5

2 SAFETY INSTRUCTIONS

General Safety Instructions

•Before using the machine, always check both it and the tractor for

roadworthiness and operational safety!

•As well as the notes in these instructions the operator is advised to

comply with the generally applicable safety at work regulations and those

relating to use of the public highway!

•The implement may only be operated, maintained and repaired by such

persons who have been made acquainted with it and who have been advised

about the dangers!

•When driving on public roads with a raised machine the lifting control lever

should be locked against unintentional lowering!

•The fitted warning and advisory plates give important information for safe

operation; adhering to these increases your own security!

•When using public roads adhere to applicable traffic rules!

•The operator should familiarise him-/herself with all controls and their functions

before starting work. During work could be too late!

•The clothing of the operator should fit tight. Avoid wearing any loose clothing!

•To avoid danger of fire keep the implement clean!

•Before beginning to drive check surroundings area (children)!

•Sitting or standing on the implement during operation or during transport is not

permissible.

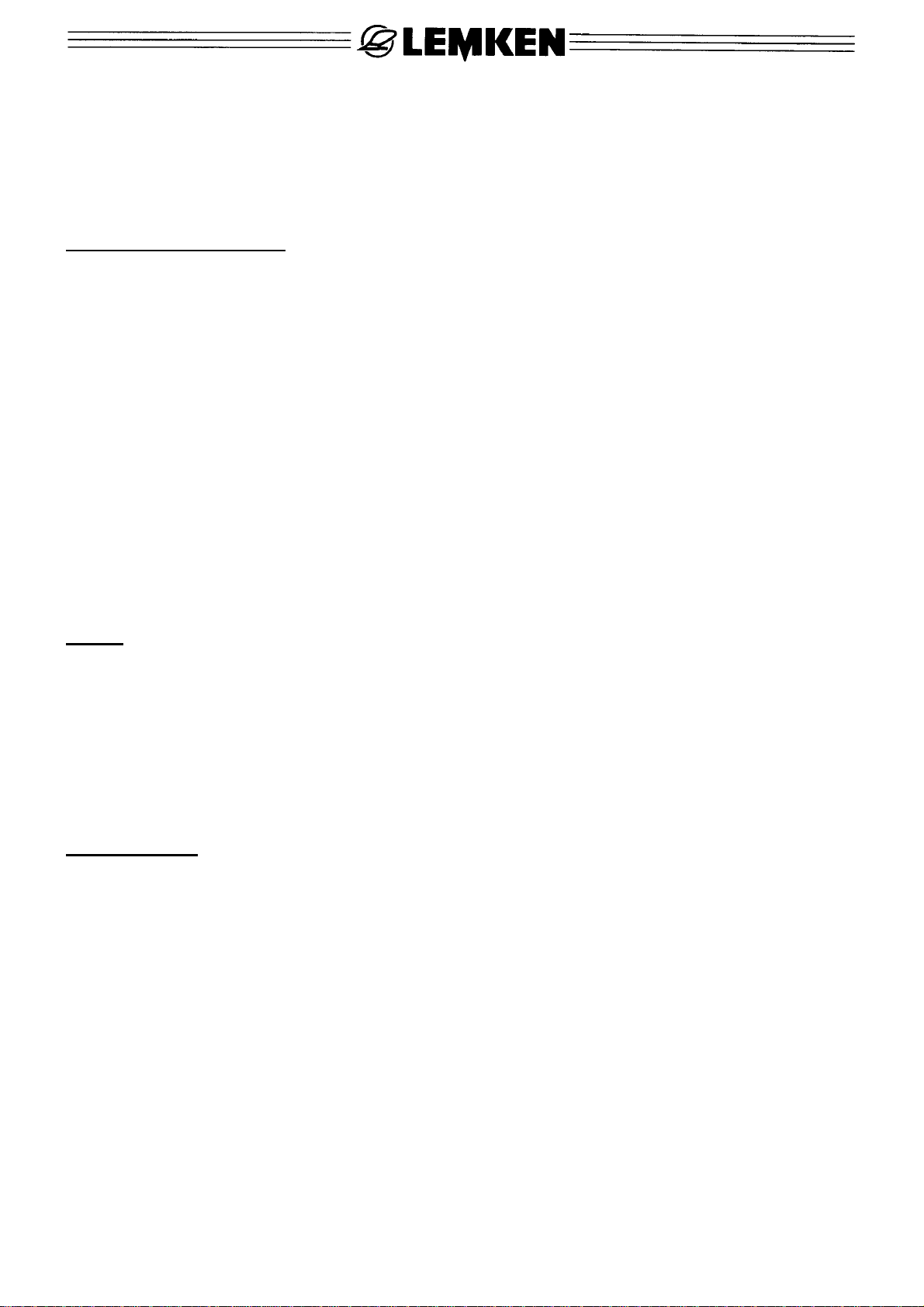

•Attach implements as advised and only to the stipulated positions!

