Page 9

TABLE 5

VSP2–1 OPERATION

HEATING MODE COOLING MODE

UNITS WITH

SINGLE–STAGE HEATING

UNITS WITH

TWO–STAGE HEATING

UNITS WITH SINGLE–

SPEED COMPRESSOR

UNITS WITH TWO–SPEED

COMPRESSOR

NON–ZONED

APPLICATIONS

When a single-stage thermostat is

used and full heating input of the

unit is required, jump terminals W1

and W2 on the burner control

board.

The HEAT LED-DS2 is lit when the

thermostat calls for heat. The ON/

OFF LED-DS3 is lit after 110 seconds

(65 seconds pre-purge and 45 se-

conds fan “ON” time) from the time

a call for heat is made. This indicates

the blower is operating in heating

speed.

NON–ZONED

APPLICATIONS

Using a two-stage thermostat with

first-stage (W1) calling, the ON/OFF

LED-DS3 is lit to indicate the blower

is operating in low speed.

When the ON/OFF LED-DS3 and

HEAT LED-DS2 are lit, the blower is

operating in heating speed and se-

cond-stage (W2) heating is calling.

HEAT LED-DS2 is lit with a call for

heat from the thermostat. ON/OFF

LED-DS3 is lit after 110 seconds

from the time a call for heat is made.

NOTE—In two-stage operation and

when there is a call for first-stage

only, the unit will always start on

high heat (second-stage) and will

automatically switch to first-stage

operation after initial unit warm-up.

NON–ZONED

APPLICATIONS

The terminals “DS” and “Y” must be

jumpered together. With a call for

cooling, terminals G, Y and DS on

the unit control board are energized

from the thermostat. HI/LOW LED–

DS1 and ON/OFF LED–DS3 are lit to

indicate the blower is operating on

high speed.

NOTE—“Y” and “DS” must be

jumpered for single-stage cooling,

non-zoned applications.

NON–ZONED

APPLICATIONS

The ON/OFF LED–DS3 is lit to indicate

the blower is operating in first stage

cooling. This LED is energized on

when a 24VAC thermostat demand is

supplied to the control (terminal “G”

on the control box terminal strip).

In second stage, the ON/OFF LED–

DS3 and HI/LOW LED–DS1 are lit to

indicate the blower is operating on

high speed (24VAC is supplied to the

unit terminal strip “Y2” from “Y2”

on the thermostat).

NOTE—“Y2” must be jumpered to

“DS” in two–speed, non–zoned

applications.

HARMONY ZONED

APPLICATIONS

The blower speed is controlled by

the PWM (pulse width modulation)

signal sent from the control center

of the zoning system to the terminal

strip’s “DS” terminal. HI/LOW LED–

DS1 and ON/OFF LED–DS3 are lit to

indicate the blower is operating.

NOTE–In Harmony II zoning ap-

plications, HTG. BLOWER jumper

must be in position #2.

HARMONY ZONED

APPLICATIONS

The blower speed is controlled by

the PWM (pulse width modulation)

signal sent from the control center

of the zoning system to the terminal

strip’s “DS” terminal. HI/LOW LED–

DS1 and ON/OFF LED–DS3 are lit to

indicate the blower is operating.

NOTE–In Harmony II zoning ap-

plications, HTG. BLOWER jumper

must be in position #2.

HARMONY ZONED

APPLICATIONS

The blower speed is controlled by

the PWM (pulse width modulation)

signal sent from the control center

of the zoning system to the terminal

strip’s “DS” terminal. HI/LOW LED–

DS1 and ON/OFF LED–DS3 are lit to

indicate the blower is operating.

HARMONY ZONED

APPLICATIONS

The blower speed is controlled by

the PWM (pulse width modulation)

signal sent from the control center

of the zoning system to the terminal

strip’s “DS” terminal. HI/LOW LED–

DS1 and ON/OFF LED–DS3 are lit to

indicate the blower is operating.

NOTE: For zone applications with Harmony, remove wire from VSP #3 terminal on burner control board, insulate end and secure

to prevent from shorting.

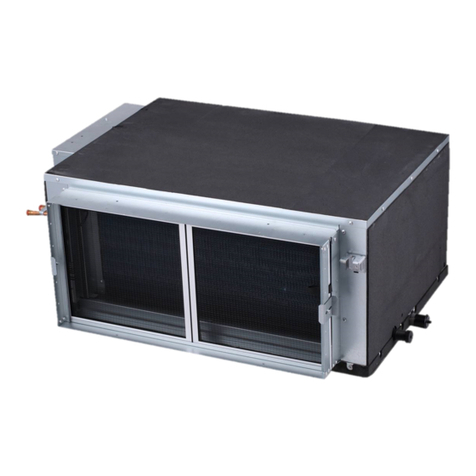

B–Blower Compartment (Figure 8)

Located inside the blower compartment are the variable

speed blower motor (B3), coil choke (L13), and the

secondary limit switches [(1)S21 and (2)S21]. To access

the blower compartment follow the steps outlined below:

1– Remove the two screws holding the blower panel to

the unit.

2– Remove the two screws (located in the middle of the

blower panel) holding the grommet for the VSP2

JP46 wires.

3– Disconnect the jack (J46) from the VSP2 and feed it

through the blower panel.

4– Disconnect thermostat wires from the terminal strip

(TB1) on the burner control board.

5– Disconnect the 120VAC (black) wire from the burner

control board going to the coil choke and feed

through the blower panel grommet.

6– Disconnect line voltage wire (white) and feed through

the blower panel grommet.

7– Lift panel up and disconnect jack plugs JP1 and JP2

(brown wires) found in the blower compartment.

8– Remove wires from the wire clips located on the

blower panel allowing more wire for movement.

9– Place panel to the side, while servicing blower.

FIGURE 7

G25MV BLOWER DOOR COMPONENTS –

BLOWER ACCESS

W

W

BRN

BRN

BLK

G25MV

SHOWN

IN UPFLOW

POSITION

5

67

8

1

2

3

4

1

1– Blower Motor (B3)

G25MV units use a three-phase, electronically controlled

D.C. brushless motor (controller converts single phase

a.c. to three phase D.C.), with a permanent-magnet-type

rotor (figure 9). Because this motor has a permanent