TABLE OF CONTENTS .................................................................................................page

PREFACE ..........................................................................................................................37

WARRANTY CONDITIONS .............................................................................................37

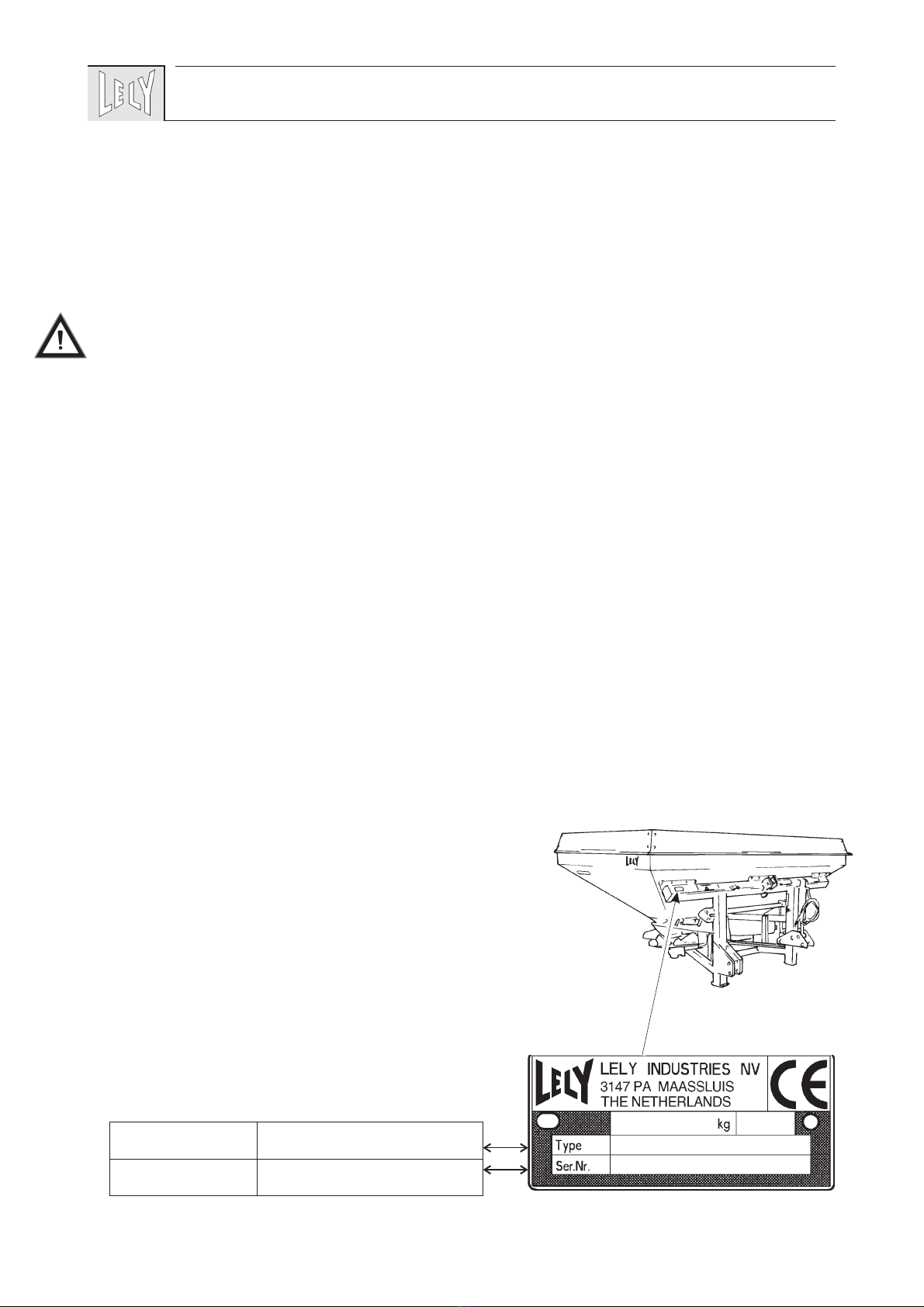

TYPE- AND SERIALNUMBER OF YOUR MACHINE...................................................37

SAFETY INSTRUCTIONS ...............................................................................................38

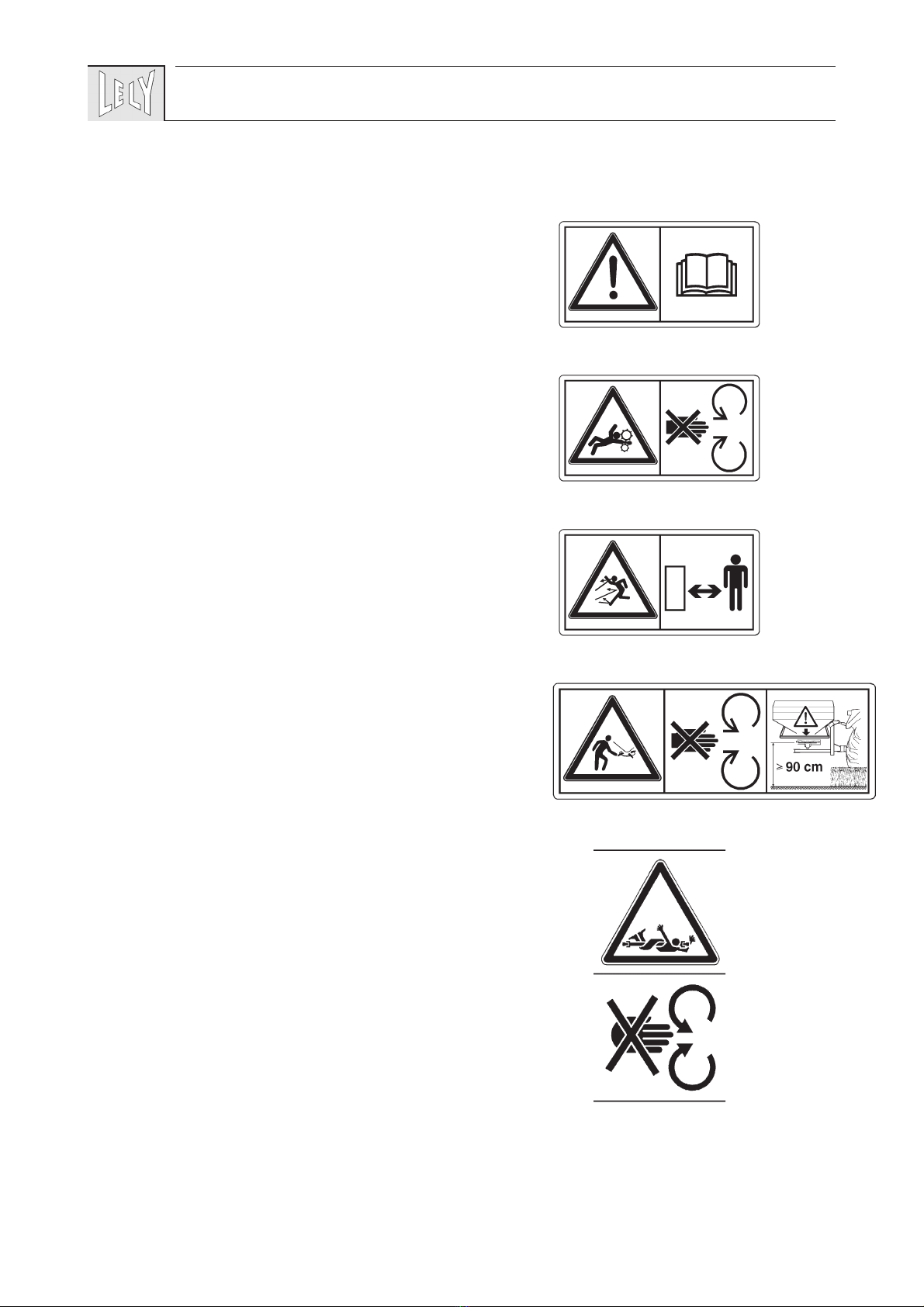

EXPLANATION OF SAFETY DECALS ATTACHED TO THE MACHINE ...................39

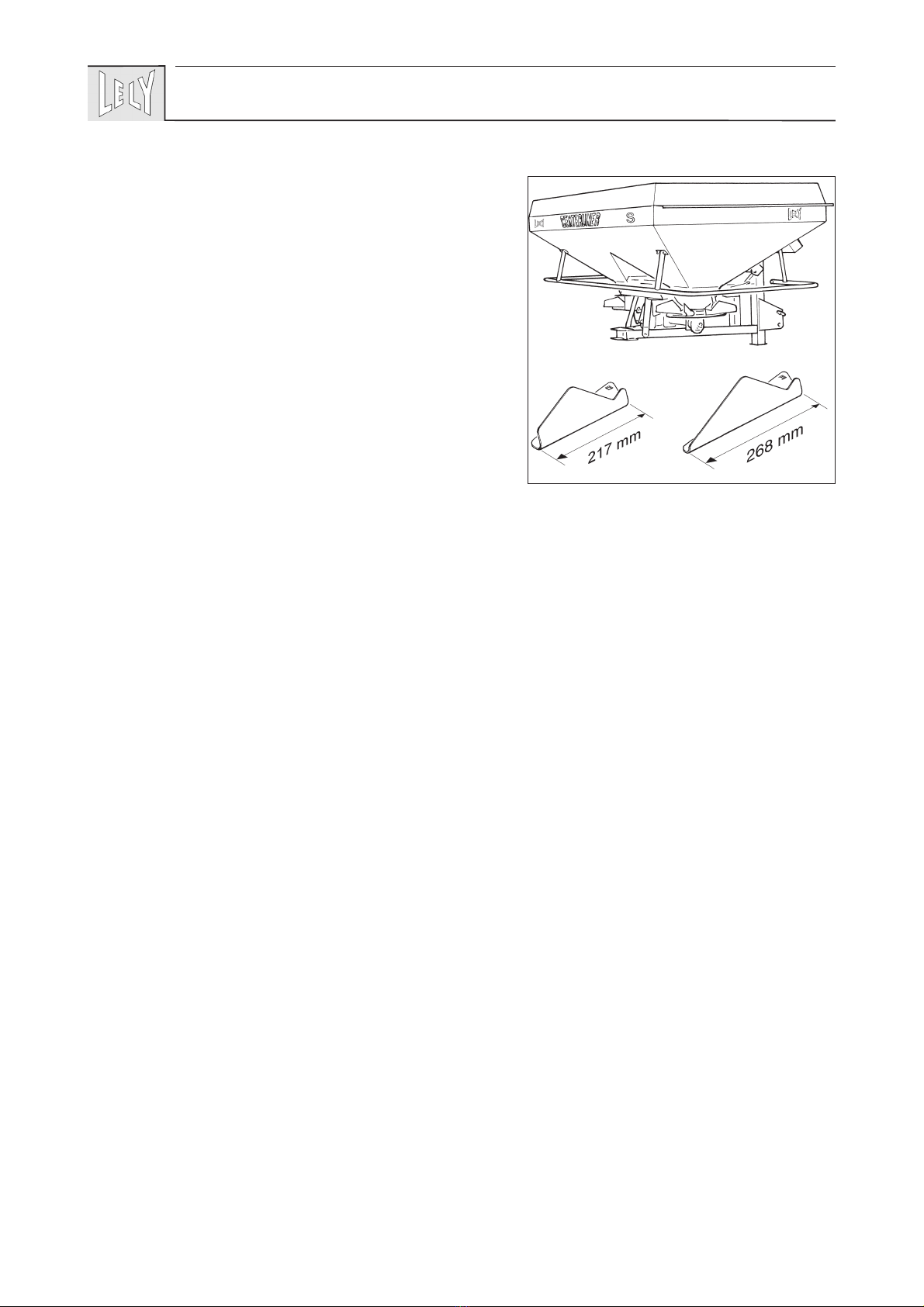

1 DESCRIPTION.............................................................................................................40

2 MOUNTING BEHIND THE TRACTOR ......................................................................42

3 TRANSPORT ...............................................................................................................43

4 MACHINE ADJUSTMENTS........................................................................................44

4.1 Output rates .......................................................................................................44

4.2 Spreading width.................................................................................................47

4.2.1 Spinner discs speed........................................................................................47

4.2.2 PTO output ...................................................................................................48

4.2.3 Forward inclination .........................................................................................49

4.3 Working height...................................................................................................49

4.4 Tilting for headland spreading.........................................................................50

5 WORKING WITH THE CENTERLINER®...................................................................51

5.1 Working with the CENTERLINER S/SL®........................................................51

5.2 Operation schedule...........................................................................................53

5.3 Check of spreading width ................................................................................53

5.4 Check of output rate .........................................................................................54

6 DISMOUNTING FROM THE TRACTOR ...................................................................55

7 MAINTENANCE ...........................................................................................................56

7.1 Maintenance after operation............................................................................56

7.2 Lubrication .........................................................................................................56

7.3 Intermittent maintenance .................................................................................57

Bijlagen

A CONDENSED OPERATING INSTRUCTIONS ...............................................61

B OPTIONAL EXTRAS.........................................................................................62

C TECHNICAL DETAILS ......................................................................................64

35