www.lemo.com

®®

Precision modular connectors to suit your application

Since its creation in Switzerland in 1946 the LEMO Group has been recognized as a global leader of circular Push-Pull

connectors and connector solutions. Today LEMO and its affiliated companies, REDEL and COELVER, are active in

more than 80 countries with the help of over 40 subsidiaries and distributors.

Over 90000 connectors

The modular design of the LEMO range provides over 90000 connectors from miniature ø 3 mm to ø 50 mm, capable of

handling cable diameters up to 30 mm and for up to 114 contacts. This vast portfolio enables you to select the ideal con-

nector configuration to suit almost any specific requirement in most markets, including medical devices, test and meas-

urement instruments, machinery, audio video broadcast, telecommunications and military.

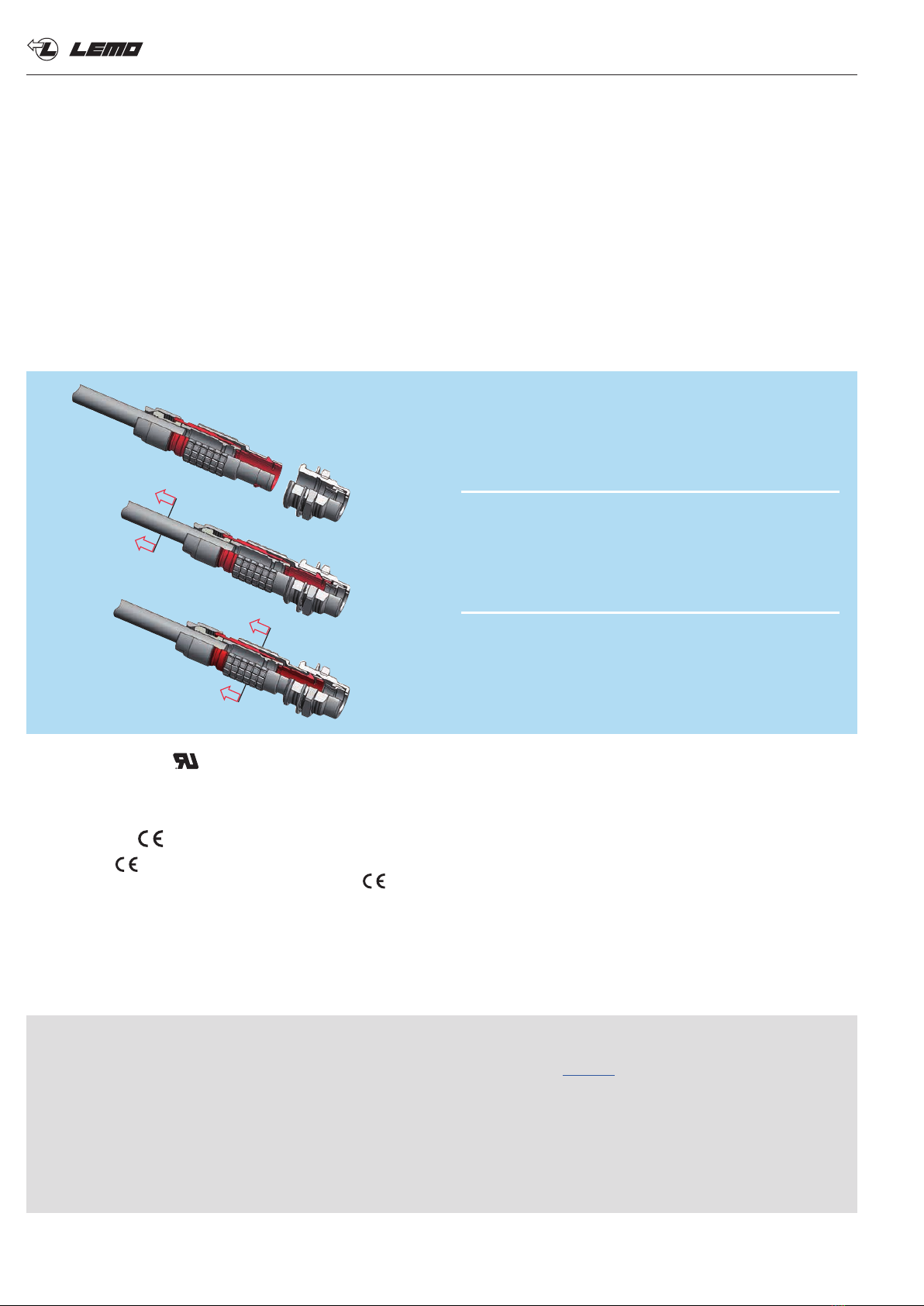

LEMO’s Push-Pull Self-Latching Connection System

This self-latching system is renowned worldwide for its easy and quick mating and unmating features. It provides absolute

security against vibration, shock or pull on the cable, and facilitates operation in a very limited space.

UL Recognition

LEMO connectors are recognized by the Underwriters Laboratories (UL). The approval of the complete system (LEMO

connector, cable and your equipment) will be easier because LEMO connectors are recognized.

