Preface

For correct installation and operation, please read all instructions carefully. Before reading the

instructions, please be aware of the following items:

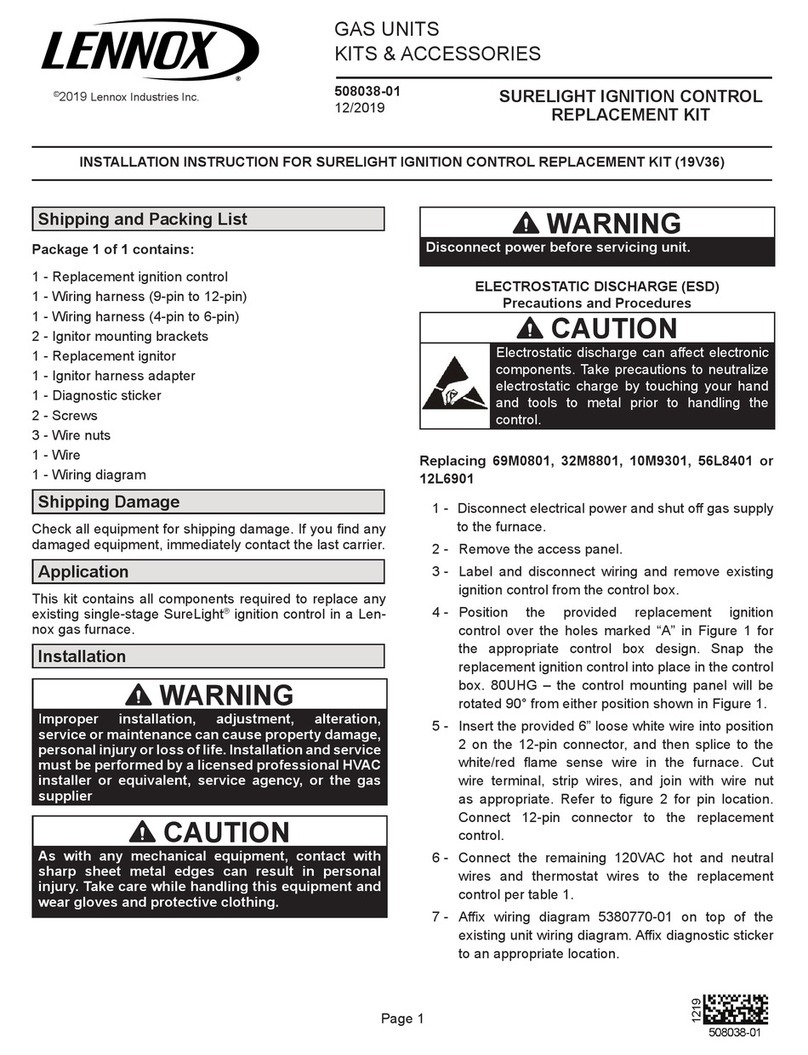

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

WARNING This mark indicates procedures which, if improperly performed, might lead to the death or

serious injury of the user.

CAUTION This mark indicates procedures which, if improperly performed, might possibly result in

personal harm to the user, or damage to property.

NOTICE is used to address practices not related to personal injury.

WARNING

(1) Instructions for installation and use of this product are provided by the manufacturer.

(2) Installation must be performed in accordance with the requirements of NEC and CEC by authorized personnel only.

(3) For the safe operation of this unit, please read and follow the instructions carefully.

(4) During operation, total capacity of indoor units should not exceed the total capacity of outdoor units. Otherwise,

poor effect of cooling or heating may result.

(5) Direct operators or maintainers should well keep this manual.

(6) If this unit fails to operate normally, please contact our service center as soon as possible and provide the following

information:

1) Content on the nameplate (model number, cooling capacity, production code, ex-factory date.

2) Malfunction details (before and after the malfunction occurs.

(7) Each unit has been strictly tested and proved to be qualified before ex-factory. In order to prevent units from being

damaged or operating normally because of improper disassembly, please do not disassemble the unit by yourself. If

you need to disassemble and check units, please contact our service center. We will send specialists to guide the

disassembly.

(8) Installation must be performed in accordance with the requirements of NEC and CEC by authorized personnel only.

User Notice

●This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be made

by children without supervision.

● Under the standby status, the unit will consume a little power for ensuring reliability of complete unit,

maintaining normal communication and preheating refrigerant. When the unit won’t be used for a long

time, cut off the power of the complete unit. However, please preheat it when operating the unit next

time.

Correct Disposal of this product

This marking indicates that this product should not be disposed with other household

wastes throughout the EU. To prevent possible harm to the environment or human health

from uncontrolled waste disposal, recycle it responsibly to promote the sustainable reuse of

material resources. To return your used device, please use the return and collection

systems or contact the retailer where the product was purchased. They can take this

product for environmental safe recycling.

R410A(R32/125:50/50):2087.5