4NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

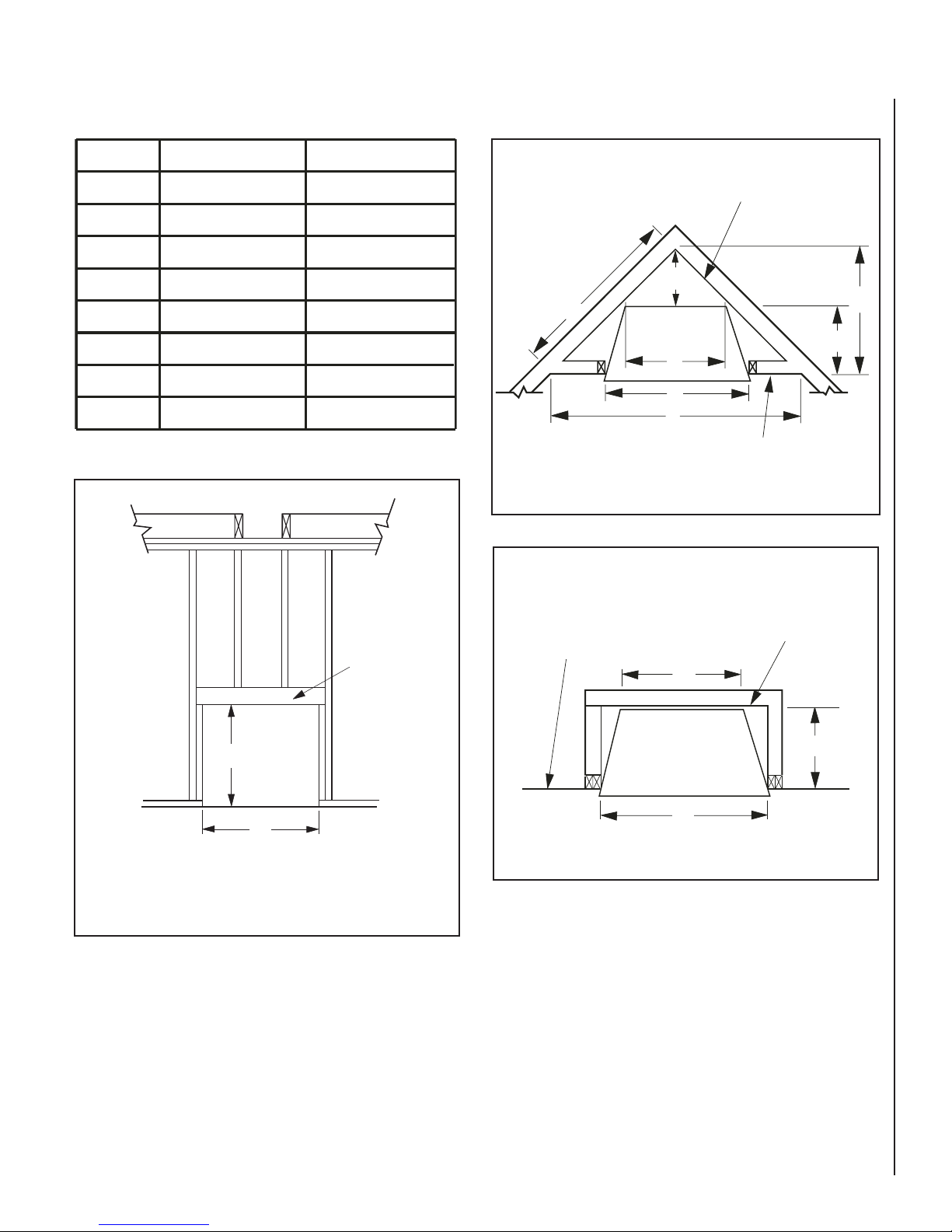

Figure 2

Whenlocatingthefireplace,considerationmust

be given to combustibles and final finishing.

See Figure 18 and confine the final location

of combustible finish materials to the "Safe

Zone". Also refer to Clearance Specifications

on page 6.