•Special care should be taken when the implement is coupled to or uncoupled

from the tractor.

•When coupling or uncoupling the implement bring the supporting stands into

the corresponding position (standing safety)!

•Fit weights only to the fixing points provided for that purposes!

•Adhere to the maximum permissible axle loads, total weights and transport

width!

•Fit and check transport gear, road lights and warning guards!

•The release ropes for quick coupler latches should hang freely and in the

lowered position must not release the quick coupling by themselves.

•Never leave the driver’s seat whilst in motion!

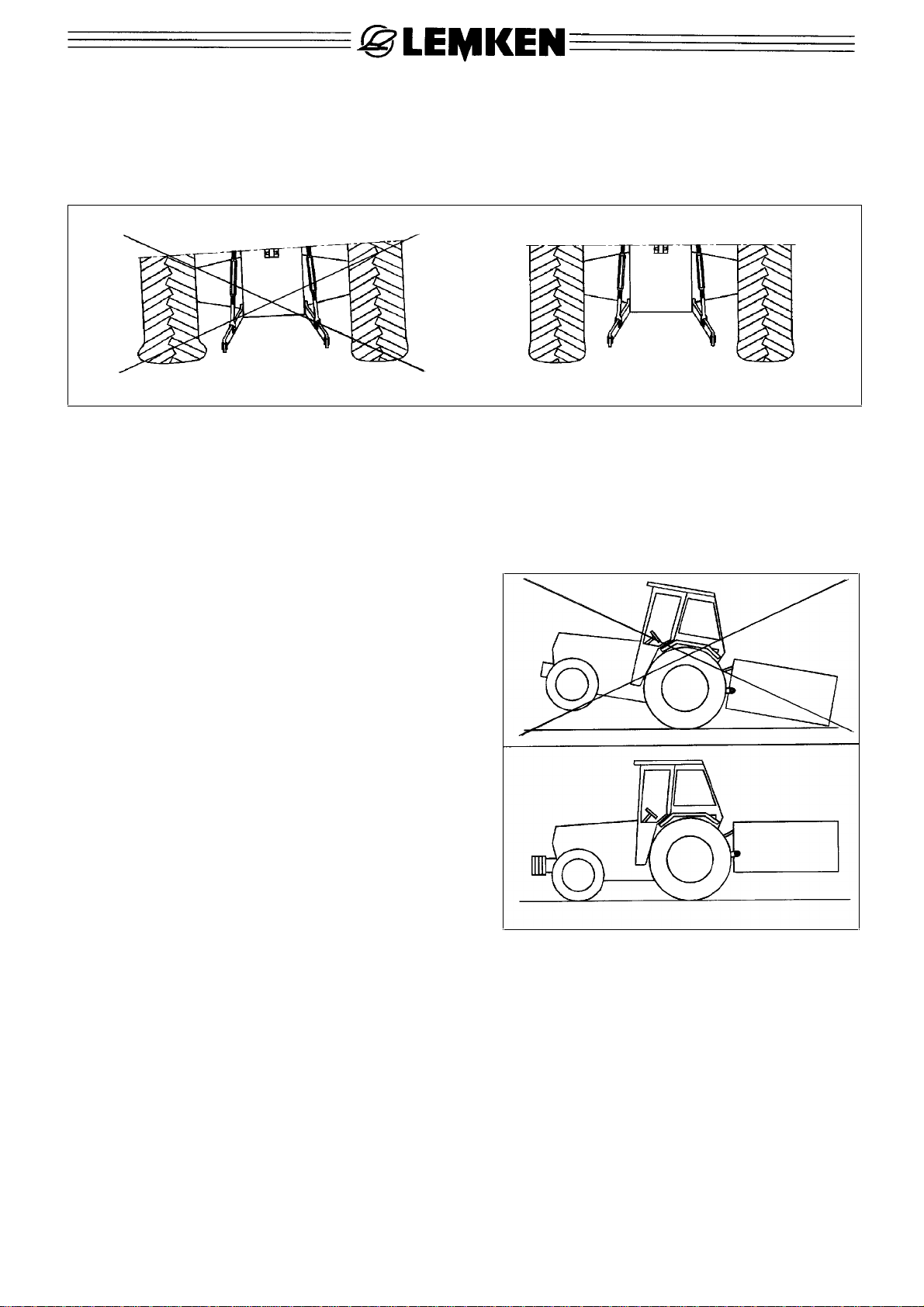

•Handling behaviour, steerability and braking are influenced by mounted imple-

ments, trailers and ballast weights. Check for sufficient steerability and braking!

•When driving round bends note the width of the machine and/or changing

centre of gravity of the implement.

•Put implement into operation only when all guards are fixed in position!

•Never stay or allow anyone to stay within the operating area!

•Never stay in the turning and slew area of the implement!

•Do not operate any hydraulic controls while anybody is in the operating area!

•On all pivoting parts actuated by power assistance (e.g. hydraulics) exists