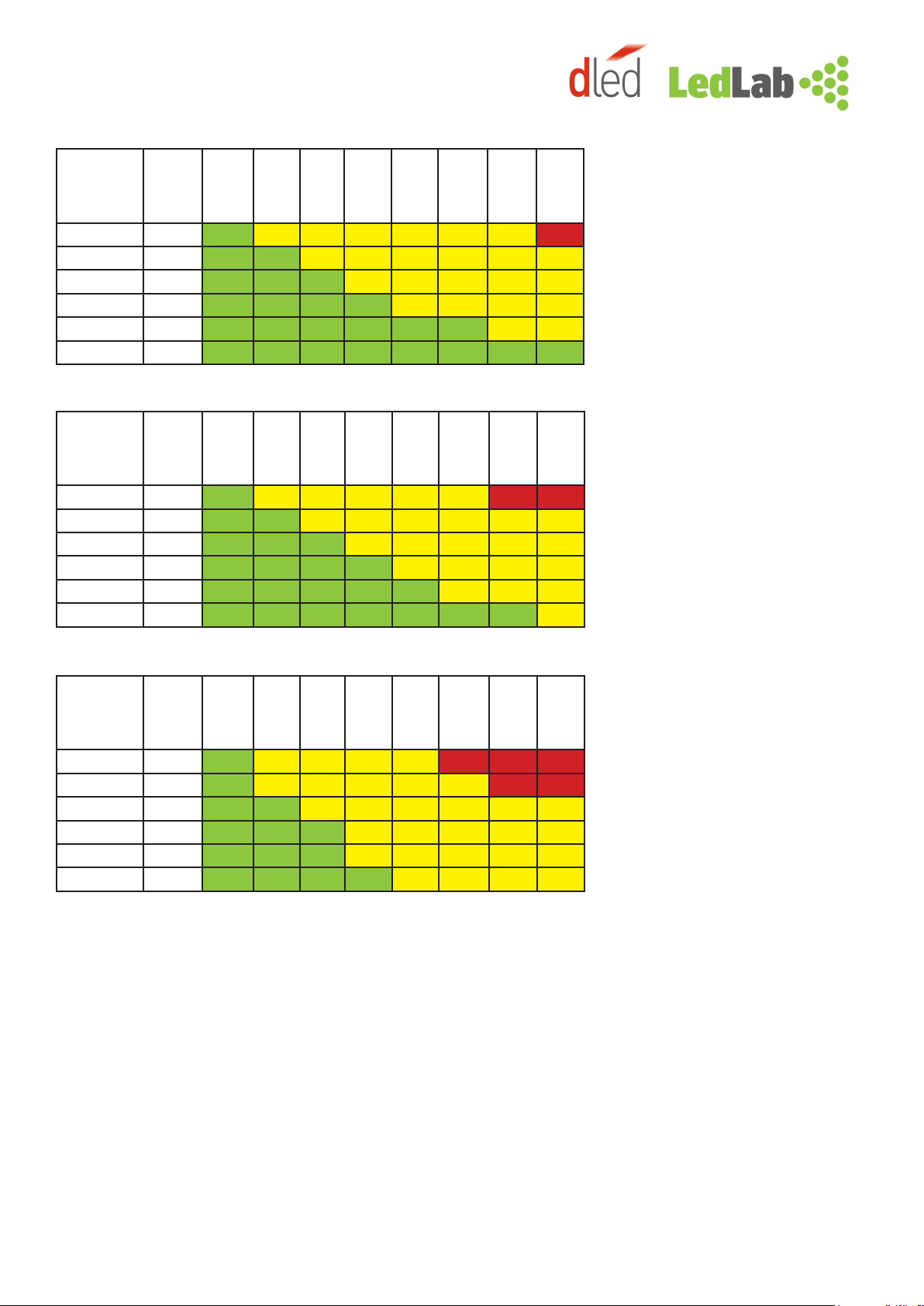

Below is a table that illustrates the relationship between the

variables

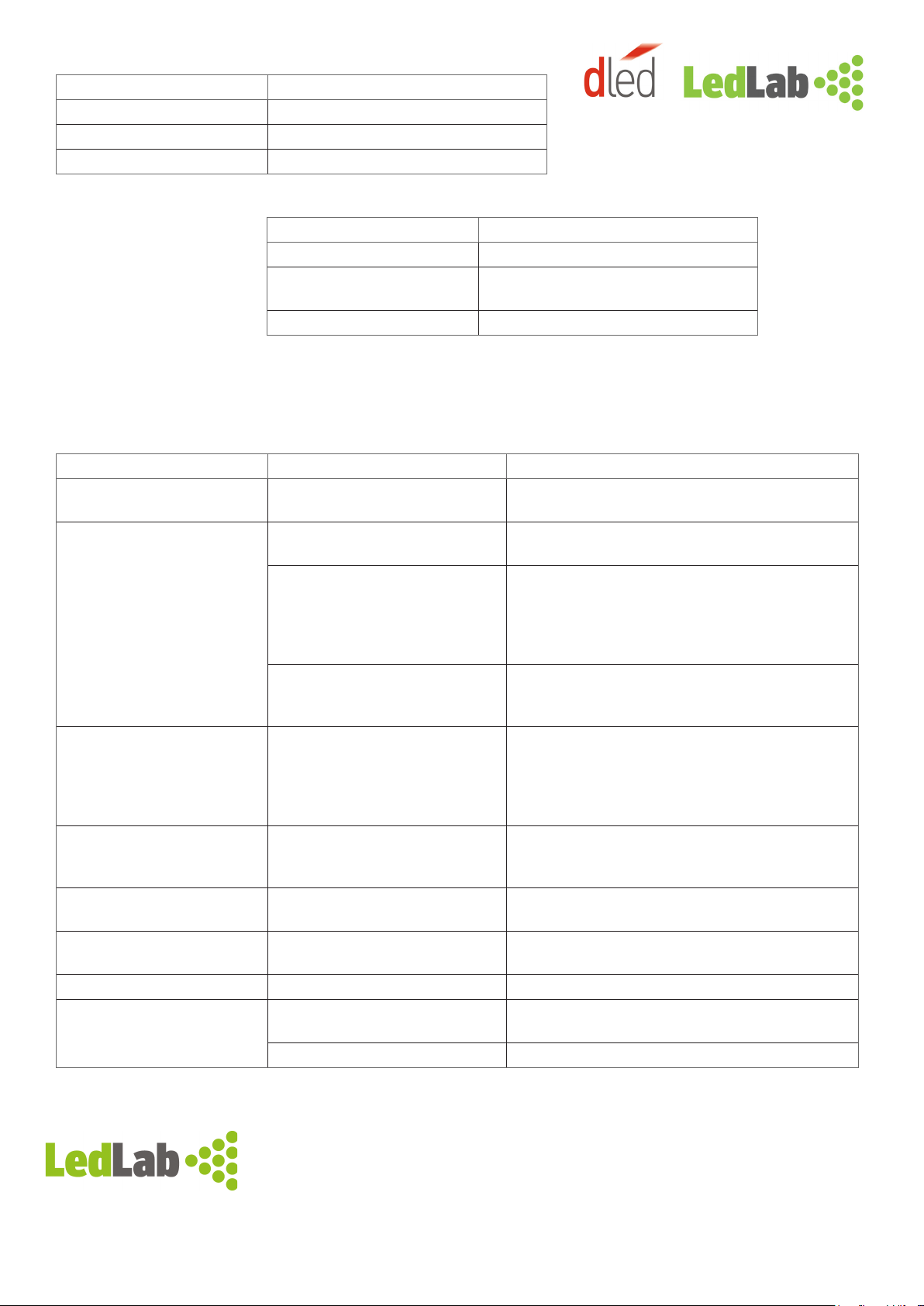

PSU selection table for High-Power LED xtures

The calculations were made assuming the following conditions:

- All 4 channels are equally loaded.

- 15% power was added to the nominal ratings as a minimal com-

pensation reserve for system eciency and drop voltage on the

output line.

The values presented in the tables of this section are general

guidelines only, and as such should be used with caution. Always

check the specications of the LED xtures used as a load and

conrm whether the conditions stated above satisfy the needed

requirements.

PSU selection table for COB LED xtures

The calculations were made assuming the following conditions:

- All 4 channels are equally loaded.

- 15% power was added to the nominal ratings as a minimal com-

pensation reserve for system eciency and drop voltage on the

output line.

- Red color means that the specied COB chain cannot be used

(due to high Vf).

The values presented in the tables of this section are general

guidelines only, and as such should be used with caution. Always

check the specications of the LED xtures used as a load and

conrm whether the conditions stated above satisfy the needed

requirements.

