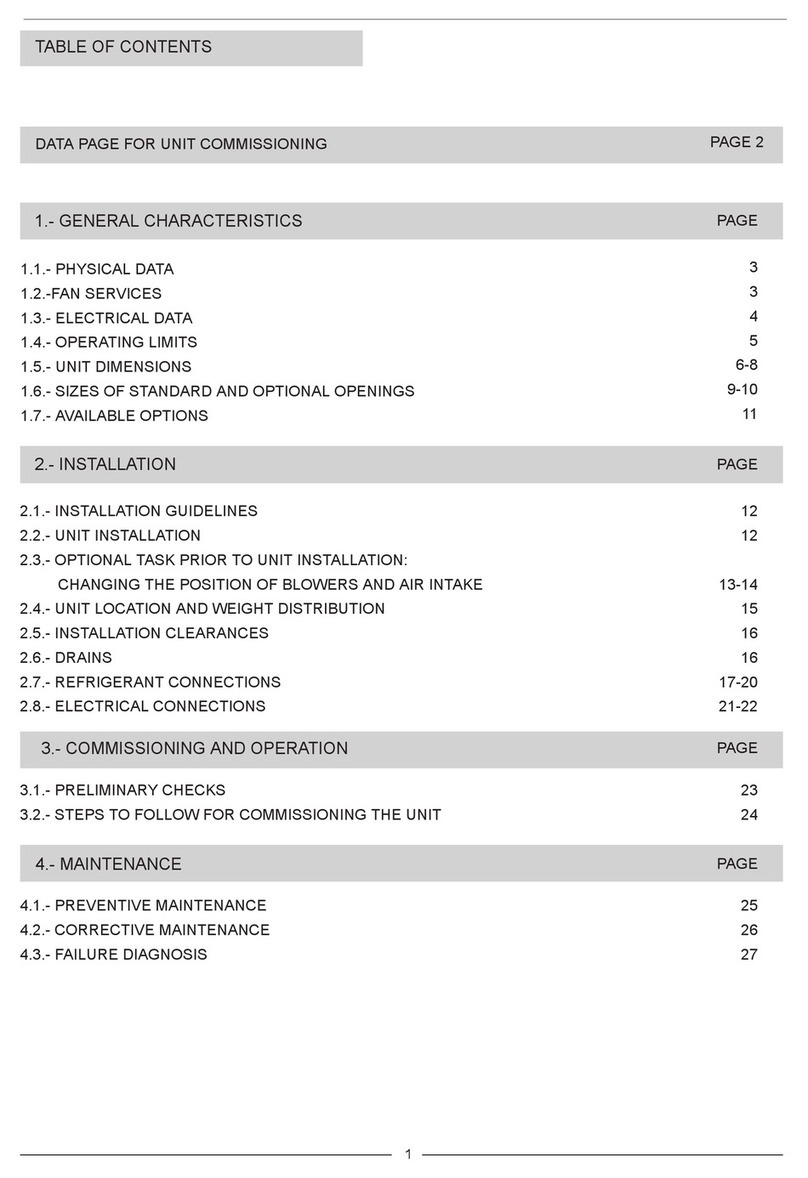

*noitallatsnInaidanaC **noitallatsnISU

,hcrop,adnarev,edargevobaecnaraelC=A

.ynoclabro,kced .ynoclabro,kced .ynoclabro,kced .ynoclabro,kced .ynoclabro,kced

*)mc03(sehcni21 **)mc03(sehcni21

ebyamtahtroodrowodniwotecnaraelC=B

.denepo .denepo .denepo .denepo .denepo

secnailpparof)mc51(ni6

)mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

)mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001<

*)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof

secnailpparof)mc51(ni6

)mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

)mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05<

**)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof

wodniwdesolcyltnenamrepotecnaraelC=C tneverpotdednemmocer)mm503("21

noitasnednocwodniw noitasnednocwodniw noitasnednocwodniw noitasnednocwodniw noitasnednocwodniw

tneverpotdednemmocer)mm922("9

noitasnednocwodniw noitasnednocwodniw noitasnednocwodniw noitasnednocwodniw noitasnednocwodniw

tiffosdetalitnevotecnaraelclacitreV=D

latnozirohanihtiwlanimretehtevobadetacol latnozirohanihtiwlanimretehtevobadetacol latnozirohanihtiwlanimretehtevobadetacol latnozirohanihtiwlanimretehtevobadetacol latnozirohanihtiwlanimretehtevobadetacol

retnecehtmorf)mm854(sehcni81foecnatsid retnecehtmorf)mm854(sehcni81foecnatsid retnecehtmorf)mm854(sehcni81foecnatsid retnecehtmorf)mm854(sehcni81foecnatsid retnecehtmorf)mm854(sehcni81foecnatsid

lanimretehtfoenil lanimretehtfoenil lanimretehtfoenil lanimretehtfoenil lanimretehtfoenil

