IMPORTANT

Watch the Online

Instructional Video

in the Support Section

at www.leighjigs.com

Step 13 Two hose adaptors, 2" (51mm) and 2 ½" (63.5mm), are included with the

VRS1200.

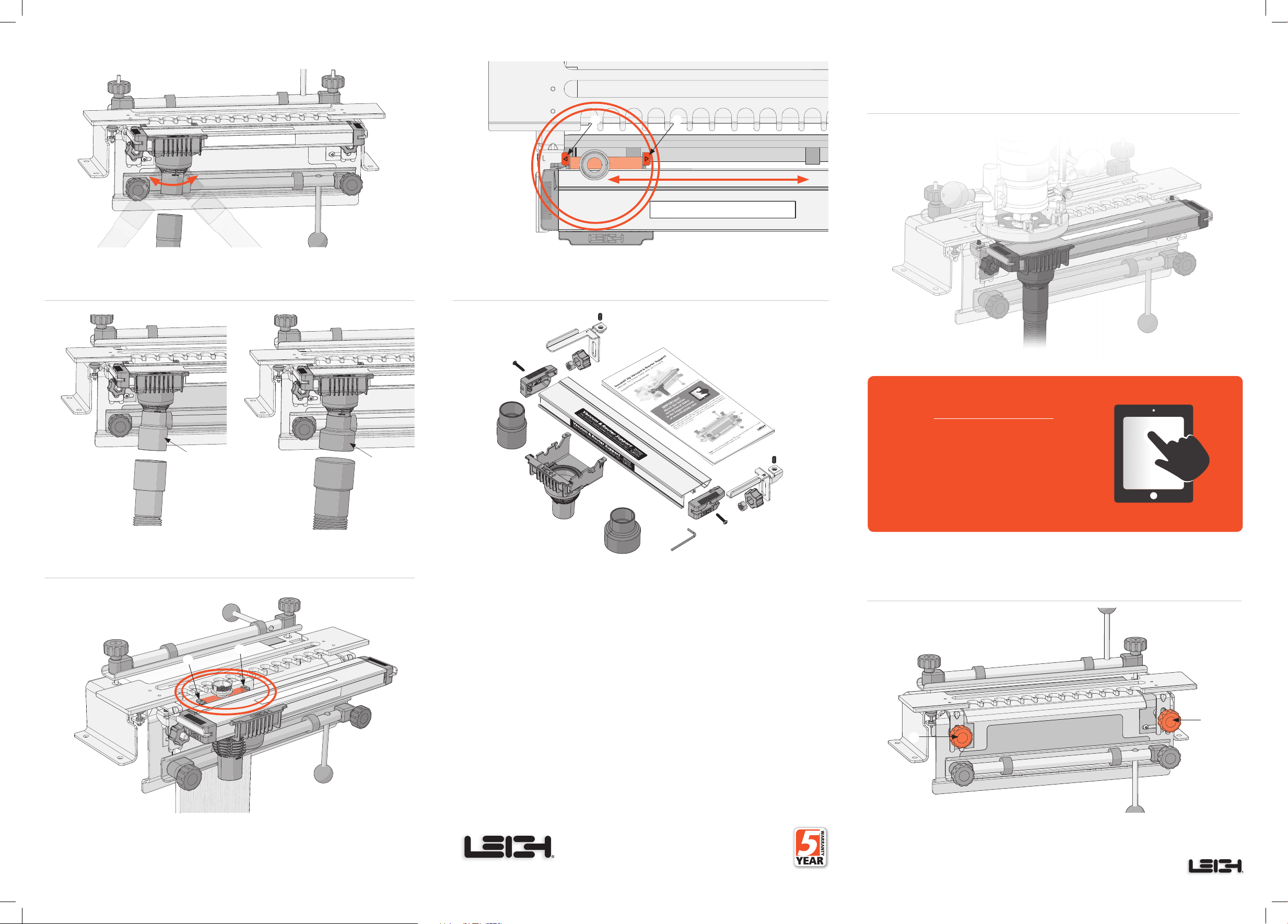

Step 14 When routing, the VRS1200 beam should be moved closer to the workpiece

for maximum chip collection. The tabs Aon either side of the vacuum box should be

close to, but not touching the workpiece. The guide bushing mounted to the router

base is positioned between the tabs of the dust collector.

Step 15 As the router moves across the beam, in and around the fingers, the guide bushing

attached to the router base contacts the vacuum box tabs

A

and moves it across the beam.

The vacuum box is always positioned for maximum dust collection.

Step 12 The swivel action vacuum port accepts a 1½"(38mm) diameter hose.Attach

your shop vacuum hose to the dust collection port on the vacuum box assembly.

Leigh Router Joinery Jigs

2" (51mm)

Adaptor 2-1/2" (63.5mm)

Adaptor

Step 2 To do the one-time setup, start by loosening the jigs template knobs Aand

raise the template about 1". Loosely tighten the knobs to hold the template in place.

A

A

Step 1 Watching the online video in addition to reading this user guide will reduce

your learning time dramatically. The video can be streamed to your smart phone or

tablet and used in your shop as a visual reference. Visit leighjigs.com and find the video

in the Support section.

A

A

Customer Support

See Online Installation & Setup Video at www.leighjigs.com

Leigh Router Joinery Jigs

Printed in China

© 2018 Leigh Industries Ltd. All rights reserved.No part of this publication may be reproduced,

stored in a retrieval system,or transmitted in any form or by any means,electronic, mechanical,

recording, or otherwise, without the prior written permission of Leigh Industries Ltd.