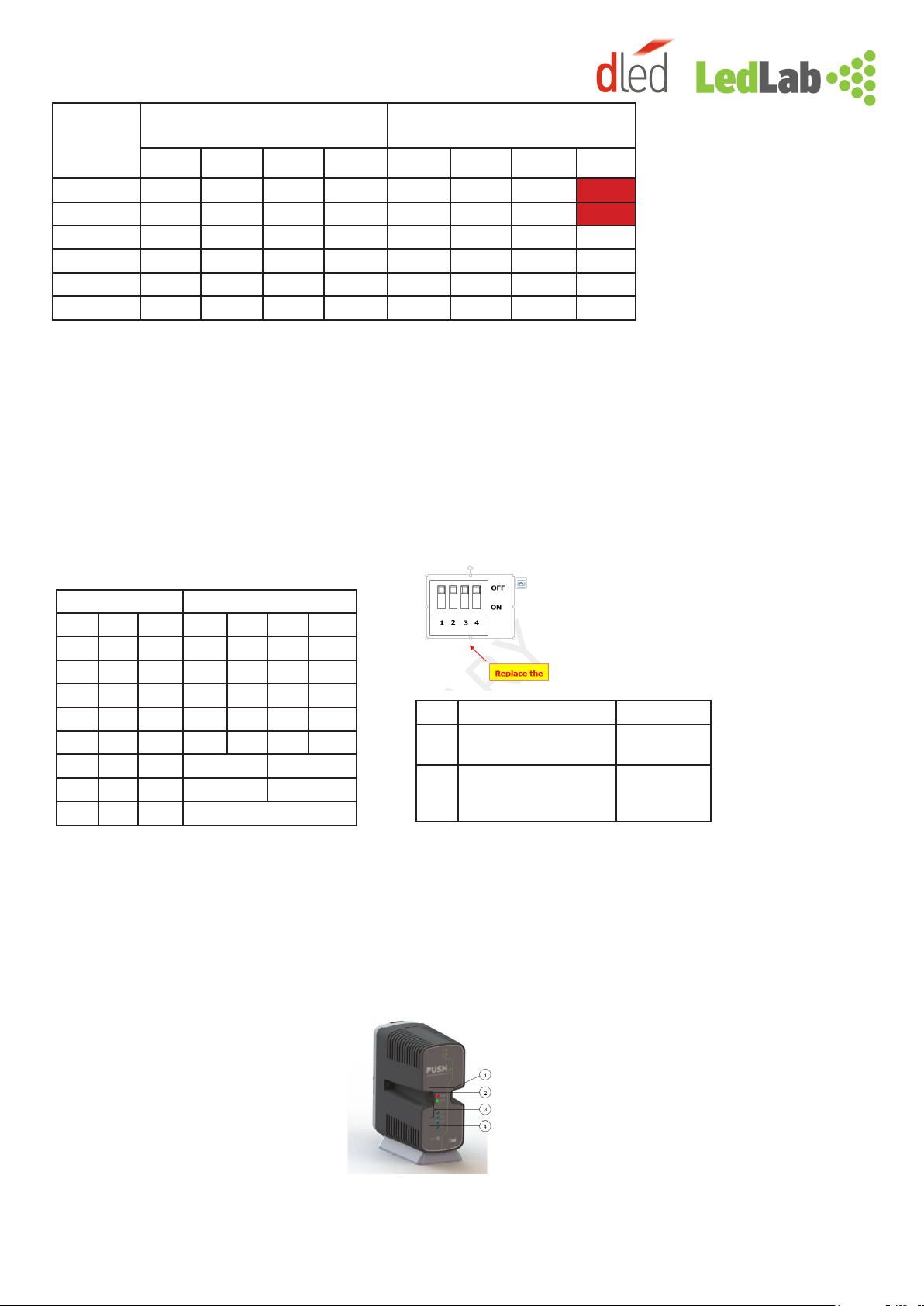

Numbers

of LEDs in

series per

channel

Total Vf

of LEDs

(typ.)

Recommen-

ded PSU

Voltage

Minimal PSU power

rating for PUSH

350mA 500mA 700mA

13,5V 24V 5,6W 8,1W 11,3W

2 7V 24V 11,3W 16,1W 22,5W

3 10,5V 24V 16,9W 24,2W 33,8W

6 21V 24V 33,8W 48,3W 67,6W

9 31,5V 48V 50,7W 72,5W 101,4W

12 42V 48V 67,6W 96,6W 135,2W

Numers

of COB

xtures in

series per

channel

Rated

power

of COB

Total Vf of COB Recommended

PSU Voltage

Minimal

PSU

power

rating for

PUSH

1050mA 1400mA 1050mA 1400mA

1

10W 9,5V 7,1V 24V 24V 23W

15W 14,3V 10,7V 24V 24V 35W

20W 19,0V 14,3V 24V 24V 46W

25W 23,8V 17,9V 48V 24V 58W

2

10W 19,0V 14,3V 24V 24V 46W

15W 28,6V 21,4V 48V 48V 69W

20W 38,1V 28,6V 48V 48V 92W

25W X 35,7V X 48V 115W

310W 28,6V 21,4V 48V 48V 69W

15W X 32,1V X 48V 104W