CE marking

CE marking means that the appliance or equipment bearing it complies with the protection requirements of one or

several European safety directives. CE marking applies to complete products or equipment, but not to electrome-

chanical components, such as connectors.

RoHS

LEMO connector specifications conforms the requirements of the RoHS directive (2011/65/EU) of the European Parliament

and the latest amendments. This directive specifies the restrictions of the use of hazardous substances in electrical and

electronic equipment marketed in Europe.

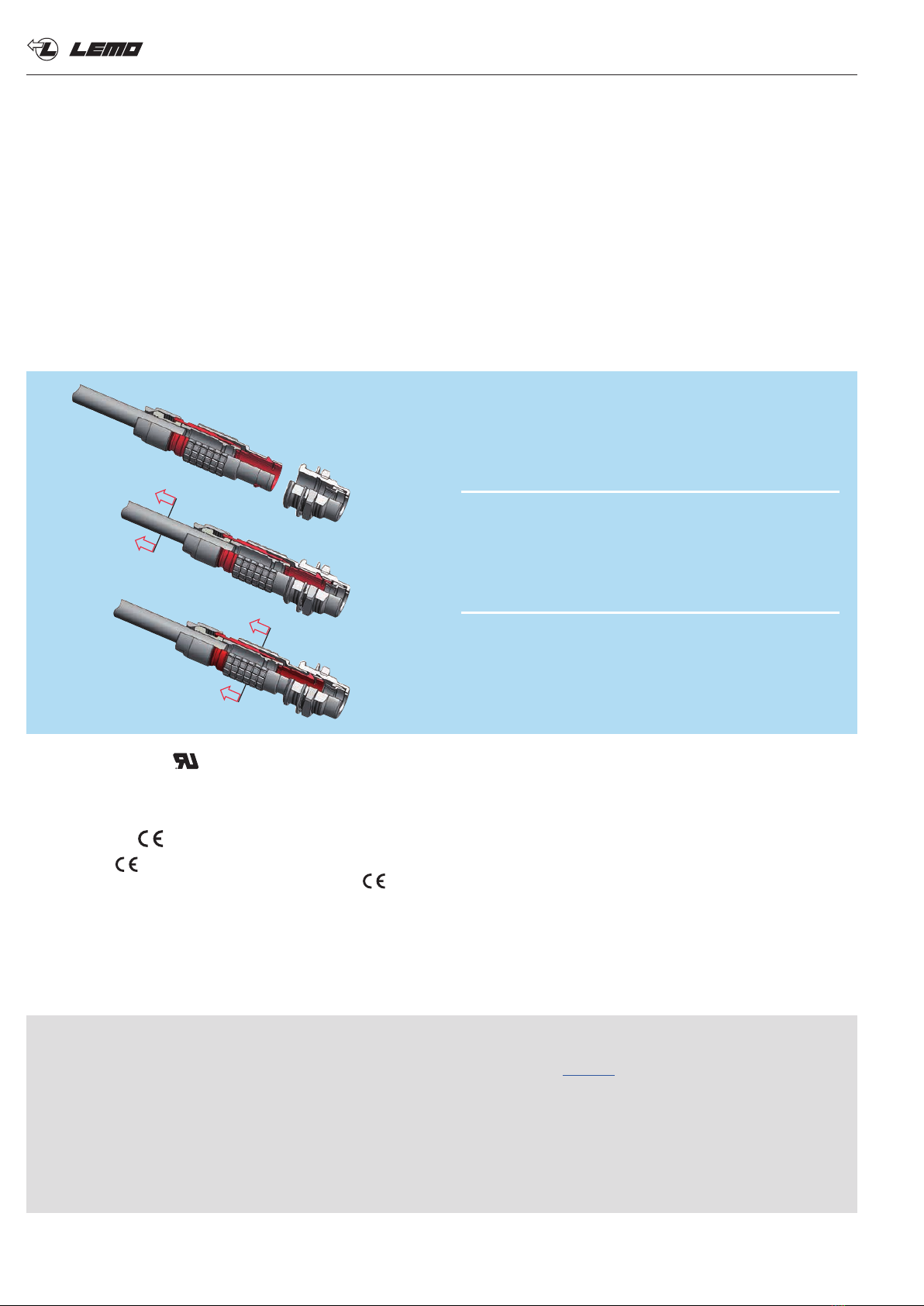

The LEMO self-latching system allows the connector

to be mated by simply pushing the plug axially into

the socket.

Once firmly latched, connection cannot be broken by

pulling on the cable or any other component part other

than the outer release sleeve.

When required, the connector is disengaged by a

single axial pull on the outer release sleeve.

This first disengages the latches and then withdraws

the plug from the socket.

Product safety notice & disclaimers

Please read and follow all instructions specified on the last page or on our website carefully and consult all relevent

national and international safety regulations for your application. Improper handling, cable assembly, or wrong use of

connectors can result in hazardous situations.

LEMO products and services are provided “as is.” LEMO makes no warranties or representations with regard to LEMO

product & services or use of them, express, implied or statutory, including for accuracy, completeness, or security.

In no event shall LEMO be liable for any direct, indirect, punitive, incidental, special consequential damages, to property

or life, whatsoever arising out of or connected with the use or misuse of LEMO’s products.