Lennox LB-114470G User manual

Other Lennox Air Conditioner Accessories manuals

Lennox

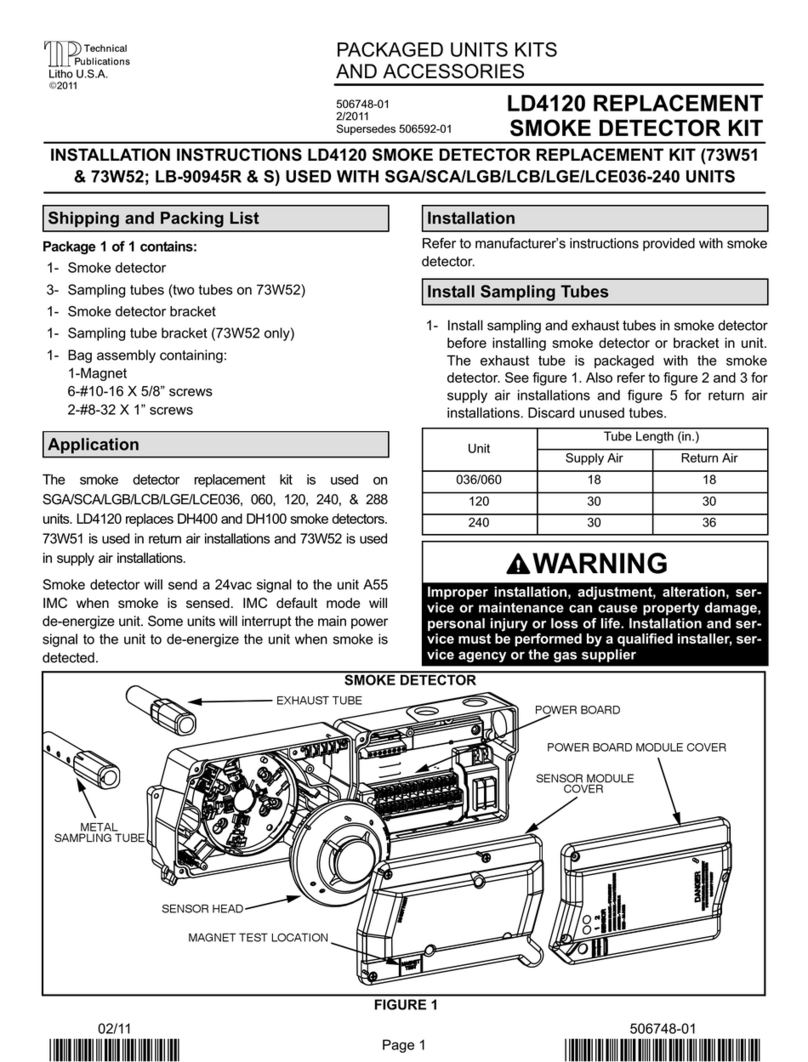

Lennox 73W51 User manual

Lennox

Lennox 31M77 User manual

Lennox

Lennox 99W41 User manual

Lennox

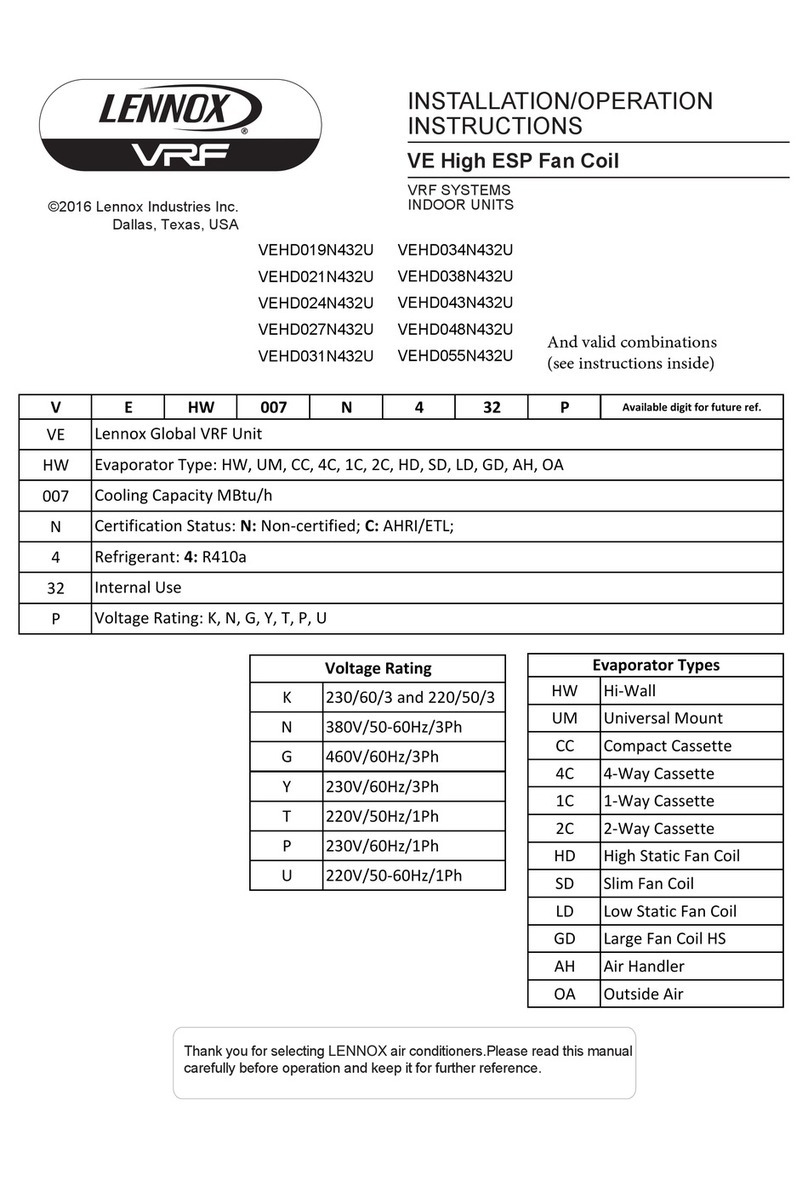

Lennox VRF VEHD019N432U Installation instructions

Lennox

Lennox 22F08 User manual

Lennox

Lennox 19V36 User manual

Lennox

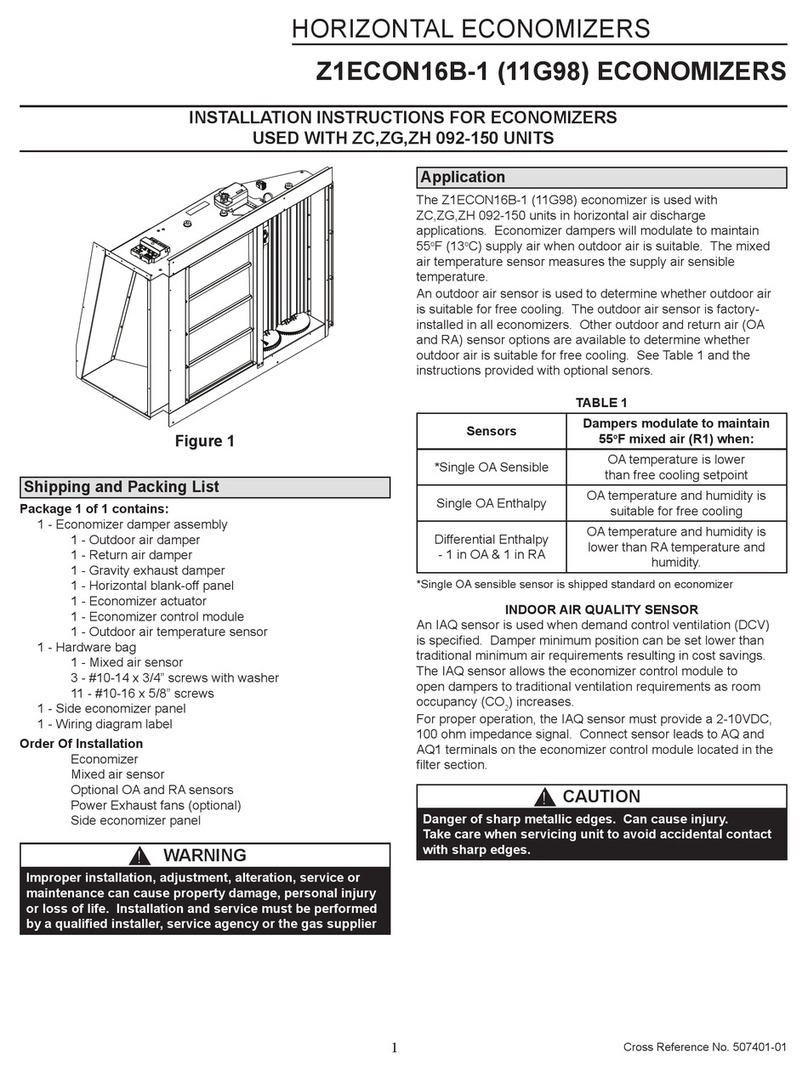

Lennox Z1ECON16B-1 User manual

Lennox

Lennox iHarmony 10C16 User manual

Lennox

Lennox 13U57 User manual

Popular Air Conditioner Accessories manuals by other brands

Mitsubishi Electric

Mitsubishi Electric PAC-SNH11HS-E installation manual

Unitary products group

Unitary products group 2CE Series installation instructions

Qlima

Qlima EU-ODZ104 user manual

Tecnosystemi

Tecnosystemi smart clima SCD500163 user manual

Waeco

Waeco AirCon Service Center ASC 5300 G operating manual

American Standard

American Standard BAYSQRD001AA Installer's guide

Bimar

Bimar AP11 Instruction booklet

Mitsubishi

Mitsubishi PAC-SJ41TM-E installation manual

Tecnosystemi

Tecnosystemi Smart Clima SCD500084 user manual

Samsung

Samsung MIM-H04U User & installation manual

Waeco

Waeco AirConServiceCenter ASC 3500 G LE operating manual

Fujitsu

Fujitsu UTZ-KXGC installation manual