Consider the effects of heat when locating

any object in front of or near the fireplace

opening.

PRE-INSTALLATION NOTES

The fireplace may be installed directly on a

combustible floor or raised on a platform of an

appropriate height. Do not place the fireplace

on vinyl or other soft floor coverings. It may,

however, be placed on flat wood, plywood,

particle board or other hard surfaces.

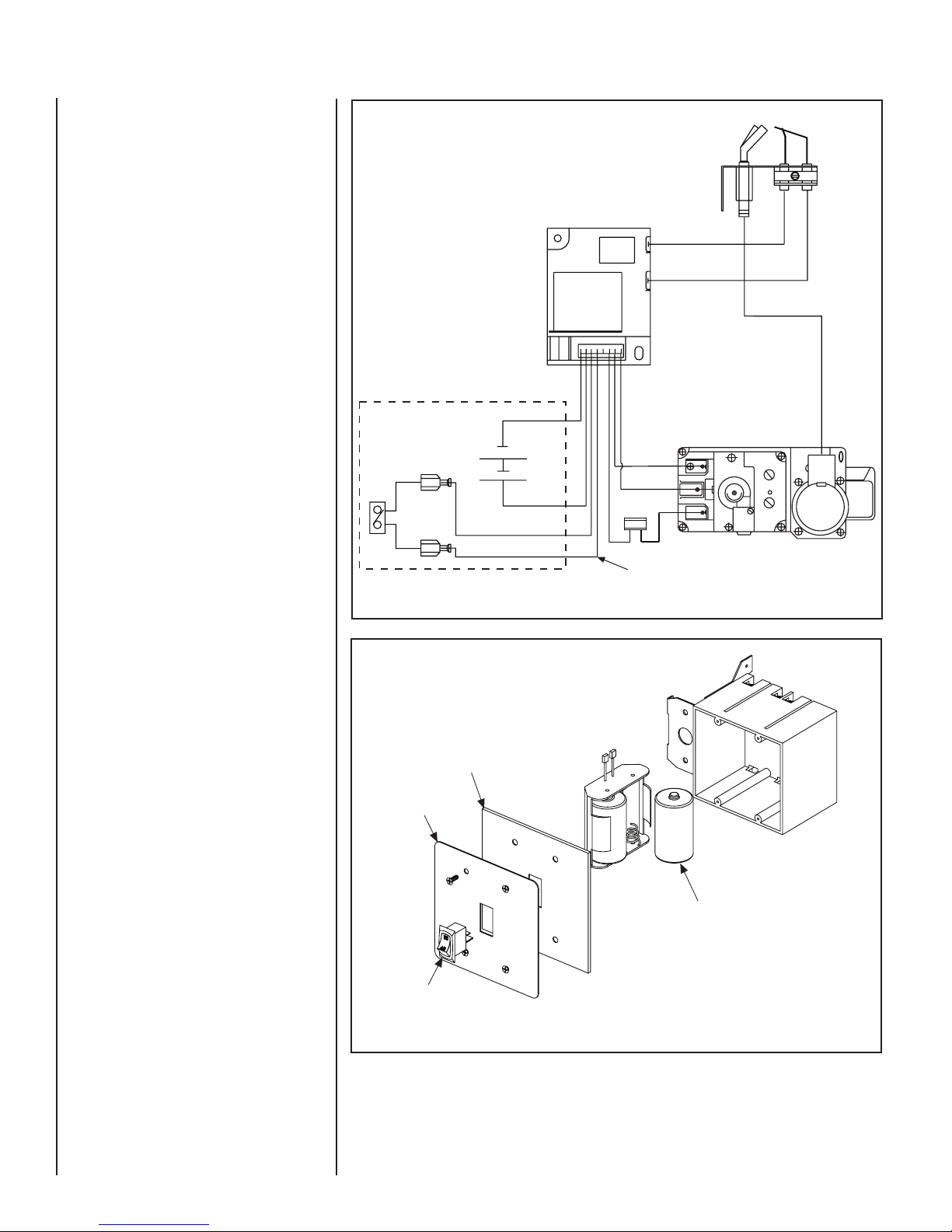

Position the electrical junction box as detailed

in LOCATION OF FIREPLACE. (The umbilical

cord is 9 feet long).