)mm854("81 )mm854("81

tiffosdetalitnevnuotecnaraelC=E )mm503("21 )mm503("21

renrocedistuootecnaraelC=F muminim)mc7.21("5 muminim)mc7.21("5

renrocedisniotecnaraelC=G

"42 "42

enilretnecfoedisnihcaeotecnaraelC=H

ylbmessarotaluger/retemevobadednetxe ylbmessarotaluger/retemevobadednetxe ylbmessarotaluger/retemevobadednetxe ylbmessarotaluger/retemevobadednetxe ylbmessarotaluger/retemevobadednetxe

teef51fothgiehanihtiw)mc19(teef3

*ylbmessarotaluger/retemehtevoba *ylbmessarotaluger/retemehtevoba *ylbmessarotaluger/retemehtevoba *ylbmessarotaluger/retemehtevoba *ylbmessarotaluger/retemehtevoba

teef51fothgiehanihtiw)mc19(teef3

**ylbmessarotaluger/retemehtevoba **ylbmessarotaluger/retemehtevoba **ylbmessarotaluger/retemehtevoba **ylbmessarotaluger/retemehtevoba **ylbmessarotaluger/retemehtevoba

teltuotnevrotalugerecivresotecnaraelC=I *)mc19(teef3 **)mc19(teef3

telniylppusrialacinahcemnonotecnaraelC=J

ynaottelnirianoitsubmocehtrognidliubot ynaottelnirianoitsubmocehtrognidliubot ynaottelnirianoitsubmocehtrognidliubot ynaottelnirianoitsubmocehtrognidliubot ynaottelnirianoitsubmocehtrognidliubot

ecnailpparehto ecnailpparehto ecnailpparehto ecnailpparehto ecnailpparehto

secnailpparof)mc51(ni6

)mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

)mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001<

*)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof

secnailpparof)mc51(ni6

)mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

)mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05<

**)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof

telniylppusrialacinahcemaotecnaraelC=K *)m38.1(teef6 )m3(teef01nihtiwfievoba)mc19(teef3

**yllatnoziroh **yllatnoziroh **yllatnoziroh **yllatnoziroh **yllatnoziroh

devaproklawedisdevapevobaecnaraelC=L

ytreporpcilbupnodetacolyawevid ytreporpcilbupnodetacolyawevid ytreporpcilbupnodetacolyawevid ytreporpcilbupnodetacolyawevid ytreporpcilbupnodetacolyawevid

‡)m31.2(teef7 ‡)m31.2(teef7

rokced,hcrop,adnarevrednuecnaraelC=M

ynoclab ynoclab ynoclab ynoclab ynoclab

‡*)mc03(sehcni21 ‡)mc03(sehcni21

.edoCnoitallatsnIenaporPdnAsaGlanoitaN1.941B-ASCtnerrucehthtiwecnadroccanI*

.sedoCsaGleuFlanoitaN45APFN/1.322ZSISNAtnerucehthtiwecnadroccanI** .sedoCsaGleuFlanoitaN45APFN/1.322ZSISNAtnerucehthtiwecnadroccanI** .sedoCsaGleuFlanoitaN45APFN/1.322ZSISNAtnerucehthtiwecnadroccanI** .sedoCsaGleuFlanoitaN45APFN/1.322ZSISNAtnerucehthtiwecnadroccanI** .sedoCsaGleuFlanoitaN45APFN/1.322ZSISNAtnerucehthtiwecnadroccanI**

sevresdnasgnillewdylimafelgnisowtneewtebdetacolsihcihwyawevirddevaproklawedisaevobayltceridetanimrettonllahstnevA‡ sevresdnasgnillewdylimafelgnisowtneewtebdetacolsihcihwyawevirddevaproklawedisaevobayltceridetanimrettonllahstnevA‡ sevresdnasgnillewdylimafelgnisowtneewtebdetacolsihcihwyawevirddevaproklawedisaevobayltceridetanimrettonllahstnevA‡ sevresdnasgnillewdylimafelgnisowtneewtebdetacolsihcihwyawevirddevaproklawedisaevobayltceridetanimrettonllahstnevA‡ sevresdnasgnillewdylimafelgnisowtneewtebdetacolsihcihwyawevirddevaproklawedisaevobayltceridetanimrettonllahstnevA‡

.sgnillewdhtob .sgnillewdhtob .sgnillewdhtob .sgnillewdhtob .sgnillewdhtob

:roolfehthtaenebsedis2muminimanonepoyllufsiynoclabrokced,hcrop,adnarevfidettimrepylnO‡* :roolfehthtaenebsedis2muminimanonepoyllufsiynoclabrokced,hcrop,adnarevfidettimrepylnO‡* :roolfehthtaenebsedis2muminimanonepoyllufsiynoclabrokced,hcrop,adnarevfidettimrepylnO‡* :roolfehthtaenebsedis2muminimanonepoyllufsiynoclabrokced,hcrop,adnarevfidettimrepylnO‡* :roolfehthtaenebsedis2muminimanonepoyllufsiynoclabrokced,hcrop,adnarevfidettimrepylnO‡*