Leigh Industries Ltd. is not an authorized dealer, distributor or service provider or otherwise

affiliated or associated with Porter Cable. 10/2018

Dovetail Jig Vacuum & Router Support

VRS1200 Fits Porter Cable 4210, 4212 & 4216

Installation & Setup Guide

For a list of Leigh dealers, visit www.leighjigs.com

US Patent No.7,507,060 B2 UK Patent No.GB2446909 Canada Patent No. 2,611,233

A A

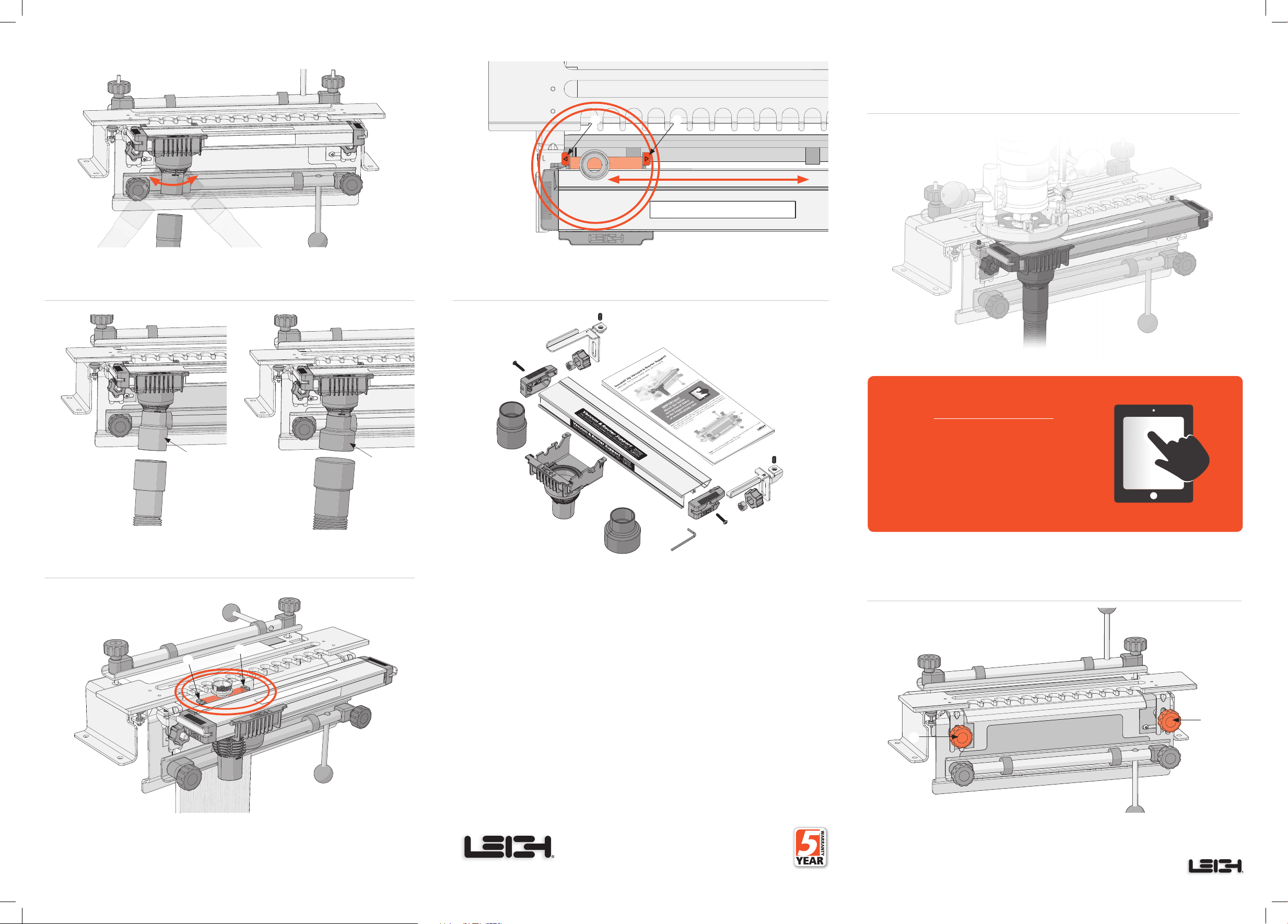

PART DESCRIPTION PART NO. QUANTITY

A VRS1200 Beam Extrusion with Decals 426105 1

BLeft Support Bracket 426175 1

CRight Support Bracket 426180 1

D Support Bracket Set Screw 1/4"- 20 x 1/2” 426185 2

E Left End Cap with Spring 426220 1

F Right End Cap with Spring 426225 1

G End Housing Screw No.8 - 32 x 1" 426190 2

H Support Bracket Knob 426207 2

I Support Bracket Nut 3/8"-16 426208 2

J Vacuum Box Assembly 426230 1

K 2" (51mm) Vacuum Box Hose Adaptor 426150 1

L 2-1/2" (63.5mm) Vacuum Box Hose Adaptor 426155 1

M Hex Key 426216 1

NFully Illustrated Setup guide 426240 1

A

B

C

D

E

F

MG

H

I

J

K

L

D

GH

I

N