NOTE -CB3OMV series evaporators use nitrogen or dry air

as a holding charge. If there is no pressure when the rubber

plugs are removed, check the coil or line set for leaks before

installing. After installation, pull a vacuum on the line set and

coil before releasing the unit charge into the system.

NOTE: See outdoor unit instructions on how to flow

nitrogen through line sets.

Step 1. Remove access panel,

Step 2, Remove the refrigerant line caps from the

refrigerant lines,

Step 3, Use a wet rag to protect TXV sensing bulb (or

remove it) when brazing suction line

connections,

Step 4, Place a wet rag against piping plate and around

the suction line connection. The wet rag must be

in place to guard against damage to the paint.

Step 5, With the wet rag in place, position field provided

elbow fitting to air handler's suction line and line

set, Start nitrogen flow before brazing.

Step 6, After the procedure is completed then remove

the wet rag,

Step 7, Place wet rag against piping plate and around

the liquid line connection. Position liquid line

elbow to air handler's suction line and to line set.

Start nitrogen flow and begin brazing both

connections and after procedure is completed

then remove both wet rags,

Step 8, Refer to instructions provided with outdoor unit for

leak testing, evacuating and charging

procedures,

Step 9. Install access panel,

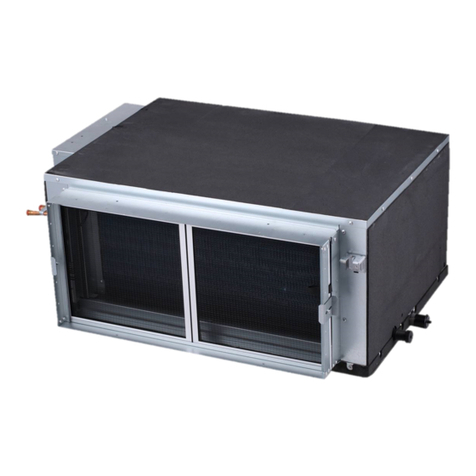

Connect the main condensate drain and route it downward

to an open drain or sump. Do not connect the drain to a

closed waste system. Refer to figure 3 for a typical

condensate trap configuration. If the auxiliary drain is not

connected, it must be plugged,

MINIMUM 1 INCH (25 MM) PIPE DIAMETER

PITCH PER 10 FEET (3048 MM)

OF LINE _. DIFFERENCE

_t .... CO,L

RAIN PAN

TRAP MUST BE DEEP ENOUGH TO OFFSET MAXIMUM STATIC

DIFFERENCE (GENERALLY, 2 INCHES [51 MM] MINIMUM).

Figure 3. Typical Condensate Drain

The following practices are recommended to ensure

condensate removal:

• The drain piping should not be smaller than the drain

connections at drain pan,

• A trap must be installed in the main drain line,

• The trap must be deep enough to offset the difference

in static pressure between drain pan and atmosphere.

Generally, two inches is satisfactory for medium static

applications.

• Horizontal runs must be sloped 1 inch per 10 feet of

drain line to offset friction,

• An open vent in the drain line will sometimes be required

due to line length, friction, and static pressure,

• Drains should be constructed in a manner to facilitate

future cleaning and should not interfere with filter

access as illustrated in figure 3,

• Auxiliary drain should run to an area where the

homeowner will notice it draining, Refer to local codes,

AIMPORTANT

You can duct mount or install filters in the cabinet, The unit

is not equipped with a filter from the factory. Note that the

filter access door fits over the access panel. Air leaks will

occur if the access panel is placed over the filter door.

Filters should be inspected monthly and must be cleaned

or replaced when they dirty to assure proper furnace

operation,

Reusable filters can be washed with water and mild

detergent, When dry, they should be sprayed with filter

handicoater prior to reinstallation. Filter handicoater is RP

Products coating #418 and is available as Lennox part

number P-8-5069. Replace throw-away type filters when

they are dirty; they cannot be cleaned.

The filter section built into the unit may be used with bottom

return air applications,

To replace filter:

Step 1, Loosen the thumbscrews holding the filter panel

in place.

Step 2. Slide the filter out of the guides on either side of

cabinet,

Step 3, Insert new filter.

Step 4, Replace panel.

See table 5 for replacement filter sizes.

Table 5. Filter Dimensi, >ns

BOTTOM RETURN SIDE RETURN

UNIT MODEL FILTER SIZE FILTER SIZE

NO. Inches (mm) Inches (mm)

CB30U-21/26 15 x 20 (381 x508) 16 x 20 (406 x 508)

CB30U-31 20 x 20 (508 x 508) 20 x 20 (508 x 508)

CB30U-41/46 20 x 22 (508 x 559) 20 x 20 (508 x 508)

CB30U-51,-65 20 x 24 (508 x 610) 20 x 20 (508 x 508)

Page 5

CB30U/CBX27UH SERIES