www.legendhydronics.com

1-866-752-2055

300 N. Opdyke Rd.

Auburn Hills, MI 48326

www.legendhydronics.com

866-752-2055

HS-808

HYDRAULIC SEPARATOR

Installation Guide

Installation / Assembly-continued

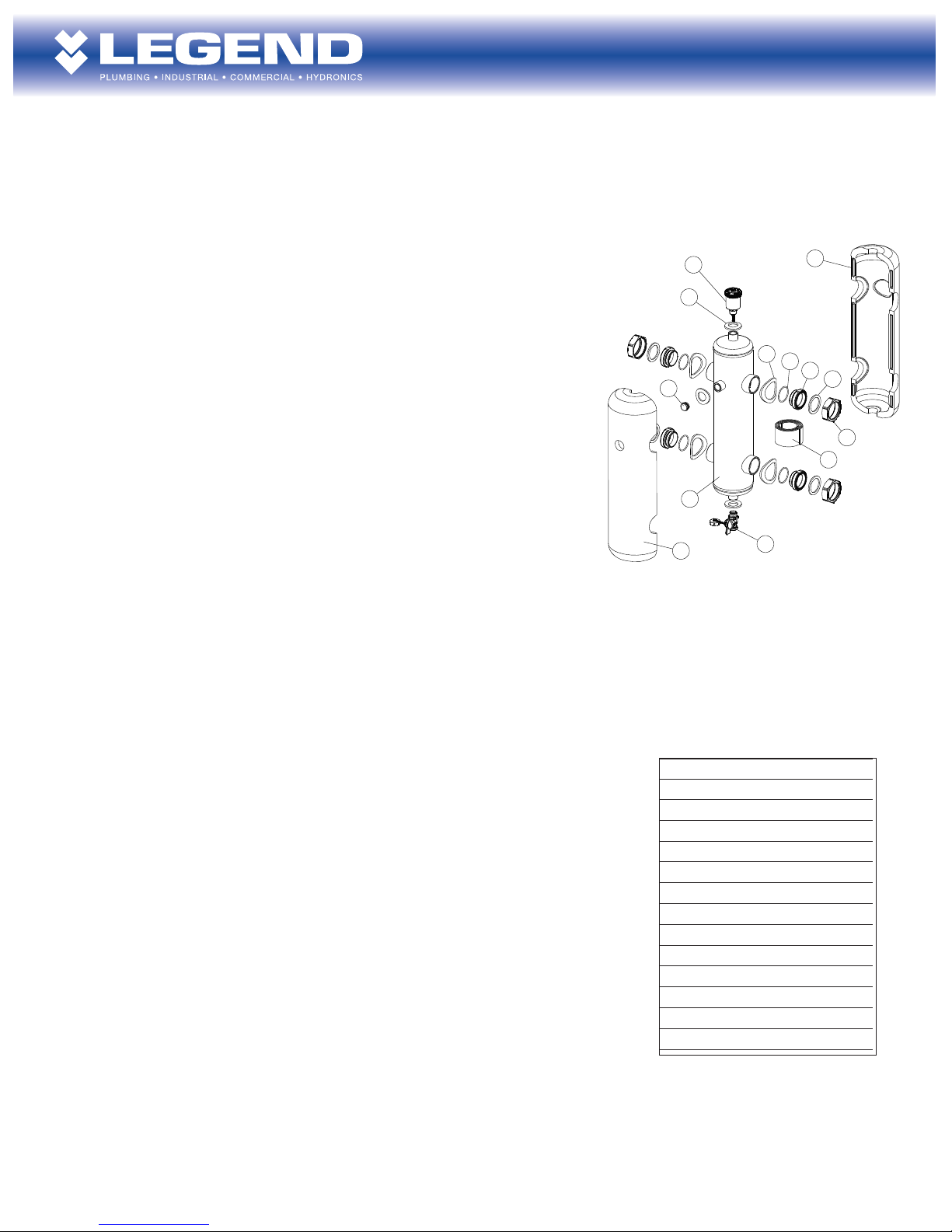

8. The Air Vent (2) should always be installed onto the 1/4” x 1/2” Service Check Adapter (included

with the Automatic Air Vent). Thread the male end of the Service Check Adapter into the top 1/2”

port on the HS-808. Thread the 1/4” male threads of the Air Vent into the Service Check Adapter

hand tight¹ only.

9. Thread the male end of the Fill/Purge Valve (3) into a lower 1/2” port of the HS-808 until tight¹.

Orient the Fill/Purge Valve so that the handle can be operated comfortably once the HS-808 is

installed. The opposite end of the Fill/Purge Valve has a 3/4” male garden hose thread (GHT) port

and includes a brass cap with plastic tether. The plastic tether should slide over the end of the GHT

port end of the Fill / Purge Valve. The brass cap, with EPDM gasket included, should be threaded on

to the GHT port of Fill / Purge Valve until ready to use.

10. Install the insulation shell, (7) & (8) on the back side rst, then on the front side. Push the two

halves together and then use the aluminum tape (9) to seal the seams and keep the two halves of

the insulation shell together.

Note: These parts seal together and to the manifold with an EPDM gasket (o-ring). One quarter (1/4) turn beyond

“hand-tight” is normally sufcient to seal properly. If turning beyond 1/4 turn is required to align gauges and

handles then do so, up to one (1) full turn beyond “hand-tight”.

