03/12

*2P0312*

506774−01

*P506774-01*

INSTALLATION INSTRUCTIONS FOR MASONRY CHIMNEY VENT ADAPTER KIT

(18M7901) USED WITH 80AF1UH, ML180UH, EL280UH and SL280UH UNITS

Litho U.S.A.

506774−01

03/2012

Supersedes 03/2011

2012

Dallas, Texas MASONRY CHIMNEY

VENT ADAPTER

GAS UNITS

KITS & ACCESSORIES

Shipping and Packing List

Package 1 of 1 contains:

1 − Vent adapter assembly

1 − Template

Application

The masonry chimney vent adapter kit allows venting of

80 percent efficient furnaces into a tile−lined masonry

chimney without the use of a listed metal lining system.

The vent adapter assembly introduces dilution air into the

flue gases, thus lowering the dew point of the gases and

inhibiting the production of condensation.

This vent adapter is designed for use with 80AF1UH,

ML180UH, EL280UH and SL280UH units installed in

upflow air discharge applications. The kit may be used

with furnaces fueled by either natural gas or LP/propane

gas. Refer to table 1 for a complete listing of the furnaces

with which this adapter kit may be used.

This kit has been CSA International certified for use with

80AF1UH, ML180UH, EL280UH and SL280UH

furnaces when installed in accordance with these

instructions.

The furnace must be installed in accordance with all

national and local building codes or, in the absence of

local codes, with the National Fuel Gas Code NFPA

54/ANSI Z223.1 (latest edition) and other applicable

codes. In Canada, installation must be in accordance

with the National Canadian Installation Code CAN/CGA

B149.1 OR B149.2 (latest edition) and other applicable

codes.

This vent adapter kit has been designed and tested for

use with 80AF1UH, ML180UH, EL280UH and SL280UH

units installed in masonry chimney vent applications in

accordance with limitations set by NFPA 54 and the

International Mechanical Code. The included vent

tables and guidelines must be followed exactly to

ensure proper vent and unit operation and to

minimize chimney wet time.

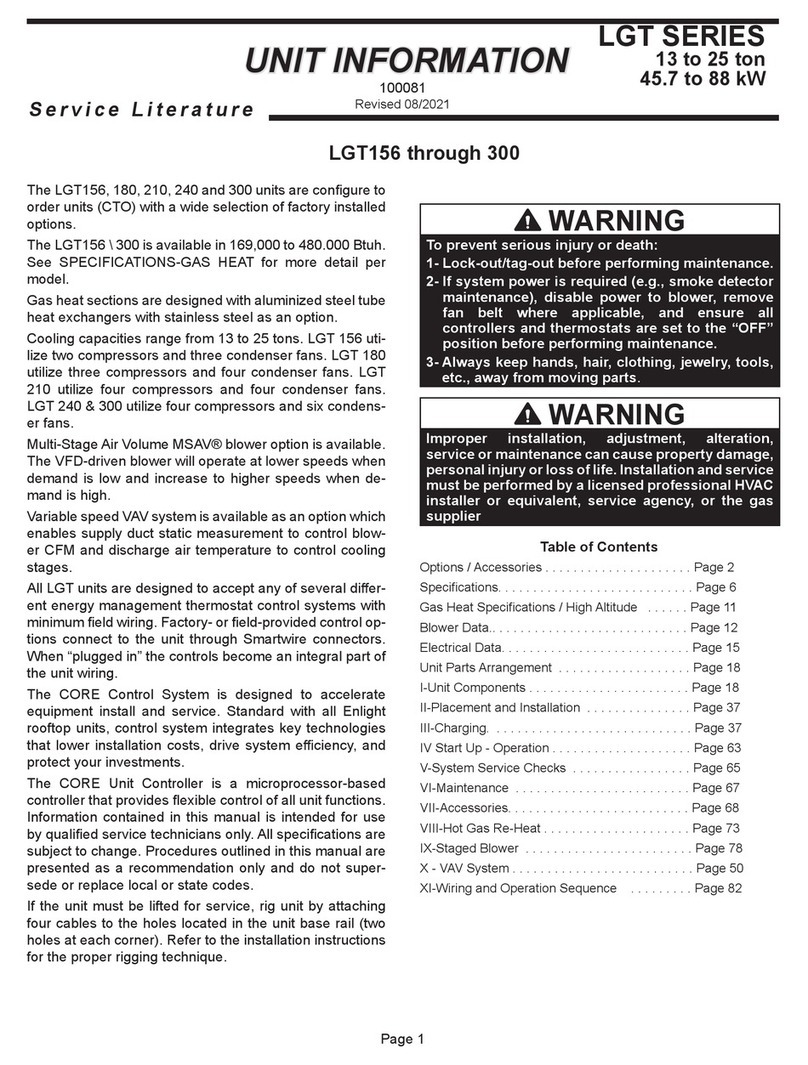

Table 1 also lists the minimum allowable winter design

temperatures for each model when used with the vent

adapter. The map in figure 1 provides winter design

temperatures for the contiguous United States. Portions

of this document are reprinted with permission from NFPA

54: National Fuel Gas Code 1999, National Fire

Protection Association, Quincy, MA 02269. This reprinted

material is not the complete and official position of the

National Fire Protection Association on the referenced

subject, which is represented only by the standard in its

entirety.

