7

Placement

WARNING

Use the provided and specied components when

installing equipment. Failure to do so may result

in unit falling, water leaking or electrical shocks,

causing personal injury or equipment or property

damage.

Check stability of unit support. If support is not

capable of carrying weight of the unit, unit may fall

causing personal injury or equipment damage.

Consider the possibility of earthquakes in your

area when installing the equipment. If the unit is

not correctly secured, it may fall, causing personal

injury or equipment damage.

Safely dispose of packing materials, which include

nails, wood and other sharp objects, as well as

plastic wrapping. Children playing with plastic

wrap or bags risk the danger of suocation.

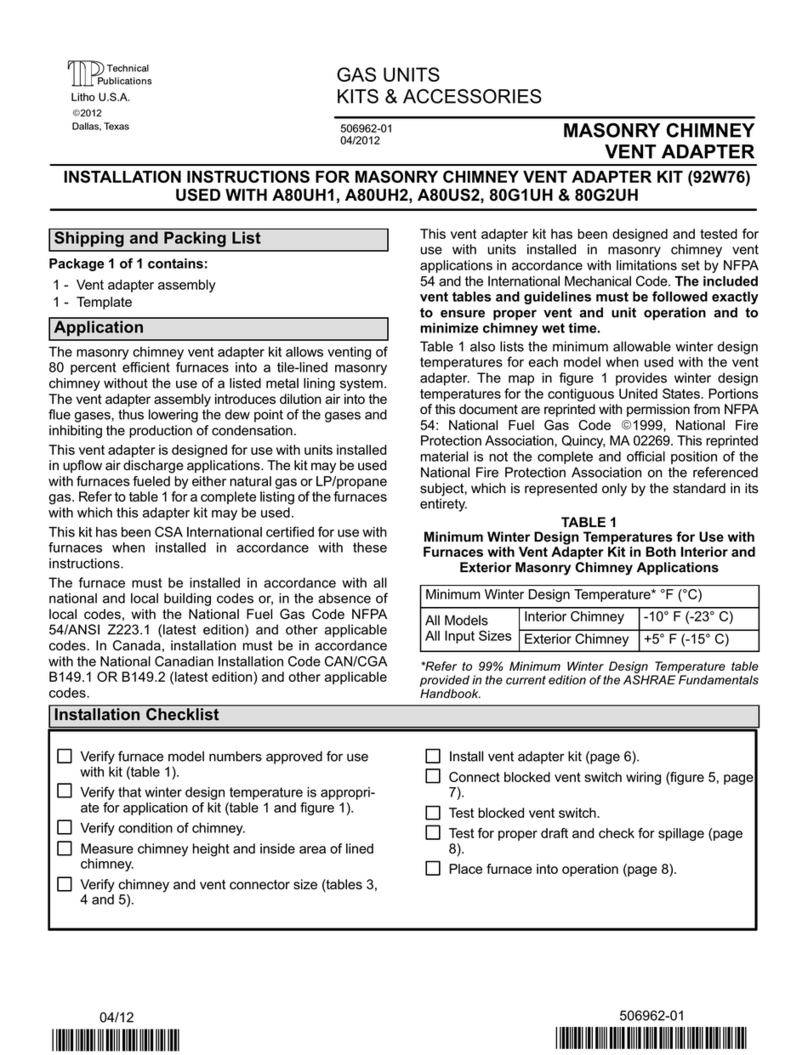

Outdoor Unit Positioning Considerations

In addition to clearances, the following items should be

considered when setting the outdoor unit:

• If low ambient cooling hood is applied, the outdoor unit

should be set at medium static pressure mode (40Pa).

Add 12 in. (305 mm) to standard mounting clearances

• Allow sucient space around unit for proper operation

and maintenance.

• Install the unit high enough above the ground or roof to

allow adequate drainage of defrost water and prevent

ice or snow build-up.

• Carefully consider how to manage defrost and

condensate water disposal to prevent ice from creating

hazardous conditions near walkways and egresses.

• Use heated tape on condensate drain line.

• Locate unit so winter prevailing winds do not blow

directly on to the outdoor unit.

• In heavy snow areas, do not locate the unit where

drifting will occur. The unit base should be elevated

above the depth of average snows.

Wind Barrier

Inlet Air

Prevailing Winter Winds

39” (991mm)

Min. Distance

Figure 1. Prevailing Winds Barrier

• Discharge air duct will remain free of obstructions at a

minimum distance of 18 ft. (5.5 m).

• Discharge air shall not be directed toward operable

windows or building fresh air intakes.

• Appliance exhaust such as drier and kitchen exhaust

vents shall maintain a minimum distance of 15 ft.

(4.5 m).

• Outdoor unit shall maintain a minimum distance of 10

ft. (3 m) from fossil fuel lines, gas meters and electri-

cal meters.

• Outdoor unit shall maintain a minimum distance of 10

ft. (3 m) away from plumbing ventilation stacks.

• Outdoor unit should maintain a minimum distance of 3

ft. (1 m) from walkways and emergency exits.

• Outdoor unit shall maintain a distance of 3 ft. (1 m)

away from electrical panels.

• Outdoor unit shall be raised 12 in. (305 mm) above

average snow fall lines.

• Weather resistant equipment supports shall be con-

structed in a manner that will minimize snow or ice

buildup.

• Outdoor unit exhaust and air intakes shall not be ob-

structed with lter material, bird screen or mesh.

• Articial heat shall not be introduced to the outdoor

unit or air intake areas.

IMPORTANT

The equipment supports must elevate the unit at least

12 in. (305 mm) above the maximum expected snow

depth.