Table of contents

1 About these instructions....................................................................................................................................... 1

1.1 Introduction......................................................................................................................................................... 1

1.2 Target groups...................................................................................................................................................... 3

1.3 Applied presentations..................................................................................................................................... 3

1.3.1 Signal words and hazard statements...................................................................................................... 3

1.3.2 Symbols and text markings........................................................................................................................ 4

1.3.3 Direction specications................................................................................................................................ 4

1.4 Further applicable documents..................................................................................................................... 5

2 Safety.............................................................................................................................................................................. 6

2.1 Machine limits..................................................................................................................................................... 6

2.2 Requirements of operators, users and service personnel................................................................... 7

2.3 General safety information............................................................................................................................ 8

2.4 Safety information on hazardous areas of the machine................................................................... 10

2.5 Safety information on structural modications................................................................................... 14

2.6 Safety information on situations............................................................................................................... 14

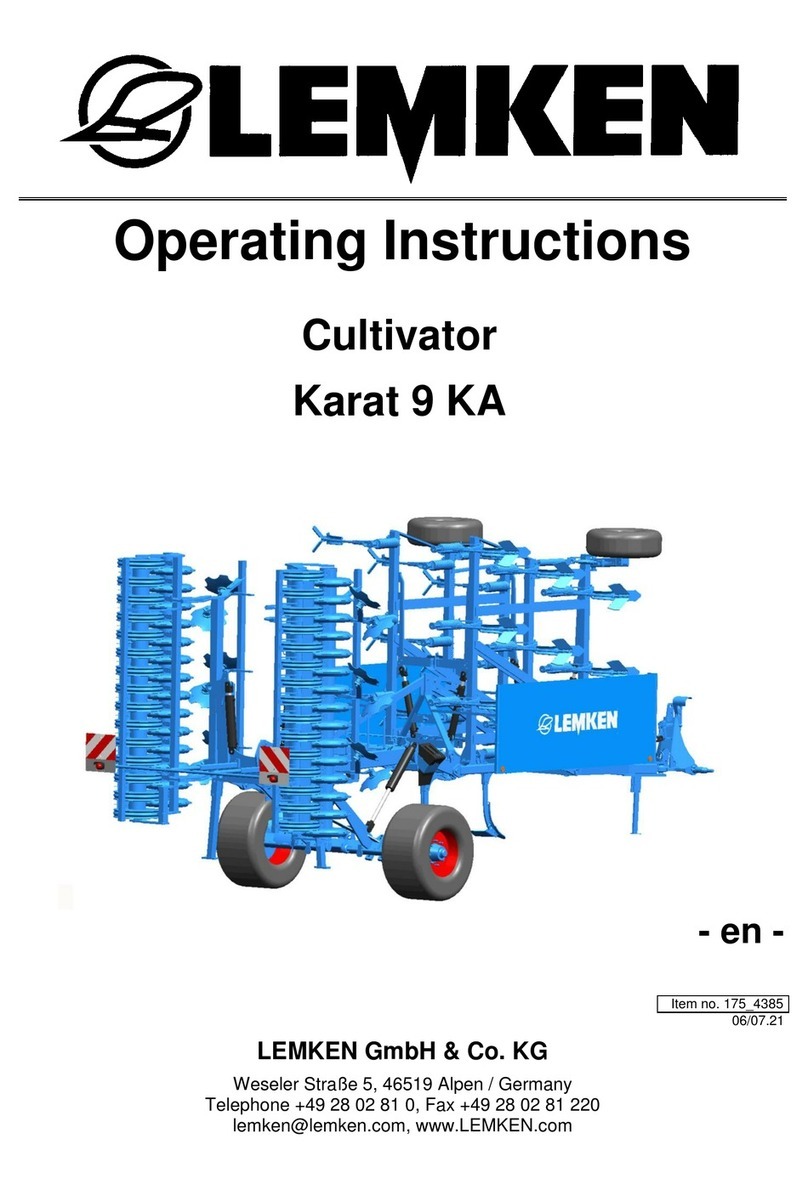

3 Design and description........................................................................................................................................ 16

3.1 Machine overview........................................................................................................................................... 16

3.2 Machine safety................................................................................................................................................. 20

3.2.1 Position of the label.................................................................................................................................... 20

3.2.2 Meaning of the labels................................................................................................................................. 21

3.2.3 Safety devices............................................................................................................................................... 24

3.3 Working tools................................................................................................................................................... 25

4 Commissioning........................................................................................................................................................ 26

4.1 Preparing an attachment............................................................................................................................. 26

4.1.1 Check machine for completeness......................................................................................................... 26

4.1.2 Ensuring suitability of the tractor.......................................................................................................... 26

4.2 Attaching the machine................................................................................................................................. 28

4.2.1 Practical knowledge - Eects of the mounting position............................................................... 28

4.2.2 Connecting the machine to the tractor............................................................................................... 33

5 Road travel................................................................................................................................................................. 39

5.1 Information on road travel........................................................................................................................... 39

5.2 Preparing for road travel.............................................................................................................................. 39

6 Operation................................................................................................................................................................... 41

6.1 Changing the setup state............................................................................................................................. 41

6.1.1 Converting the shares ............................................................................................................................... 41

6.1.2 Changing shares at the quick-change system.................................................................................. 44

6.1.3 Mounting the weed harrow..................................................................................................................... 46

Table of contents

en-GB | Item no. 17516276 | BA 01/2023-09 I