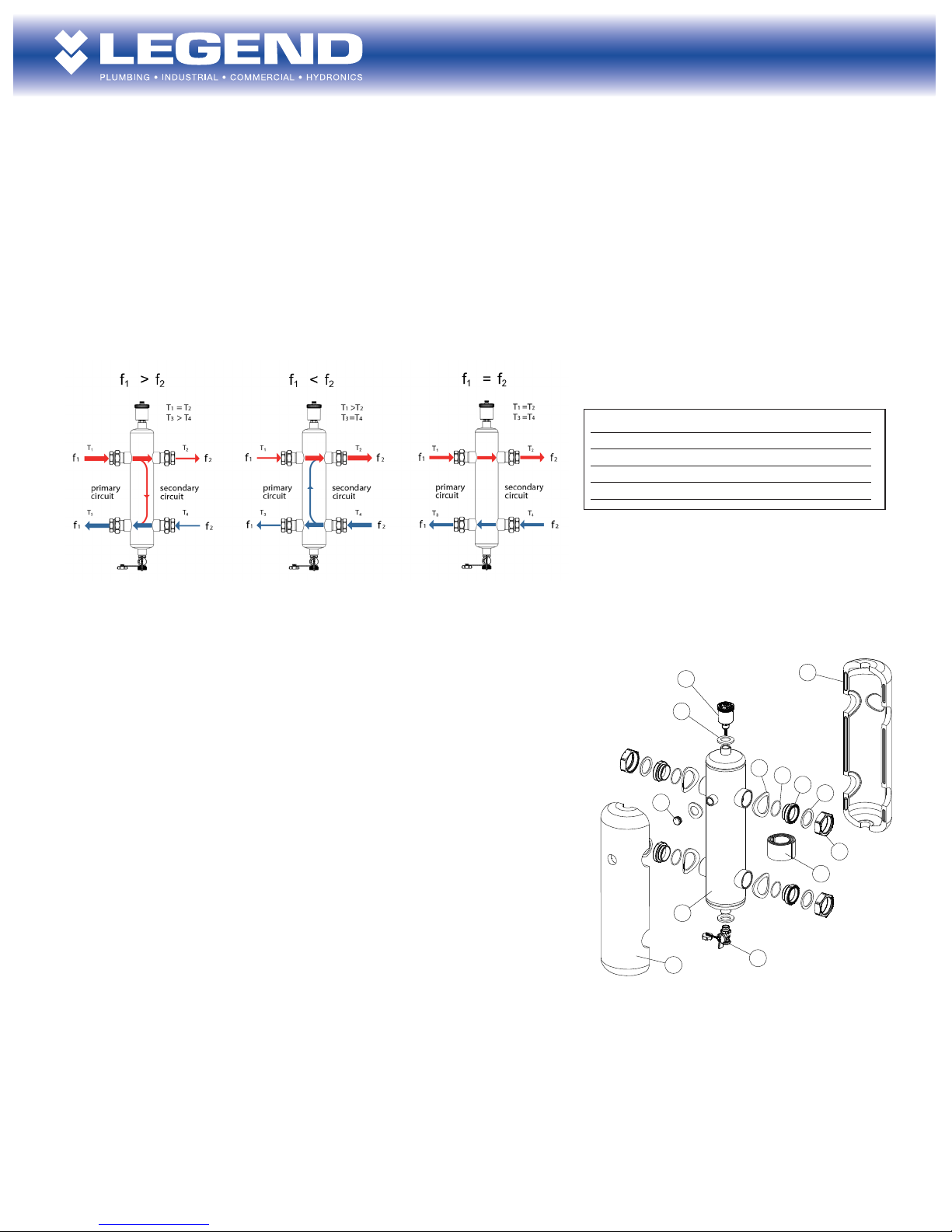

PART

1 Body

2Automatic Air Vent w/ Check

3Drain Valve w/ GHT

4 Temp. / Pressure Port Plug

5Adhesive Insulation Ring Lg (x4)

6Adhesive Insulation Ring Sm (x3)

7Insulation Shell, front

8Insulation Shell, back

9 Insulation Tape

10 O-Ring

11 MPT body adapter

12 Adapter gasket

13 Union nut

1

2

6

8

4

511

10

12

13

9

3

7

Maintenance

A. Air Vent cleaning (as recommended by system designer, typically once per year minimum) – Remove the

air vent from the 1/4” x 1/2” service check adapter by un-threading counter-clock wise, as quickly as possible.

While un-threading the air vent from the check valve, a small amount of system uid may leak (drip) out, but

should stop upon nal removal from the check valve. This is normal as the check valve mechanism does not

complete close off until the air vent is fully removed. Un-thread the cap on the air vent, counter-clock wise

and remove the internal plastic components. Rinse the plastic components with clean water to wash off any

debris. Check and rinse, as needed, any debris from within the brass air vent body prior to reinserting the plastic

components. Re-attached the air vent cap by tightly threading clock-wise onto the air vent body. Replace the air

vent back into the 1/4” female threads of the check valve, hand tight only.

B. Debris blow out (as recommend by system designer, typically within 1 week of system start-up and a

minimum of once per year thereafter) – If possible, close the isolation valves for the HS-808 to isolate it from

system pressure. If isolation valves have not been installed, the following instructions can still be followed;

however special care should be used when opening the drain valve as excessive loss of system uid may occur.

Remove the brass cap from the GHT on the drain valve. Attach a drain hose with GHT female connection to

the end of the drain valve and locate the open end of the hose in a bucket or suitable drain location. Open the

drain valve (no more than 2 seconds at a time if the HS-808 has not been isolated) to allow the debris collected

at the bottom of the HS-808 to blow out through the hose and into the bucket or suitable drain location. Once

completed, remove the hose from the drain valve and re-install the cap.

C. Check system pressure into the HS-808, slowly reapply system pressure and check for leaks. Once it’s

conrmed that there are no leaks, the system can be put back into operation. Especially if no isolation valves were

used, you may need to repeat the ll/purge procedures recommended by the system designer to replace lost uid

and repressurize the system.