Be sure the fireplace rests on a solid continu-

ous floor or platform with appropriate framing

for support.

The fireplace may be positioned and then the

framing built around it, or the framing may be

constructed and the fireplace positioned into

the opening.

Usually, no special floor support is needed for

the fireplace, however, to be certain:

1.Estimate the total weight of the fireplace sys-

temincluding surroundmaterialssuchasbrick,

stone,etc.,tobeinstalled. Shippingweightsfor

the fireplace may be found on page 8.

2.Measurethe squarefootageofthefloorspace

to be occupied by the system, surrounds and

hearth extensions.

3. Note the decking construction, i.e. 2 x 6’s,

2 x 8’s or 2 x 10’s, single or double joists, type

and thickness of floor boards.

4. Use this information and consult your local

building code to determine if you need ad-

ditional support.

If you plan to raise the fireplace and hearth

extension, build the platform assembly then

position fireplace and hearth extension on

top. Secure the platform to the floor to prevent

possible shifting.

ASSEMBLY STEPS

Note: The following steps represent the normal

sequence of installation. Each installation is

unique, however, and might require a different

sequence.

1. Position firebox prior to framing or into

prepared framing (non-combustible framing

is recommended).

2.Positiontheelectricaljunctionboxas detailed

in LOCATION OF FIREPLACE.

(The umbilical cord is 9 feet long).

3.Waterproofthefireplaceorinstallthe optional

drip pan (see Waterproofing The Fireplace and

Figure 3 on page 5 ).

4.Plumbgasline.(Gasconnectionsshouldonly

beperformedbyanexperienced,licensed/certi-

fied tradesman.)

5. Complete the installation, finish wall mate-

rial, surround and hearth extension to your

individual taste.

6. Assemble and attach optional accessories.

Study the three dimensional illustration (Fig-

ure 1 ) to get a general idea of each element

of your fireplace system.

WATERPROOFING THE FIREPLACE

Although the fireplace is designed to operate

safely outdoors, rain may enter the hearth area,

condensation and can cause water to collect

inside the fireplace bottom.

To prevent water collection, the builder must

provide a means to drain water from under

the fireplace by building or installing a water

collector of the builders choice, before posi-

tioning the fireplace in its location.

Special care must be taken when the fireplace is

installed against an exterior wall. The enclosure

surrounding the fireplace on the sides and back

must be treated as an exterior wall.

Lennox does provide an optional drain pan to

assist weatherproofing the fireplace.

H4651 DPSS36 Drain Pan for E36ODG, H4652

DPSS42 Drain Pan for E42ODG.

ASSEMBLY OUTLINE

Before You Start

Check your inventory list to be sure you have

all the necessary parts supplied in good us-

able condition. Check also for any concealed

damage.

LOCATION OF FIREPLACE

Carefully select the proper location for any

obstructions, clearance to side wall(s), air

availability, locationandaesthetics.Withproper

pre-planning,a slightadjustmentof afewinches

can save considerable time and expense later

during construction and assembly. See Figure

2for some examples.

When choosing a location, care must be taken

to avoid places where flooding or running water

may be a problem.

Identify the desired location for the battery

pack/ON/OFFswitch junction box location. This

should be easily accessible and convenient for

use and high enough on the wall to be protected

from water and drifted snow.

Do not use these appliances if any part of

the gas supply, control or burner has been

submerged under water. Immediately call a

qualified, professional service technician to

inspect the appliance and to replace any parts

of the control system and any gas control which

have been under water.

Carefully consider the position of the fireplace

opening with respect to the location of adjacent

ornearbystairwells,doors, windows,walkways

and over hanging trees, patios and wires.

LIVING SPACE

PATIO

Optional

Hearth

Extension