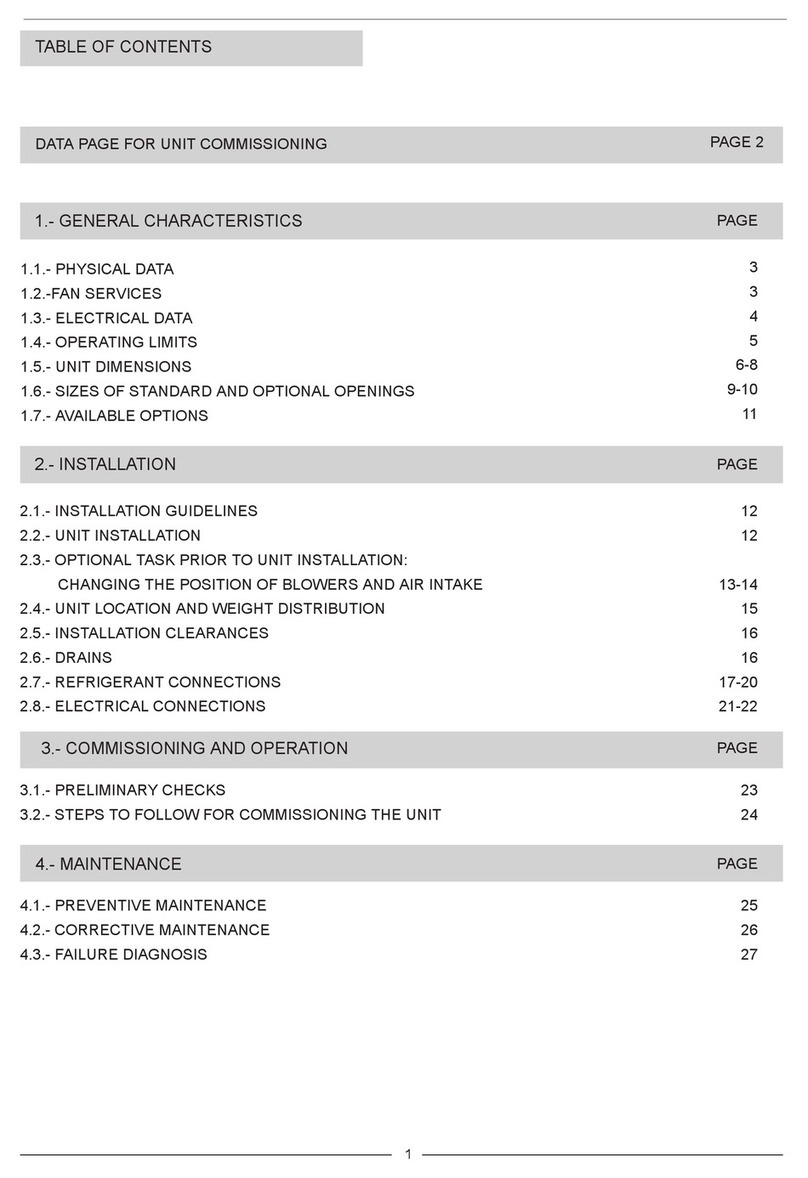

TABLE 1

Minimum Winter Design Temperatures for Use with

80AF1UH, ML180UH, EL280UH and SL280UH

Furnaces with Vent Adapter Kit in Both Interior and

Exterior Masonry Chimney Applications

Minimum Winter Design Temperature* °F (°C)

All Models

All Input Sizes

Interior Chimney −10° F (−23° C)

Exterior Chimney +5° F (−15° C)

*Refer to 99% Minimum Winter Design Temperature table

provided in the current edition of the ASHRAE Fundamentals

Handbook.

Installation Checklist

Verify furnace model numbers approved for use

with kit (table 1).

Verify that winter design temperature is appropri-

ate for application of kit (table 1 and figure 1).

Verify condition of chimney.

Measure chimney height and inside area of lined

chimney.

Verify chimney and vent connector size (tables 3,

4 and 5).

Install vent adapter kit (page 6).

Connect blocked vent switch wiring (figure 5, page

7).

Test blocked vent switch.

Test for proper draft and check for spillage (page

8).

Place furnace into operation (page 8).